[WIP] V-slot 3d printer/CNC machine

Posted by Jacoby6000

|

[WIP] V-slot 3d printer/CNC machine October 20, 2013 03:33AM |

Registered: 10 years ago Posts: 4 |

This is currently in the planning stage, while I build a repstrap for myself.

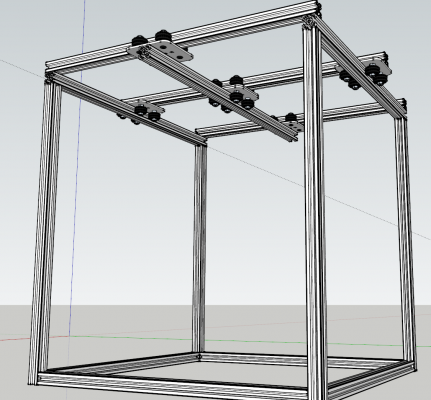

Here's a screenshot of what I have so far

And here is the sketchup file (hosted on mediafire)

frame-with-gantry

So far, I've designed an independent X/Y gantry, so they aren't adding extra stress to eachother. I don't like the idea of a moving bed, because that's where the print/material goes, and I can see some problems with that.

The X/Y gantry will probably not use wheels at the hub like it is now, but rather something that slides around in the slot. Those wheels are too bulky, and I'm hoping to replace them with something else.

I plan on making the bed move along the Z-axis, rather than attaching a big Z-axis assembly to the gantry.

I'm very new to this, so I'm open to any and all suggestions. I plan on building this, and if It's good enough and not too expensive, I'll stick it on the wiki. I plan on keeping all updates in this thread, until then.

If this is an awful idea, let me know now, so I don't get too far into it

Edited 1 time(s). Last edit at 10/20/2013 03:45AM by Jacoby6000.

Here's a screenshot of what I have so far

And here is the sketchup file (hosted on mediafire)

frame-with-gantry

So far, I've designed an independent X/Y gantry, so they aren't adding extra stress to eachother. I don't like the idea of a moving bed, because that's where the print/material goes, and I can see some problems with that.

The X/Y gantry will probably not use wheels at the hub like it is now, but rather something that slides around in the slot. Those wheels are too bulky, and I'm hoping to replace them with something else.

I plan on making the bed move along the Z-axis, rather than attaching a big Z-axis assembly to the gantry.

I'm very new to this, so I'm open to any and all suggestions. I plan on building this, and if It's good enough and not too expensive, I'll stick it on the wiki. I plan on keeping all updates in this thread, until then.

If this is an awful idea, let me know now, so I don't get too far into it

Edited 1 time(s). Last edit at 10/20/2013 03:45AM by Jacoby6000.

|

Re: [WIP] V-slot 3d printer/CNC machine October 20, 2013 11:50AM |

Registered: 11 years ago Posts: 1,049 |

How are the axes driven, belt, leadscrew?

How are belts led thru system?

Where are motors mounted?

With trolley in center the XY axes may be over constrained

and require large torque to move or forever binding

How is extruder mounted?

See Gigabot for design ideas

[www.re3d.org]

How are belts led thru system?

Where are motors mounted?

With trolley in center the XY axes may be over constrained

and require large torque to move or forever binding

How is extruder mounted?

See Gigabot for design ideas

[www.re3d.org]

|

Re: [WIP] V-slot 3d printer/CNC machine October 20, 2013 12:47PM |

Registered: 10 years ago Posts: 4 |

This is a very early draft, but my plan is to have 6 motors total. 2 for x, 2 for y, 1 for Z, and finally one for the extruder.

I plan on using the lightest extruder I can find, to reduce the weight of the whole gantry assembly. For mounting the extruder, I'm going to use a larger mounting plate at the gantry hub, and affixing it to that through some means.

The x and Y axis will be belt driven, and I'll mount the motors to the frame, perpendicular to the axis they're driving (pretty standard, I think). I'm hoping having 2 motors per horizontal axis will prevent any binding that may happen.

The Z axis will be driven by lead screws. I'm not entirely sure how I'm going to go about that, yet. I'm thinking one lead screw at each corner of the printing bed, all driven by one belt that runs around all four, being driven by one motor.

I'll have an updated design later tonight, and then my explanation will probably make more sense.

This is my first time designing anything mechanical. I'm a programmer, and so this is a little outside my comfort zone. I'm totally open to any advice. I'm sure I need it.

Edited 1 time(s). Last edit at 10/20/2013 12:48PM by Jacoby6000.

I plan on using the lightest extruder I can find, to reduce the weight of the whole gantry assembly. For mounting the extruder, I'm going to use a larger mounting plate at the gantry hub, and affixing it to that through some means.

The x and Y axis will be belt driven, and I'll mount the motors to the frame, perpendicular to the axis they're driving (pretty standard, I think). I'm hoping having 2 motors per horizontal axis will prevent any binding that may happen.

The Z axis will be driven by lead screws. I'm not entirely sure how I'm going to go about that, yet. I'm thinking one lead screw at each corner of the printing bed, all driven by one belt that runs around all four, being driven by one motor.

I'll have an updated design later tonight, and then my explanation will probably make more sense.

This is my first time designing anything mechanical. I'm a programmer, and so this is a little outside my comfort zone. I'm totally open to any advice. I'm sure I need it.

Edited 1 time(s). Last edit at 10/20/2013 12:48PM by Jacoby6000.

|

Re: [WIP] V-slot 3d printer/CNC machine October 20, 2013 03:37PM |

Registered: 11 years ago Posts: 1,049 |

I would think you would have TWO motors on z axis

one on either side --- can't see ONE with a huge cantalever?

So the extruder will hang off trolly --- taking up 4-6" of Z height?

or

a flange on the trolly taking up X or Y travel

I wonder why the designers at Gigabot didn't design like yours

oh --- they are only mechanical engineers and want to sell a $5000 machine.

Please read about over contraining a mechanical system with rolling components.

one on either side --- can't see ONE with a huge cantalever?

So the extruder will hang off trolly --- taking up 4-6" of Z height?

or

a flange on the trolly taking up X or Y travel

I wonder why the designers at Gigabot didn't design like yours

oh --- they are only mechanical engineers and want to sell a $5000 machine.

Please read about over contraining a mechanical system with rolling components.

|

Re: [WIP] V-slot 3d printer/CNC machine October 20, 2013 04:03PM |

Registered: 10 years ago Posts: 4 |

After reading, it seems like the trolly design is inherently bad. The only way I can think of to reduce the the constraining is to stick with only two wheels per axis on the trolly. But then I wonder how Stable that would be. I really don't want to ditch the main concept, because I'd like to have an xy gantry where the axis' are doing an equal amount of work. I suppose if there's nothing I can do I could ditch it, but I'm wondering if there are more options?

As for the extruder problem, I'm not too worried about that

If this works well, it'll be very easily scalable (perhaps support beams would be need to be set at the mid points on the horizontal bars as the only structural difference).

On the Z - axis, that's what I'm least sure of at this point. I expect it to change a lot from what I imagined.

I'm doing this all as a learning experience. As I said before, I've never done anything mechanical, ever.

Do you have any suggestions?

As for the extruder problem, I'm not too worried about that

If this works well, it'll be very easily scalable (perhaps support beams would be need to be set at the mid points on the horizontal bars as the only structural difference).

On the Z - axis, that's what I'm least sure of at this point. I expect it to change a lot from what I imagined.

I'm doing this all as a learning experience. As I said before, I've never done anything mechanical, ever.

Do you have any suggestions?

|

Re: [WIP] V-slot 3d printer/CNC machine October 21, 2013 02:02PM |

Registered: 11 years ago Posts: 1,049 |

I was wondering why you tied X axis to the cross beam

instead of just moving the trolly along the Y-axis for X travel.

What does tieing X-axis to frame do?

X-Y travel force the trolly around -- a indirect forcing around of X-Y trolly.

was this to eliminate any motors on a moving axis?

Your wheels are side loaded, tearing tires off bearings,

instead of normal radial loading with vertical wheels/trollies

instead of just moving the trolly along the Y-axis for X travel.

What does tieing X-axis to frame do?

X-Y travel force the trolly around -- a indirect forcing around of X-Y trolly.

was this to eliminate any motors on a moving axis?

Your wheels are side loaded, tearing tires off bearings,

instead of normal radial loading with vertical wheels/trollies

|

Re: [WIP] V-slot 3d printer/CNC machine October 24, 2013 07:49PM |

Registered: 10 years ago Posts: 16 |

Do yourself a favor and take a look at CoreXY. I've actually been looking at desiging a printer based around the v-slot extrusions, and corexy seems to be the way to go because it helps to minimize the moving mass. Additionally, you will get much better results if you have the two center beams parallel with a gap in the middle for a gantry. The way things are right now you must keep the two moving beams perfectly perpendicular or the whole gantry will lock up. If I have time, I will try and post my own mock-up this weekend so that you can see an alternate way of making the XY gantry. Its a good start, and I really love the idea of V-slot because it offers great scaling, and allows for uncluttered, minimalist designs.

|

Re: [WIP] V-slot 3d printer/CNC machine October 26, 2013 12:39AM |

Registered: 10 years ago Posts: 4 |

Jacoby, I've been toying with a similar idea. Build area ~400mmx400mm. The only parts that aren't off the shelf openbuilds would be the z-axis acme scews/nuts and the extruder mount. I'm not totally convinced that the accuracy would be fantastic but the way it all goes together so easily makes it tempting to give it a try.

|

Re: [WIP] V-slot 3d printer/CNC machine December 05, 2013 05:53AM |

Registered: 10 years ago Posts: 2 |

|

Re: [WIP] V-slot 3d printer/CNC machine December 18, 2013 10:18AM |

Registered: 10 years ago Posts: 4 |

After two months of actually building stuff, I've come to the decision to switch out the gantry with a corexy style mechanism. I don't know when I'll get to be able to work on any of it, especially on the holidays.

I've also decided that in addition to the corexy, I'm going to stick a moving knot in there (maybe) to stabilize the Z axis for larger scale printers. My assumption is that, while a moving knot is made to keep the X and Y axis' parallel, it's also adding a fair amount of support to the Z axis, assuming it's tight enough. I may not even have to go with the moving knot idea, but if it starts to sag in the center of the gantry of larger scale printers, it's a potential fix. Perhaps in builds with sagging, you'd use a bowden extruder to drive the filament, so the carriage only has to carry itself and the hot end. Maybe you'd do that even in builds without sagging.

I've also decided that in addition to the corexy, I'm going to stick a moving knot in there (maybe) to stabilize the Z axis for larger scale printers. My assumption is that, while a moving knot is made to keep the X and Y axis' parallel, it's also adding a fair amount of support to the Z axis, assuming it's tight enough. I may not even have to go with the moving knot idea, but if it starts to sag in the center of the gantry of larger scale printers, it's a potential fix. Perhaps in builds with sagging, you'd use a bowden extruder to drive the filament, so the carriage only has to carry itself and the hot end. Maybe you'd do that even in builds without sagging.

Sorry, only registered users may post in this forum.