MendelMax 1.5 Marinus - My build

Posted by Ohmarinus

|

MendelMax 1.5 Marinus - My build July 28, 2013 01:46PM |

Admin Registered: 11 years ago Posts: 3,096 |

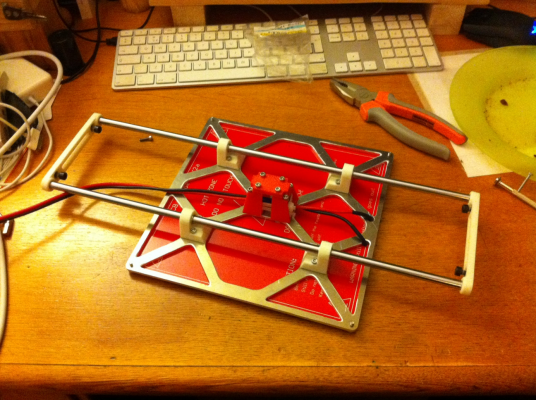

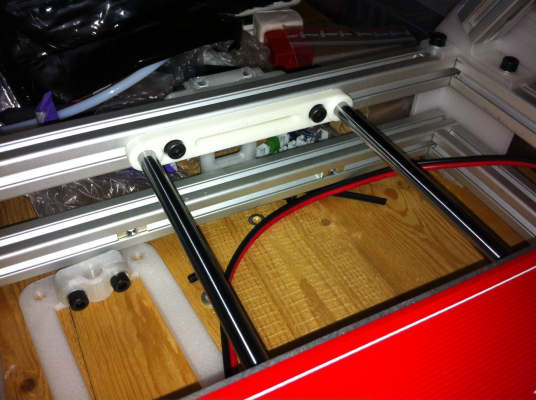

Hi guys, so after a long time of thinking, ordering, waiting, re-designing and putting together parts I am finally finalizing my MendelMax 1.5

Here are some pictures, the machine is still not done, but there is already a lot of work done.

This is the second 3D-printer I'm building, after working with the first one for 4 months, I decided to build a second printer that improved all the problems I've been having with the first printer.

This model is a MendelMax 1.5 but it has a lot of improvements that I made myself, for example the X-carriage system. This is a vertical one, instead of the original horizontal system, which causes the linear bearing to wear out less and make it slide across from left to right with more ease.

The extruder is using a Bowden system, this means that the extruder is mounted on the frame, instead of on the X-carriage. This makes the printhead lighter and therefor faster. printing with more speed and more precision.

The usual smooth rods are now not just metal, they consist of hard-chromed rods with an 8mm diameter. The linear bearings are usually of the LM8UU type, but I took the freedom to re-design the linear system with slide-bushings with a PTFE liner instead of linear (LM8UU) ball-bearings, yet again making the system lighter and less prone to wear.

The threaded rods that move the whole Z-axis (up) are slimmed down from M8 rods to M5 rods, which allow movement with greater precision (from 1.25mm pre rotation to 0.8mm per rotation) and also reduce weight on the entire rod, so it takes less force to move the rod.

To be continued. The machine isn't finished yet!

MendelMax 1.5 Marinus imgur album

Edited 2 time(s). Last edit at 01/13/2014 11:45PM by MattMoses.

Here are some pictures, the machine is still not done, but there is already a lot of work done.

This is the second 3D-printer I'm building, after working with the first one for 4 months, I decided to build a second printer that improved all the problems I've been having with the first printer.

This model is a MendelMax 1.5 but it has a lot of improvements that I made myself, for example the X-carriage system. This is a vertical one, instead of the original horizontal system, which causes the linear bearing to wear out less and make it slide across from left to right with more ease.

The extruder is using a Bowden system, this means that the extruder is mounted on the frame, instead of on the X-carriage. This makes the printhead lighter and therefor faster. printing with more speed and more precision.

The usual smooth rods are now not just metal, they consist of hard-chromed rods with an 8mm diameter. The linear bearings are usually of the LM8UU type, but I took the freedom to re-design the linear system with slide-bushings with a PTFE liner instead of linear (LM8UU) ball-bearings, yet again making the system lighter and less prone to wear.

The threaded rods that move the whole Z-axis (up) are slimmed down from M8 rods to M5 rods, which allow movement with greater precision (from 1.25mm pre rotation to 0.8mm per rotation) and also reduce weight on the entire rod, so it takes less force to move the rod.

To be continued. The machine isn't finished yet!

MendelMax 1.5 Marinus imgur album

Edited 2 time(s). Last edit at 01/13/2014 11:45PM by MattMoses.

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 02:31PM |

Registered: 11 years ago Posts: 730 |

That MendelMax printer looks very nice with white printed parts. Great job.

I see you used the vertical X axis of the Prusa i3. I've been thinking of doing the same on my AO-100 (a MendelMax 1.0-1.5 clone with the original Prusa Mendel's build envelope). Only I want to go further and open up the front like the latest RepRaps (Mendel90, Prusa i3, MendelMax 2.0). I find the front frame gets in the way, changing filament in the extruder is a hassle. I want to improve access.

What will be your build volume? Someone on the Lulzbot forum made a mod on his AO-101 to increase the print height from 100mm to 160mm. [forum.lulzbot.com]

I see you used the vertical X axis of the Prusa i3. I've been thinking of doing the same on my AO-100 (a MendelMax 1.0-1.5 clone with the original Prusa Mendel's build envelope). Only I want to go further and open up the front like the latest RepRaps (Mendel90, Prusa i3, MendelMax 2.0). I find the front frame gets in the way, changing filament in the extruder is a hassle. I want to improve access.

What will be your build volume? Someone on the Lulzbot forum made a mod on his AO-101 to increase the print height from 100mm to 160mm. [forum.lulzbot.com]

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 03:27PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi Normand  and thanks! Indeed, I did plan the build a little bit ahead. The filament used for the parts is the 'clear ABS' from repraper.com but I bought it at a Dutch reseller (www.filamentenmeer.nl) because it was easier for me to buy it there.

and thanks! Indeed, I did plan the build a little bit ahead. The filament used for the parts is the 'clear ABS' from repraper.com but I bought it at a Dutch reseller (www.filamentenmeer.nl) because it was easier for me to buy it there.

I have measured my build volume to be between 160 and 180 mm in the Z-height.

For the X & Y, it it still a bit of a problem because I haven't been able to build my printbed (yes that retard was me, with the aluminum plate trouble hahaha), and the companies I have found here in holland that sell aluminum plate material always charge the price of a full plate so I have to buy a whole plate for around the price of ~50 to 60 euro's and then have it cut up and pay a very strange high shipping cost hahaha (20 euros instead of the usual 6.75 euros.. WHY). I don't ever see this printbed becoming reality

At the academy where I am studying I can buy the aluminum at the bottom price and cut the sheets myself, but ofcourse the school is closed during the summer so this means I either have to pay far too much for just a little or wait until early september until I can finish the machine. Tomorrow I'll head out into town again to look for alternatives.

I see what you mean with the open front, I like that in the MendelMax 2.0 but the 2.0 version has this thing that it doesn't use smooth rods in the X-carriage, which I dislike because it's not possible for beginners to use a different type of carriage that is based on a smooth rod system. And it requires the builder to use a laser cutter, from my experience, having a small design lasercut will not be very cost-effective However, plastics and woods are much less expensive to cut than metals.

However, plastics and woods are much less expensive to cut than metals.

I would encourage you to see if you can implement a vertical X-system, it not only looks good, but it also gives good accessibility and together with the bowden extruder system it will be even more accessible. However, I have placed the extruder on the backside of the machine, and I am now realizing it is a dumb decision because every time I want to do something filament-related, this means I have to turn the machine around, so I'll mount it in the frontside instead.

Do you have pictures of your machine?

- Marinus

ps Oh and I have discovered Tefspray/PTFE lubricant! Damn, what a great product it just stays on the material you put it on and doesn't attract that must dust and crap, great lubricant! It works great with the linear bushings

Edited 2 time(s). Last edit at 07/28/2013 03:52PM by Ohmarinus.

and thanks! Indeed, I did plan the build a little bit ahead. The filament used for the parts is the 'clear ABS' from repraper.com but I bought it at a Dutch reseller (www.filamentenmeer.nl) because it was easier for me to buy it there.

and thanks! Indeed, I did plan the build a little bit ahead. The filament used for the parts is the 'clear ABS' from repraper.com but I bought it at a Dutch reseller (www.filamentenmeer.nl) because it was easier for me to buy it there.I have measured my build volume to be between 160 and 180 mm in the Z-height.

For the X & Y, it it still a bit of a problem because I haven't been able to build my printbed (yes that retard was me, with the aluminum plate trouble hahaha), and the companies I have found here in holland that sell aluminum plate material always charge the price of a full plate so I have to buy a whole plate for around the price of ~50 to 60 euro's and then have it cut up and pay a very strange high shipping cost hahaha (20 euros instead of the usual 6.75 euros.. WHY). I don't ever see this printbed becoming reality

At the academy where I am studying I can buy the aluminum at the bottom price and cut the sheets myself, but ofcourse the school is closed during the summer so this means I either have to pay far too much for just a little or wait until early september until I can finish the machine. Tomorrow I'll head out into town again to look for alternatives.

I see what you mean with the open front, I like that in the MendelMax 2.0 but the 2.0 version has this thing that it doesn't use smooth rods in the X-carriage, which I dislike because it's not possible for beginners to use a different type of carriage that is based on a smooth rod system. And it requires the builder to use a laser cutter, from my experience, having a small design lasercut will not be very cost-effective

However, plastics and woods are much less expensive to cut than metals.

However, plastics and woods are much less expensive to cut than metals.I would encourage you to see if you can implement a vertical X-system, it not only looks good, but it also gives good accessibility and together with the bowden extruder system it will be even more accessible. However, I have placed the extruder on the backside of the machine, and I am now realizing it is a dumb decision because every time I want to do something filament-related, this means I have to turn the machine around, so I'll mount it in the frontside instead.

Do you have pictures of your machine?

- Marinus

ps Oh and I have discovered Tefspray/PTFE lubricant! Damn, what a great product it just stays on the material you put it on and doesn't attract that must dust and crap, great lubricant! It works great with the linear bushings

Edited 2 time(s). Last edit at 07/28/2013 03:52PM by Ohmarinus.

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 04:07PM |

Registered: 11 years ago Posts: 730 |

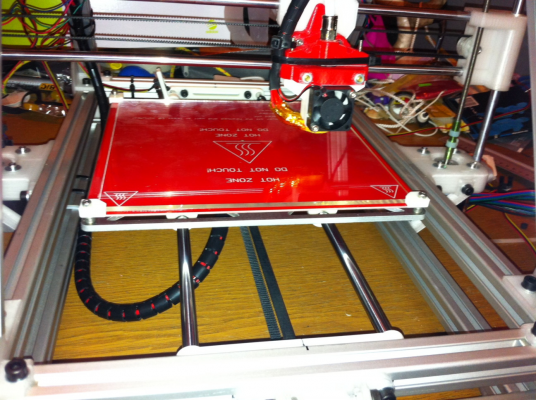

Yes, here's a picture :

The AO-100 and AO-101 (which was the successor) are downsized MendelMax 1.0/1.5 that were sold assembled and calibrated by Lulzbot, a company from Colorado, USA. They are now discontinued. They made a lot of changes on the MM design. For example the top printed braces are placed toward the outside rather than the inside, which IMHO makes more sense from an accessibility perspective. All smooth rods are 8mm, the threaded rods are massive 3/8-12 ACME leadscrews which may not be such a good idea. (3/8 of an inch is 9.5mm) They are placed inward of the smooth rods rather than outward.

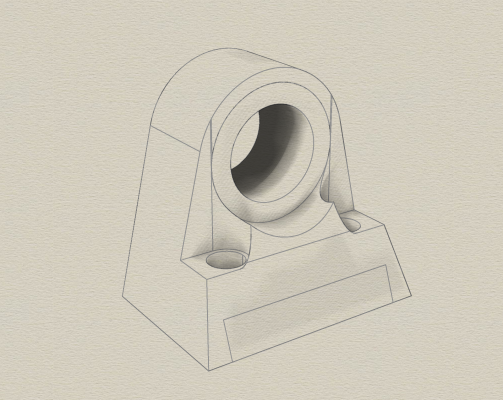

I don't know why they changed the X-ends to make them in 2 pieces, a top and bottom that sandwich the smooth rods. Instead of LM8UU bushings it uses small pillow block bushings.

The Z motor brackets are printed in one piece rather than with fastened braces like the original MM design.

The heated bed is the plain old PCB heatbed Mk1. I hear the Mk2 heats faster...

Lulzbot printers are designed for ABS. With my printer I got three 5lbs. (2.27kg) spools of 3mm ABS filament, one black, one red and one natural (regrettably filament is not included anymore with new printers). That's a lot of plastic that'll last me a while! I'm surprised with the troubles people have here printing with ABS because right from the start I had almost no trouble. I just have to use ABS-acetone solution on the PET covered borosilicate glass bed to make the prints stick. But I have yet to print very large parts.

The extruder is the Greg's Wade Reloaded from Jonas Kuehling. The hot end is a Budaschnozzle 1.1 (the Buda is Lulzbot's design, but I think they were inspired by another hot end). I purchased a Buda 2.0 that is supposed to be more reliable. I'll swap it when I come around to doing my upgrades. BTW the Buda does not require a fan to cool its upper section, at least for ABS.

My print volume is 185x190x100mm. I don't get 200mm in the X axis that I'm supposed to, I found out I lose 15mm because of the extruder motor that otherwise would hit the left Z leadscrew. I'm working on a redesigned extruder that raises the motor, straighten it (the fact it's slanted makes me crazy ) so I can move my X endstop outward and get that 15mm back.

) so I can move my X endstop outward and get that 15mm back.

As for your aluminum bed... Maybe you can find an European supplier (or Chinese for that matter, may be cheaper and usually shipping costs almost nothing with them with no customs fees) which sells ready-made beds? The Lulzbot bed is made of two aluminum sheets, the top one sitting on standoffs. They sell both of the parts in their store and it's compatible with MM but it would be very expensive shipping and customs fees for you.

Cheers

Norm

Edited 3 time(s). Last edit at 07/28/2013 04:12PM by NormandC.

The AO-100 and AO-101 (which was the successor) are downsized MendelMax 1.0/1.5 that were sold assembled and calibrated by Lulzbot, a company from Colorado, USA. They are now discontinued. They made a lot of changes on the MM design. For example the top printed braces are placed toward the outside rather than the inside, which IMHO makes more sense from an accessibility perspective. All smooth rods are 8mm, the threaded rods are massive 3/8-12 ACME leadscrews which may not be such a good idea. (3/8 of an inch is 9.5mm) They are placed inward of the smooth rods rather than outward.

I don't know why they changed the X-ends to make them in 2 pieces, a top and bottom that sandwich the smooth rods. Instead of LM8UU bushings it uses small pillow block bushings.

The Z motor brackets are printed in one piece rather than with fastened braces like the original MM design.

The heated bed is the plain old PCB heatbed Mk1. I hear the Mk2 heats faster...

Lulzbot printers are designed for ABS. With my printer I got three 5lbs. (2.27kg) spools of 3mm ABS filament, one black, one red and one natural (regrettably filament is not included anymore with new printers). That's a lot of plastic that'll last me a while! I'm surprised with the troubles people have here printing with ABS because right from the start I had almost no trouble. I just have to use ABS-acetone solution on the PET covered borosilicate glass bed to make the prints stick. But I have yet to print very large parts.

The extruder is the Greg's Wade Reloaded from Jonas Kuehling. The hot end is a Budaschnozzle 1.1 (the Buda is Lulzbot's design, but I think they were inspired by another hot end). I purchased a Buda 2.0 that is supposed to be more reliable. I'll swap it when I come around to doing my upgrades. BTW the Buda does not require a fan to cool its upper section, at least for ABS.

My print volume is 185x190x100mm. I don't get 200mm in the X axis that I'm supposed to, I found out I lose 15mm because of the extruder motor that otherwise would hit the left Z leadscrew. I'm working on a redesigned extruder that raises the motor, straighten it (the fact it's slanted makes me crazy

) so I can move my X endstop outward and get that 15mm back.

) so I can move my X endstop outward and get that 15mm back.

As for your aluminum bed... Maybe you can find an European supplier (or Chinese for that matter, may be cheaper and usually shipping costs almost nothing with them with no customs fees) which sells ready-made beds? The Lulzbot bed is made of two aluminum sheets, the top one sitting on standoffs. They sell both of the parts in their store and it's compatible with MM but it would be very expensive shipping and customs fees for you.

Cheers

Norm

Edited 3 time(s). Last edit at 07/28/2013 04:12PM by NormandC.

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 04:21PM |

Registered: 11 years ago Posts: 730 |

Quote

Ohmarinus

I see what you mean with the open front, I like that in the MendelMax 2.0 but the 2.0 version has this thing that it doesn't use smooth rods in the X-carriage, which I dislike because it's not possible for beginners to use a different type of carriage that is based on a smooth rod system. And it requires the builder to use a laser cutter, from my experience, having a small design lasercut will not be very cost-effective

Maxbots went with aluminum parts because printing part kits is time consuming. When he started to sell MendelMaxes 1.x he could hardly keep up. He says that it shouldn't be hard to replace them with printed parts, but I haven't seen any people who did it yet. The linear rails the MM2 uses for X and Y look nice but they are very expensive, just look at the Makers Toolworks website...

I'm sure the design can be adapted to use plain old smooth rods for the X and Y carriages. But that'll require quite some design work.

I like what Stephanie Shaltes is planning, an aluminum t-slot version of the Prusa i3. [plus.google.com]

Since I haven't built my printer I'm a little intimidated by the process of making such big changes by myself... Apart from minor troubles my printer is working fine as it is!

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 05:28PM |

Registered: 12 years ago Posts: 199 |

|

Re: MendelMax 1.5 Marinus - My build July 28, 2013 10:03PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, thanks for the advice, however, they charge € 22,32 for shipping the materials..

I guess there is just no other way ://

And I've written them an email a while ago if they can guarantee that the aluminum plates are perfectly flat, because I need to have them as flat as possible.

Also gonna get a few anodized plates to test what type of aluminum works best. Since anodized is a harder type, maybe it is better as a printbed, no idea, just a test

For now my idea was to order:

2x 3mm normal alu

2x 2mm normal alu

2x 2mm anodized

I don't think I need to go thicker than 2mm however 3mm aluminum may come in handy, just for tryouts.

I just found out that the heatplate isn't flat, I bought it at G3D but it's already some time ago I ordered it, so I hope I can fix it to the aluminum in some way that lets me force it into a flat shape.

With those aluminum plates it will cost me 40 euros to have them cut and delivered.

Will decide on the order tomorrow. However I really need them to answer my email about if the plates are going to be undistorted.

jand Wrote:

-------------------------------------------------------

> Hi Marinus,

>

> If you want to buy aluminium sheets goto

> www.aluminiumopmaat.nl

> You can buy sheets cut to size and not pay for a

> big sheet.

>

> Jan

I guess there is just no other way ://

And I've written them an email a while ago if they can guarantee that the aluminum plates are perfectly flat, because I need to have them as flat as possible.

Also gonna get a few anodized plates to test what type of aluminum works best. Since anodized is a harder type, maybe it is better as a printbed, no idea, just a test

For now my idea was to order:

2x 3mm normal alu

2x 2mm normal alu

2x 2mm anodized

I don't think I need to go thicker than 2mm however 3mm aluminum may come in handy, just for tryouts.

I just found out that the heatplate isn't flat, I bought it at G3D but it's already some time ago I ordered it, so I hope I can fix it to the aluminum in some way that lets me force it into a flat shape.

With those aluminum plates it will cost me 40 euros to have them cut and delivered.

Will decide on the order tomorrow. However I really need them to answer my email about if the plates are going to be undistorted.

jand Wrote:

-------------------------------------------------------

> Hi Marinus,

>

> If you want to buy aluminium sheets goto

> www.aluminiumopmaat.nl

> You can buy sheets cut to size and not pay for a

> big sheet.

>

> Jan

|

Re: MendelMax 1.5 Marinus - My build July 31, 2013 12:28AM |

|

Re: MendelMax 1.5 Marinus - My build July 31, 2013 07:41AM |

Admin Registered: 11 years ago Posts: 3,096 |

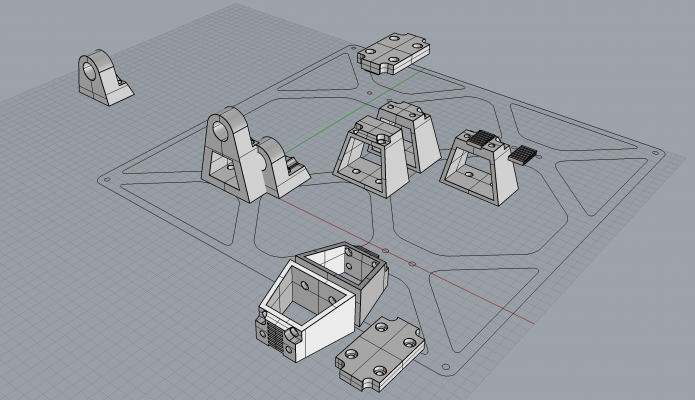

Hi Bill, I actually have the source files available, I've posted some in another topic, but they are wrong. Good you mention it, I'll remove those and post the correct files in this topic.

I will post the STL's and the OpenSCAD files later today, was just about to go outside

Thanks for your comment

To be honest I don't know if the axis-distance between the Z-smooth rod and the threaded rod is similar on your machine. I have changed the Prusa i3 OpenSCAD files to match my MendelMax 1.5 because I had already printed the Z-motor mounts.

In the X-ends I have beefed up the bushing-holders and nut-holders a bit and lined out the blocks that hold the bushings and nut-holder so they look like 'one piece'.

The bushings I've used have an ID of ø 8mm and OD of ~10mm, the thickness of the nut holder is for a M5 nut and the threaded rod hole is in a similar scale.

I will post the STL's and the OpenSCAD files later today, was just about to go outside

Thanks for your comment

To be honest I don't know if the axis-distance between the Z-smooth rod and the threaded rod is similar on your machine. I have changed the Prusa i3 OpenSCAD files to match my MendelMax 1.5 because I had already printed the Z-motor mounts.

In the X-ends I have beefed up the bushing-holders and nut-holders a bit and lined out the blocks that hold the bushings and nut-holder so they look like 'one piece'.

The bushings I've used have an ID of ø 8mm and OD of ~10mm, the thickness of the nut holder is for a M5 nut and the threaded rod hole is in a similar scale.

|

Re: MendelMax 1.5 Marinus - My build August 03, 2013 01:11PM |

Registered: 12 years ago Posts: 972 |

|

Re: MendelMax 1.5 Marinus - My build August 11, 2013 04:53PM |

Registered: 12 years ago Posts: 1,236 |

I've bought some thick alu sheet from ebay but it was bent from being cut by shears instead of sawn.

If you want flat aluminium, try aluminium tool plate. This is made from a more brittle alloy, so should not be bent, but can be sawn or drilled.

I bought "EcoCast" alu plate from a UK company, [www.aluminiumwarehouse.co.uk]. Unfortunately, it is hard to avoid expensive shipping on these orders.

If you want flat aluminium, try aluminium tool plate. This is made from a more brittle alloy, so should not be bent, but can be sawn or drilled.

I bought "EcoCast" alu plate from a UK company, [www.aluminiumwarehouse.co.uk]. Unfortunately, it is hard to avoid expensive shipping on these orders.

|

Re: MendelMax 1.5 Marinus - My build August 12, 2013 10:13AM |

Admin Registered: 11 years ago Posts: 3,096 |

Eventually found a lasercutting service that offered me the panels for 20 euros ex tax and shipping!

However, after paying 1,5 week ago I haven't heard from them anymore.... Not even a reply on my question when it will arrive to my home..

They are a Dutch company, I'm also from the Netherlands, so I really hope I hear from them soon...

However, after paying 1,5 week ago I haven't heard from them anymore.... Not even a reply on my question when it will arrive to my home..

They are a Dutch company, I'm also from the Netherlands, so I really hope I hear from them soon...

|

Re: MendelMax 1.5 Marinus - My build August 13, 2013 08:59PM |

Registered: 11 years ago Posts: 730 |

|

Re: MendelMax 1.5 Marinus - My build August 14, 2013 06:46PM |

Admin Registered: 11 years ago Posts: 3,096 |

Finally I got it today. Turned out they didn't lasercut it, but CNC'ed it. Weird!

Anyway, it looks good. The holes are too small so I have to drill them out manually, and there is a lot of sharp bits 'n pieces left on the edges, they didn't clean it up so I have to file everything down. I guess it's a good price still for what I got. The 3mm top plate is a bit too heavy maybe for my printer. I want it to be light and easy to move. So I will only use the bottom-part.

Meanwhile I have ordered still a bit more parts for the machine so I can finally finish my hotend-carriage design and start putting the machine to work! Haha.

Anyway, it looks good. The holes are too small so I have to drill them out manually, and there is a lot of sharp bits 'n pieces left on the edges, they didn't clean it up so I have to file everything down. I guess it's a good price still for what I got. The 3mm top plate is a bit too heavy maybe for my printer. I want it to be light and easy to move. So I will only use the bottom-part.

Meanwhile I have ordered still a bit more parts for the machine so I can finally finish my hotend-carriage design and start putting the machine to work! Haha.

|

Re: MendelMax 1.5 Marinus - My build August 15, 2013 02:21PM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, after filing all the edges with a small file for 1,5 hours I discovered the holes for the M3 bolts were too small. No problem! I bought a kit for tapping M3 thread and now I don't need any nuts to assemble the printbed

All I'm waiting for now is a new heater cartridge, I don't like wire-wound resistors, however I can use one, I don't want to, they tend to fail very quickly in my setup.

The whole X-carriage is also finished, with a really nice self-designed cooling apparatus. I hope the images are clear:

All I'm waiting for now is a new heater cartridge, I don't like wire-wound resistors, however I can use one, I don't want to, they tend to fail very quickly in my setup.

The whole X-carriage is also finished, with a really nice self-designed cooling apparatus. I hope the images are clear:

|

Re: MendelMax 1.5 Marinus - My build August 15, 2013 02:39PM |

Registered: 12 years ago Posts: 972 |

|

Re: MendelMax 1.5 Marinus - My build August 15, 2013 04:54PM |

Admin Registered: 11 years ago Posts: 3,096 |

Yeah I know  but I got myself the 20mm version so I hope it fits. Otherwise I would have to reprint the whole air-duct with a special cut-out. No problem

but I got myself the 20mm version so I hope it fits. Otherwise I would have to reprint the whole air-duct with a special cut-out. No problem

The air-duct is modular, I could even enhance the model to be printed in even smaller bits to suppress the warp-factors to keep it from detaching from the printbed.

misan Wrote:

-------------------------------------------------------

> Very nice indeed.

>

> But heat cartridge may be difficult to fit in such

> a tight space.

but I got myself the 20mm version so I hope it fits. Otherwise I would have to reprint the whole air-duct with a special cut-out. No problem

but I got myself the 20mm version so I hope it fits. Otherwise I would have to reprint the whole air-duct with a special cut-out. No problem

The air-duct is modular, I could even enhance the model to be printed in even smaller bits to suppress the warp-factors to keep it from detaching from the printbed.

misan Wrote:

-------------------------------------------------------

> Very nice indeed.

>

> But heat cartridge may be difficult to fit in such

> a tight space.

|

Re: MendelMax 1.5 Marinus - My build December 22, 2013 05:33PM |

Admin Registered: 11 years ago Posts: 3,096 |

Oh man, I was so tired of finishing my MendelMax 1.5 last summer.. Only stupid problems all the time. Parts that didn't work well together, being stuck on deciding how to improve parts but not having the time to improve them...

So, now it's christmas holidays, the assessments at the art academy are done (I study Inter-Architecture and boy did I get a good assessment!!! >> More energy to work on other things again ).

).

I decided to pick up the work on my 2nd 3D printer again, time to finish the MendelMax!

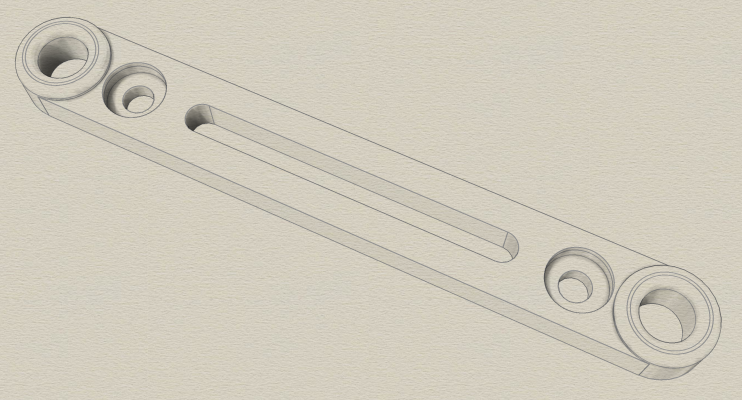

First of all, today I designed a new Y-carriage system. It only uses four bolts, four washers and the other 'usual' stuff. By system I mean the way the Y-carriage connects to the frame. But I guess the pictures tell more than a thousand words.

I wanted to create a piece that simply holds the Y-rods in place and does so, while keeping the carriage as close as possible to the chrome rods that it sits on.

For the next days I will work on the Hotend-mount. If has to be fricking finished soon!!! Damn, last time the Thermistor turned out to be broken, I had finished the complete hotend construction and then the thermistor didn't register anything.. So I had to cut open the entire roll of kapton and glass-fiber insulation

Apparently imgur albums are not working anymore on here... Oh my, now all the images in this topic are gone...

Edited 3 time(s). Last edit at 12/22/2013 05:44PM by Ohmarinus.

So, now it's christmas holidays, the assessments at the art academy are done (I study Inter-Architecture and boy did I get a good assessment!!! >> More energy to work on other things again

).

).I decided to pick up the work on my 2nd 3D printer again, time to finish the MendelMax!

First of all, today I designed a new Y-carriage system. It only uses four bolts, four washers and the other 'usual' stuff. By system I mean the way the Y-carriage connects to the frame. But I guess the pictures tell more than a thousand words.

I wanted to create a piece that simply holds the Y-rods in place and does so, while keeping the carriage as close as possible to the chrome rods that it sits on.

For the next days I will work on the Hotend-mount. If has to be fricking finished soon!!! Damn, last time the Thermistor turned out to be broken, I had finished the complete hotend construction and then the thermistor didn't register anything.. So I had to cut open the entire roll of kapton and glass-fiber insulation

Apparently imgur albums are not working anymore on here... Oh my, now all the images in this topic are gone...

Edited 3 time(s). Last edit at 12/22/2013 05:44PM by Ohmarinus.

|

Re: MendelMax 1.5 Marinus - My build December 22, 2013 05:38PM |

Registered: 11 years ago Posts: 730 |

|

Re: MendelMax 1.5 Marinus - My build December 22, 2013 05:40PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi Normand, thanks for your reply, I saw it too, have fixed it now with just the images in the post itself. A shame the imgur galleries don't work on here anymore, now I have to search through all my old posts and repair it.. Meanwhile you can now see the pictures

Man this sucks, I can't edit my old posts!!!!!!!!! I wish the admins could allow an iFrame again when it's for imgur... Now my whole topic is messed up and I can promise you my images were very good!

Edited 1 time(s). Last edit at 12/22/2013 05:46PM by Ohmarinus.

Man this sucks, I can't edit my old posts!!!!!!!!! I wish the admins could allow an iFrame again when it's for imgur... Now my whole topic is messed up and I can promise you my images were very good!

Edited 1 time(s). Last edit at 12/22/2013 05:46PM by Ohmarinus.

|

Re: MendelMax 1.5 Marinus - My build December 22, 2013 06:03PM |

Registered: 11 years ago Posts: 730 |

Maybe you could ask about it in the "Administration, Announcements, Policy" forum? [forums.reprap.org]

|

Re: MendelMax 1.5 Marinus - My build December 25, 2013 07:50AM |

Admin Registered: 11 years ago Posts: 3,096 |

Wanted to finish the printer today, however, suddenly not all four feet are all touching the ground...

I have re-measured the entire frame and checked if every corner is straight, I cannot find the reason why the printer suddenly is unstable. Is used to be stable on all four corners, touching my table. Also checked on another flat table to be sure. Clueless now.

Would it be wise to completely dismantle the entire printer and just rebuild it again from the bottom?

I have re-measured the entire frame and checked if every corner is straight, I cannot find the reason why the printer suddenly is unstable. Is used to be stable on all four corners, touching my table. Also checked on another flat table to be sure. Clueless now.

Would it be wise to completely dismantle the entire printer and just rebuild it again from the bottom?

|

Re: MendelMax 1.5 Marinus - My build December 25, 2013 11:50AM |

Registered: 12 years ago Posts: 548 |

|

Re: MendelMax 1.5 Marinus - My build December 25, 2013 12:31PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

stephenrc

Loosen all the screws and while pressing down on the top, tighten the screws.

I adjusted the frame a little bit, but I was letting it sit there after I did that and then after 15 minutes I heard a piece of plastic cracking mildly like *pling* as if a layer cracked just a little bit. I cannot find out where exactly and the structural integrity seems to be still ok.

I'll try to get the machine running and the first thing I'll print when it finally works will be a 2nd set of parts for itself

This time in PLA instead of ABS. I'm very curious to see how it holds up, however I am a true believer in the fact that I think ABS is better than PLA for machine parts because I heard the PLA can even become soft in the sun!

This time in PLA instead of ABS. I'm very curious to see how it holds up, however I am a true believer in the fact that I think ABS is better than PLA for machine parts because I heard the PLA can even become soft in the sun!

|

Re: MendelMax 1.5 Marinus - My build December 25, 2013 08:07PM |

Admin Registered: 11 years ago Posts: 3,096 |

Pffff finally time for bed.

I have finished the Y-carriage and yesterday I finished the X-carriage as you can see in pictures above.

Here's a short movie showing the Y-carriage:

[youtu.be]

Tomorrow I'll start hooking up the controller and the PSU and start testing if all the electronics work the way they should

I will look for instructions on commissioning Ramps 1.4 electronics because I would like to first test all the stepper drivers and set them correctly and make sure nothing is shorted (I have measured all wires already with a multimeter to make sure my wiring isn't faulty) and I've also completed the wire-loom from the PSU to the Ramps, with a nice split to hook up the 11A and the 5A to the same PSU output. To finish things, I've tried to create plug-in connectors for the first time for certain parts so I can switch out and adjust parts of the printer with other parts.

Also, I will have a bowden extruder, which is new for me, so I am very curious to see how that works out. I am doubting on using the extruder I have now, because it's a weird design and I am not sure if it will work. The hobbed bolt I ordered is also a bit strange, I am afraid it might break down quickly as the metal is softer than what I'm used to.

I have finished the Y-carriage and yesterday I finished the X-carriage as you can see in pictures above.

Here's a short movie showing the Y-carriage:

[youtu.be]

Tomorrow I'll start hooking up the controller and the PSU and start testing if all the electronics work the way they should

I will look for instructions on commissioning Ramps 1.4 electronics because I would like to first test all the stepper drivers and set them correctly and make sure nothing is shorted (I have measured all wires already with a multimeter to make sure my wiring isn't faulty) and I've also completed the wire-loom from the PSU to the Ramps, with a nice split to hook up the 11A and the 5A to the same PSU output. To finish things, I've tried to create plug-in connectors for the first time for certain parts so I can switch out and adjust parts of the printer with other parts.

Also, I will have a bowden extruder, which is new for me, so I am very curious to see how that works out. I am doubting on using the extruder I have now, because it's a weird design and I am not sure if it will work. The hobbed bolt I ordered is also a bit strange, I am afraid it might break down quickly as the metal is softer than what I'm used to.

|

Re: MendelMax 1.5 Marinus - My build December 25, 2013 08:33PM |

Registered: 11 years ago Posts: 730 |

|

Re: MendelMax 1.5 Marinus - My build December 26, 2013 08:29AM |

Admin Registered: 11 years ago Posts: 3,096 |

Correctemundo. I am relying on the fact that I build the printbed so well, that I will not use leveling. However, if it turns out I really have to use it, I will simply make an extra plate of aluminum and attach it on top of the printbed like I created my last carriage on the Air 2.

Maybe I'm over-confident, but so far everything looks incredibly level I hope it turns out 'really' level when I start testing to make prints. I have arranged a spool of PLA and a Borosilicate glass of 200x200mm.

I hope it turns out 'really' level when I start testing to make prints. I have arranged a spool of PLA and a Borosilicate glass of 200x200mm.

If the printbed turns out to be not completely level, I will first cry and then I will probably have to completely dismantle it all again fun fun funnnnnnnnnnnnnnn

fun fun funnnnnnnnnnnnnnn

Edit:

I've assessed the situation and if needed, I can add springs and printed ABS spring-loaded corners to the bed. I need to design printed corner brackets anyway to keep the borosilicate glass in place. Only thing I'll have to redo is the thermistor placement.

Edited 1 time(s). Last edit at 12/26/2013 08:40AM by Ohmarinus.

Maybe I'm over-confident, but so far everything looks incredibly level

I hope it turns out 'really' level when I start testing to make prints. I have arranged a spool of PLA and a Borosilicate glass of 200x200mm.

I hope it turns out 'really' level when I start testing to make prints. I have arranged a spool of PLA and a Borosilicate glass of 200x200mm.If the printbed turns out to be not completely level, I will first cry and then I will probably have to completely dismantle it all again

fun fun funnnnnnnnnnnnnnn

fun fun funnnnnnnnnnnnnnnEdit:

I've assessed the situation and if needed, I can add springs and printed ABS spring-loaded corners to the bed. I need to design printed corner brackets anyway to keep the borosilicate glass in place. Only thing I'll have to redo is the thermistor placement.

Edited 1 time(s). Last edit at 12/26/2013 08:40AM by Ohmarinus.

|

Re: MendelMax 1.5 Marinus - My build December 26, 2013 11:32AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: MendelMax 1.5 Marinus - My build December 26, 2013 11:42AM |

Registered: 11 years ago Posts: 730 |

|

Re: MendelMax 1.5 Marinus - My build December 26, 2013 02:51PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

NormandC

Nice! I might print myself some corner brackets to replace the bulldog clips. They take much space.

Are you able do draw them yourself? I still have to make a v2 of the brackets, I made them too small haha. Learned a lot from the first set, but first I am going to check all the electronics and see if they work like they should. Really curious to see also if the Bowden system works as intended

How does your heatbed look atm? Wish me luck!

Sorry, only registered users may post in this forum.