Possibility of an anthropomorphic robot handyman

Posted by Nikita K

|

Possibility of an anthropomorphic robot handyman November 19, 2013 03:23AM |

Registered: 10 years ago Posts: 2 |

Basically, the idea is to create a robot can effectively use tools designed for humans.

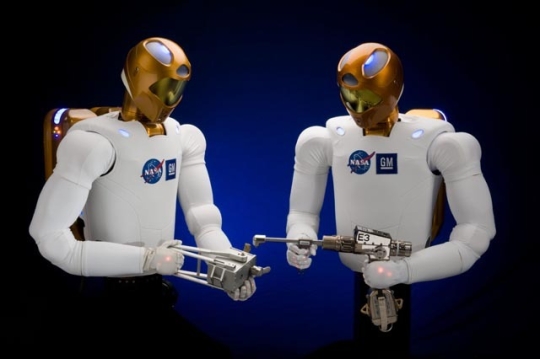

The idea isn't new. Many organisations such as NASA and DARPA are working on their own variats. There are also many anthropomorphic robots of any size and price range available commercially, though most of them are either completely inadequate at handling any sort of tool, or extremely expensive,

The purpose of this thread is to discuss the feasibility and practicality of creating such a robot.

Why use tools?

There are many advantages to having a robot that can use tools.

- Hand tools get the job done and are cheap, but require a steady hand and for you to spend your own energy laboring all day.

- Having a robot use hand tools effectively gives you the power and precision of a large CNC machine.

- You do not have to pay for a specialized machine, and you do not have to design a separate robot (or separate end effector) for each task.

- A robot can bravely march into any environment and work with dangerous equipment and materials. You do not have to worry about getting your arm chopped off or molten metal spilling over your pants. If you absolutely have to work with something dangerous, let a robot do that instead.

Why anthropomorphic?

If you want a robot that interacts with a human-centric environment, it would have to somewhat resemble a human. The upright frame of a humanoid is the most advanced frame that can walk through a doorway, halls, ladders, and messy crowded workshops. The two legs allow for greatest mobility, although technologically difficult and can, for the most part, be replaced by wheels. The human hand, on the other hand, is not easily replaceable.

Take a look at some of the tools that a robot would have to deal with. There are many manipulators that are quite good at picking up a specific kind of objects, and some that do reasonably well with a wide variety of objects (such as the ground-coffee ball vacuum manipulator) but the only manipulator that can adequately manipulate the whole spectrum of tools developed for the human hand, is the human hand.

Ideal case

The final shape of the project, as I see it, would be a very anthropomorphic robot. Here are some requirements:

- Matches or exceeds human abilities on the range of motion, speed, and strength.

- Able to move with great agility and precision.

- Employs advanced passive-dynamic bipedal walking, i.e. able to walk or run quickly and efficiently on any terrain.

- Able to use any tool designed for humans as it was intended to be used.

- Can be commanded by voice to perform most manual tasks (ones that do not require much decision making).

- Can be programmed by voice (i.e. told how to perform new tasks), shown, or guided through the process.

- Can recognize some classes of objects

- Can navigate through unknown environment

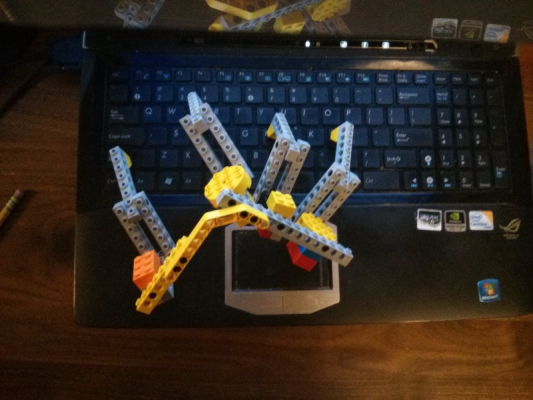

First stage: dexterous hand

The first step in making such a robot, as I see it, is simply making a human-like hand and attaching it to a simple manipulator arm. It should be possible to create a single hand with simple servos and 3d-printed plastic mechanical parts. Keep in mind though, a hand has many requirements to satisfy before it can be considered useful.

Let's look at a human hand. Look at your hand right now. It should have five fingers, plus or minus. Each finger has 4 degrees of freedom (up/down, left/right, and two more pairs of up/down for the two joints in the finger). Like any manipulator, each finger has a range of motion or envelope (the volume of space encompassing all position that the tip can possibly reach). Four fingers have similar position and envelope. The thumb however is attached opposite of the other fingers, and has a wider envelope. Most of this peculiar arrangement can be explained theoretically, although some things are still a mystery to me.

Trivia: 8 fingers (other than thumbs) are together strong enough to lift the whole weight of a human. In other words, each finger can alone lift about 15 kg. It's hard to say how this translates to torque though, but I'll give 4.4 Nm (Newton-meters) as a ball-park for joint torque involved.

Theoretical study of theoretical fingers

I'll try to explain why the hand has fingers, and how does having a certain number of fingers relate to being able to grasp various shapes.

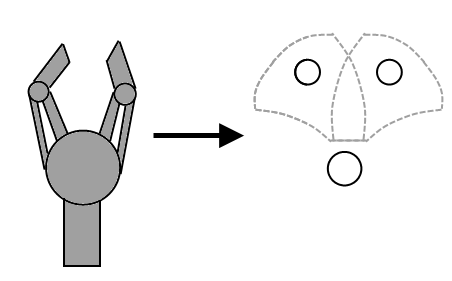

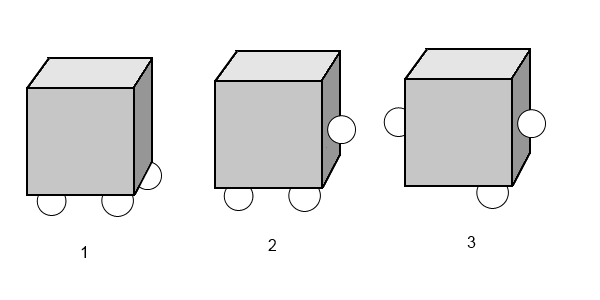

First of all, look at a traditional claw. Two fingers, two degrees of freedom each.

The white circles represent tips of the manipulator, i.e. points that can collide with an object to apply a force to it. The gray dashed line marks the envelope, all the points reachable by each of the tips. This is to get you familiar with the notation used here. As you can see, the base of the hand is also considered a tip here.

Now the principal function of a finger, as I see it, is to apply force to an object, at a particular offset, and in a particular direction. This force does not allow an object to move past the tip in some direction, and makes it difficult to slide tangent to that point.

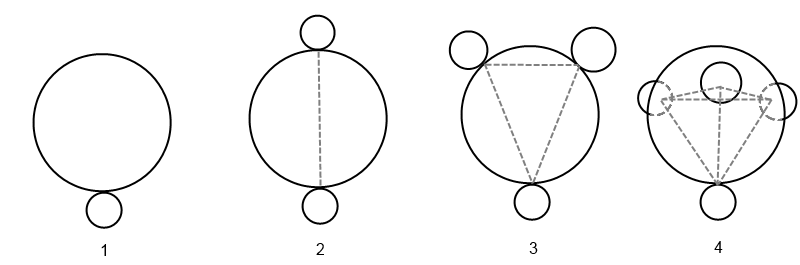

The number of points (fingers) that touch the object determine just how restricted it's motion is. One point is enough to keep an object from falling due to gravity, but does not restrict it's motion much. Two points restrict motion along a line, and with enough force, can pinch an object to prevent motion alltogether (for small loads), however they do not provide much resistance to rotation. Three points can restrict an object in a plane, and usually provide a good grip for most objects (except for long ones, such as sticks or hammers. Since the only thing preventing rotation is friction, if the outside force acting on an object gets even a little bit of lever distance it can cause rotation). Four points (corresponding to three fingers and the base of the hand) can form a tetrahedron and completely restrict both motion and rotation of the object, and are thus preferrable - any possible rotation of the object would end up pushing against at least one of the tips, so the force preventing motion is compression rather than friction-based. Five points (four fingers and a base) are no different from four points, but one finger is free to do something else, such as push a button on the object, without compromising the stability of the grip.

Therefore, if we want a hand to pick up a power drill and use it, it will need at least four fingers.

I will also shortly go over some more subtle things you can do with fingers.

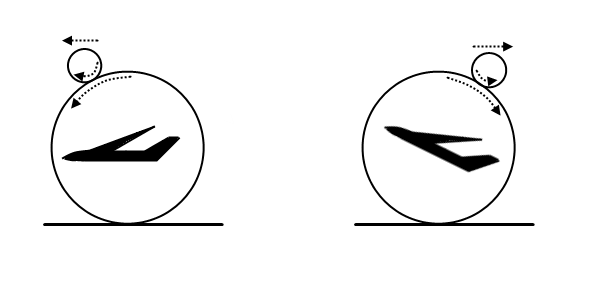

Firstly, rolling. With one finger stationary (or replaced by flat plane), another finger can push the object while maintaining a rolling contact (and thus still restricting it's motion). This way three points of contact can control the orientation of the object without ever letting go of it. It's a useful technique that can drastically reduce the amount of overall hand/arm motion needed for a particular manipulation.

Secondly, crawling (at least that's what I call it). If there are enough points of contact to make sure the object doesn't do anything crazy for at least a short time, the rest of the fingers can be freely repositioned to anywhere on the object in order to get a better grip. This is similar to a spider (or a hexapod robot) crawling/walking by moving one leg at a time, while standing on the rest.

Summary of hand requirements

- At least four fingers, arranged radially to grasp round and cylindrical objects.

- Each finger should be able to position it's tip with 3 DOF.

- Each finger should be as long as an average human finger and have a similar range of motion.

- Each finger should needs up to 4.4 N*m of torque. Alternatively, it should be able to lift 15 kg or one-sixth of the robot's total weight, whichever is larger.

- Lifting 5 kg with one finger should be more than sufficient for most applications though.

- The peculiar positioning of the thumb is not necessary in general case. It's only used for some really weird manipulations such as using a touch-screen phone with one finger.

- Each finger should be able to go through it's full range of motion on any axis three times per second.

- Fingers should be covered with rubber or similar high-friction material.

- Fingers should have some degree of force sensitivity. It is necessary to measure somehow the force applied to an object.

Current status

I am currently designing the hand part of the robot, electronics needed and forces involved and such. Once my 3d printer is working correctly, I should be able to print a prototype hand... sometime between now and never.

Let me hear your comments and suggestions!

|

Re: Possibility of an anthropomorphic robot handyman November 20, 2014 06:13PM |

Registered: 11 years ago Posts: 256 |

Robots are used for repetitive tasks because they can be optimized for those tasks. A humanoid robot cannot replace a CNC machine, because if he was stiff enough he could not move effectively. Honda has well over 20 million bucks into the Asimo, and it is still learning to walk. Humanoid robots will one day do the things you speak of, and on the following day, which I believe James Cameron refers to as judgement day...

Most processes that would use the skills of a robot are better pre engineered, very large/accurate 3D printers will one day eliminate all labor from manufactured goods. What you might find more rewarding, and a wee bit less costly, is making a contribution to the field of prosthetics. Your interest in humanoid motion is something you could pursue to develop, say, a working hand for someone who's lost one. And don't be dissuaded because you are not the first, there is still a long way to go, between a makerbot hand and the 6 million dollar man.

Most processes that would use the skills of a robot are better pre engineered, very large/accurate 3D printers will one day eliminate all labor from manufactured goods. What you might find more rewarding, and a wee bit less costly, is making a contribution to the field of prosthetics. Your interest in humanoid motion is something you could pursue to develop, say, a working hand for someone who's lost one. And don't be dissuaded because you are not the first, there is still a long way to go, between a makerbot hand and the 6 million dollar man.

|

Re: Possibility of an anthropomorphic robot handyman November 22, 2014 06:27AM |

Admin Registered: 13 years ago Posts: 7,000 |

Sorry, only registered users may post in this forum.