DiffBot - Differential Screw-Driven XY Gantry

Posted by Apsu

|

DiffBot - Differential Screw-Driven XY Gantry September 22, 2019 09:16PM |

Registered: 7 years ago Posts: 143 |

Hey folks,

After spending many years on my Tripteron and Delteron projects, I recently came up with a new and, I believe completely unique, parallel XY gantry design. I've been developing it for about a month now, and figured I'd post about it here.

I call it DiffBot, and there's an in-depth writeup with pictures and animations here.

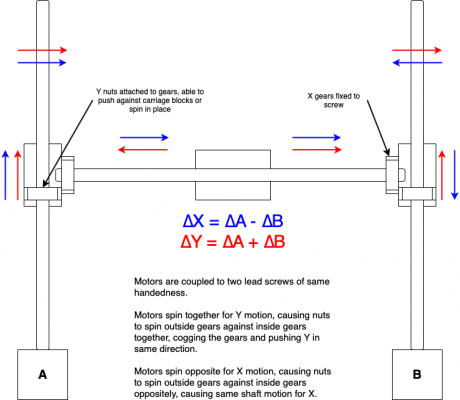

The general idea is to use screws (leadscrews in the prototype) to transfer motion along X and Y axes, with two differential motors like you'd have in an H-Bot/CoreXY setup. The unique part is that I am driving nuts on the motor-connected screws differentially. They can operate in 3 modes:

The next unique thing is I have each screw nut attached to a bevel gear in a gearbox, and each of those are connected to mating bevel gears attached to another screw, that goes across the gantry between the two gearboxes, which serves as the X axis.

Altogether it looks like this:

It's important to note that the Y geared-nuts are free to rotate with the screw or travel along it, and that the X gears are rigidly attached to the X screw. Furthermore, the X gears mate with the Y gears on the "inside" edges; this means if the Y gears try to spin the same way, the X gears will try to spin oppositely, and lock. This is a key part of how the mechanism is able to function and change between the 3 modes listed above.

I have an animation illustrating some of this idea here.

The next key thing to understand is that putting a gear on a screw nut gives a torque advantage to mode 2 vs mode 1 based on the screw's 'lead' -- the distance the threads travel linearly with one revolution of the screw. This can be a little tricky to explain, because there's almost no discussion of this concept when learning about screw physics, since the nut is almost always assumed to be fixed rigidly in place, so all the torque it sees converts to friction and linear force. But if you take a screw and nut threaded on it but otherwise free, and spin the screw, you can easily see the nut spins with it.

The torque vs linear force is in a ratio based on the helix angle. You can see this too with a simple thought experiment. If you imagine a screw with a very fine thread, it's "fine" because the threads meet at a very small angle, which provides tremendous torque multiplication, and the nut would want to travel down the screw more easily than rotate with it, because very little thread contact will push it in that direction.

On the opposite extreme, imagine a shaft that's splined lengthwise, or with a very long slow helix of thread. A nut on such a shaft would have a very large helix angle (180º for the spline), and almost all the force would be transmitted as torque, rotating the nut with the shaft, and almost none pushing along it.

So we can take from these extremes that there's a ratio of "wants to spin in place (with the screw)" and "wants to travel down the screw (and not spin)", based on the screw lead.

---

The screws I'm using for prototyping are Tr8x8, or trapezoidal-threaded 8mm diameter 8mm/rev lead. While screws with a longer lead allow for faster motion transfer and may be beneficial, Tr8x8's are common and cheap. In addition, the helix angle, via the formula angle = arctan(lead/(pi*effective_diameter)), is ~18º, which is enough to provide good mode 2 torque with very small gantry cogging. The rest of the discussion here is based on using screws of this lead or longer.

---

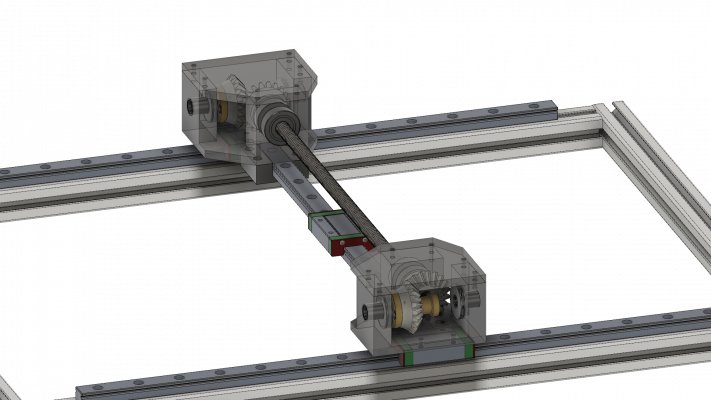

Now, with the background theory out of the way, the actual differential function of this gantry comes into play based on the gear arrangement and the fact the gear-nuts can switch modes based on where the resistance comes from. First, an example gearbox layout with fixed spacing just to get an idea of the gantry setup:

It only takes a slight amount of resistance on the nut to switch the gear-nut into mode 2 (spinning with the screw), or a slight amount of resistance on the gear teeth to switch to mode 1. The gantry and gear arrangement makes this easy, since the X gears mesh on opposite sides of the Y gears.

If you spin both Y screws the same way and speed, they will try to turn the X gears opposite, lock, and the Y nuts will travel down the screws, resulting in equal Y motion (mode 1).

If you spin both Y screws the opposite way and speed, they will try to turn the X gears the same, and X will rotate, resulting in X motion (mode 2). In addition, since each Y screw is spinning oppositely, any amount of the torque that attempts to move the nuts along the screws will be in opposite directions. The rigid connection across the gantry via the X screw/rail will resist this, reinforcing the mode 2 behavior.

As mentioned above, the screw lead will make the resistance required for mode 2 much smaller than mode 1 as the screw lead increases. This means that *unlike* an H-Bot, there is not a large gantry cogging torque to deal with.

---

Mode 3 requires special explanation, as it isn't entirely intuitive how it works given the screw/nut ratios and gear differential behavior, so I will try to make it clear.

For diagonal gantry motion (X and Y at the same time, in some ratio), the motor inputs are at different speeds. For the simple case of 45 degree motion, which is equal speed in X and Y, one motor will be held still while the other moves twice as fast. This is the same as H-Bot/CoreXY, of course.

Let's call the held motor side A, and the spinning side B. As the B screw spins, it tries to spin the Yb gear nut, Xb gear, which turns Xa, and tries to turn Ya. Since A is held still, Ya will rotate around the A screw, moving the gantry in Y.

When A moves along Y, the rigid X rail/screw tries to move the B side, which pushes the Yb gear-nut along the B screw, which changes the speed it rotates with the screw.

Since physics is effectively instantaneous, the result of this chain of kinematic relationships is that the Y gear-nuts will rotate X at a ratio to how fast they move along Y based on the speed difference between the A and B screws, or a mix of modes 1 and 2, which is mode 3.

---

Hopefully this is a clear enough description and explanation of the mechanisms and kinematic relationships of DiffBot, and I'm happy to clarify further if something doesn't make sense. As is tradition, I have built some prototype gearboxes and they are able to easily switch between modes with minor resistance, so I am not considering this mechanism to require proof, just design refinement and building full prototypes.

I'm in the process of constructing working prototypes and will update with pics/video of it moving soon. If you made it this far through that word soup, thanks for reading, and if you're going to be at ERRF this year, I am working hard to have a working DiffBot to show off there!

Edited 4 time(s). Last edit at 09/22/2019 11:43PM by Apsu.

After spending many years on my Tripteron and Delteron projects, I recently came up with a new and, I believe completely unique, parallel XY gantry design. I've been developing it for about a month now, and figured I'd post about it here.

I call it DiffBot, and there's an in-depth writeup with pictures and animations here.

The general idea is to use screws (leadscrews in the prototype) to transfer motion along X and Y axes, with two differential motors like you'd have in an H-Bot/CoreXY setup. The unique part is that I am driving nuts on the motor-connected screws differentially. They can operate in 3 modes:

- [1] Kept from rotating, moving along the screw (the usual way to use screw nuts)

[2] Kept from moving along the screw, rotating in-place with it

[3] Both rotating with the screw and moving along it in some ratio

The next unique thing is I have each screw nut attached to a bevel gear in a gearbox, and each of those are connected to mating bevel gears attached to another screw, that goes across the gantry between the two gearboxes, which serves as the X axis.

Altogether it looks like this:

It's important to note that the Y geared-nuts are free to rotate with the screw or travel along it, and that the X gears are rigidly attached to the X screw. Furthermore, the X gears mate with the Y gears on the "inside" edges; this means if the Y gears try to spin the same way, the X gears will try to spin oppositely, and lock. This is a key part of how the mechanism is able to function and change between the 3 modes listed above.

I have an animation illustrating some of this idea here.

The next key thing to understand is that putting a gear on a screw nut gives a torque advantage to mode 2 vs mode 1 based on the screw's 'lead' -- the distance the threads travel linearly with one revolution of the screw. This can be a little tricky to explain, because there's almost no discussion of this concept when learning about screw physics, since the nut is almost always assumed to be fixed rigidly in place, so all the torque it sees converts to friction and linear force. But if you take a screw and nut threaded on it but otherwise free, and spin the screw, you can easily see the nut spins with it.

The torque vs linear force is in a ratio based on the helix angle. You can see this too with a simple thought experiment. If you imagine a screw with a very fine thread, it's "fine" because the threads meet at a very small angle, which provides tremendous torque multiplication, and the nut would want to travel down the screw more easily than rotate with it, because very little thread contact will push it in that direction.

On the opposite extreme, imagine a shaft that's splined lengthwise, or with a very long slow helix of thread. A nut on such a shaft would have a very large helix angle (180º for the spline), and almost all the force would be transmitted as torque, rotating the nut with the shaft, and almost none pushing along it.

So we can take from these extremes that there's a ratio of "wants to spin in place (with the screw)" and "wants to travel down the screw (and not spin)", based on the screw lead.

---

The screws I'm using for prototyping are Tr8x8, or trapezoidal-threaded 8mm diameter 8mm/rev lead. While screws with a longer lead allow for faster motion transfer and may be beneficial, Tr8x8's are common and cheap. In addition, the helix angle, via the formula angle = arctan(lead/(pi*effective_diameter)), is ~18º, which is enough to provide good mode 2 torque with very small gantry cogging. The rest of the discussion here is based on using screws of this lead or longer.

---

Now, with the background theory out of the way, the actual differential function of this gantry comes into play based on the gear arrangement and the fact the gear-nuts can switch modes based on where the resistance comes from. First, an example gearbox layout with fixed spacing just to get an idea of the gantry setup:

It only takes a slight amount of resistance on the nut to switch the gear-nut into mode 2 (spinning with the screw), or a slight amount of resistance on the gear teeth to switch to mode 1. The gantry and gear arrangement makes this easy, since the X gears mesh on opposite sides of the Y gears.

If you spin both Y screws the same way and speed, they will try to turn the X gears opposite, lock, and the Y nuts will travel down the screws, resulting in equal Y motion (mode 1).

If you spin both Y screws the opposite way and speed, they will try to turn the X gears the same, and X will rotate, resulting in X motion (mode 2). In addition, since each Y screw is spinning oppositely, any amount of the torque that attempts to move the nuts along the screws will be in opposite directions. The rigid connection across the gantry via the X screw/rail will resist this, reinforcing the mode 2 behavior.

As mentioned above, the screw lead will make the resistance required for mode 2 much smaller than mode 1 as the screw lead increases. This means that *unlike* an H-Bot, there is not a large gantry cogging torque to deal with.

---

Mode 3 requires special explanation, as it isn't entirely intuitive how it works given the screw/nut ratios and gear differential behavior, so I will try to make it clear.

For diagonal gantry motion (X and Y at the same time, in some ratio), the motor inputs are at different speeds. For the simple case of 45 degree motion, which is equal speed in X and Y, one motor will be held still while the other moves twice as fast. This is the same as H-Bot/CoreXY, of course.

Let's call the held motor side A, and the spinning side B. As the B screw spins, it tries to spin the Yb gear nut, Xb gear, which turns Xa, and tries to turn Ya. Since A is held still, Ya will rotate around the A screw, moving the gantry in Y.

When A moves along Y, the rigid X rail/screw tries to move the B side, which pushes the Yb gear-nut along the B screw, which changes the speed it rotates with the screw.

Since physics is effectively instantaneous, the result of this chain of kinematic relationships is that the Y gear-nuts will rotate X at a ratio to how fast they move along Y based on the speed difference between the A and B screws, or a mix of modes 1 and 2, which is mode 3.

---

Hopefully this is a clear enough description and explanation of the mechanisms and kinematic relationships of DiffBot, and I'm happy to clarify further if something doesn't make sense. As is tradition, I have built some prototype gearboxes and they are able to easily switch between modes with minor resistance, so I am not considering this mechanism to require proof, just design refinement and building full prototypes.

I'm in the process of constructing working prototypes and will update with pics/video of it moving soon. If you made it this far through that word soup, thanks for reading, and if you're going to be at ERRF this year, I am working hard to have a working DiffBot to show off there!

Edited 4 time(s). Last edit at 09/22/2019 11:43PM by Apsu.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 03:55AM |

Registered: 7 years ago Posts: 507 |

Very interesting. I don't think I've fully grasped the way it work yet. but most of it makes sense.

A couple of possible issues is that but bevel gears and trapezoidal lead screws have backlash, and you have them setup in series with each other, so their backlash is cumulative. Aside from the usual backlash issues that would normally cause, since both motors need to work together and sometimes in different directions this could cause them to engage at different times, and one motor would be slightly behind the other. This could lead to racking or an unintentional movements in X or Y (I think specifically X) where the second motor engages late and doesn't cancel all of the motion of the first motor that it should. Second issue I imagine is sort of "parasitic" friction might prevent the nuts turning freely on the lead screw as required for X moves, Again I imagine this could lead to unintentional moves in the Y axis I think or racking.

I could be completely off base here, just my immediate thoughts. Really neat though, I'm really interested in fixed motor designs with an XY stationary bed. This is the first lead screw based one I've seen which is really cool (other than ultimaker style ones where the perimeter belts are replaced by leadscrews, but that design isn't intrinsically lead screw or belt based like this one).

P.s. really liked your tripteron and similar designs. It's a shame patents really stunt further experimentation in that area for now.

A couple of possible issues is that but bevel gears and trapezoidal lead screws have backlash, and you have them setup in series with each other, so their backlash is cumulative. Aside from the usual backlash issues that would normally cause, since both motors need to work together and sometimes in different directions this could cause them to engage at different times, and one motor would be slightly behind the other. This could lead to racking or an unintentional movements in X or Y (I think specifically X) where the second motor engages late and doesn't cancel all of the motion of the first motor that it should. Second issue I imagine is sort of "parasitic" friction might prevent the nuts turning freely on the lead screw as required for X moves, Again I imagine this could lead to unintentional moves in the Y axis I think or racking.

I could be completely off base here, just my immediate thoughts. Really neat though, I'm really interested in fixed motor designs with an XY stationary bed. This is the first lead screw based one I've seen which is really cool (other than ultimaker style ones where the perimeter belts are replaced by leadscrews, but that design isn't intrinsically lead screw or belt based like this one).

P.s. really liked your tripteron and similar designs. It's a shame patents really stunt further experimentation in that area for now.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 04:17AM |

Registered: 7 years ago Posts: 143 |

Thanks for the kind words on the *pteron work!

You are indeed correct that backlash and friction are the enemy here, but I think they can be mitigated fairly well. My current design is using spiral bevel/helical gear profiles, which mate extremely well and have almost no detectable backlash (more on this in a sec). I am also using carefully fixed spacing and sizing of parts to maintain a solid gear mesh without it being too "deep" that friction ramps up. The bearing choices are back to back 608s (precision, not skateboard!) for X preloaded via a locking collar, and PTFE lined sleeves plus axial thrust needle rollers for Y. It's a very rigid assembly that maintains the gear relationship very well.

As for the screw backlash, I started with spring loaded anti-backlash nuts and shifting springs around variously, but for now I decided to switch to acetal/POM nuts, which are quite low on backlash, so for low-temp prototyping it's basically solved. I can't feel or see backlash on the POM nuts unlike the brass ones.

Lastly, backlash in the gear teeth isn't much of a concern because it gets divided into the axes via the screw -> nut ratio, and that ratio is in our favor on this point. As an example, 1deg of tooth-tooth backlash would result in 1/360rev * 8mm/rev = 0.02mm linear backlash. With my current 20 tooth gears, the max it could be is 18deg (360/20), or 18/360 * 8 = 0.4mm. But that's the size of an entire tooth, and really not possible. Mechanically speaking, to still be meshed, it probably can't go past about 5deg worst possible case, which is 0.1mm. That's at least comparable if not much better than belt resolutions for X/Y if your gear mesh is good.

I'm not worried about parasitic effects for now, as you get those in belted systems that aren't aligned/tensioned/constructed well. I think the theory is sound and capable of being done well, so the fun challenge for me is to see how well I can do it with printed and off the shelf parts, first. Then I'll probably get custom made parts and see how far I can take it. Maybe some other folks will join in and try their own ideas as well

You are indeed correct that backlash and friction are the enemy here, but I think they can be mitigated fairly well. My current design is using spiral bevel/helical gear profiles, which mate extremely well and have almost no detectable backlash (more on this in a sec). I am also using carefully fixed spacing and sizing of parts to maintain a solid gear mesh without it being too "deep" that friction ramps up. The bearing choices are back to back 608s (precision, not skateboard!) for X preloaded via a locking collar, and PTFE lined sleeves plus axial thrust needle rollers for Y. It's a very rigid assembly that maintains the gear relationship very well.

As for the screw backlash, I started with spring loaded anti-backlash nuts and shifting springs around variously, but for now I decided to switch to acetal/POM nuts, which are quite low on backlash, so for low-temp prototyping it's basically solved. I can't feel or see backlash on the POM nuts unlike the brass ones.

Lastly, backlash in the gear teeth isn't much of a concern because it gets divided into the axes via the screw -> nut ratio, and that ratio is in our favor on this point. As an example, 1deg of tooth-tooth backlash would result in 1/360rev * 8mm/rev = 0.02mm linear backlash. With my current 20 tooth gears, the max it could be is 18deg (360/20), or 18/360 * 8 = 0.4mm. But that's the size of an entire tooth, and really not possible. Mechanically speaking, to still be meshed, it probably can't go past about 5deg worst possible case, which is 0.1mm. That's at least comparable if not much better than belt resolutions for X/Y if your gear mesh is good.

I'm not worried about parasitic effects for now, as you get those in belted systems that aren't aligned/tensioned/constructed well. I think the theory is sound and capable of being done well, so the fun challenge for me is to see how well I can do it with printed and off the shelf parts, first. Then I'll probably get custom made parts and see how far I can take it. Maybe some other folks will join in and try their own ideas as well

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 05:49AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 07:01AM |

Registered: 11 years ago Posts: 5,780 |

Interesting, but I suspect the hardware to make it work is going to be pretty expensive. My experience with using cheap gears to make a belt lifted Z axis tells me that any flaws in the gears are going to show up as repeating defects in the prints each time each of the gears makes one rev. You're going to need very high quality (read expensive) gears to make it work well. What happens to print quality as the gears wear?

Edited 1 time(s). Last edit at 09/23/2019 07:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 09/23/2019 07:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 07:09AM |

Admin Registered: 16 years ago Posts: 13,886 |

... if this works, it will at least eliminate the elasticity of the belts ..

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 10:06AM |

Registered: 7 years ago Posts: 143 |

Quote

the_digital_dentist

Interesting, but I suspect the hardware to make it work is going to be pretty expensive. My experience with using cheap gears to make a belt lifted Z axis tells me that any flaws in the gears are going to show up as repeating defects in the prints each time each of the gears makes one rev. You're going to need very high quality (read expensive) gears to make it work well. What happens to print quality as the gears wear?

I don't think it has to be that expensive. My current printed gears are based on CAD models from off the shelf metal ones from places like McMaster and KHK, where the prices are in the $20-30 range, and can work for at least half the gears I'm using as-is. I'd also say that Z is a bit more sensitive to backlash or irregularity (in terms of visual result) than X and Y, which is why belted Z can be challenging.

As for wear, I'm not too worried about it at the moment. The loads involved are relatively small and not constant (unlike Z lifting a heavy bed assembly) compared to the material choices, especially with metal.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 10:12AM |

Registered: 7 years ago Posts: 143 |

Quote

MKSA

.

A CoreXY is also a "differential" based system.

I fail to see the advantages, as for issues, you noticed a few already.

There's quite a few potential advantages if executed well. I mention a bunch at the bottom of the github document, but to recap:

No long complex belt paths means less issues with tensioning/alignment/pulleys/tiny bearings/hysteresis/stretch/temperature.

Easier material choices to fully enclose the gantry in a high-temp enclosure for the most challenging materials, like PEEK.

Simple and relatively cheap assembly with low part count.

Easier to change mechanical ratios without dealing with pulley sizes increasing.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 12:07PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Apsu

Quote

MKSA

.

A CoreXY is also a "differential" based system.

I fail to see the advantages, as for issues, you noticed a few already.

There's quite a few potential advantages if executed well. I mention a bunch at the bottom of the github document, but to recap:

No long complex belt paths means less issues with tensioning/alignment/pulleys/tiny bearings/hysteresis/stretch/temperature.

Easier material choices to fully enclose the gantry in a high-temp enclosure for the most challenging materials, like PEEK.

Simple and relatively cheap assembly with low part count.

Easier to change mechanical ratios without dealing with pulley sizes increasing.

What kind of test did you carry to back your claims ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 12:16PM |

Registered: 7 years ago Posts: 143 |

Quote

MKSA

What kind of test did you carry to back your claims ?

I'm not sure you're following what I'm presenting here. The items I listed as potential benefits over a belted system are observations of facts based on assuming a well-executed build in terms of materials and mechanical construction. There's no testing required to note the advantage of a screw over a belt in the aspects I mentioned. Or that the part count is lower than a CoreXY, or that you don't need to worry about the small bearings used in 5mm bore pulleys. And so on.

Doesn't mean it's an automatic win, there's a lot of engineering going on here and ways to fail. Plus there's factual disadvantages that need to be overcome, like requiring a higher motor RPM for lower screw leads to achieve equivalent gantry speeds to belts, something that small frame stepper motors struggle with.

If there's something about this list of obvious observations you think needs to be tested, please elaborate.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 02:37PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Apsu

Quote

MKSA

What kind of test did you carry to back your claims ?

I'm not sure you're following what I'm presenting here. The items I listed as potential benefits over a belted system are observations of facts based on assuming a well-executed build in terms of materials and mechanical construction. There's no testing required to note the advantage of a screw over a belt in the aspects I mentioned. Or that the part count is lower than a CoreXY, or that you don't need to worry about the small bearings used in 5mm bore pulleys. And so on.

Doesn't mean it's an automatic win, there's a lot of engineering going on here and ways to fail. Plus there's factual disadvantages that need to be overcome, like requiring a higher motor RPM for lower screw leads to achieve equivalent gantry speeds to belts, something that small frame stepper motors struggle with.

If there's something about this list of obvious observations you think needs to be tested, please elaborate.

Don't worry, I followed, found this mechanism "obvious" and didn't need to read you "explanation" but I consider irrelevant your list of obvious advantages from obvious observations

OK on a computer simulation not in real life.

So do a prototype THEN do a list of REAL pro and cons.

Please avoid listing the build shortcomings of other machines for ex. the small bearings used in CoreXY.

Edited 1 time(s). Last edit at 09/23/2019 02:38PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 02:41PM |

Registered: 7 years ago Posts: 143 |

Quote

MKSA

Quote

Apsu

Quote

MKSA

What kind of test did you carry to back your claims ?

I'm not sure you're following what I'm presenting here. The items I listed as potential benefits over a belted system are observations of facts based on assuming a well-executed build in terms of materials and mechanical construction. There's no testing required to note the advantage of a screw over a belt in the aspects I mentioned. Or that the part count is lower than a CoreXY, or that you don't need to worry about the small bearings used in 5mm bore pulleys. And so on.

Doesn't mean it's an automatic win, there's a lot of engineering going on here and ways to fail. Plus there's factual disadvantages that need to be overcome, like requiring a higher motor RPM for lower screw leads to achieve equivalent gantry speeds to belts, something that small frame stepper motors struggle with.

If there's something about this list of obvious observations you think needs to be tested, please elaborate.

Don't worry, I followed, found this mechanism "obvious" and didn't need to read you "explanation" but I consider irrelevant your list of obvious advantages from obvious observations

OK on a computer simulation not in real life.

So do a prototype THEN do a list of REAL pro and cons.

Please avoid listing the build shortcomings of other machines for ex. the small bearings used in CoreXY.

Nah. I tried to engage you in a discussion but since it's such an obvious mechanism you didn't read what I wrote, I will return the favor. Best of luck to you

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 03:17PM |

Registered: 11 years ago Posts: 1,049 |

Perhaps a sprial bevel gear

[www.thingiverse.com]

they are very smooth and used in Hi torque applications (differentials)

?What is the best (smoothest) right angle gear configuration?

Have to also consider the locking of the gear?

[www.thingiverse.com]

they are very smooth and used in Hi torque applications (differentials)

?What is the best (smoothest) right angle gear configuration?

Have to also consider the locking of the gear?

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 03:26PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Apsu

Nah. I tried to engage you in a discussion but since it's such an obvious mechanism you didn't read what I wrote, I will return the favor. Best of luck to you

Listen, I don't need to read your explanation to see how it works. I can even tell you that in theory it works BUT I question your claims.

So no need for "conversation", just build the prototypes and prove your points.

Don't count on luck though.

"Never repeat a successful experiment"

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 03:30PM |

Registered: 7 years ago Posts: 143 |

Quote

cozmicray

Perhaps a sprial bevel gear

[www.thingiverse.com]

they are very smooth and used in Hi torque applications (differentials)

?What is the best (smoothest) right angle gear configuration?

Have to also consider the locking of the gear?

Yes indeed, I am actually using spiral bevel gears right now. They are excellent for this application. I'm not sure what you mean by "locking" though. Do you mean fastening to the X screw and Y nuts? For that I'm using a set screw on X geasr and 4 screws in the bottom of the Y gears to lock the screw nuts inside them.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 05:23PM |

Admin Registered: 16 years ago Posts: 13,886 |

... an interesting "slip-free" alternative to gears are two strong ring-magnets with beveled perimeters

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 06:00PM |

Registered: 12 years ago Posts: 1,450 |

Quote

MKSA

.............................................................................

So no need for "conversation", just build the prototypes and prove your points.

.......................................

Hmmm, and I always thought that a forum was a place you come to discuss ideas, to have a conversation.

I never realised that it is just a place to present a glorious and finished design, unsullied by the input from anybody else.

Mike

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 06:02PM |

Registered: 7 years ago Posts: 143 |

Quote

leadinglights

Quote

MKSA

.............................................................................

So no need for "conversation", just build the prototypes and prove your points.

.......................................

Hmmm, and I always thought that a forum was a place you come to discuss ideas, to have a conversation.

I never realised that it is just a place to present a glorious and finished design, unsullied by the input from anybody else.

Mike

Exactly why I presented my work in progress, theory, and plans, to start a conversation here instead of just on the discords and chats I'm in lately. Guess we both missed the mark ;P

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 06:03PM |

Registered: 7 years ago Posts: 143 |

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 23, 2019 06:52PM |

Admin Registered: 16 years ago Posts: 13,886 |

... if they were with bores, they would be perfekt - [www.supermagnete.de]

Could be a single magnet with an iron counterpart too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Could be a single magnet with an iron counterpart too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 24, 2019 12:16AM |

Registered: 6 years ago Posts: 1,007 |

Quote

leadinglights

Quote

MKSA

.............................................................................

So no need for "conversation", just build the prototypes and prove your points.

.......................................

Hmmm, and I always thought that a forum was a place you come to discuss ideas, to have a conversation.

I never realised that it is just a place to present a glorious and finished design, unsullied by the input from anybody else.

Mike

Computer animation are indeed great "discussion piece".

How about resuming the conversation when there is a prototype ?

Will wait.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 24, 2019 03:15PM |

Registered: 7 years ago Posts: 619 |

Quote

leadinglights

Quote

MKSA

.............................................................................

So no need for "conversation", just build the prototypes and prove your points.

.......................................

Hmmm, and I always thought that a forum was a place you come to discuss ideas, to have a conversation.

I never realised that it is just a place to present a glorious and finished design, unsullied by the input from anybody else.

Mike

Oh, don't mind MKSA, he always gets up on the wrong side of the bed. I personally like to read about interesting new ideas. New ideas move all of us forward, just not always in the direction we think we're moving...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 25, 2019 01:34AM |

Registered: 7 years ago Posts: 507 |

Well someone came out from under the bridge.

Anyways, the "parasitic" effect I was meaning mostly is if friction between the nut and screw causing the nut to spin with the screw (thus not moving axially as it should) rather than stay stationary when you want it, or vice versa friction in the bevel gears stopping the nut from rotating freely with the lead screw (and thus causing it to move axially when not intended). These would possibly cause racking, which would make these sources of friction worse and so on. I'm planning on finally getting to build a CNC either late this year or early next year and I'd be happy to help with the prototyping and R'n'D.

As for backlash, I just remembered this type of anti backlash nut I saw a while ago, might be useful.

[eu.makerdise.com]

The spring force is applied radially via a collet type system. They means that axial forces in the direction of the screw (say cutting forces on a router/mill) can't compress the spring and reintroduce the backlash.

Also a suggestion for the bevel gears if backlash is an issue, you could use two angle drums coupled by a cable. These sorts of mechanisms are very low backlash and very cheap/easy to make compared to bevel and spiral bevel gears.

Also I think there's a way to simplify the mechanics. If you used two different Y axis screws, one left handed one right handed. Then added a worm wheel to either end of the X axis screw which mates to the Y axis leadscrews. I think this would give the same mechanical response with fewer parts. I could be wrong, haven't had too much time to think this through. The two different Y screws might not be necessary now that I think about it, maybe they can be the same handed-ness.

Edited 3 time(s). Last edit at 09/25/2019 01:42AM by Trakyan.

Anyways, the "parasitic" effect I was meaning mostly is if friction between the nut and screw causing the nut to spin with the screw (thus not moving axially as it should) rather than stay stationary when you want it, or vice versa friction in the bevel gears stopping the nut from rotating freely with the lead screw (and thus causing it to move axially when not intended). These would possibly cause racking, which would make these sources of friction worse and so on. I'm planning on finally getting to build a CNC either late this year or early next year and I'd be happy to help with the prototyping and R'n'D.

As for backlash, I just remembered this type of anti backlash nut I saw a while ago, might be useful.

[eu.makerdise.com]

The spring force is applied radially via a collet type system. They means that axial forces in the direction of the screw (say cutting forces on a router/mill) can't compress the spring and reintroduce the backlash.

Also a suggestion for the bevel gears if backlash is an issue, you could use two angle drums coupled by a cable. These sorts of mechanisms are very low backlash and very cheap/easy to make compared to bevel and spiral bevel gears.

Also I think there's a way to simplify the mechanics. If you used two different Y axis screws, one left handed one right handed. Then added a worm wheel to either end of the X axis screw which mates to the Y axis leadscrews. I think this would give the same mechanical response with fewer parts. I could be wrong, haven't had too much time to think this through. The two different Y screws might not be necessary now that I think about it, maybe they can be the same handed-ness.

Edited 3 time(s). Last edit at 09/25/2019 01:42AM by Trakyan.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 25, 2019 03:52AM |

Registered: 7 years ago Posts: 143 |

Quote

Trakyan

Well someone came out from under the bridge.

Anyways, the "parasitic" effect I was meaning mostly is if friction between the nut and screw causing the nut to spin with the screw (thus not moving axially as it should) rather than stay stationary when you want it, or vice versa friction in the bevel gears stopping the nut from rotating freely with the lead screw (and thus causing it to move axially when not intended). These would possibly cause racking, which would make these sources of friction worse and so on. I'm planning on finally getting to build a CNC either late this year or early next year and I'd be happy to help with the prototyping and R'n'D.

As for backlash, I just remembered this type of anti backlash nut I saw a while ago, might be useful.

[eu.makerdise.com]

The spring force is applied radially via a collet type system. They means that axial forces in the direction of the screw (say cutting forces on a router/mill) can't compress the spring and reintroduce the backlash.

Also a suggestion for the bevel gears if backlash is an issue, you could use two angle drums coupled by a cable. These sorts of mechanisms are very low backlash and very cheap/easy to make compared to bevel and spiral bevel gears.

Also I think there's a way to simplify the mechanics. If you used two different Y axis screws, one left handed one right handed. Then added a worm wheel to either end of the X axis screw which mates to the Y axis leadscrews. I think this would give the same mechanical response with fewer parts. I could be wrong, haven't had too much time to think this through. The two different Y screws might not be necessary now that I think about it, maybe they can be the same handed-ness.

Yeah, I follow you on the friction. It's a concern but the static setup I'm achieving currently with a fixed spacer instead of spring system is resulting in really low friction on both gears and nut.

I'm hoping to avoid belts/cables/anything flexible, if possible. Part of why I'm pursuing screws and gears in the first place

As for worms, I considered it as well, and different handedness screws! Two problems I see are that the driven worm can't backdrive the pinion, so each pinion would see a locked X axis kinematically at all times, and second problem is that you can't get a 1:1 worm gear ratio.

Great thoughts though, and help prototyping with someone with a CNC would be awesome, sounds fun.

---

Edit: Added a video of just the Y gear-nut operating in some of the modes in different directions with only minor fingertip force on the screw. It's here. And yes, I know one of the thrust bearings has some eccentricity, and neither of them are greased so they're noisy. That'll come later ;P

Edited 1 time(s). Last edit at 09/25/2019 04:04AM by Apsu.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 25, 2019 06:54PM |

Registered: 7 years ago Posts: 507 |

I get you on not wanting flexibility from cables, but what I'm talking about the cables are very short, they are only enough to wrap around the two drums that are almost touching in a figure 8 type arrangement, they serve to take out backlash/slop more than transmit force. It was just a suggestion for some ghetto low backlash gears.

Why would the worm need to back drive the pinion? All the motive force comes from the Y screws being driven by the motor, the worm wheel shouldn't ever be driving the screws. You're right that you wont get a 1:1 gear ratio. Perhaps using a higher lead on the X axis screw to make up for the gear reduction from the worm? Or maybe just say its a feature not a bug

Upon some closer thinking, what would be needed for the worm-wormwheel version I think is not different handed-ness of screws, but have one leadscrew connected at the top of a wormwheel, the second at the bottom. That way when both Y screws are trying to advance forward or backward, they try to turn the X screw in opposite directions so it doesn't rotate, and instead the worm wheels advance along the leadscrew giving Y axis movement. Similarly, when the Y screws turn in different directions they will both turn the worm wheels in the same direction, so the X screw spins giving X axis movement. This sort of combines the lead-nut and bevel gears into one using the worm wheel which shortens the component list and reduces sources of backlash. The asymmetry of this design (one leadscrew contacting on top, one on bottom) bugs me though, your version looks more pleasing to the eye.

A side effect is that this setup could be cantilevered (I personally wouldn't want to, but ya'know), Two parallel lead screws (your driven lead screws) with a worm wheel sandwiched between and another leadscrew attached to that worm wheel acts as your other axis. I'm sort of rambling here.

But wow, your setup is very easy to back drive, maybe I'm overthinking the parasitic friction.

Why would the worm need to back drive the pinion? All the motive force comes from the Y screws being driven by the motor, the worm wheel shouldn't ever be driving the screws. You're right that you wont get a 1:1 gear ratio. Perhaps using a higher lead on the X axis screw to make up for the gear reduction from the worm? Or maybe just say its a feature not a bug

Upon some closer thinking, what would be needed for the worm-wormwheel version I think is not different handed-ness of screws, but have one leadscrew connected at the top of a wormwheel, the second at the bottom. That way when both Y screws are trying to advance forward or backward, they try to turn the X screw in opposite directions so it doesn't rotate, and instead the worm wheels advance along the leadscrew giving Y axis movement. Similarly, when the Y screws turn in different directions they will both turn the worm wheels in the same direction, so the X screw spins giving X axis movement. This sort of combines the lead-nut and bevel gears into one using the worm wheel which shortens the component list and reduces sources of backlash. The asymmetry of this design (one leadscrew contacting on top, one on bottom) bugs me though, your version looks more pleasing to the eye.

A side effect is that this setup could be cantilevered (I personally wouldn't want to, but ya'know), Two parallel lead screws (your driven lead screws) with a worm wheel sandwiched between and another leadscrew attached to that worm wheel acts as your other axis. I'm sort of rambling here.

But wow, your setup is very easy to back drive, maybe I'm overthinking the parasitic friction.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 25, 2019 07:24PM |

Registered: 7 years ago Posts: 143 |

Quote

Trakyan

I get you on not wanting flexibility from cables, but what I'm talking about the cables are very short, they are only enough to wrap around the two drums that are almost touching in a figure 8 type arrangement, they serve to take out backlash/slop more than transmit force. It was just a suggestion for some ghetto low backlash gears.

Why would the worm need to back drive the pinion? All the motive force comes from the Y screws being driven by the motor, the worm wheel shouldn't ever be driving the screws. You're right that you wont get a 1:1 gear ratio. Perhaps using a higher lead on the X axis screw to make up for the gear reduction from the worm? Or maybe just say its a feature not a bug

Upon some closer thinking, what would be needed for the worm-wormwheel version I think is not different handed-ness of screws, but have one leadscrew connected at the top of a wormwheel, the second at the bottom. That way when both Y screws are trying to advance forward or backward, they try to turn the X screw in opposite directions so it doesn't rotate, and instead the worm wheels advance along the leadscrew giving Y axis movement. Similarly, when the Y screws turn in different directions they will both turn the worm wheels in the same direction, so the X screw spins giving X axis movement. This sort of combines the lead-nut and bevel gears into one using the worm wheel which shortens the component list and reduces sources of backlash. The asymmetry of this design (one leadscrew contacting on top, one on bottom) bugs me though, your version looks more pleasing to the eye.

A side effect is that this setup could be cantilevered (I personally wouldn't want to, but ya'know), Two parallel lead screws (your driven lead screws) with a worm wheel sandwiched between and another leadscrew attached to that worm wheel acts as your other axis. I'm sort of rambling here.

But wow, your setup is very easy to back drive, maybe I'm overthinking the parasitic friction.

There's benefits to keeping both axes in the same plane, too, chief of which is keeping the torque moments from being more complex and multi-axis. Given that, I think the bevel setup is a solid choice to continue to pursue for now. It's good you're thinking about robustness and future assembly ideas though!

And yeah what I have now is quite low friction in both directions because of the carefully measured spacing of parts to keep the gear-nut loaded firmly on the thrust bearing behind it, so either direction it's driven it doesn't change the gear mesh depth.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 27, 2019 10:49PM |

Registered: 7 years ago Posts: 143 |

Update time!

It works!!

First moves

X only then Y only

The left gearbox has some spacing issues and extra tooth-tooth backlash as a result, but that's fixable. I'm just super excited that it works on stock CoreXY kinematics and demonstrates all three differential behavior modes correctly.

I'm going to get the X carriage connected to the X screw with a nut and work on the gear mesh, then I'll record a more comprehensive video with clear demonstration of function and commentary.

It works!!

First moves

X only then Y only

The left gearbox has some spacing issues and extra tooth-tooth backlash as a result, but that's fixable. I'm just super excited that it works on stock CoreXY kinematics and demonstrates all three differential behavior modes correctly.

I'm going to get the X carriage connected to the X screw with a nut and work on the gear mesh, then I'll record a more comprehensive video with clear demonstration of function and commentary.

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 28, 2019 08:00AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 28, 2019 11:10AM |

Registered: 7 years ago Posts: 143 |

|

Re: DiffBot - Differential Screw-Driven XY Gantry September 29, 2019 08:02AM |

Registered: 5 years ago Posts: 155 |

This a very interesing idea.

If you suffer from backlash in the gears, you can try a friction drive (with 90 degree pivoted), or the idea of [www.youtube.com]

Looking forward your further development!

Edited 1 time(s). Last edit at 09/29/2019 08:25AM by JoergS5.

If you suffer from backlash in the gears, you can try a friction drive (with 90 degree pivoted), or the idea of [www.youtube.com]

Looking forward your further development!

Edited 1 time(s). Last edit at 09/29/2019 08:25AM by JoergS5.

Sorry, only registered users may post in this forum.