Newbie with ambitious build

Posted by _Adrian_

|

Newbie with ambitious build January 31, 2014 05:21PM |

Registered: 10 years ago Posts: 21 |

Hey guys...

I figured I'd start a "little" project with my kids as we started a CNC Mill build that slowly got pushed to the side.

It was supposed to be a gantry ( Cartesian) style mill 1000mm x 750mm 600mm ( L x W x H ) which is quite a fair sized mill for "home" use!

Now they were wondering if we could still build something as a family project of course.

Seen my buddy pose a few pictures of the things hes been printing and was thinking what a great idea !!

He basically was clueless about my setup and gave me 3 pieces of advice :

1. - Controller - Ramps 1.4

2. - Use 1.75mm filament and use 0.3mm Nozzle for better quality, however this will make it slower

3. - J-head hot end

So onto doing some homework...

I already have quite a bit of stuff that accumulated towards that Mill so might as well put it to use!

List of materials on hand...

- Extruded Aluminum T-Slot Beams ( Metric )

- 1000mm x 750mm T-Slot Modular Table Top

- 4x Applied Motion STM23Q-3AE

- Antek PS-10N50N24

- 2x 1000mm x 20mm FSLB ( Fully Supported Linear Bearing ) w/ BB Slide Blocks

- 1x 1150mm ACME Lead-screw with Zero-Lash Nut

- 2x 650mm x 20mm FSLB w/ BB Slide Blocks

- 2x 750mm ACME Lead-screw w/ Zero-Lash Nut

- 2x 700mm x 20mm Linear Bearing with BB Slide Blocks

Plus... SS Hardware, SKF Bearings and Housings for the lead screws, etc...

Yes I know...

Its complete overkill, but I have it sitting here collecting dust so why not actually put it to use!

So... My questions are :

1 - Are the Stepper Motor Drivers compatible and can they be used with the Ramps 1.4 ?

2 - Is a heated "work area" required ?

3 - Whats your input on other nozzles and are dual/quad nozzles worth the upgrade ?

4 - Software ??

Edited 1 time(s). Last edit at 01/31/2014 05:36PM by _Adrian_.

I figured I'd start a "little" project with my kids as we started a CNC Mill build that slowly got pushed to the side.

It was supposed to be a gantry ( Cartesian) style mill 1000mm x 750mm 600mm ( L x W x H ) which is quite a fair sized mill for "home" use!

Now they were wondering if we could still build something as a family project of course.

Seen my buddy pose a few pictures of the things hes been printing and was thinking what a great idea !!

He basically was clueless about my setup and gave me 3 pieces of advice :

1. - Controller - Ramps 1.4

2. - Use 1.75mm filament and use 0.3mm Nozzle for better quality, however this will make it slower

3. - J-head hot end

So onto doing some homework...

I already have quite a bit of stuff that accumulated towards that Mill so might as well put it to use!

List of materials on hand...

- Extruded Aluminum T-Slot Beams ( Metric )

- 1000mm x 750mm T-Slot Modular Table Top

- 4x Applied Motion STM23Q-3AE

- Antek PS-10N50N24

- 2x 1000mm x 20mm FSLB ( Fully Supported Linear Bearing ) w/ BB Slide Blocks

- 1x 1150mm ACME Lead-screw with Zero-Lash Nut

- 2x 650mm x 20mm FSLB w/ BB Slide Blocks

- 2x 750mm ACME Lead-screw w/ Zero-Lash Nut

- 2x 700mm x 20mm Linear Bearing with BB Slide Blocks

Plus... SS Hardware, SKF Bearings and Housings for the lead screws, etc...

Yes I know...

Its complete overkill, but I have it sitting here collecting dust so why not actually put it to use!

So... My questions are :

1 - Are the Stepper Motor Drivers compatible and can they be used with the Ramps 1.4 ?

2 - Is a heated "work area" required ?

3 - Whats your input on other nozzles and are dual/quad nozzles worth the upgrade ?

4 - Software ??

Edited 1 time(s). Last edit at 01/31/2014 05:36PM by _Adrian_.

|

Re: Newbie with ambitious build January 31, 2014 07:08PM |

Registered: 12 years ago Posts: 1,236 |

1. Yes, I think they should work ok. You would just step, dir and enable to the RAMPS.

2. A heated bed is not essential for PLA, although for large parts it can help prevent warping. For ABS it is pretty much a must.

3. 1.75 mm filament allows smaller lighter extruder, but if you are using lead screw you may not be able to exploit that. The hotends are usually compatible between extruders, so you could change that later.

4. Repetier, Sprinter, Marlin are all commonly used firmwares. Repetier host or pronterface are probably main host software.

You'll need a 12V supply for the RAMPS/Arduino.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

2. A heated bed is not essential for PLA, although for large parts it can help prevent warping. For ABS it is pretty much a must.

3. 1.75 mm filament allows smaller lighter extruder, but if you are using lead screw you may not be able to exploit that. The hotends are usually compatible between extruders, so you could change that later.

4. Repetier, Sprinter, Marlin are all commonly used firmwares. Repetier host or pronterface are probably main host software.

You'll need a 12V supply for the RAMPS/Arduino.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Newbie with ambitious build February 01, 2014 12:22AM |

Registered: 10 years ago Posts: 21 |

Quote

bobc

1. Yes, I think they should work ok. You would just step, dir and enable to the RAMPS.

2. A heated bed is not essential for PLA, although for large parts it can help prevent warping. For ABS it is pretty much a must.

3. 1.75 mm filament allows smaller lighter extruder, but if you are using lead screw you may not be able to exploit that. The hotends are usually compatible between extruders, so you could change that later.

4. Repetier, Sprinter, Marlin are all commonly used firmwares. Repetier host or pronterface are probably main host software.

You'll need a 12V supply for the RAMPS/Arduino.

Thanks for the input.

I was going to get a Arduino 2560, that was untill i saw your signature LOL

I have the Due so im going to use that instead with the RAMPS-FD as i would like to house it in a smaller case with a separate enclosure with a dedicated power supply to trigger other major components in the printer.

Also want to add a nice graphic display so i can keep an eye on it as its progressing. this will be connected to the printer via a unmbilical that will be removable.

( Remember now kids... All manufacturers do give out free samples

including TE ... )

including TE ... )The motor supply will have a softstart and it will be off untill the Due is powered up, it will trigger by it to turn on.

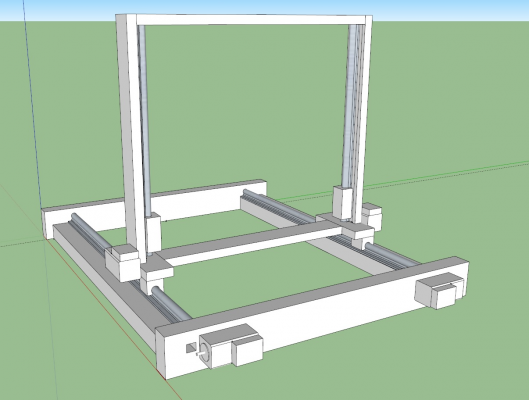

Nothing is built yet...

Switching to a belt is easily done and not work as the state of it right now is no more than just a SketchUp Drawing.

I have a few friends that work in machine shops around the city and would pitch in at a moments notice.

Thats why I'm on here to educate myself and learn what would be the best and fastest way to make this.

I was planning on moving the head using a belt as its easier then the lead screw and far more faster, however since there is no extreme resolution required as in comparison to a mill where really fine detail is required.

Either way...

This is where im at...

|

Re: Newbie with ambitious build February 01, 2014 03:31AM |

Registered: 10 years ago Posts: 21 |

A bit more progress on the drawing...

I think I will have to use lead screws for the X axis though as it will have to hold the weight of the extruding/print head otherwise it will drop when you turn it off.

Not a good idea when the kids will play with it... Guaranteed that something will be broken !

How warm does the work top have to be ??

I think I will have to use lead screws for the X axis though as it will have to hold the weight of the extruding/print head otherwise it will drop when you turn it off.

Not a good idea when the kids will play with it... Guaranteed that something will be broken !

How warm does the work top have to be ??

|

Re: Newbie with ambitious build February 01, 2014 10:09AM |

Registered: 12 years ago Posts: 1,236 |

The heatbed is usually run at 95-100 deg C for ABS, around 60 for PLA.

Be aware that Rev 1A of RAMPS-FD has some undesirable issues, but is still usable (and surprisingly cheap). Rev 2a is nearing finalisation, but I can't guarantee it will go into production, although hopefully some Chinese manufacturer will pick it up.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Be aware that Rev 1A of RAMPS-FD has some undesirable issues, but is still usable (and surprisingly cheap). Rev 2a is nearing finalisation, but I can't guarantee it will go into production, although hopefully some Chinese manufacturer will pick it up.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Newbie with ambitious build February 01, 2014 01:41PM |

Registered: 10 years ago Posts: 21 |

Ahh... you can always try PCB Express, but then again...

Tons of support from china to make a buck LOL

Anyway, I have some older SCSI U320 10' Cables kicking around that I can use for the umbilical and on the printer end I can use some of the TE connectors ( If not time to go scour the site for Smaples / Freebies )

Now a quick question about end stops...

Do you guys use one for each end or just one for the home/park position ?

Trying to work out my wiring here LOL

SO far im at :

5 Motors - 4 wires each

6 Limit Switches

6 Thermo Couples

2 Heater Relays ( SSR )

Since there is no major current I will most likely use ribbon cables for signal and 18-20 Ga for the heavy loads

Tons of support from china to make a buck LOL

Anyway, I have some older SCSI U320 10' Cables kicking around that I can use for the umbilical and on the printer end I can use some of the TE connectors ( If not time to go scour the site for Smaples / Freebies )

Now a quick question about end stops...

Do you guys use one for each end or just one for the home/park position ?

Trying to work out my wiring here LOL

SO far im at :

5 Motors - 4 wires each

6 Limit Switches

6 Thermo Couples

2 Heater Relays ( SSR )

Since there is no major current I will most likely use ribbon cables for signal and 18-20 Ga for the heavy loads

|

Re: Newbie with ambitious build February 02, 2014 02:24AM |

Registered: 10 years ago Posts: 67 |

You may want to rethink using a gantry style design for a 3D printer. Ideally, you want the printer to move fast, so that means keeping the moving mass as low as possible, particularly in X and Y. I would think that moving the entire X and Z axis in a gantry would really slow things down.

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

|

Re: Newbie with ambitious build February 02, 2014 03:52AM |

Registered: 10 years ago Posts: 21 |

Quote

manton

You may want to rethink using a gantry style design for a 3D printer. Ideally, you want the printer to move fast, so that means keeping the moving mass as low as possible, particularly in X and Y. I would think that moving the entire X and Z axis in a gantry would really slow things down.

That's where the torque from the bigger motors come in... most use standard NEMA17 motors which come in at a measely 56oz/in compared to the 210oz/in of the motors im using.

Also note how low the Y and Z axis motors are mounted for low slung weight... another feature thats not in the drawing is the stiffening struts on each side creating a bit of triangulation therefore reinforcing the structure further more.

The screws im using are countersunk...

The hole will be drilled on a drill press, however instead of countersinking which removes material I will press in most of the material and then countersink the other 10-15% so it creates a clean yet strong surface for them.

Thanks for your input though...

|

Re: Newbie with ambitious build February 02, 2014 05:28AM |

Registered: 10 years ago Posts: 67 |

The problem is that if you are using a belt drive system, the belt is not really rigid and acts like a spring, so if you move fast, you have to stop, and it takes time to slow down without all kinds of ringing. If you try to move a large mass quickly (or any mass for that matter, but the larger it is the worse it is), and stop it quickly, you will end up with lots of ringing, and this will show up in your prints. Unless you use a more rigid drive system like a screw, then there isn't much you can do, other than to lower the acceleration, which lowers the torque requirement as well.

The speeds that 3D printers run at is typically much faster than a router or milling machine. Using a Ramps board, I peak out at around 300mm/s (limited by the stepping rate of the firmware I suspect). This is about 720ipm, which would be really fast if you were moving a bunch of mass around as well.

I'm sure you will have no problem getting it to print with the design you are proposing, but I would be surprised if it would work as well as a printer with lower moving mass. All the problems with running at high speed just get magnified as the mass goes up, and you can't fix all of it with a larger motor. There are pretty good reasons why we see the printer designs that we do. The newer designs seem to find ways to lower the moving mass to new lower limits, which allows them to accelerate faster, and ultimately allows faster printing speeds for a given area.

Good luck with your project.

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

The speeds that 3D printers run at is typically much faster than a router or milling machine. Using a Ramps board, I peak out at around 300mm/s (limited by the stepping rate of the firmware I suspect). This is about 720ipm, which would be really fast if you were moving a bunch of mass around as well.

I'm sure you will have no problem getting it to print with the design you are proposing, but I would be surprised if it would work as well as a printer with lower moving mass. All the problems with running at high speed just get magnified as the mass goes up, and you can't fix all of it with a larger motor. There are pretty good reasons why we see the printer designs that we do. The newer designs seem to find ways to lower the moving mass to new lower limits, which allows them to accelerate faster, and ultimately allows faster printing speeds for a given area.

Good luck with your project.

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

|

Re: Newbie with ambitious build February 02, 2014 12:00PM |

Registered: 12 years ago Posts: 1,236 |

Unfortunately, although the mechanics of CNC and 3D printing seem quite similar, in practice if you follow the requirements to the logical end, the 3D printer ends up look quite different to the CNC machine. I think it is a rabbit hole a lot of people try to go down, but in the end not many are successful.

If you have high lead screws and good motors, then the speed issue can be addressed, but you still want to minimise moving mass. I think I would be inclined to fix the gantry, and have a moving table on the Y axis.

Of course, if it is a learning exercise, then going off the beaten path can find new ways of doing things.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

If you have high lead screws and good motors, then the speed issue can be addressed, but you still want to minimise moving mass. I think I would be inclined to fix the gantry, and have a moving table on the Y axis.

Of course, if it is a learning exercise, then going off the beaten path can find new ways of doing things.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Newbie with ambitious build February 02, 2014 02:06PM |

Registered: 10 years ago Posts: 21 |

Well gents,

The ball screws I have are made in England by a machine shop that specializing in Mini DIY CNC components.

They are 20mm diameter and 1400mm ( 1200mm threaded area ) and hardened. Came with 2 bearing blocks ( 1 fixed and 1 floated ), Zero Lash Ball Nut.

The moving the table is more work as the frame has to be longer in order to be able to use the full area.

Also in order to keep the table true you need the bearings to be far appart enough to keep it from yawing.

Given the table length at 1000mm the most effective spot for the bearings would be 25% of total length of the work area, which would make it 250mm from the edge of the table inwards.

However this isnt the most efficient spot as the length of the linear bearing has to be least 75% longer then the length of the table/work area. Then a more efficient spot would be 35% ( at 350mm from the edge of the work area )

At this point, in order to be able to use the the complete area, the linear bearings must be at least 1650mm, which makes it inadequate fit on top of a coffee table ( mines 1200mm x 600mm )

The motors shouldnt be an issue as they have more than enough torque and they can and will do microstepping which gives a 0.9 Degree resolution. Also to keep in mind is the fact that these motors will have the voltage and amperage required to work at their full rating so that isnt going to be an issue and with the capability of running up to 3000RPM is more than adequate in my head.

These are all points that I have long studdied and thought about.

I started working on the Mini CNC project about 2 or 3 years ago and didn't start collecting parts till about 3 or 4 months ago... homework first then spend the money!

The ball screws I have are made in England by a machine shop that specializing in Mini DIY CNC components.

They are 20mm diameter and 1400mm ( 1200mm threaded area ) and hardened. Came with 2 bearing blocks ( 1 fixed and 1 floated ), Zero Lash Ball Nut.

The moving the table is more work as the frame has to be longer in order to be able to use the full area.

Also in order to keep the table true you need the bearings to be far appart enough to keep it from yawing.

Given the table length at 1000mm the most effective spot for the bearings would be 25% of total length of the work area, which would make it 250mm from the edge of the table inwards.

However this isnt the most efficient spot as the length of the linear bearing has to be least 75% longer then the length of the table/work area. Then a more efficient spot would be 35% ( at 350mm from the edge of the work area )

At this point, in order to be able to use the the complete area, the linear bearings must be at least 1650mm, which makes it inadequate fit on top of a coffee table ( mines 1200mm x 600mm )

The motors shouldnt be an issue as they have more than enough torque and they can and will do microstepping which gives a 0.9 Degree resolution. Also to keep in mind is the fact that these motors will have the voltage and amperage required to work at their full rating so that isnt going to be an issue and with the capability of running up to 3000RPM is more than adequate in my head.

These are all points that I have long studdied and thought about.

I started working on the Mini CNC project about 2 or 3 years ago and didn't start collecting parts till about 3 or 4 months ago... homework first then spend the money!

|

Re: Newbie with ambitious build February 02, 2014 02:30PM |

Registered: 10 years ago Posts: 21 |

|

Re: Newbie with ambitious build February 05, 2014 11:57PM |

Registered: 10 years ago Posts: 239 |

interesting project Adrian. Thinking about making my own 3d printer/router too. I have the big machining centers (Haas/Milltronics) to make all the nice parts but have yet to settle on the configuration. Have you seen this one [e3d-online.com] ? What shop in England are you getting your lead screws from.

Edited 2 time(s). Last edit at 02/05/2014 11:58PM by Bill Clark.

Edited 2 time(s). Last edit at 02/05/2014 11:58PM by Bill Clark.

|

Re: Newbie with ambitious build February 07, 2014 08:23PM |

Registered: 10 years ago Posts: 21 |

Quote

Bill Clark

interesting project Adrian. Thinking about making my own 3d printer/router too. I have the big machining centers (Haas/Milltronics) to make all the nice parts but have yet to settle on the configuration. Have you seen this one [e3d-online.com] ? What shop in England are you getting your lead screws from.

Sorry, I'm not closely paying attention... My buddy's wife just had a baby so me and the family been over there helping them out a bit till they get into the "groove" LOL

I got all my stuff from Merchant Dice LTD

|

Re: Newbie with ambitious build February 11, 2014 01:34PM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Newbie with ambitious build February 12, 2014 06:27PM |

Registered: 10 years ago Posts: 21 |

|

Re: Newbie with ambitious build February 13, 2014 02:16PM |

Registered: 10 years ago Posts: 75 |

I hate to suggest more alternatives, but I attempted to address the gantry problem by moving just the base of the Y Axis, so the uprights of the gantry are rigid to the frame.

I have not tested it yet, as the main components have just come together and I'm still waiting on electronics and such.

Those are NEMA 23's @ 286 oz/in holding torque. That should give a good reference of scale. Build volume is 9x9x9" or 225mm^3

I have not tested it yet, as the main components have just come together and I'm still waiting on electronics and such.

Those are NEMA 23's @ 286 oz/in holding torque. That should give a good reference of scale. Build volume is 9x9x9" or 225mm^3

|

Re: Newbie with ambitious build February 13, 2014 04:44PM |

Registered: 10 years ago Posts: 21 |

Not a bad design, but not uporting the bottom of the screws can lead to some issues...

The main issue with people building gantry style units is the lack of strenth and stability.

of your looking to meve the gantry around you need to have it braced well enough that it wont vibrate / shift while when the head is being swung about.

My design has a wide footrint at the base the spread the load and not only will it be tied in with the proper hardware, but it wil be triungulated from the end of each bearing to the top forming an A frame.

Also most if this will be tied as mentione earlier with extran long screws ( My rule of thumb was always use hardware at least 1.5 or 2x longer than the thickness item your bolting ) and loctite blue so it wont loosen over time.

My other choice is to build a CUBOID with a sliding H frame and hang the print head that way, however...

That would require 4 screws to keep the frame level on the Z axis and x and y could possibly be belted to reduce weight.

Edited 1 time(s). Last edit at 02/13/2014 04:45PM by _Adrian_.

The main issue with people building gantry style units is the lack of strenth and stability.

of your looking to meve the gantry around you need to have it braced well enough that it wont vibrate / shift while when the head is being swung about.

My design has a wide footrint at the base the spread the load and not only will it be tied in with the proper hardware, but it wil be triungulated from the end of each bearing to the top forming an A frame.

Also most if this will be tied as mentione earlier with extran long screws ( My rule of thumb was always use hardware at least 1.5 or 2x longer than the thickness item your bolting ) and loctite blue so it wont loosen over time.

My other choice is to build a CUBOID with a sliding H frame and hang the print head that way, however...

That would require 4 screws to keep the frame level on the Z axis and x and y could possibly be belted to reduce weight.

Edited 1 time(s). Last edit at 02/13/2014 04:45PM by _Adrian_.

|

Re: Newbie with ambitious build February 14, 2014 10:42AM |

Registered: 10 years ago Posts: 75 |

Adrian,

Thanks for the suggestion on the bottom of the threads, I plan to print a bracket that will let me mount a bearing to support those down low. That is why the thread goes so far down, the nut will never actually travel that far.

I think you are right about the gantry, if you throw more torque at it, the speed should not be a problem to achieve, not to mention some people are just more patient than others.

Are you going with the standard reprap stepper drivers? If so from my research I've found that these look the best as far as cooling goes. I know this is a huge debate, but the logic seemed reasonable in from the description. [www.panucatt.com]

I know that I'm leaving almost half my torque on the table by using these small drivers, but the price is right and I can upgrade if needed.

Thanks for the suggestion on the bottom of the threads, I plan to print a bracket that will let me mount a bearing to support those down low. That is why the thread goes so far down, the nut will never actually travel that far.

I think you are right about the gantry, if you throw more torque at it, the speed should not be a problem to achieve, not to mention some people are just more patient than others.

Are you going with the standard reprap stepper drivers? If so from my research I've found that these look the best as far as cooling goes. I know this is a huge debate, but the logic seemed reasonable in from the description. [www.panucatt.com]

I know that I'm leaving almost half my torque on the table by using these small drivers, but the price is right and I can upgrade if needed.

|

Re: Newbie with ambitious build February 14, 2014 02:31PM |

Registered: 10 years ago Posts: 21 |

Im using to what I originally thought was a standard NEMA23 but got Applied Motion STM23Q-3AE which have the drivers and encoder built in

All i need to do is feed the power to the motor along with Step +/- and Dir +/- and everything else is going to be fed directly from the RAMPS-FD Board.

For firmware I still have to see if which one is compatible with the Due

Edited 1 time(s). Last edit at 02/14/2014 02:31PM by _Adrian_.

All i need to do is feed the power to the motor along with Step +/- and Dir +/- and everything else is going to be fed directly from the RAMPS-FD Board.

For firmware I still have to see if which one is compatible with the Due

Edited 1 time(s). Last edit at 02/14/2014 02:31PM by _Adrian_.

|

Re: Newbie with ambitious build February 14, 2014 02:47PM |

Registered: 10 years ago Posts: 75 |

Wow, I wish some of those would fall off a truck by my house. Those are pricey little boogers. Very nice though.

I'm just going with the Azteeg3/Marlin setup, as it seems like it is really well adopted and well worked out, but I do see the shift to 32 bit coming up. For the money, I'll just upgrade later. It seems people are getting good prints on the 8 bit AVR, so I'm sticking with it for now.

And to be clear, yours are NEMA 23, but that is just a frame / mounting size. You can get all sorts of servos, steppers, gear boxes, etc, in NEMA 23, so when most people say "my reprap uses NEMA 17", they are leaving out a TON of info about what they are actually using. Most people just assume standard issue NEMA 17 size single stack stepper motors I think.

Mine are NEMA 23 triple stack, meaning they have 3 sets of windings, when some NEMA 23's have just one, or two for a double stack.

Just from reading the description, it looks like it might be difficult if you wanted to actually close the loop on your drives. It uses the incremental encoder for special functions, but it may not actually close the loop, or let you close the loop externally on your hardware. Is that something you were planning to do? I have not yet researched which firmwares support closed loop operation. In your case, I'm not sure how you would get to the signal to EMC2 for instance for loop closure.

I'm just going with the Azteeg3/Marlin setup, as it seems like it is really well adopted and well worked out, but I do see the shift to 32 bit coming up. For the money, I'll just upgrade later. It seems people are getting good prints on the 8 bit AVR, so I'm sticking with it for now.

And to be clear, yours are NEMA 23, but that is just a frame / mounting size. You can get all sorts of servos, steppers, gear boxes, etc, in NEMA 23, so when most people say "my reprap uses NEMA 17", they are leaving out a TON of info about what they are actually using. Most people just assume standard issue NEMA 17 size single stack stepper motors I think.

Mine are NEMA 23 triple stack, meaning they have 3 sets of windings, when some NEMA 23's have just one, or two for a double stack.

Just from reading the description, it looks like it might be difficult if you wanted to actually close the loop on your drives. It uses the incremental encoder for special functions, but it may not actually close the loop, or let you close the loop externally on your hardware. Is that something you were planning to do? I have not yet researched which firmwares support closed loop operation. In your case, I'm not sure how you would get to the signal to EMC2 for instance for loop closure.

|

Re: Newbie with ambitious build February 14, 2014 04:29PM |

Registered: 10 years ago Posts: 21 |

|

Re: Newbie with ambitious build February 14, 2014 04:39PM |

Registered: 10 years ago Posts: 75 |

|

Re: Newbie with ambitious build February 14, 2014 05:19PM |

Registered: 10 years ago Posts: 21 |

LOL I guess so LOL

I have stumbled across a box last night in the crawl space that I thought it was misplaced in the move...

( Yes... I'm still unpacking my own stuff as everyone else came first... I was on a scavanger hunt for a spare fan for one of my servers as the one took a poo )

WOW... I got way too much stuff LMAO

In the box:

4 x Nema23 425oz-in,3A

4 x DM542 128 MICROSTEP Driver

2 x 350w 36v power supply ( SMPS )

1 x 250w 12V power supply ( SMPS )

I'm quite happy tho...

A buddy that wants the STM's for his mini-mill and he's willing to pay me nice coin for these, so I might just unload these to him LOL

Edited 1 time(s). Last edit at 02/14/2014 05:21PM by _Adrian_.

I have stumbled across a box last night in the crawl space that I thought it was misplaced in the move...

( Yes... I'm still unpacking my own stuff as everyone else came first... I was on a scavanger hunt for a spare fan for one of my servers as the one took a poo )

WOW... I got way too much stuff LMAO

In the box:

4 x Nema23 425oz-in,3A

4 x DM542 128 MICROSTEP Driver

2 x 350w 36v power supply ( SMPS )

1 x 250w 12V power supply ( SMPS )

I'm quite happy tho...

A buddy that wants the STM's for his mini-mill and he's willing to pay me nice coin for these, so I might just unload these to him LOL

Edited 1 time(s). Last edit at 02/14/2014 05:21PM by _Adrian_.

|

Re: Newbie with ambitious build February 14, 2014 05:50PM |

Registered: 10 years ago Posts: 75 |

|

Re: Newbie with ambitious build February 14, 2014 09:11PM |

Registered: 10 years ago Posts: 21 |

Quote

Tired2

Nice find, my junk boxes are not that well stocked.

Well i bought them in the spring and we moved into the new place earlier this past summer.

After the move i notice that a few things were missing so i just wrote them off as they were given away with some of the kids stuff that they grew out of.

At least i found them, but makes me wonder what else is there that I overlooked and the wife and the kids just shoved out of the way and stuck it here into storage.

|

Re: Newbie with ambitious build February 15, 2014 06:18PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

_Adrian_

LOLI guess soLOL

I have stumbled across a box last night in the crawl space that I thought it was misplaced in the move...

( Yes... I'm still unpacking my own stuff as everyone else came first... I was on a scavanger hunt for a spare fan for one of my servers as the one took a poo )

WOW...I got way too much stuffLMAO

In the box:LOL

4 x Nema23 425oz-in,3A

4 x DM542 128 MICROSTEP Driver

2 x 350w 36v power supply ( SMPS )

1 x 250w 12V power supply ( SMPS )

I'm quite happy tho...

A buddy that wants the STM's for his mini-mill and he's willing to pay me nice coin for these, so I might just unload these to him

Hehehe

Edited 3 time(s). Last edit at 02/15/2014 06:27PM by Ohmarinus.

|

Re: Newbie with ambitious build February 16, 2014 12:15PM |

Registered: 10 years ago Posts: 21 |

Quote

Ohmarinus

Quote

_Adrian_

LOLI guess soLOL

I have stumbled across a box last night in the crawl space that I thought it was misplaced in the move...

( Yes... I'm still unpacking my own stuff as everyone else came first... I was on a scavanger hunt for a spare fan for one of my servers as the one took a poo )

WOW...I got way too much stuffLMAO

In the box:LOL

4 x Nema23 425oz-in,3A

4 x DM542 128 MICROSTEP Driver

2 x 350w 36v power supply ( SMPS )

1 x 250w 12V power supply ( SMPS )

I'm quite happy tho...

A buddy that wants the STM's for his mini-mill and he's willing to pay me nice coin for these, so I might just unload these to him

Hehehe

Wow... someones bored :rolleyes:

|

Re: Newbie with ambitious build February 19, 2014 11:33AM |

Registered: 10 years ago Posts: 21 |

Quote

bobc

Be aware that Rev 1A of RAMPS-FD has some undesirable issues, but is still usable (and surprisingly cheap). Rev 2a is nearing finalisation, but I can't guarantee it will go into production, although hopefully some Chinese manufacturer will pick it up.

How do you tell the revisions apart ??

( Besides markings )

Also whats the compatibility with the LCD kit from the RAMPS 1.4 ?

Edited 1 time(s). Last edit at 02/19/2014 09:29PM by _Adrian_.

|

Re: Newbie with ambitious build April 02, 2014 07:57PM |

Registered: 10 years ago Posts: 17 |

Quote

_Adrian_

Quote

bobc

Be aware that Rev 1A of RAMPS-FD has some undesirable issues, but is still usable (and surprisingly cheap). Rev 2a is nearing finalisation, but I can't guarantee it will go into production, although hopefully some Chinese manufacturer will pick it up.

How do you tell the revisions apart ??

( Besides markings )

Also whats the compatibility with the LCD kit from the RAMPS 1.4 ?

This topic covers Ramps FD issues and status.

Sorry, only registered users may post in this forum.