1 or 2 rails for y axis?

Posted by witor

|

1 or 2 rails for y axis? December 14, 2018 04:58PM |

Registered: 6 years ago Posts: 63 |

I am planning on using Robotdigg MGN 12 rails for my Y axis. My initial plan was to use 2 rails for y axis to make me print bed solid stable. Is it an overkill? Would one rail be enough? Are 2 rails going to give too much friction and mass due to extra carriages?

What about the carriages, one or two per rail?

What about the carriages, one or two per rail?

|

Re: 1 or 2 rails for y axis? December 14, 2018 06:05PM |

Registered: 5 years ago Posts: 62 |

|

Re: 1 or 2 rails for y axis? December 14, 2018 06:46PM |

Registered: 6 years ago Posts: 63 |

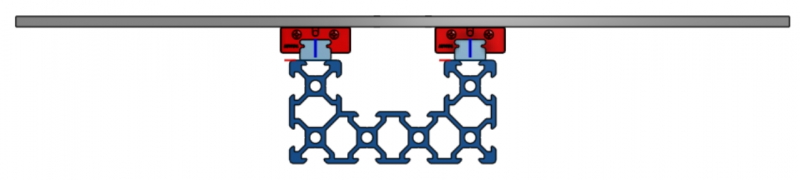

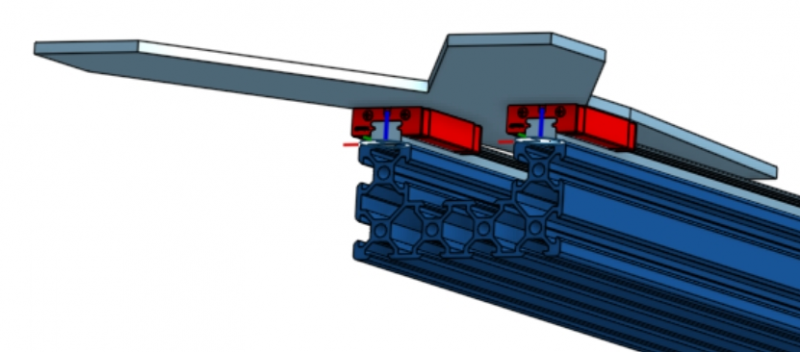

This is my idea at the moment. I am thinking about using a c shaped extrusion (40x80). Bed is 30x30. Rails are not spread very far but c extrusion should make aliment of rails a bit easier and should be rock solid. There will be enough space for belt inside the c extrusion. I am planning on using 3-4 mm carbon fiber kind of H shaped plate as a support for the heated bed. Any comments or criticism of my idea are more than welcomed.

|

Re: 1 or 2 rails for y axis? December 14, 2018 08:52PM |

Registered: 5 years ago Posts: 62 |

That looks OK and should be wide enough apart for those types of bearings IMO.

Tighten down one rail down first. Then slide the bed all the way to one end and tighten half of the second rail. Slide the bed to the opposite end and tighten the second half of the second rail. Repeat if necessary.

This is how I aligned the 2 rails on one of my printers, it seemed to work well and doesn't involve measuring aside from putting the first rail parallel with the frame.

Tighten down one rail down first. Then slide the bed all the way to one end and tighten half of the second rail. Slide the bed to the opposite end and tighten the second half of the second rail. Repeat if necessary.

This is how I aligned the 2 rails on one of my printers, it seemed to work well and doesn't involve measuring aside from putting the first rail parallel with the frame.

|

Re: 1 or 2 rails for y axis? December 15, 2018 03:24AM |

Registered: 8 years ago Posts: 5,232 |

Is it the bed you're showing or just the 'frog' below?

Do you plan to use three carriers and how do you adjust bed-level?

Instead of the C-beam, I'd go for two individual 2020 beams mounted on a solid bottom plate ( eg. 12-19mm MDF ). That way you can mount the other stuff on the same base plate. Of course you can mount the C-beam on a solid base, too.

Do you plan to use three carriers and how do you adjust bed-level?

Instead of the C-beam, I'd go for two individual 2020 beams mounted on a solid bottom plate ( eg. 12-19mm MDF ). That way you can mount the other stuff on the same base plate. Of course you can mount the C-beam on a solid base, too.

|

Re: 1 or 2 rails for y axis? December 15, 2018 08:32AM |

Registered: 11 years ago Posts: 5,780 |

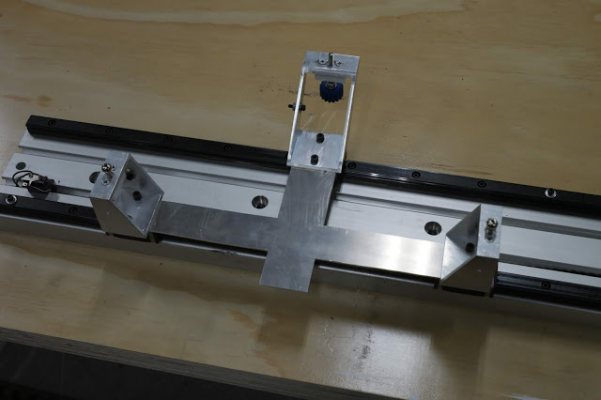

The Y axis in SoM is built similar to your diagram, but I used a 1" thick aluminum plate that has some t-slots. The good thing about this type of construction is the two guide rails stay aligned and the entire Y axis can be pulled out of the machine as a unit if you need to service it.

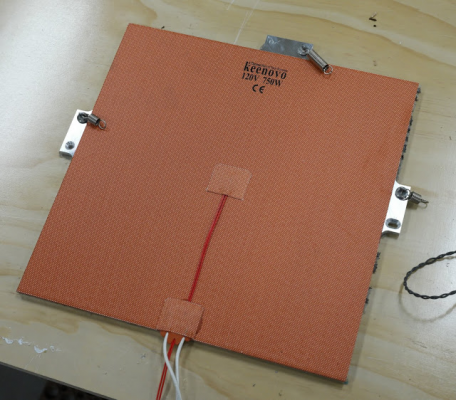

I put one rail down the center of the bed plate and the other off to one side. I am rebuilding it now replacing a ball screw drive with a belt, using a kinematic mount for the bed plate, and using a line powered heater. Aligning the center of the bed over one guide rail allows for very solid coupling of the bed's reference and pitch adjusters to the bearing blocks on that rail. The screws are anchored in teflon blocks that won't soften or melt when the bed is heated.

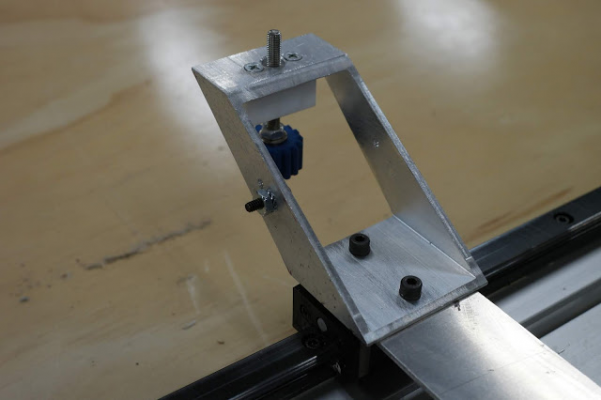

This is what the reference and pitch adjusters look like:

Here's the underside of the bed plate. Notice the chamfered hole in one ear (left) and the chamfered slot in the other (right). That allows the bed to expand when heated without causing anything to bend. That hole and slot sit on spherical head screws, and the third leveler, which controls roll about the Y axis, is just a screw contacting the flat bottom of the third ear (top) on the bed plate. There are springs at each leveler to hold the bed plate down on the screws. The bed plate is 1/4" thick MIC6 tooling plate.

This is the roll adjuster:

I put the carriage plate directly on the bearing blocks so it would be located far from the bed plate and heater. It is just 2.5 mm thick aluminum and all it does is couple the bearing blocks to each other. It's possible it will flex a little during operation, but it shouldn't matter because the bed plate is only solidly coupled to the reference screw. Movement of the other adjusters relative to the reference (if the carriage plate flexes) won't matter because the bed plate is free to slide on those adjusters anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I put one rail down the center of the bed plate and the other off to one side. I am rebuilding it now replacing a ball screw drive with a belt, using a kinematic mount for the bed plate, and using a line powered heater. Aligning the center of the bed over one guide rail allows for very solid coupling of the bed's reference and pitch adjusters to the bearing blocks on that rail. The screws are anchored in teflon blocks that won't soften or melt when the bed is heated.

This is what the reference and pitch adjusters look like:

Here's the underside of the bed plate. Notice the chamfered hole in one ear (left) and the chamfered slot in the other (right). That allows the bed to expand when heated without causing anything to bend. That hole and slot sit on spherical head screws, and the third leveler, which controls roll about the Y axis, is just a screw contacting the flat bottom of the third ear (top) on the bed plate. There are springs at each leveler to hold the bed plate down on the screws. The bed plate is 1/4" thick MIC6 tooling plate.

This is the roll adjuster:

I put the carriage plate directly on the bearing blocks so it would be located far from the bed plate and heater. It is just 2.5 mm thick aluminum and all it does is couple the bearing blocks to each other. It's possible it will flex a little during operation, but it shouldn't matter because the bed plate is only solidly coupled to the reference screw. Movement of the other adjusters relative to the reference (if the carriage plate flexes) won't matter because the bed plate is free to slide on those adjusters anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1 or 2 rails for y axis? December 15, 2018 12:22PM |

Registered: 6 years ago Posts: 63 |

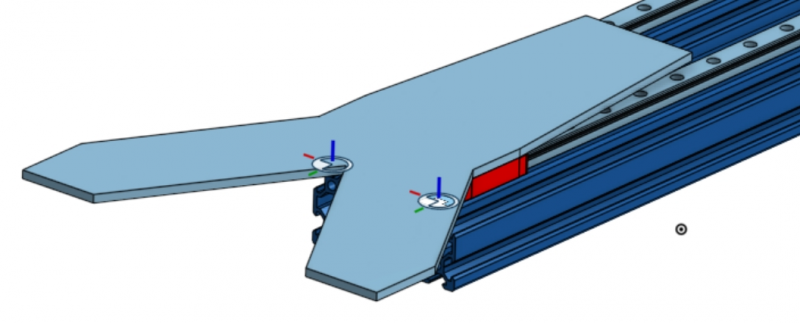

How far apart are y axis rails on SoM? I see that you are using 2 carriages alon one rail which definitely improves stability, but also requires longer rails to achieve required range of movement. I was thinking about something like this:

Y shaped piece would be 4mm carbon fiber. On all 3 support corners I was planing on using teflon blocks with the kinematic links to the bed (like you did) my main concern is that the carbon piece will flex and rails will have a tiny bit of play, together producing movement (rotation) about x axis (front and back of the bed might go up and down as bed moves along y axis). That was the reason I asked my first question about number of rails and carriages sufficient to keep it rigid. Have you tried one carriage on each rail or have you rejected this idea straight away as not being rigid enough? Am I kidding myself thinking that one block on each rail will suffice?

Edited 3 time(s). Last edit at 12/15/2018 01:39PM by witor.

Y shaped piece would be 4mm carbon fiber. On all 3 support corners I was planing on using teflon blocks with the kinematic links to the bed (like you did) my main concern is that the carbon piece will flex and rails will have a tiny bit of play, together producing movement (rotation) about x axis (front and back of the bed might go up and down as bed moves along y axis). That was the reason I asked my first question about number of rails and carriages sufficient to keep it rigid. Have you tried one carriage on each rail or have you rejected this idea straight away as not being rigid enough? Am I kidding myself thinking that one block on each rail will suffice?

Edited 3 time(s). Last edit at 12/15/2018 01:39PM by witor.

|

Re: 1 or 2 rails for y axis? December 15, 2018 08:58PM |

Registered: 11 years ago Posts: 5,780 |

You've got a large moving mass supported by a very small base. The CF that supports the bed plate is going to flex, tilting the bed every time the it reverses direction.

It's much more stable if the base is larger, as close to the size of the bed plate as you can make it. In my design the pitch and reference levelers are supported directly on the bearing blocks. It requires one guide rail that is 2 x the bed's Y dimension- the other can be shorter, but it is very stable.

You've got two bearing blocks supporting the plate in the X direction, but there are no forces applied in that direction (except maybe when you're prying a print off the bed). All the forces that act on the bed are in the Y direction. That's where it needs support the most.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It's much more stable if the base is larger, as close to the size of the bed plate as you can make it. In my design the pitch and reference levelers are supported directly on the bearing blocks. It requires one guide rail that is 2 x the bed's Y dimension- the other can be shorter, but it is very stable.

You've got two bearing blocks supporting the plate in the X direction, but there are no forces applied in that direction (except maybe when you're prying a print off the bed). All the forces that act on the bed are in the Y direction. That's where it needs support the most.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1 or 2 rails for y axis? December 16, 2018 09:40AM |

Registered: 6 years ago Posts: 63 |

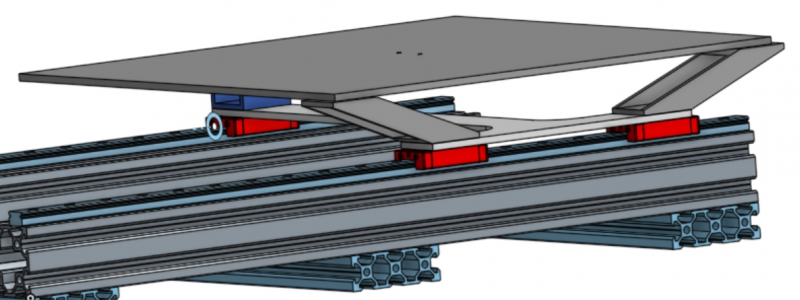

After changing my plan to this, which I think would be ok in terms of stability:

I realised that if I put a thick, sturdy bed on top which would be about 1kg I will have problem with too much mass moving back and forth which will definitely have a negative effect on the quality of the print. I tried to avoid core XY mechanics due to its complexity, but it looks like if I really want good quality prints coreXY is the way to go. This brings me back to square 1 - the decision which printer to go for. The more I think about it the more certain I am that UMMD is the way to go. I have to intensify my hunt for some quality linear guides (without braking the bank!).

Would you recommend any particular brands or specific types to search for? How did you decide which rails to go for? How did you find them? I am going to put a few alerts on ebay to get notification if something pops up. The problem is that I don't really know yet what to look for.

I realised that if I put a thick, sturdy bed on top which would be about 1kg I will have problem with too much mass moving back and forth which will definitely have a negative effect on the quality of the print. I tried to avoid core XY mechanics due to its complexity, but it looks like if I really want good quality prints coreXY is the way to go. This brings me back to square 1 - the decision which printer to go for. The more I think about it the more certain I am that UMMD is the way to go. I have to intensify my hunt for some quality linear guides (without braking the bank!).

Would you recommend any particular brands or specific types to search for? How did you decide which rails to go for? How did you find them? I am going to put a few alerts on ebay to get notification if something pops up. The problem is that I don't really know yet what to look for.

|

Re: 1 or 2 rails for y axis? December 16, 2018 10:12AM |

Registered: 11 years ago Posts: 5,780 |

Since you're designing the machine yourself, you have a lot of freedom in part selection, which will ultimately save you money over building to someone else's BOM, and designing the mechanism before the enclosure will all but guarantee that you'll hit your target print envelope. I see many "designs" that focus on pretty computer renderings of the enclosure (minus all the ugly electronics and cables) without much thought given to the mechanism.

I look for used Japanese linear guides on ebay. Look for brands like IKO, THK, and NSK. Some may argue that you don't know what you're going to end up with when you order used linear guides, so they buy cheap, new chinesium parts and then fret about replacing the balls because the bearing blocks wobble. I've never had a problem with a used Japanese made linear guide and I would rather take my chances on getting a bad one than throw money into the toilet by buying a poor quality product. Avoid anything claiming to be "hiwin". HiWin is a Taiwanese company that makes quality linear guides but the are about 100 factories in China cranking out crappy HiWin knockoffs and outright counterfeits using hiwin's part numbering scheme (mgn-xx, mgh-xx, etc.). The length doesn't matter, as long as they are long enough- you can cut them down to final size using a cutoff wheel on a grinder. If you're planning on a 300x300 mm bed plate, then make sure the linear guides for the X and Y axes are at least 400-500 mm long because the extruder carriage is going to take up some space.

When you search ebay, use the advanced search features to exclude things like hiwin, rail, shaft, mgn, and mgh. There will be hundreds of overpriced listings and a few reasonably priced listings, so you have to look at a lot of them to find a good deal. Here's a quick find: [www.ebay.com] The 12 and 15 mm size rails seem to be the most common and that's usually where you'll find the best deals. Make sure you get parts that come with enough bearing blocks for whatever you're trying to do. Buying the bearing blocks separate from the rails is hard to do and tends to be expensive.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I look for used Japanese linear guides on ebay. Look for brands like IKO, THK, and NSK. Some may argue that you don't know what you're going to end up with when you order used linear guides, so they buy cheap, new chinesium parts and then fret about replacing the balls because the bearing blocks wobble. I've never had a problem with a used Japanese made linear guide and I would rather take my chances on getting a bad one than throw money into the toilet by buying a poor quality product. Avoid anything claiming to be "hiwin". HiWin is a Taiwanese company that makes quality linear guides but the are about 100 factories in China cranking out crappy HiWin knockoffs and outright counterfeits using hiwin's part numbering scheme (mgn-xx, mgh-xx, etc.). The length doesn't matter, as long as they are long enough- you can cut them down to final size using a cutoff wheel on a grinder. If you're planning on a 300x300 mm bed plate, then make sure the linear guides for the X and Y axes are at least 400-500 mm long because the extruder carriage is going to take up some space.

When you search ebay, use the advanced search features to exclude things like hiwin, rail, shaft, mgn, and mgh. There will be hundreds of overpriced listings and a few reasonably priced listings, so you have to look at a lot of them to find a good deal. Here's a quick find: [www.ebay.com] The 12 and 15 mm size rails seem to be the most common and that's usually where you'll find the best deals. Make sure you get parts that come with enough bearing blocks for whatever you're trying to do. Buying the bearing blocks separate from the rails is hard to do and tends to be expensive.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1 or 2 rails for y axis? December 16, 2018 11:03AM |

Registered: 6 years ago Posts: 63 |

In UMMD you went for 24 mm rails for x and y axis. Was there a specific mechanical reason why you went for such wide rails, or you just happened to find some rails of that size for a reasonable price so you went for them?

Guides you linked in the previous post would be good for the Z axis, right?

Guides you linked in the previous post would be good for the Z axis, right?

|

Re: 1 or 2 rails for y axis? December 16, 2018 10:26PM |

Registered: 11 years ago Posts: 5,780 |

I used what was available for a reasonable price at the time.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1 or 2 rails for y axis? December 17, 2018 08:06PM |

Registered: 6 years ago Posts: 63 |

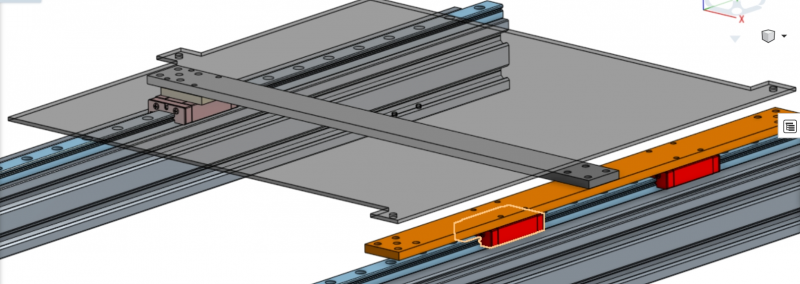

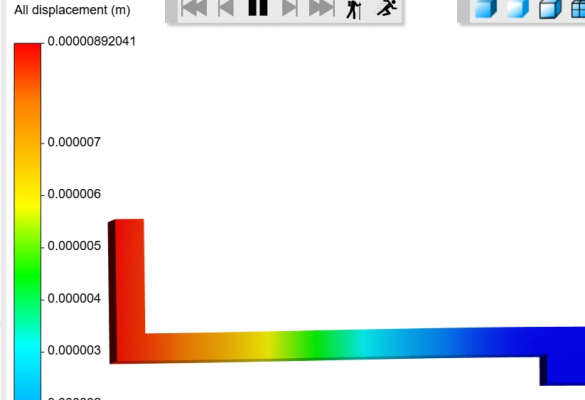

I did an estimate of how much something like UMMD will cost (considering that I will have to import a lot of stuff) and I got a bit scared... I knew it will be more than few hundred dollars but the actual figure is a bit steep. Before spending some serious bucks on rails and worm gearbox I decided to one more time revise my initial idea. At the moment this looks promising to me:

I will build the y axis assembly (which shouldn't be to expensive, test it and then make a final decision.

T shaped link is 5mm thick, 25mm wide carbon fiber. Bed will be supported in 3 places by quite long M4 screws in teflon blocks. Transparent part on the image will be a thin (2mm) aluminium with a 30x30cm heater glued to it. Aluminium piece will have 'ears' sticking up (not yet on the picture) which will hold a ultrabase print bed or glass with buildtak in place on top of aluminium. Bed support overhanging from carriage is about 7cm. I have done some simulations to check how much I would deform under load. After applying 10N downward force to the end of it moved by only 9 micro meters. Even with more load I think it should be stiff enough and carbon should absorb vibrations slightly better compared to aluminium.

The distance between 2 rails is quite large and I am not sure if one belt will suffice. Has anyone tried motor like this driving 2 belts. Sounds like an interesting idea to me

I will build the y axis assembly (which shouldn't be to expensive, test it and then make a final decision.

T shaped link is 5mm thick, 25mm wide carbon fiber. Bed will be supported in 3 places by quite long M4 screws in teflon blocks. Transparent part on the image will be a thin (2mm) aluminium with a 30x30cm heater glued to it. Aluminium piece will have 'ears' sticking up (not yet on the picture) which will hold a ultrabase print bed or glass with buildtak in place on top of aluminium. Bed support overhanging from carriage is about 7cm. I have done some simulations to check how much I would deform under load. After applying 10N downward force to the end of it moved by only 9 micro meters. Even with more load I think it should be stiff enough and carbon should absorb vibrations slightly better compared to aluminium.

The distance between 2 rails is quite large and I am not sure if one belt will suffice. Has anyone tried motor like this driving 2 belts. Sounds like an interesting idea to me

Sorry, only registered users may post in this forum.