Converted Z-axis to Belt Drive

Posted by runninfarmer

|

Converted Z-axis to Belt Drive February 12, 2014 09:30PM |

Registered: 10 years ago Posts: 105 |

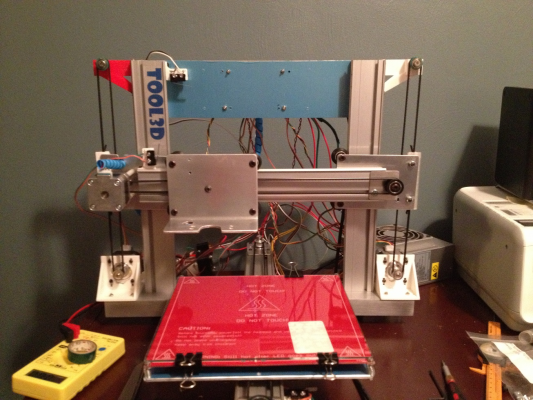

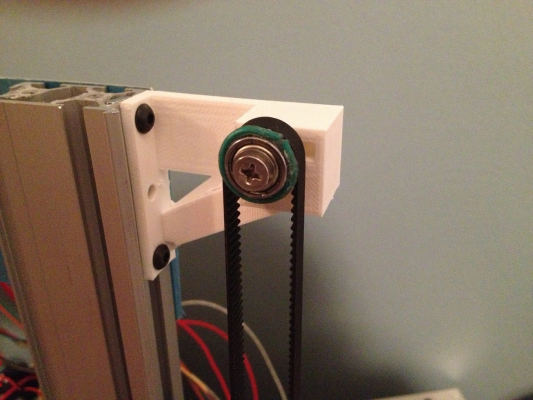

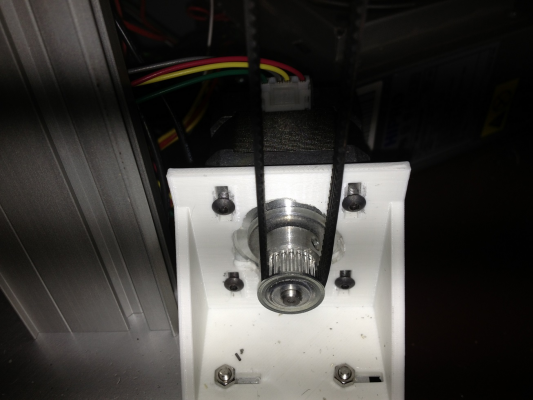

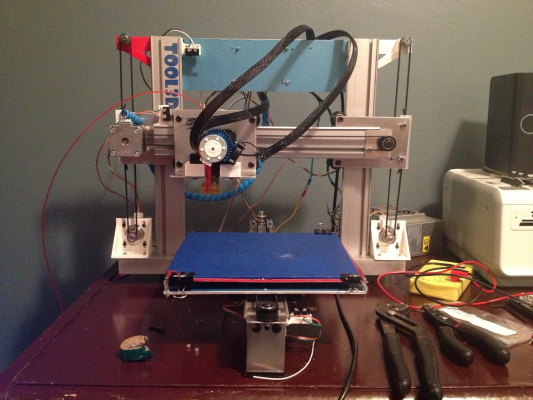

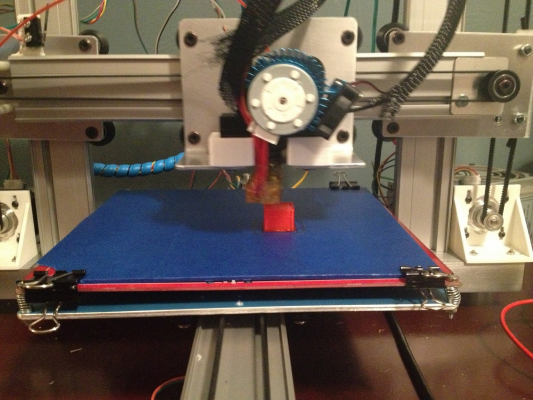

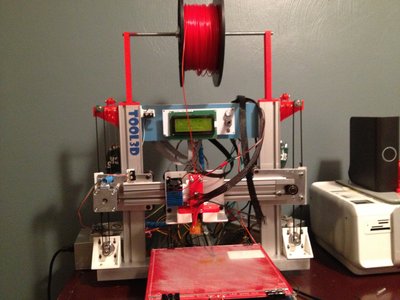

I have an ord bot and converted the z-axis to belt drive. If any one has an ord bot or similar type printer with lead screws, you might be interested in making the conversion. Here's a link to it on thingverse: [www.thingiverse.com]

Here's a video of it on youtube: [www.youtube.com]

Here's a video of it on youtube: [www.youtube.com]

|

Re: Converted Z-axis to Belt Drive February 13, 2014 06:47PM |

Registered: 11 years ago Posts: 334 |

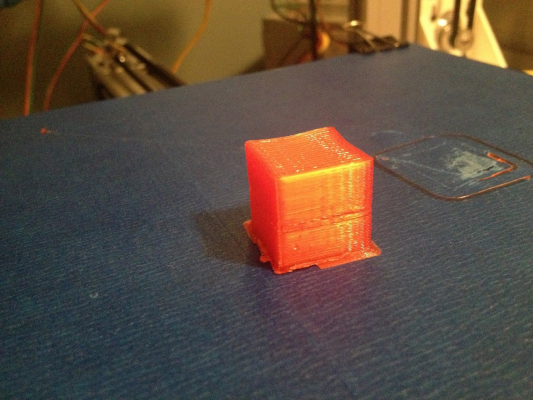

Do you have any pics of prints from the machine?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Converted Z-axis to Belt Drive February 13, 2014 08:16PM |

Registered: 10 years ago Posts: 105 |

|

Re: Converted Z-axis to Belt Drive February 18, 2014 09:15PM |

Registered: 10 years ago Posts: 105 |

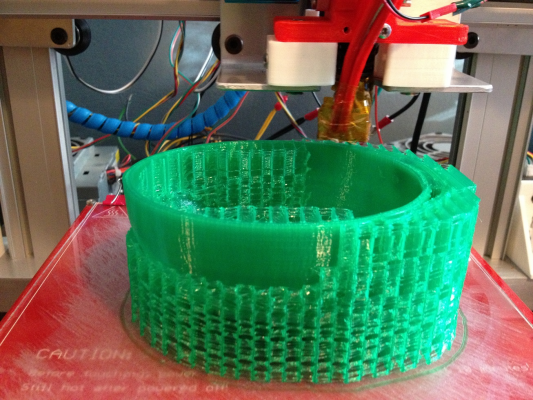

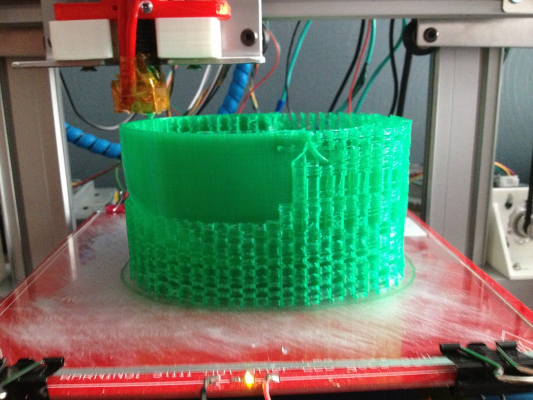

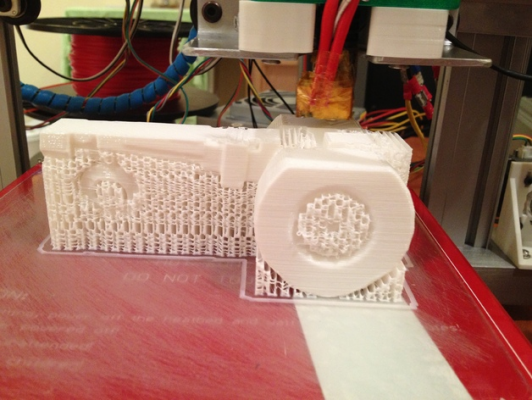

I finally got my new Ramps driver and was able to do a a first print! I'm very happy with the first print. Still need to fine tune my steps/mm, but the layers looked really good. I got a little excited and tried to yank off my test cube while it was warm and deformed it, oops. Here are some pics:

Here's a video of it printing: [www.youtube.com]

Edited 1 time(s). Last edit at 02/18/2014 09:25PM by runninfarmer.

Here's a video of it printing: [www.youtube.com]

Edited 1 time(s). Last edit at 02/18/2014 09:25PM by runninfarmer.

|

Re: Converted Z-axis to Belt Drive March 10, 2014 11:45PM |

Registered: 10 years ago Posts: 105 |

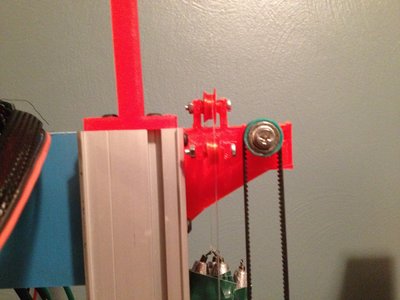

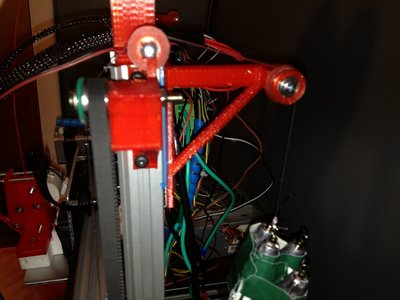

I have now implemented a counter balance pulley system so I no longer have to worry about my bed crashing on shutdown! Uses 2 lbs worth of lead sinkers and some 30 lb test fishing line. I will update my thingiverse page. Here are some pics:

|

Re: Converted Z-axis to Belt Drive March 25, 2014 09:38PM |

Registered: 11 years ago Posts: 334 |

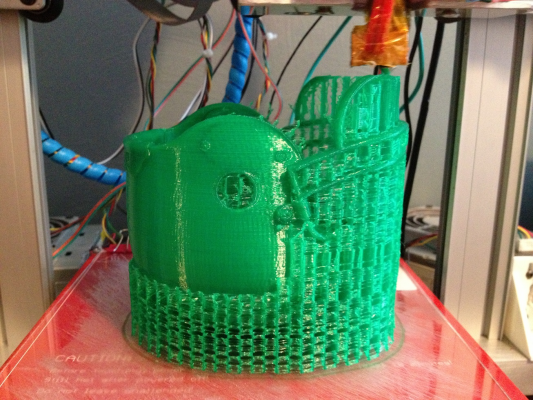

Have you printed anything big yet? I am really curious to hear if this has completely eliminated Z-Banding.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Converted Z-axis to Belt Drive March 25, 2014 10:42PM |

Registered: 10 years ago Posts: 105 |

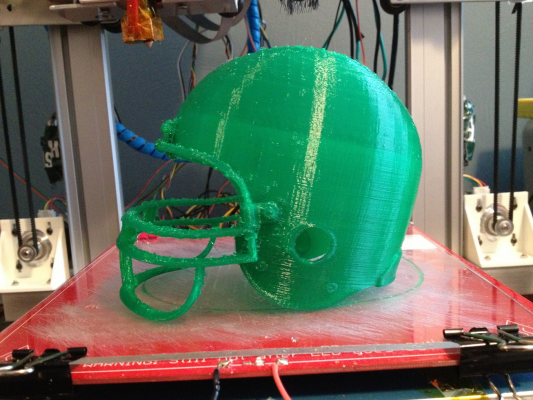

I have done a a couple football helmets for family memebers with pretty good results. One took 15 hrs and the other took 20 hrs. Layers are great at 0.2 mm, just didn't have any retraction so that shows with some artifacts. Here's some pics of the 20 hr one:

Edited 2 time(s). Last edit at 03/25/2014 10:53PM by runninfarmer.

Edited 2 time(s). Last edit at 03/25/2014 10:53PM by runninfarmer.

|

Re: Converted Z-axis to Belt Drive July 13, 2014 11:59PM |

Registered: 10 years ago Posts: 87 |

I was wondering when someone was going to attempt this. I'have been contemplating doing this on my FrankenDel build to make it different. It would definitely eliminate any shake that may be induced by a acme rod that wasn't quite straight.

Any other results to post??

Edited 1 time(s). Last edit at 07/13/2014 11:59PM by RC-CnC.

Any other results to post??

Edited 1 time(s). Last edit at 07/13/2014 11:59PM by RC-CnC.

|

Re: Converted Z-axis to Belt Drive July 16, 2014 01:03PM |

Registered: 10 years ago Posts: 105 |

Hi Rc-CNC,

I ended up selling my printer, but I have printed some nice objects with the belt driven Z axis. Here's a couple pics of a pulling tractor I printed, it's on my thingiverse page:

One of the main drawbacks with a belt driven z-axis is the "drop" once the motors are shut off. The counter pulley system works, but it does complicate it somewhat. You can't beat the fast response of the belts though, making them really nice for homing and calibrating. They also do get rid of the wobbling from screws, provided your linear rails are true. I'm working on my own design and I'm still unsure of using a belt driven z-axis for it or not.

Edited 1 time(s). Last edit at 07/16/2014 01:06PM by runninfarmer.

I ended up selling my printer, but I have printed some nice objects with the belt driven Z axis. Here's a couple pics of a pulling tractor I printed, it's on my thingiverse page:

One of the main drawbacks with a belt driven z-axis is the "drop" once the motors are shut off. The counter pulley system works, but it does complicate it somewhat. You can't beat the fast response of the belts though, making them really nice for homing and calibrating. They also do get rid of the wobbling from screws, provided your linear rails are true. I'm working on my own design and I'm still unsure of using a belt driven z-axis for it or not.

Edited 1 time(s). Last edit at 07/16/2014 01:06PM by runninfarmer.

|

Re: Converted Z-axis to Belt Drive July 16, 2014 06:52PM |

Registered: 10 years ago Posts: 814 |

|

Re: Converted Z-axis to Belt Drive July 16, 2014 08:33PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Converted Z-axis to Belt Drive July 17, 2014 01:28PM |

Registered: 10 years ago Posts: 105 |

Depending on the Z-axis configuration, NEMA 23's should have enough detent torque to hold it up. For the Ord bot, I don't think they will. When the x-axis is apart of the z-axis, the added weight from the x-axis motor is substantial (~200g or so). It's best to belt drive a Z-axis with table only, as opposed to an additional axis with it in my opinion.

Geared NEMA motors would be the ultimate way to prevent drop or the worm drive as mentioned by Mike. I think the worm drive could get complicated/costly to implement, though I don't know since I've never worked with one. Another issue with NEMA 23's is current requirement vs board limitations. I'm not sure how well RAMPs would support NEMA 23's.

Geared NEMA motors would be the ultimate way to prevent drop or the worm drive as mentioned by Mike. I think the worm drive could get complicated/costly to implement, though I don't know since I've never worked with one. Another issue with NEMA 23's is current requirement vs board limitations. I'm not sure how well RAMPs would support NEMA 23's.

|

Re: Converted Z-axis to Belt Drive September 26, 2014 05:34AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Converted Z-axis to Belt Drive September 29, 2014 05:43PM |

Registered: 9 years ago Posts: 189 |

you can easily get Nema 23s working with RAMPS via external Drivers.

I saw a schematic of someone attaching stepper driers like these:

[www.arceurotrade.co.uk]

to his ramps.

If anybody is interested, I can upload the schematic here for you guys to tinker with it.

Alex

I saw a schematic of someone attaching stepper driers like these:

[www.arceurotrade.co.uk]

to his ramps.

If anybody is interested, I can upload the schematic here for you guys to tinker with it.

Alex

|

Re: Converted Z-axis to Belt Drive October 08, 2014 10:35PM |

Registered: 9 years ago Posts: 42 |

You can also double, triple or quadruple the belts on a Z stage with pulleys to effectively gear down the Z motor and use a basic NEMA17. I'm doing a build at the moment with tripled belts on the Z bed lift (and CoreXY for the hotend), i.e. it takes 3 rotations of the 20T GT2 pulley to move the bed by 40mm (motor pulley circumference).

With 0.65Nm stepper, that's about 30kg of lifting force; I don't yet know if it will drop when powered off but I expect not (or at least slowly) due to the gear ratio.

A geared/wormed stepper seems a bad idea due to backlash if you ever intend to do Z-lifts while printing. Gearing via pulleys should have better backlash behaviour due to being under tension, and it does not increase the stress on the belt or pulley teeth.

Edited 1 time(s). Last edit at 10/08/2014 10:36PM by polyglot.

With 0.65Nm stepper, that's about 30kg of lifting force; I don't yet know if it will drop when powered off but I expect not (or at least slowly) due to the gear ratio.

A geared/wormed stepper seems a bad idea due to backlash if you ever intend to do Z-lifts while printing. Gearing via pulleys should have better backlash behaviour due to being under tension, and it does not increase the stress on the belt or pulley teeth.

Edited 1 time(s). Last edit at 10/08/2014 10:36PM by polyglot.

|

Re: Converted Z-axis to Belt Drive October 09, 2014 01:09PM |

Registered: 10 years ago Posts: 105 |

I have played with using more pulleys to divide up the force necessary to support the carriage. Problems can arise in terms of finding solid anchor points for the pulleys. I found I was running out of convenient extrusion space, until the design would get too complicated. It's definitely better to get something like that working than counterweights.

Edited 1 time(s). Last edit at 10/09/2014 01:09PM by runninfarmer.

Edited 1 time(s). Last edit at 10/09/2014 01:09PM by runninfarmer.

Sorry, only registered users may post in this forum.