Filament-out sensor

Posted by the_digital_dentist

|

Filament-out sensor December 02, 2016 12:35AM |

Registered: 11 years ago Posts: 5,780 |

You want to know if your printer design is idiot proof? Leave it at a makerspace for a while!

My printer has been at the Milwaukee Makerspace for almost a year, but for some reason, it has only recently had problems with either filament running out or breaking during a print, or after a print someone running the end of the filament into the extruder, necessitating an extruder tear-down to get the piece of filament out of the hot-end so that new filament can be loaded. After four tear-downs in as many weeks I decided to to try prevent the problem.

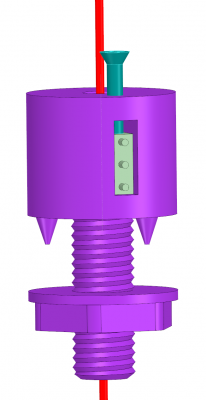

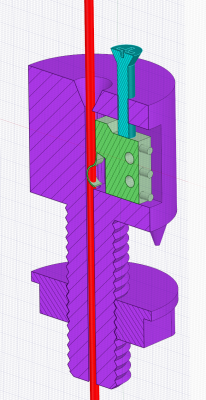

I designed a butt-simple filament-out detector that will connect to the SmoothieBoard to pause the printer if the filament runs out during a print. It should (may?) also prevent a silly person from running the end of the filament into the extruder. It won't help if the filament breaks between the detector and the extruder or if said silly person cuts the filament there and runs it into the extruder. The detector consists of a printed tube with a slot for a lever-type microswitch. The filament depresses the lever and opens the NC contacts (and closes the NO contacts). When the filament runs out, the lever pops up and the switch state flips. The design is specifically for my printer with a 1" PIR foam top cover, so I used a threaded body with antirotation spikes and a nut to mount the whole thing on the printer. The design can easily be adapted to any lever-type microswitch you have, and if you don't need the threaded part of the tube, delete it.

I tried to keep it as simple as possible, so adjustment is done by inserting a piece of filament, pushing the switch into the slot until it clicks, then tightening the screw to hold the switch. It doesn't get much easier. The filament is passing through a 2.8 mm diameter tube, so it fits very easily. If you made the hole a little bigger you could use it for 3 mm filament. If the filament is curled coming off the spool the tube creates a little friction but nothing compared to a Bowden or other filament feed tube.

Design here: [www.youmagine.com]

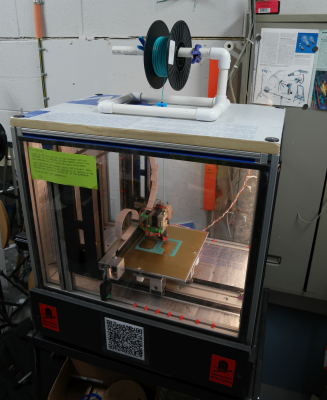

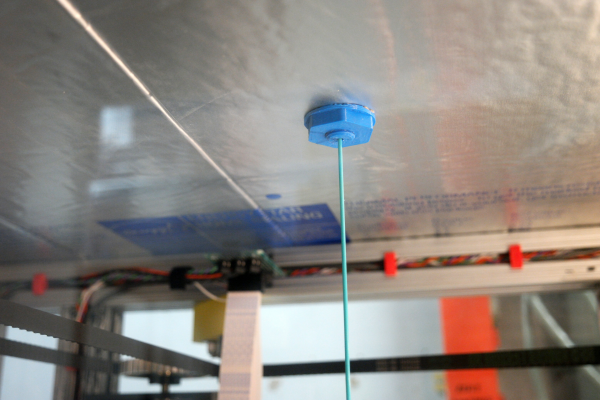

Here's the printer with the sensor mounted, but not yet wired:

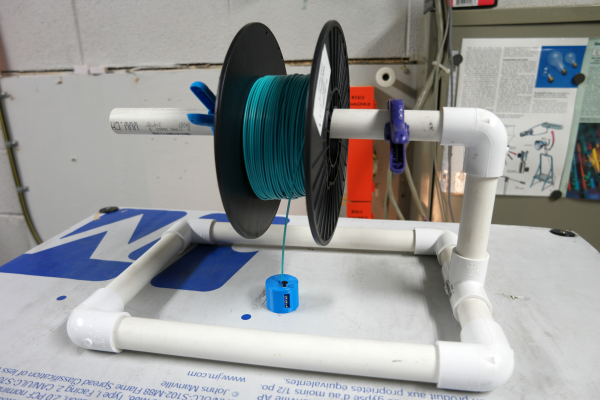

Here it is viewed from the top side of the printer:

Here it is from the inside of the printer:

Please forgive the poor quality of the print- my CubeX Duo isn't fully tuned up yet. Soon...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My printer has been at the Milwaukee Makerspace for almost a year, but for some reason, it has only recently had problems with either filament running out or breaking during a print, or after a print someone running the end of the filament into the extruder, necessitating an extruder tear-down to get the piece of filament out of the hot-end so that new filament can be loaded. After four tear-downs in as many weeks I decided to to try prevent the problem.

I designed a butt-simple filament-out detector that will connect to the SmoothieBoard to pause the printer if the filament runs out during a print. It should (may?) also prevent a silly person from running the end of the filament into the extruder. It won't help if the filament breaks between the detector and the extruder or if said silly person cuts the filament there and runs it into the extruder. The detector consists of a printed tube with a slot for a lever-type microswitch. The filament depresses the lever and opens the NC contacts (and closes the NO contacts). When the filament runs out, the lever pops up and the switch state flips. The design is specifically for my printer with a 1" PIR foam top cover, so I used a threaded body with antirotation spikes and a nut to mount the whole thing on the printer. The design can easily be adapted to any lever-type microswitch you have, and if you don't need the threaded part of the tube, delete it.

I tried to keep it as simple as possible, so adjustment is done by inserting a piece of filament, pushing the switch into the slot until it clicks, then tightening the screw to hold the switch. It doesn't get much easier. The filament is passing through a 2.8 mm diameter tube, so it fits very easily. If you made the hole a little bigger you could use it for 3 mm filament. If the filament is curled coming off the spool the tube creates a little friction but nothing compared to a Bowden or other filament feed tube.

Design here: [www.youmagine.com]

Here's the printer with the sensor mounted, but not yet wired:

Here it is viewed from the top side of the printer:

Here it is from the inside of the printer:

Please forgive the poor quality of the print- my CubeX Duo isn't fully tuned up yet. Soon...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Filament-out sensor December 02, 2016 07:45PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Filament-out sensor December 02, 2016 08:15PM |

Registered: 11 years ago Posts: 5,780 |

It's one more thing to have to wire, and if you're careful about operating your machine, you won't have any problems with filament running out during a print. I never had a problem after I learned about this sort of thing the hard way a few years ago and modified my printer operation- I started weighing spools before long prints to make sure there was sufficient filament. The problem has recently cropped up at the makerspace where noobs have been running the machine. I attempted to teach proper operational procedures, but there's a lot to absorb and it is going to take a while to get everyone on-board. In the mean time, I'll probably be fitting other printers at the space with similar filament-out switches.

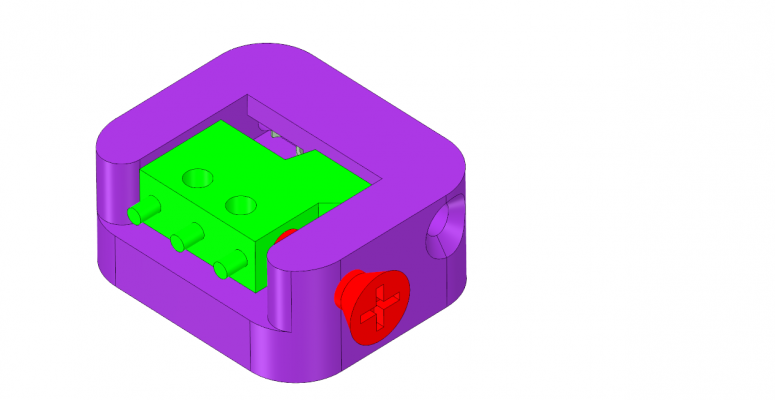

I designed a minimalist type version for screwing to a flat panel that has a 25 mm long filament path to reduce friction with curled filament:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I designed a minimalist type version for screwing to a flat panel that has a 25 mm long filament path to reduce friction with curled filament:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.