The Dbot, a new reprap!

Posted by Andreas15

|

The Dbot, a new reprap! August 10, 2015 11:43AM |

Registered: 8 years ago Posts: 90 |

Hi everybody!

I'll begin by introducing myself. I'm Andreas Desmedt, a 15 year old student from Belgium. I do engineering at school. I love technologie, CAD designing and windsurfing :p . I had a Velleman Vertex K8400 as first printer, wich I assembled myself.

I began this project about a month ago. I knew a little bit about 3D printing already and I knew how they worked, so research was done fast. Then I began desiging my own reprap : The Drebot!

The Dbot (coming from my back name) is actually a combination of some of printers. I tried taking the best aspects and combine these. My main goals where making it cheap, keeping it compact and make it good looking. After a week or 2 designing I fully CAD'ed my design. I began searching some parts on aliexpress and ebay finding cheap but "OK" quality parts. I had to keep the costs low, and my goal was set on 300 dollars so I had to compare everything and make sure I found the best price/quality components.

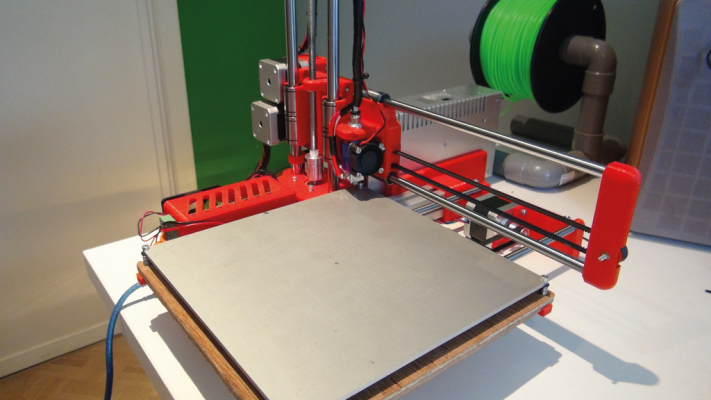

The base of the printer is a 3030 aluminium extrusion, everything is mounted on this extrusion, wich means everything is tight and compact, making it easy to carry or put away. The Z axis is made out off 2 12mm rods with a carriage attached to it using 4 LM12UU bearings. In this carriage, there are 2 8mm rods mounted, wich are for the X axis. The carriage for the X axis is mounted using 3 LM8UU bearings, two on the bottom and one on the top. For the Y axis, I also use 2 8mm rods. The wooden plate for the heatbed is attached to the rods using 3 LM8UU bearings. Both X and Y axis are driven by NEMA17 motors using GT2 belts. The Z axis is driven by a M8 threaded rod. The Dbot is controlled by a Ramps 1.4 motherboard, and powered by a 360W LED PSU, wich are both also mounted onto the 3030 aluminium extrusion. The extruder is a fully self designed extruder, wich is also printable. This is done to keep the costs low. Both the extruder motor and the motor that powers the X axis are located on the opposite site and used as a counterweight for the X axis rods and carriage. The ramps board is located in a casing with a fan, for proper cooling. The bed itself is a MK3 heatbed. The printers volume is 200(X)x190(Y)x185(Z), wich is almost the whole heatbed capacity. I invented my own heatbed nut mounts, so you only have to turn the screw to level the bed and don't think about the nuts.

Allot of thanks to Cliff Mellangård, helping me with the software.

I hope you like him! If there is enough interest, I will make a wiki page for it and share all the files.

Printer in action:

[www.youtube.com]

Edited 2 time(s). Last edit at 08/10/2015 11:51AM by Andreas15.

I'll begin by introducing myself. I'm Andreas Desmedt, a 15 year old student from Belgium. I do engineering at school. I love technologie, CAD designing and windsurfing :p . I had a Velleman Vertex K8400 as first printer, wich I assembled myself.

I began this project about a month ago. I knew a little bit about 3D printing already and I knew how they worked, so research was done fast. Then I began desiging my own reprap : The Drebot!

The Dbot (coming from my back name) is actually a combination of some of printers. I tried taking the best aspects and combine these. My main goals where making it cheap, keeping it compact and make it good looking. After a week or 2 designing I fully CAD'ed my design. I began searching some parts on aliexpress and ebay finding cheap but "OK" quality parts. I had to keep the costs low, and my goal was set on 300 dollars so I had to compare everything and make sure I found the best price/quality components.

The base of the printer is a 3030 aluminium extrusion, everything is mounted on this extrusion, wich means everything is tight and compact, making it easy to carry or put away. The Z axis is made out off 2 12mm rods with a carriage attached to it using 4 LM12UU bearings. In this carriage, there are 2 8mm rods mounted, wich are for the X axis. The carriage for the X axis is mounted using 3 LM8UU bearings, two on the bottom and one on the top. For the Y axis, I also use 2 8mm rods. The wooden plate for the heatbed is attached to the rods using 3 LM8UU bearings. Both X and Y axis are driven by NEMA17 motors using GT2 belts. The Z axis is driven by a M8 threaded rod. The Dbot is controlled by a Ramps 1.4 motherboard, and powered by a 360W LED PSU, wich are both also mounted onto the 3030 aluminium extrusion. The extruder is a fully self designed extruder, wich is also printable. This is done to keep the costs low. Both the extruder motor and the motor that powers the X axis are located on the opposite site and used as a counterweight for the X axis rods and carriage. The ramps board is located in a casing with a fan, for proper cooling. The bed itself is a MK3 heatbed. The printers volume is 200(X)x190(Y)x185(Z), wich is almost the whole heatbed capacity. I invented my own heatbed nut mounts, so you only have to turn the screw to level the bed and don't think about the nuts.

Allot of thanks to Cliff Mellangård, helping me with the software.

I hope you like him! If there is enough interest, I will make a wiki page for it and share all the files.

Printer in action:

[www.youtube.com]

Edited 2 time(s). Last edit at 08/10/2015 11:51AM by Andreas15.

|

Re: The Dbot, a new reprap! August 10, 2015 06:32PM |

Registered: 9 years ago Posts: 204 |

|

Re: The Dbot, a new reprap! August 10, 2015 07:01PM |

Registered: 9 years ago Posts: 127 |

|

Re: The Dbot, a new reprap! August 10, 2015 08:26PM |

Registered: 8 years ago Posts: 90 |

Quote

Ezrec

Looks to require a minimal number of 'vitamins', and a small number of plastic parts - good job!

I also commend you for using the extrusion - the 'bought accuracy' of a precut piece is something that few people understand how to use properly.

Thanks! What do you actually mean with your last sentence?

|

Re: The Dbot, a new reprap! August 10, 2015 09:36PM |

Registered: 10 years ago Posts: 814 |

|

Re: The Dbot, a new reprap! August 11, 2015 08:28AM |

Registered: 8 years ago Posts: 90 |

|

Re: The Dbot, a new reprap! August 11, 2015 09:45AM |

Registered: 10 years ago Posts: 814 |

|

Re: The Dbot, a new reprap! August 11, 2015 11:11AM |

Registered: 8 years ago Posts: 90 |

|

Re: The Dbot, a new reprap! August 13, 2015 11:06PM |

Registered: 9 years ago Posts: 127 |

By 'bought accuracy', I mean that often purchasing a square piece of material is often more square than one you cut yourself.

The same goes for flatness (which is why sheet glass is such a popular DIY build platform, and my choice of melanine covered MDF for large projects), diameters (ie pipes and rods) and other 'precision properties' of objects.

By using a pre-cut extrusion, and basing your precision around it's from-the-factory precision, you can save yourself a lot of calibration time.

The same goes for flatness (which is why sheet glass is such a popular DIY build platform, and my choice of melanine covered MDF for large projects), diameters (ie pipes and rods) and other 'precision properties' of objects.

By using a pre-cut extrusion, and basing your precision around it's from-the-factory precision, you can save yourself a lot of calibration time.

|

Re: The Dbot, a new reprap! August 14, 2015 08:21PM |

Registered: 8 years ago Posts: 90 |

|

Re: The Dbot, a new reprap! August 14, 2015 10:16PM |

Registered: 9 years ago Posts: 50 |

Sorry, only registered users may post in this forum.