Roots blower

Posted by leadinglights

|

Roots blower November 26, 2014 12:28PM |

Registered: 12 years ago Posts: 1,450 |

My hot end has an air ring around the nozzle with the air fed through a silicone tube from a remote pump, I have been using an aquarium pump but this cannot easily be controlled by the G-code. After spending some time looking at what was available I decided to make one.

The normal axial fan is not an option as it can't push much air through a thin (6mm bore) tube. Centrifugal fans are a little better, but one to give the required pressure would have deep blades like a turbocharger compressor and balancing becomes a problem. Piston and diaphragm pumps deliver more pressure than needed but at too small a flow - they are also noisy. The Roots blower is a good all round solution.

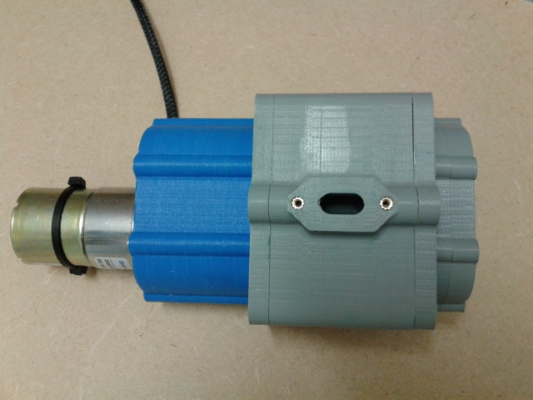

The completed Roots blower pump

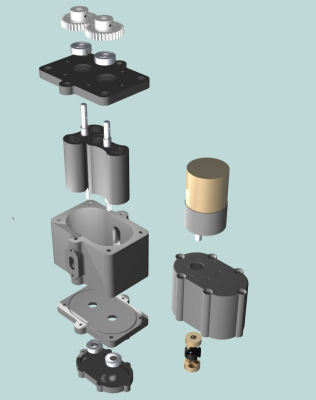

Rendering of the CAD files

Rotors and body from an earlier try - clearance between parts was too large

The Roots blower working. Delivery is 15 l/min (0.5CFM)and maximum pressure is about 0.8kPa (3.2" of water)

For this to work well the printer needs to be very well calibrated - It wasn't but now is.

Mike

The normal axial fan is not an option as it can't push much air through a thin (6mm bore) tube. Centrifugal fans are a little better, but one to give the required pressure would have deep blades like a turbocharger compressor and balancing becomes a problem. Piston and diaphragm pumps deliver more pressure than needed but at too small a flow - they are also noisy. The Roots blower is a good all round solution.

The completed Roots blower pump

Rendering of the CAD files

Rotors and body from an earlier try - clearance between parts was too large

The Roots blower working. Delivery is 15 l/min (0.5CFM)and maximum pressure is about 0.8kPa (3.2" of water)

For this to work well the printer needs to be very well calibrated - It wasn't but now is.

Mike

|

Re: Roots blower November 27, 2014 02:13AM |

Registered: 10 years ago Posts: 580 |

Very nicely done!

Can you show a photo of the print head arrangement?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Can you show a photo of the print head arrangement?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Roots blower November 27, 2014 04:26AM |

Registered: 12 years ago Posts: 1,450 |

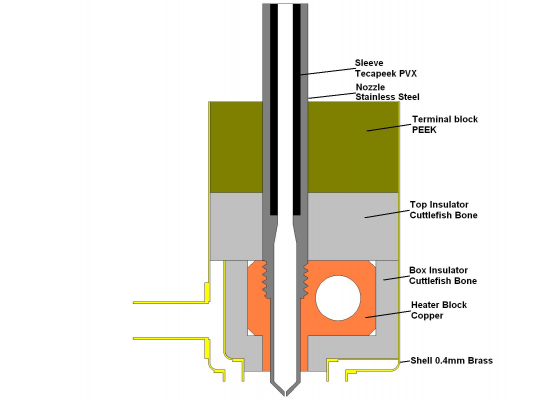

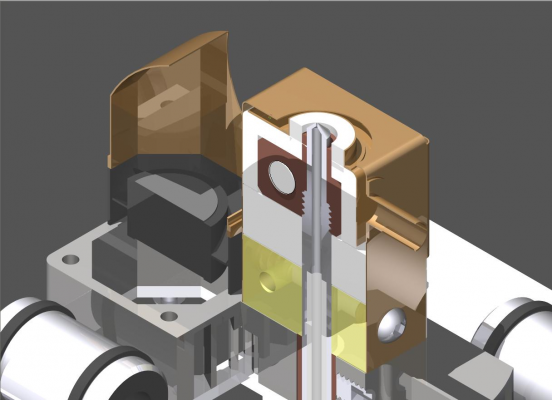

Hopefully these will give the general idea. Please do not try Tekapeek (graphite loaded PEEK) shown in one of the diagrams - it was an abject failure.

View on bottom of hot end on a Mendel Prusa

Section showing parts

Section showing area fan/heatsink cooler

Edit: I have been looking for any photos showing the ducting, but the closest I have is a Youtube video. The silicone tube is clearly visible but the cooling was an older and inferior type.

[www.youtube.com]

Mike

Edited 1 time(s). Last edit at 11/27/2014 04:30AM by leadinglights.

View on bottom of hot end on a Mendel Prusa

Section showing parts

Section showing area fan/heatsink cooler

Edit: I have been looking for any photos showing the ducting, but the closest I have is a Youtube video. The silicone tube is clearly visible but the cooling was an older and inferior type.

[www.youtube.com]

Mike

Edited 1 time(s). Last edit at 11/27/2014 04:30AM by leadinglights.

|

Re: Roots blower November 28, 2014 04:50AM |

Registered: 10 years ago Posts: 580 |

|

Re: Roots blower November 29, 2014 02:12PM |

Registered: 12 years ago Posts: 1,450 |

I reported on my experiments with cuttlefish bone in [forums.reprap.org]

Briefly though: Cuttlefish bone is an exceptional insulator and can take the maximum temperature of any credible plastic extruder. However, it is very fragile. I use thin brass shim to build a protective box around the cuttlefish bone.

Mike

Briefly though: Cuttlefish bone is an exceptional insulator and can take the maximum temperature of any credible plastic extruder. However, it is very fragile. I use thin brass shim to build a protective box around the cuttlefish bone.

Mike

|

Re: Roots blower December 09, 2014 12:40PM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Roots blower January 03, 2015 07:49PM |

Registered: 9 years ago Posts: 189 |

This looks like a very nice idea for sure!

thanks for documenting your work here -

will look into it and try to adapt to my prusa i3.

my normal fan-cooling results in too much cooling down of the hot-end, since the air flow is not guided enough.

Alex

Edited 1 time(s). Last edit at 01/03/2015 07:49PM by Alexander1984.

thanks for documenting your work here -

will look into it and try to adapt to my prusa i3.

my normal fan-cooling results in too much cooling down of the hot-end, since the air flow is not guided enough.

Alex

Edited 1 time(s). Last edit at 01/03/2015 07:49PM by Alexander1984.

|

Re: Roots blower January 12, 2015 09:44PM |

Registered: 9 years ago Posts: 120 |

Sorry, only registered users may post in this forum.