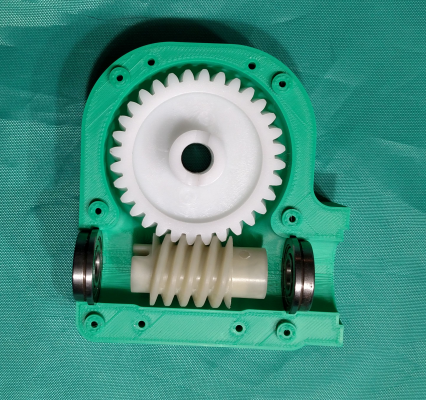

Small side project: 16:1 worm gear reducer for NEMA-23 motor

Posted by the_digital_dentist

|

Small side project: 16:1 worm gear reducer for NEMA-23 motor January 26, 2017 12:21AM |

Registered: 11 years ago Posts: 5,780 |

While researching worm gear drives for my CoreXY printer with belt lifted Z axis, I ran into plastic worm and disc gear sets on ebay for $8. They are made for garage door openers. I ordered a set and designed a housing for them. One side of the shell is printed and the bearings and gears fit perfectly. The motor attaches on the right side. The other half of the shell is printing now. I'll still have to make the shafts for the gears- planning on turning them on a lathe.

If it works OK, I'll put the design on my web site, and I'll probably design another version for NEMA-17 size motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If it works OK, I'll put the design on my web site, and I'll probably design another version for NEMA-17 size motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Small side project: 16:1 worm gear reducer for NEMA-23 motor January 26, 2017 12:41PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Small side project: 16:1 worm gear reducer for NEMA-23 motor February 02, 2018 07:54PM |

Registered: 8 years ago Posts: 1 |

|

Re: Small side project: 16:1 worm gear reducer for NEMA-23 motor February 02, 2018 10:58PM |

Registered: 11 years ago Posts: 5,780 |

I have not finished that project.

I did build a coreXY printer in which the bed is belt lifted and uses a 30:1 worm gear reducer to prevent bed drop when power is cut. It works perfectly. I used an OnDrives Rino gear reducer that comes with NEMA-23 motor for $108 via ebay (used). I operate the 1.8A motor at 1A and it has plenty of torque to lift the 3.5 kg bed/support plus 4kg print load. The motor never gets more than about 5C above ambient.

There is zero backlash because the weight of the bed/support/print keeps the gear teeth engaged at all times, no matter what direction the mechanism is moving. It will even work fine as the gears wear.

You can get backlash if you use counterweights or elastic cords to prevent the bed from crashing with a geared stepper.

[drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 02/02/2018 11:01PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I did build a coreXY printer in which the bed is belt lifted and uses a 30:1 worm gear reducer to prevent bed drop when power is cut. It works perfectly. I used an OnDrives Rino gear reducer that comes with NEMA-23 motor for $108 via ebay (used). I operate the 1.8A motor at 1A and it has plenty of torque to lift the 3.5 kg bed/support plus 4kg print load. The motor never gets more than about 5C above ambient.

There is zero backlash because the weight of the bed/support/print keeps the gear teeth engaged at all times, no matter what direction the mechanism is moving. It will even work fine as the gears wear.

You can get backlash if you use counterweights or elastic cords to prevent the bed from crashing with a geared stepper.

[drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 02/02/2018 11:01PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.