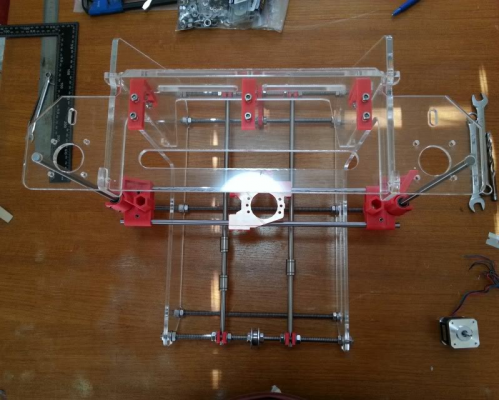

My first RepRap - Prusa Air V2

Posted by ashhhhh

|

My first RepRap - Prusa Air V2 January 24, 2013 08:03PM |

Registered: 11 years ago Posts: 56 |

Hey all,

I thought it was about time I joined up here, my names Ash and im in Australia.

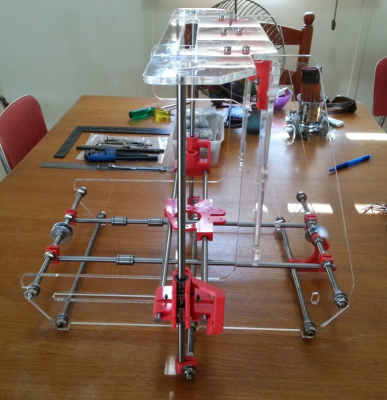

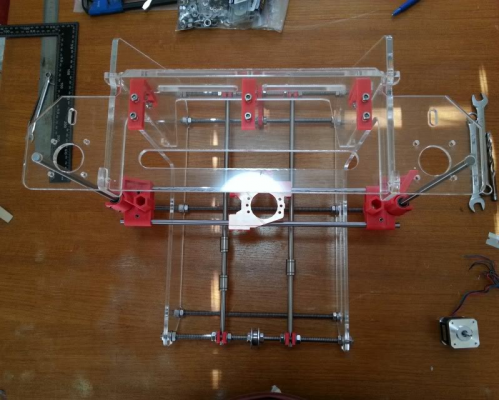

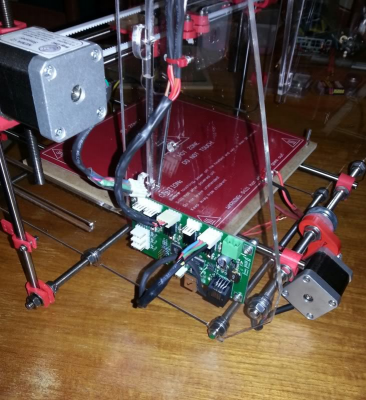

Over the last month or so I have been building an Air V2.

Im running Gen 6 electronics, a J Head Hot-end, heated bed and T2,5 belts with NEMA17 motors.

Its coming along nicely so far but I have had to contend with a number of faulty and damaged parts from various suppliers.

That's life I guess.

At present I am fighting an issue where the belts work their way to one edge of the bearing and rub on the fender washer, I have the plastic printed "bearing guides" to resolve this but cannot work out how they are meant to stay in place.

Can anyone advise?

Thanks

Ash

I thought it was about time I joined up here, my names Ash and im in Australia.

Over the last month or so I have been building an Air V2.

Im running Gen 6 electronics, a J Head Hot-end, heated bed and T2,5 belts with NEMA17 motors.

Its coming along nicely so far but I have had to contend with a number of faulty and damaged parts from various suppliers.

That's life I guess.

At present I am fighting an issue where the belts work their way to one edge of the bearing and rub on the fender washer, I have the plastic printed "bearing guides" to resolve this but cannot work out how they are meant to stay in place.

Can anyone advise?

Thanks

Ash

|

Re: My first RepRap - Prusa Air V2 January 25, 2013 05:37AM |

Registered: 11 years ago Posts: 791 |

Hi Ash,

I build a machine that is similar to your Prusa Air2. I am building my ninth one now with several improvements.

The frame is similar as it was derived from the Air2, but everything else is different. The frame was laser cut from acrylic, the plastic printed parts on mine are laser cut aluminium and powder coated. The Z nuts are hand machined zero backlash.

I also had the same problem with the belts running to one side and on the first machine I was using fender washers too.

I designed a two piece bearing cover with a skirt on each side, the pieces fit over the bearing and are Super Glued in place. Never had one fail yet.

The advantage of having the skirts is that they turn with the bearing while fender washers just sit stationary and the belt can rub on the side.

I will take some photos soon and add them to this forum so you may get a few ideas to help you.

Cheers,

Reg

I build a machine that is similar to your Prusa Air2. I am building my ninth one now with several improvements.

The frame is similar as it was derived from the Air2, but everything else is different. The frame was laser cut from acrylic, the plastic printed parts on mine are laser cut aluminium and powder coated. The Z nuts are hand machined zero backlash.

I also had the same problem with the belts running to one side and on the first machine I was using fender washers too.

I designed a two piece bearing cover with a skirt on each side, the pieces fit over the bearing and are Super Glued in place. Never had one fail yet.

The advantage of having the skirts is that they turn with the bearing while fender washers just sit stationary and the belt can rub on the side.

I will take some photos soon and add them to this forum so you may get a few ideas to help you.

Cheers,

Reg

|

Re: My first RepRap - Prusa Air V2 January 25, 2013 06:24AM |

Registered: 11 years ago Posts: 56 |

Thanks Reg, id be interested to see your pics - seconds like a nice machine.

Yeah there is plenty of room for improvement. The X carriage especially is very flimsy, the weight of the motor causes it to flex and move the hot-end - I'm sure it will cause problems.

I hope to get it working well enough to allow printing of some upgrades.

Yeah there is plenty of room for improvement. The X carriage especially is very flimsy, the weight of the motor causes it to flex and move the hot-end - I'm sure it will cause problems.

I hope to get it working well enough to allow printing of some upgrades.

|

Re: My first RepRap - Prusa Air V2 January 25, 2013 07:11AM |

Registered: 11 years ago Posts: 11 |

|

Re: My first RepRap - Prusa Air V2 January 25, 2013 10:57PM |

Registered: 11 years ago Posts: 791 |

Hi Ash,

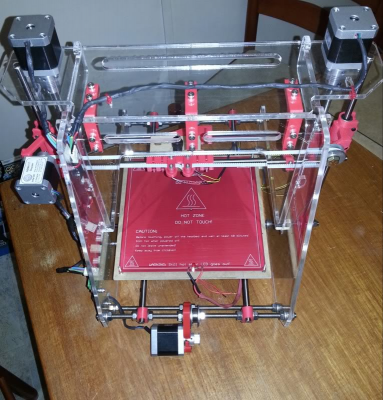

The first machine I built had wooden parts instead of plastic. I was then able to print out plastic parts and found the problems, so I re-designed everything in aluminium.

I am using a modified QU-BD extruder direct drive, very light and reliable. I also make my own now for the other machines.

I found a problem with the Z nuts on your model, I ran several spools of filament through the machine to test it for problems and found that the Z nuts wore out and caused slipping and jamming on the threads. I change over to hand machined Acetal nuts with zero backlash and did away with the springs. You will be able to see better in a photo.

The mount that I am using will be modified slightly for adding multiple extruders on a bigger machine, still based on the Prusa Air as it is very rigid and stable.

I will take some better photos soon when I get back from a trip I have to make.

Aluminium carriage showing how the extruder is attached.

The prototype machine before production. Have now sent over a dozen spools of plastic through this machine with no problems so far.

Made the extrudter easy to remove and also will use the same method for multiple extruders with silicone rubber do-nuts underneath mounting nuts to allow adjustment of hight of each extruder.

Swapping the plastic parts for the new aluminium parts.

Modified QU-BD extruder, small changes to make it better.

Laser cutting the Prusa Air frame parts (modified)

Linear bearings used throughout the machine.

Hand machined Z nuts from Acetal plastic, no backlash.

First batch of model 1 machines being assembled, now working on a second model that will all be powder coated in various colour selections.

The first machine I built had wooden parts instead of plastic. I was then able to print out plastic parts and found the problems, so I re-designed everything in aluminium.

I am using a modified QU-BD extruder direct drive, very light and reliable. I also make my own now for the other machines.

I found a problem with the Z nuts on your model, I ran several spools of filament through the machine to test it for problems and found that the Z nuts wore out and caused slipping and jamming on the threads. I change over to hand machined Acetal nuts with zero backlash and did away with the springs. You will be able to see better in a photo.

The mount that I am using will be modified slightly for adding multiple extruders on a bigger machine, still based on the Prusa Air as it is very rigid and stable.

I will take some better photos soon when I get back from a trip I have to make.

Aluminium carriage showing how the extruder is attached.

The prototype machine before production. Have now sent over a dozen spools of plastic through this machine with no problems so far.

Made the extrudter easy to remove and also will use the same method for multiple extruders with silicone rubber do-nuts underneath mounting nuts to allow adjustment of hight of each extruder.

Swapping the plastic parts for the new aluminium parts.

Modified QU-BD extruder, small changes to make it better.

Laser cutting the Prusa Air frame parts (modified)

Linear bearings used throughout the machine.

Hand machined Z nuts from Acetal plastic, no backlash.

First batch of model 1 machines being assembled, now working on a second model that will all be powder coated in various colour selections.

Sorry, only registered users may post in this forum.