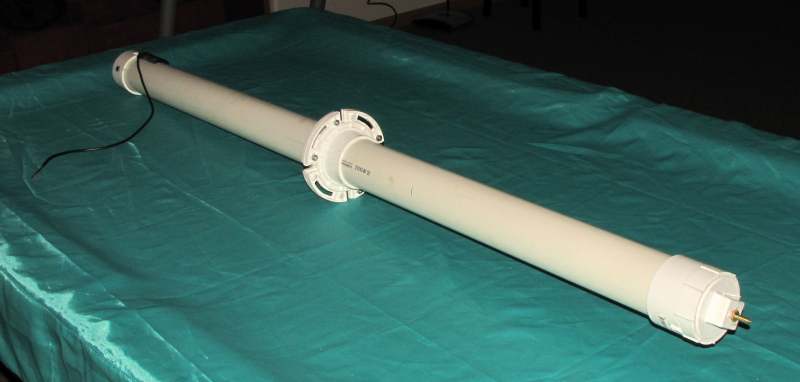

3.5 liter chocolate extruder

Posted by the_digital_dentist

|

3.5 liter chocolate extruder July 03, 2015 12:25AM |

Registered: 11 years ago Posts: 5,780 |

Testing begins tomorrow! Planning initial test with pancake batter because I can control viscosity by varying powder to water ratio, and it's a lot cheaper than chocolate.

http://milwaukeemakerspace.org/2015/07/making-a-plunger-for-a-chocolate-syringe/

http://milwaukeemakerspace.org/2015/07/making-a-plunger-for-a-chocolate-syringe/

|

Re: 3.5 liter chocolate extruder July 03, 2015 01:52AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: 3.5 liter chocolate extruder July 03, 2015 10:25AM |

Registered: 11 years ago Posts: 5,780 |

I will be wrapping the outside with heater wire and insulation, and using a PID controller to regulate temperature. I haven't decided if I'll melt the chocolate inside the extruder or melt it outside and pour it in. Melting it inside the syringe will be a very slow process because I can't let heater wire get too hot or the pipe will get damaged. Ultimately an aluminum or steel pipe will be a better way to go, but for test purposes PVC will do.

The whole thing comes apart for easy clean-out. Running hot water through it should melt any chocolate residue and allow easy wash out with detergent.

I'm not sure how to deal with air bubbles in the chocolate yet, other than just inverting the whole thing and pushing them out with the plunger. I don't know if the viscosity of the molten chocolate will allow the bubbles to rise or if they will stay suspended in the chocolate. The viscosity changes rapidly over just a few degrees, so maybe warming it beyond extrusion temperature to debubble it, followed by a cool down period to final extrusion temperature/viscosity will be in order. A vibrator may help, or maybe I can use vacuum degassing.

I have devised a so far untested scheme for cooling/solidifying the chocolate as it comes out of the extruder nozzle. I'll be testing that after I'm satisfied that I have a workable extrusion process.

The whole thing comes apart for easy clean-out. Running hot water through it should melt any chocolate residue and allow easy wash out with detergent.

I'm not sure how to deal with air bubbles in the chocolate yet, other than just inverting the whole thing and pushing them out with the plunger. I don't know if the viscosity of the molten chocolate will allow the bubbles to rise or if they will stay suspended in the chocolate. The viscosity changes rapidly over just a few degrees, so maybe warming it beyond extrusion temperature to debubble it, followed by a cool down period to final extrusion temperature/viscosity will be in order. A vibrator may help, or maybe I can use vacuum degassing.

I have devised a so far untested scheme for cooling/solidifying the chocolate as it comes out of the extruder nozzle. I'll be testing that after I'm satisfied that I have a workable extrusion process.

|

Re: 3.5 liter chocolate extruder July 04, 2015 04:57PM |

Registered: 11 years ago Posts: 5,780 |

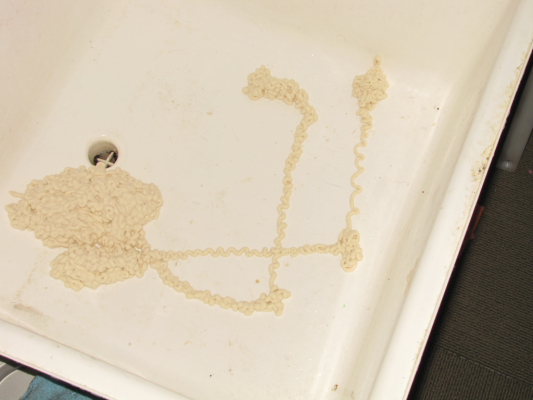

First test an unqualified success!

Edited 1 time(s). Last edit at 07/04/2015 04:59PM by the_digital_dentist.

Edited 1 time(s). Last edit at 07/04/2015 04:59PM by the_digital_dentist.

|

Re: 3.5 liter chocolate extruder July 05, 2015 02:26AM |

Registered: 8 years ago Posts: 5,232 |

Hmm, where´s my comment about bubbles?

I made a proposal to use a vent in the piston, that lets air pass, but closes, when a solid paste tries to pass through.

google search

Anyway, from the video I´d say it partly works, but the extruded amount of choc will become unpredictable, when you use a DC motor for it. From the sound in the video I could tell, it slowed down, when it started to compress.

In the nozzle you could use a pressure release valve. Only, when a certain pressure is reached, the paste can pass. This way you won´t have a dribbling nozzle.

With a pressure sensor you could add a way of control to the process, too.

-Olaf

I made a proposal to use a vent in the piston, that lets air pass, but closes, when a solid paste tries to pass through.

google search

Anyway, from the video I´d say it partly works, but the extruded amount of choc will become unpredictable, when you use a DC motor for it. From the sound in the video I could tell, it slowed down, when it started to compress.

In the nozzle you could use a pressure release valve. Only, when a certain pressure is reached, the paste can pass. This way you won´t have a dribbling nozzle.

With a pressure sensor you could add a way of control to the process, too.

-Olaf

|

Re: 3.5 liter chocolate extruder July 05, 2015 08:05AM |

Registered: 11 years ago Posts: 5,780 |

That demo was running at 50-100X the speed that will be used in the final printer, so I am not too concerned about the slow down under load. That slow down occurs when the chocolate starts extruding, and I think it will remain more or less constant once it does because the inside of the syringe will reach an equilibrium pressure between the push from the plunger and the venting at the nozzle, assuming that molten chocolate is an incompressible fluid, which may or may not be the case, and I can get all the air out before extruding. I would have preferred a stepper motor to drive it, but couldn't figure out how to calculate the amount of force required push the chocolate through the nozzle, so I couldn't calculate the motor torque required. The next generation extruder will use a stepper.

The whole thing will be inverted in operation (dramatically reduces floor space required), so if the air is able to rise in the chocolate, it will be vented before the printing starts. I think air will mainly be a problem if I melt the chocolate in the syringe by adding solid chips. If the chocolate is melted outside the syringe and then poured into the extruder air will be much less of a problem. If air bubbles can't rise in the chocolate at print temperature, I may run a cycle at higher temperature to thin it and let air rise, maybe with a vacuum pump connected to the nozzle, then let it cool to print temperature.

The printing device I have planned now will operate at a more or less constant extrusion rate, and will not do any retracting until the "print" is finished. I won't be attempting anything like a full-on FDM printer. Yet.

The air/goo valve is a nice idea, but assumes that all the air in the syringe forms a single bubble that will arrive at the valve before the chocolate does. If some of the chocolate gets there first, the valve stops working and you still have a bunch of air in the syringe.

This is all speculation. We'll see how it behaves soon enough.

The whole thing will be inverted in operation (dramatically reduces floor space required), so if the air is able to rise in the chocolate, it will be vented before the printing starts. I think air will mainly be a problem if I melt the chocolate in the syringe by adding solid chips. If the chocolate is melted outside the syringe and then poured into the extruder air will be much less of a problem. If air bubbles can't rise in the chocolate at print temperature, I may run a cycle at higher temperature to thin it and let air rise, maybe with a vacuum pump connected to the nozzle, then let it cool to print temperature.

The printing device I have planned now will operate at a more or less constant extrusion rate, and will not do any retracting until the "print" is finished. I won't be attempting anything like a full-on FDM printer. Yet.

The air/goo valve is a nice idea, but assumes that all the air in the syringe forms a single bubble that will arrive at the valve before the chocolate does. If some of the chocolate gets there first, the valve stops working and you still have a bunch of air in the syringe.

This is all speculation. We'll see how it behaves soon enough.

|

Re: 3.5 liter chocolate extruder July 06, 2015 01:35AM |

Registered: 8 years ago Posts: 5,232 |

Quote

The air/goo valve is a nice idea, but assumes that all the air in the syringe forms a single bubble that will arrive at the valve before the chocolate does. If some of the chocolate gets there first, the valve stops working and you still have a bunch of air in the syringe.

In my dissapeared post I proposed the valve for a syringe, that isn´t filled completely with choc when you insert the piston. Then there would be a lot of air, I assumed.

-Olaf

|

Re: 3.5 liter chocolate extruder July 21, 2015 06:51AM |

Registered: 8 years ago Posts: 17 |

|

Re: 3.5 liter chocolate extruder July 23, 2015 11:55PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: 3.5 liter chocolate extruder July 24, 2015 12:31AM |

Registered: 9 years ago Posts: 705 |

|

Re: 3.5 liter chocolate extruder July 24, 2015 01:38AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: 3.5 liter chocolate extruder July 24, 2015 06:21AM |

Registered: 10 years ago Posts: 903 |

|

Re: 3.5 liter chocolate extruder July 24, 2015 07:58AM |

Registered: 14 years ago Posts: 3,742 |

No, just good business sense - get the customer to come back over and over and over again!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: 3.5 liter chocolate extruder July 26, 2015 11:14PM |

Registered: 11 years ago Posts: 5,780 |

Quote

rhmorrison

No, just good business sense - get the customer to come back over and over and over again!

Please dude, patient is the preferred vernacular, not customer...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 3.5 liter chocolate extruder September 13, 2015 12:36AM |

Registered: 11 years ago Posts: 5,780 |

Update: I tested the turntable screw drive mechanism today:

Chocolate printer screw drive test

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Chocolate printer screw drive test

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 3.5 liter chocolate extruder September 14, 2015 09:37AM |

Registered: 9 years ago Posts: 344 |

|

Re: 3.5 liter chocolate extruder September 14, 2015 10:00AM |

Registered: 11 years ago Posts: 5,780 |

It's pretty big. Right now it's assembled by just pounding the PVC pipe pieces together with a rubber mallet- it is too big to fit through normal doorways when assembled, so it will be kept as a "kit" to allow transport.

I have a friend helping write code for the controller right now, and we're working feverishly to get it ready for the Milwaukee Maker Faire. It may make its first ever print at the faire, though I'm reluctant to haul it out if I don't know for sure that it's working.

I have to make a new plunger for the extruder- it seems that the silicone I used shrunk a bit in the couple months since I made the first one and it doesn't fit very tightly in the extruder pipe any more. I'll be printing the mold and recasting that part this week.

Edited 1 time(s). Last edit at 09/14/2015 10:06AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have a friend helping write code for the controller right now, and we're working feverishly to get it ready for the Milwaukee Maker Faire. It may make its first ever print at the faire, though I'm reluctant to haul it out if I don't know for sure that it's working.

I have to make a new plunger for the extruder- it seems that the silicone I used shrunk a bit in the couple months since I made the first one and it doesn't fit very tightly in the extruder pipe any more. I'll be printing the mold and recasting that part this week.

Edited 1 time(s). Last edit at 09/14/2015 10:06AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 3.5 liter chocolate extruder September 14, 2015 10:05AM |

Registered: 9 years ago Posts: 344 |

Sorry, only registered users may post in this forum.