File handles

Posted by JamesK

|

File handles December 29, 2016 09:27PM |

Registered: 9 years ago Posts: 1,873 |

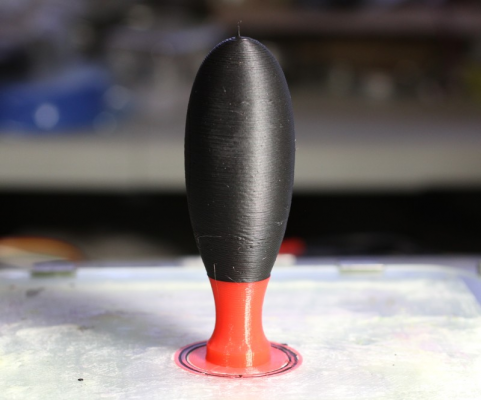

It's a simple thing, but I've been meaning to make some new handles for my files for ages. Finally got around to it and put some TPE to good use. These feel great!

The red one is PETG, the blue PLA. Printing TPE over PLA is easier than PETG, but the PETG is easier to fit on the file.

I put the STLs on thingiverse if anyone is interested: [www.thingiverse.com]

The red one is PETG, the blue PLA. Printing TPE over PLA is easier than PETG, but the PETG is easier to fit on the file.

I put the STLs on thingiverse if anyone is interested: [www.thingiverse.com]

|

Re: File handles December 30, 2016 02:51AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: File handles January 01, 2017 10:33AM |

Registered: 12 years ago Posts: 2,470 |

That looks good

I had some problems with TPE where it ´sis not want to stick to any othe rmaterial. TPU on the other hand seems to connect rather nicely.

I am currently giving the file heft a try using ABS and TPU with a bit different setup then you, i print the 2 perimeters with TPU and the infill with ABS

[youtu.be]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

I had some problems with TPE where it ´sis not want to stick to any othe rmaterial. TPU on the other hand seems to connect rather nicely.

I am currently giving the file heft a try using ABS and TPU with a bit different setup then you, i print the 2 perimeters with TPU and the infill with ABS

[youtu.be]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: File handles January 01, 2017 11:20AM |

Registered: 9 years ago Posts: 1,873 |

That's a good approach, and I love your dual carriage set up. It makes me envious every time I see that in operation

Tpu is much nicer to print with than tpe, and is fantastically strong as well, but for grips I like the softness of tpe. I had to print at 10mm/s to get the tpe to print reliably for this, which was tedious. At least the pla was going down at 60mm/s.

Tpu is much nicer to print with than tpe, and is fantastically strong as well, but for grips I like the softness of tpe. I had to print at 10mm/s to get the tpe to print reliably for this, which was tedious. At least the pla was going down at 60mm/s.

|

Re: File handles January 01, 2017 11:46AM |

Registered: 12 years ago Posts: 2,470 |

10mm/s? The TPU prints at 80. I can go higher, but then the surface quality starts to detoriate. I am pretty much in love with that stuff, if only it were available at Shore D70 or such.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: File handles January 01, 2017 12:56PM |

Registered: 9 years ago Posts: 1,873 |

Yes, the TPE is the softest filament I have - 80A, really feels like rubber, but it's a huge pain to print with. I can normally get 15 mm/s when printing it single extusion, but I was having problems with it separating on the first attempt with this print. I slowed it down, added a lot more cooling fan and changed the core from abs to pla, so I don't know which change made the most difference. I've been printing TPU at 30, but I tend towards low speeds and accelerations, so I could believe there's plenty of room to go faster. I haven't experimented with the print speeds on a lot of the filaments since putting in a larger nozzle, so I'm flying blind a lot of the time at the moment. The TPE was using a 0.9mm nozzle and printing 1mm wide.

|

Re: File handles January 01, 2017 01:47PM |

Registered: 12 years ago Posts: 2,470 |

With soft TPE (Ninjaflex) i could up speed quite a lot before it gave up. It went well past 100mm/s. This was only possible because i spent a lot of time finetuning my extruder for very soft filament. The extruder i currently use is not as extreme but more practical in every day use.

Don't bother to try with FPE [www.plastic2print.com]

It has the rigidity i was looking for, but it sticks to nothing. I had to design mechanical interlock into parts to get any use out of it.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Don't bother to try with FPE [www.plastic2print.com]

It has the rigidity i was looking for, but it sticks to nothing. I had to design mechanical interlock into parts to get any use out of it.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: File handles January 01, 2017 03:19PM |

Registered: 9 years ago Posts: 1,873 |

That's very impressive - I couldn't get near 100mm/s (with typical extrusion sizes) without the filament buckling between the drive gear and the throat entrance, even with the throat touching the gear/idler. I guess you designed in some extra filament support in the area between the drive gear and throat?

Thanks for the tip on FPE. I recently tried soft PLA (https://filaments.ca/collections/2-85mm-3d-filaments/products/soft-pla-white-3-00mm?variant=1269775560) and found it very easy to print and quite compatible with other plastics. It even glues nicely to acrylic/plexiglass using plumbers plastic glues, so I'm planning on using it to make hinged windows on my next build.

Thanks for the tip on FPE. I recently tried soft PLA (https://filaments.ca/collections/2-85mm-3d-filaments/products/soft-pla-white-3-00mm?variant=1269775560) and found it very easy to print and quite compatible with other plastics. It even glues nicely to acrylic/plexiglass using plumbers plastic glues, so I'm planning on using it to make hinged windows on my next build.

|

Re: File handles January 02, 2017 02:18AM |

Registered: 12 years ago Posts: 2,470 |

For the >100 i actually used a bowden setup. The bowden went through the extruder and i only cut in small openings from two sides into it to give the gear and the idler access to the filament.

It was difficult to load and unload, but fast. My current setup is a classic direct extruder design with some extra support for the filament close to the gear and idler, just as you proposed.

I haven't tried soft PLA yet, maybe once i'm bored with TPU

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

It was difficult to load and unload, but fast. My current setup is a classic direct extruder design with some extra support for the filament close to the gear and idler, just as you proposed.

I haven't tried soft PLA yet, maybe once i'm bored with TPU

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Sorry, only registered users may post in this forum.