Large cable driven coreXY mechanism

Posted by the_digital_dentist

|

Large cable driven coreXY mechanism July 27, 2018 01:11AM |

Registered: 11 years ago Posts: 5,780 |

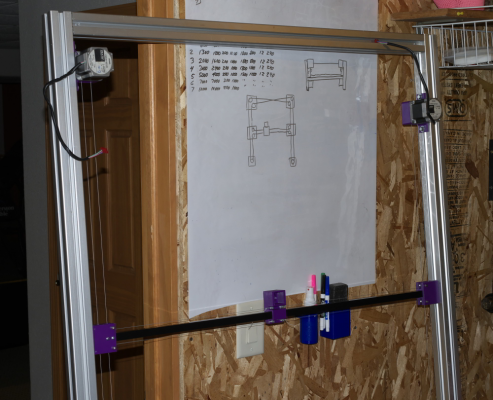

I'm working on a sand table project for the Milwaukee MakerFaire (the last weekend in September), so I designed and built a corexy mechanism to move the magnet around. This mechanism will be on the underside of the table, with about 15 mm of sand on top.

I finished printing the parts and assembling them so I decided to mount the parts on a frame for testing- I haven't done anything with cable drive before so this is an interesting experiment for me. The cable is 90 lb test dyneema fishing line. I printed the drive pulleys, motor mounts and all the other pulley mounts. The drive pulleys have 3 1/2 turns of the cable to get adequate friction to operate without slipping (I hope). When I push it manually it seems to work well. I intend to connect the motors to a controller this weekend and let it run for several hours to see if there is any slippage or other failure. Cables are tensioned by sliding the motor mounts in the t-slot frame and tightening down the screws. The motors are 180 oz-in NEMA-23 units that I had sitting around. The X axis is a 16 mm square aluminum tube (it seems to be powder coated).

The final size of the table will be 1.9m x 1m, about the size of the frame I am testing in. This is half of the test frame- the room is too small to get the whole thing in one picture. The frame is made of 45 mm square t-slot picked up at a scrap yard for $2 per lb.

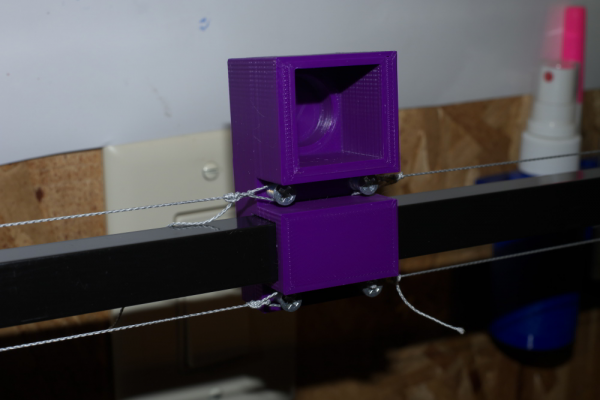

This is the magnet carriage- the cables attach to screws that have teflon tubing to prevent the screw threads from cutting the cable. The magnet is a 1" cube N52 neodymium type that fits loosley in the square tube. There will be a spring under it in the circular depression to keep the magnet pushed up against the underside of the table and follow the contour even if it sags under the weight of the sand.

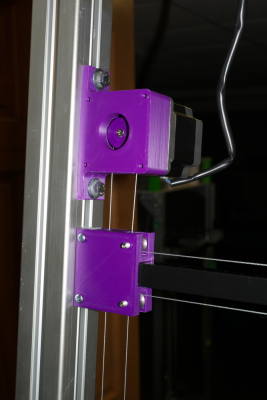

Here's one motor mount and one of the Y axis pulley blocks. I made sure that all the cables run parallel to the rails.

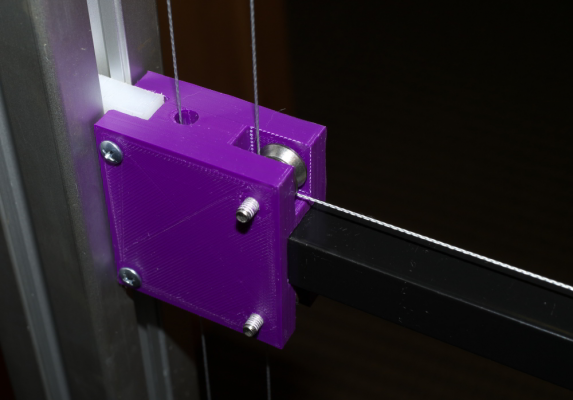

Here's one of the Y axis pulley blocks. The white piece in the t-slot is UHMW PE that slides easily and quietly. The black tube is the X axis guide.

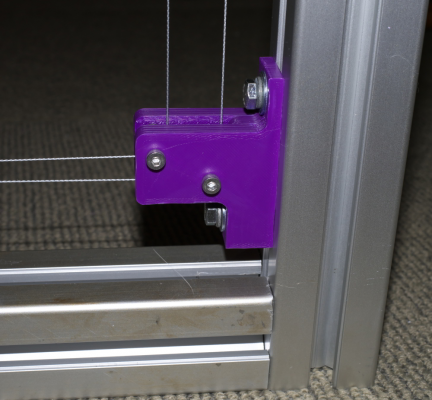

Here's one of the corner pulley blocks- the cables can be tightened by sliding these pulleys along the t-slot.

One thing I have learned about dealing with a cable drive is the difficulty in running the cable everywhere, especially to get it wrapped around the drive pulleys and keep it there before the tension is applied. I think I'm going to redesign the motor mounts to make it easier to get the cables on the drive pulleys.

Edited 1 time(s). Last edit at 07/27/2018 08:22AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I finished printing the parts and assembling them so I decided to mount the parts on a frame for testing- I haven't done anything with cable drive before so this is an interesting experiment for me. The cable is 90 lb test dyneema fishing line. I printed the drive pulleys, motor mounts and all the other pulley mounts. The drive pulleys have 3 1/2 turns of the cable to get adequate friction to operate without slipping (I hope). When I push it manually it seems to work well. I intend to connect the motors to a controller this weekend and let it run for several hours to see if there is any slippage or other failure. Cables are tensioned by sliding the motor mounts in the t-slot frame and tightening down the screws. The motors are 180 oz-in NEMA-23 units that I had sitting around. The X axis is a 16 mm square aluminum tube (it seems to be powder coated).

The final size of the table will be 1.9m x 1m, about the size of the frame I am testing in. This is half of the test frame- the room is too small to get the whole thing in one picture. The frame is made of 45 mm square t-slot picked up at a scrap yard for $2 per lb.

This is the magnet carriage- the cables attach to screws that have teflon tubing to prevent the screw threads from cutting the cable. The magnet is a 1" cube N52 neodymium type that fits loosley in the square tube. There will be a spring under it in the circular depression to keep the magnet pushed up against the underside of the table and follow the contour even if it sags under the weight of the sand.

Here's one motor mount and one of the Y axis pulley blocks. I made sure that all the cables run parallel to the rails.

Here's one of the Y axis pulley blocks. The white piece in the t-slot is UHMW PE that slides easily and quietly. The black tube is the X axis guide.

Here's one of the corner pulley blocks- the cables can be tightened by sliding these pulleys along the t-slot.

One thing I have learned about dealing with a cable drive is the difficulty in running the cable everywhere, especially to get it wrapped around the drive pulleys and keep it there before the tension is applied. I think I'm going to redesign the motor mounts to make it easier to get the cables on the drive pulleys.

Edited 1 time(s). Last edit at 07/27/2018 08:22AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism July 27, 2018 02:45AM |

Admin Registered: 16 years ago Posts: 13,886 |

... how big is the "elasticity" with your setup? - you can measure it by blocking one slide and "pulling" the other side with a "known force" ... we did this to measure the stiffness of CNC-mills by fixing a wire to the free slider and hook a basket with 20kg load to it ... for the wires 2kg should be enough to get measurable flexion ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism July 28, 2018 02:16AM |

Registered: 8 years ago Posts: 5,232 |

I've also made some experiemts with magnets and steel balls and I found: the ball won't follow the magnet exactly, when they are both the same size. The magnet should be smaller in diameter or requires a cone shaped steel coupler that collects the magnet force.

Even worse with a square or rectangular magnet. Depending on the direction you want to drag, the center_to_edge distance of the magnet varies.

PS: I like the PTFE sliders. Reminds me off my Compact Carrier. If the table will run 24/7 you'd better pick Delrin. It'll last longer and slides well too.

Edited 1 time(s). Last edit at 07/28/2018 02:22AM by o_lampe.

Even worse with a square or rectangular magnet. Depending on the direction you want to drag, the center_to_edge distance of the magnet varies.

PS: I like the PTFE sliders. Reminds me off my Compact Carrier. If the table will run 24/7 you'd better pick Delrin. It'll last longer and slides well too.

Edited 1 time(s). Last edit at 07/28/2018 02:22AM by o_lampe.

|

Re: Large cable driven coreXY mechanism July 28, 2018 11:19AM |

Registered: 11 years ago Posts: 5,780 |

I've been playing with the magnet and some 15 mm balls. The magnet is polarized so one half is N and the other half is S pole. If you put the ball on the side which is both N and S, it won't center itself, but if you put it on the faces that are all N or all S it seems to stay centered and likewise when dragging the ball with the magnet on the other side of a piece of wood, it seems to follow OK. I'll try to make a miniature sand enclosure to test it. If needed I'll add a steel piece to the magnet to concentrate to flux.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism July 28, 2018 12:56PM |

Admin Registered: 16 years ago Posts: 13,886 |

... yes, you'll need a "focussed" field to get a "sharp" gradient to center the steel ball.

Beside of a conus shaped iron piece on the magnet pole, you can use an iron cylinder too ... or stack several magnets with different sizes (e.g. 20, 10 and 5mm diameters), what will give more holding force, than an iron core with a single magnet

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Beside of a conus shaped iron piece on the magnet pole, you can use an iron cylinder too ... or stack several magnets with different sizes (e.g. 20, 10 and 5mm diameters), what will give more holding force, than an iron core with a single magnet

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism July 28, 2018 01:55PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Large cable driven coreXY mechanism July 28, 2018 04:41PM |

Admin Registered: 16 years ago Posts: 13,886 |

... yes -- I've used ferrofluid on neodym-magnets for stick'n'slip-free bearings and iron-microspheres for MRF (Magneto-Rheological-Fluids) on electro-magnets for special actuators and "femto-pumps"

Powdered iron is not so good for this sort of applications - search for "carbonyl iron microspheres" -- this are perfectly round iron particles coated with silizium to prevent oxidizing and spontaneous combustion ... have some with three different grades - specified as "HQ", "DC" and "CC" (size distributions around 1, 10 and 50 microns) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Powdered iron is not so good for this sort of applications - search for "carbonyl iron microspheres" -- this are perfectly round iron particles coated with silizium to prevent oxidizing and spontaneous combustion ... have some with three different grades - specified as "HQ", "DC" and "CC" (size distributions around 1, 10 and 50 microns) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism July 28, 2018 09:49PM |

Registered: 11 years ago Posts: 5,780 |

My car has struts with MRF that can be switched on/off to instantly stiffen the suspension. I can't wait to find out how much it costs to replace them...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism July 29, 2018 01:49PM |

Registered: 5 years ago Posts: 155 |

|

Re: Large cable driven coreXY mechanism July 29, 2018 03:29PM |

Admin Registered: 16 years ago Posts: 13,886 |

... both, FF and MRF are composed with oil, so no adhesion.

But you can use FF to temporary create "suction cups" under planar surfaces ... or "sink" a piece into a puddle of MRF and activate a strong magnet beneath -- it's like wax, when magnetized, but a "muddy" fluid without magnetic field ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But you can use FF to temporary create "suction cups" under planar surfaces ... or "sink" a piece into a puddle of MRF and activate a strong magnet beneath -- it's like wax, when magnetized, but a "muddy" fluid without magnetic field ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism July 30, 2018 01:46PM |

Registered: 5 years ago Posts: 155 |

You are right, no adhesion is bad for printing LOL

Those fluids are very interesting, there are even some yt videos how to produce something similar. MICR Toner is interesting e. g. as a base.

For use cases the properties should be regarded. I have some ideas like decelerate a linear guide faster, fix Z axis, make haptic AR/VR solutions, moulds for injection moulding and similar ideas.

I wonder whether a neodym-ferro emulsion would strengthen the effect.

Those fluids are very interesting, there are even some yt videos how to produce something similar. MICR Toner is interesting e. g. as a base.

For use cases the properties should be regarded. I have some ideas like decelerate a linear guide faster, fix Z axis, make haptic AR/VR solutions, moulds for injection moulding and similar ideas.

I wonder whether a neodym-ferro emulsion would strengthen the effect.

|

Re: Large cable driven coreXY mechanism July 30, 2018 02:01PM |

Admin Registered: 16 years ago Posts: 13,886 |

... this was my first youtube video upload -- showing some effects/behaviour of MRF

[www.youtube.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[www.youtube.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism July 30, 2018 04:12PM |

Registered: 5 years ago Posts: 155 |

|

Re: Large cable driven coreXY mechanism July 30, 2018 05:28PM |

Registered: 11 years ago Posts: 5,780 |

I have redesigned the motor mount based on some work done by polygonhell. The new version will prevent the cable from walking up and down the drive pulleys, wrapping over itself, and making all sorts of interesting plinking sounds as the mechanism moves. My biggest concern with it is that there may not be enough friction to drive the mechanism without slipping. I'll print it tonight and test it tomorrow, I think. In the meantime, I've added homing switches to the original build and intend to connect the mechanism to a smoothieboard and try driving it tonight. Simepl wiring- two motor cables and two homing switch cables.

I used some industrial snap switches for homing because they were handy and quick and easy to mount, but I'm thinking of a redesign using a pair of reed switches and magnets to sense when the X and Y axes are in home positions. The big magnet might be OK for sensing the X home position. We'll see. A couple drops of hot melt glue will hold magnets and reed switches in position. I want to avoid doing any wiring on the moving parts if possible.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I used some industrial snap switches for homing because they were handy and quick and easy to mount, but I'm thinking of a redesign using a pair of reed switches and magnets to sense when the X and Y axes are in home positions. The big magnet might be OK for sensing the X home position. We'll see. A couple drops of hot melt glue will hold magnets and reed switches in position. I want to avoid doing any wiring on the moving parts if possible.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism July 30, 2018 05:51PM |

Admin Registered: 16 years ago Posts: 13,886 |

Quote

JoergS5

Nice, long time since 2007, so you have a lot of experience!

... I've started with this sort of "tinkering" around 1990, so more than enough time, to gain some experience

Most of the "serious" development in the area of micro/nanotech was done between 2001 and 2005, but didn't post or publish due to NDA's or other restrictions

Then, from 2006 on, I've dropped most of this "commercial fuss" and started with more OS related projects like RepRap

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Large cable driven coreXY mechanism August 02, 2018 11:17PM |

Registered: 11 years ago Posts: 5,780 |

The second generation of the mechanism is done and tested and appears to be doing what it's supposed to. No more plinky noises from the cable wrapping over itself on the drive pulleys. I bumped up the acceleration and speed and it seems to work fine, without any slipping, though I may have to run it for several hours to verify.

Video here: [vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Video here: [vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism August 03, 2018 02:39AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Large cable driven coreXY mechanism August 03, 2018 06:55AM |

Registered: 11 years ago Posts: 5,780 |

He could sell his services to do advertising on the beach... put in a spray paint car or two and hang it on a wall or tow it behind a car or even a bicycle and he's got an instant graffiti machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Large cable driven coreXY mechanism August 04, 2018 07:54AM |

Registered: 5 years ago Posts: 155 |

|

Re: Large cable driven coreXY mechanism August 08, 2018 03:58AM |

Registered: 8 years ago Posts: 5,232 |

Just saw a video about 'sphericons'. Maybe a nice alternative to the boring steel ball?

Sorry, only registered users may post in this forum.