Printed slides or wheels for T-Slot aluminium extrusions?

Posted by Dejay

|

Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 12:34AM |

Registered: 9 years ago Posts: 210 |

I want to build a larger scale coreXY printer sometimes in the future (about 600 to 1000mm width, depending on feasibility) and would like to use aluminium extrusions for the carriage because of reduced weight, costs and increased stiffness compared to steel rods.

I realize these are a lot of questions and probably also a bit lazy, and I should probably do my own homework and research more of this myself . I know there are formulas to calculate the "bendiness" of rods / pipes based on physical properties and cross section area, but maybe someone has done some research or has experience comparing the precision of T-Slot extrusions to V-Slot or rods. Anyways I'll post them here in the hopes someone has some answers or someone else is asking himself the same questions. I don't even have my first 3D printer yet, and I will experiment with this as soon as I get it running.

. I know there are formulas to calculate the "bendiness" of rods / pipes based on physical properties and cross section area, but maybe someone has done some research or has experience comparing the precision of T-Slot extrusions to V-Slot or rods. Anyways I'll post them here in the hopes someone has some answers or someone else is asking himself the same questions. I don't even have my first 3D printer yet, and I will experiment with this as soon as I get it running.

- How well suited are standard T-Slot aluminium extrusions for linear motion? (For example from motendis.com) Or should I use something that is specifically designed for linear motion like V-Slot? V-Slot unfortunately is more than 4 times as expensive in Europe though.

- Is openbeam or makerbeam better suited for linear motion than standard T-Slot?

- Is the precision high enough on T-Slot or will it wobble too much?

- Could the potential up and down wobble of extrusions be negated by automatic print bed leveling? (Moving the print bed up and down while moving)

- How do I measure the precision / straightness of extrusions? What are cheap tools or methods to quantify precision?

- Should I use wheels (motendis has wheels that fit inside the T-Slot) or slides (quieter than ball bearings)?

- Since igus / iglidur uses a kind of "mini sleds" for contact with tube bearings for round bearings, couldn't I just print out some sliders out of nylon or acetal? They could simply be rectangular and adjustable for play.

- Would sheets of UHMW polyethylene that I cut into a rectangular shape be better? Or would it be better to use UHMW tape on a printed slider instead of cutting blocks myself?

- Is there a simple online calculator to calculate how much extrusions will bend under a certain load?

- What extrusions I should use for the carriage? (2 direct extruders / hotends on 600mm x axis, maybe about 2 Kg?). 20x20 T-Slot, 30x30 T-Slot, 20x40, 20x60 or 20x80 V-Slot...

I realize these are a lot of questions and probably also a bit lazy, and I should probably do my own homework and research more of this myself

. I know there are formulas to calculate the "bendiness" of rods / pipes based on physical properties and cross section area, but maybe someone has done some research or has experience comparing the precision of T-Slot extrusions to V-Slot or rods. Anyways I'll post them here in the hopes someone has some answers or someone else is asking himself the same questions. I don't even have my first 3D printer yet, and I will experiment with this as soon as I get it running.

. I know there are formulas to calculate the "bendiness" of rods / pipes based on physical properties and cross section area, but maybe someone has done some research or has experience comparing the precision of T-Slot extrusions to V-Slot or rods. Anyways I'll post them here in the hopes someone has some answers or someone else is asking himself the same questions. I don't even have my first 3D printer yet, and I will experiment with this as soon as I get it running.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 12:56AM |

Registered: 9 years ago Posts: 210 |

PS: Forgot to add about 6) and 8): Jay Coture had some success using printed slides for his Kossel Mini (presumably misumi extrusions). Some links:

[www.youtube.com]

[groups.google.com]

[reprapandme.blogspot.com]

[www.thingiverse.com]

[forums.reprap.org]

Link to the new(?) iglidur material filament:

[www.igus.eu]

Edited 1 time(s). Last edit at 06/13/2014 01:11AM by Dejay.

[www.youtube.com]

[groups.google.com]

[reprapandme.blogspot.com]

[www.thingiverse.com]

[forums.reprap.org]

Link to the new(?) iglidur material filament:

[www.igus.eu]

Edited 1 time(s). Last edit at 06/13/2014 01:11AM by Dejay.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 07:45AM |

Registered: 9 years ago Posts: 21 |

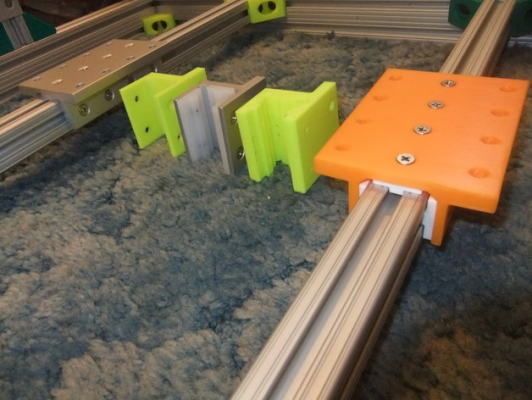

I am just now building a printer out of t-slot extrusions. I plan to use printed PLA sliders, so far it looks very promising. I just print the parts to fit the extrusions exactly (too tight to move) , then heat them up with hot water and force the slider over the extrusion. I then move the silder across the whole range of motion and after a few seconds it moves freely. I think the PLA leaves some deposit on the anodised surface of the extrusion which reduces friction. Silicone spray works well as a lubricant.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 06:05PM |

Registered: 11 years ago Posts: 39 |

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 06:15PM |

Registered: 9 years ago Posts: 210 |

Quote

RaoulDuke

I am just now building a printer out of t-slot extrusions. I plan to use printed PLA sliders, so far it looks very promising. I just print the parts to fit the extrusions exactly (too tight to move) , then heat them up with hot water and force the slider over the extrusion. I then move the silder across the whole range of motion and after a few seconds it moves freely. I think the PLA leaves some deposit on the anodised surface of the extrusion which reduces friction. Silicone spray works well as a lubricant.

Thanks for your info!

Did you use sliders that go into the T-Slot? I wondered why even have something inside the T-Slot, since a rectangle should be ridgid enough. But probably the inside of the extrusions is less prone to be affected by slight bends or surface damage and thus is more precise.

I wonder if adjustable sliders with screws are better or heat fitted ones? Like this one:

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 08:42PM |

Registered: 9 years ago Posts: 21 |

So far, my printer is far from complete, so i have no long term experience. The guy who built the kossel mini didn´t use adjustable sliders, and I think the part in your picture is overengineered. Someone put some research into this (can´t find the page right now) and found that the aluminum wears more than the PLA, so an adjustable silder will just jam on the more worn sections of aluminum eventually.

My sliders look just like the one in your picture, without the adjustable bit...

My sliders look just like the one in your picture, without the adjustable bit...

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 08:51PM |

Registered: 9 years ago Posts: 21 |

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? June 13, 2014 11:16PM |

Registered: 11 years ago Posts: 205 |

When you slide on a T-slot extrusion you aren't actually sliding on aluminum. You are sliding on aluminum oxide from the anodizing. It is actually harder than alloy steel, but very thin. The real issue is that sliding has on average 10 times more friction than rolling, and stick-slip too. So if you are going build a larger machine with slides you really want larger motors, heavier belts, and drives with more power, a larger power supply.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? November 06, 2014 06:25AM |

Registered: 9 years ago Posts: 12 |

Use V-slot and their mini v-wheels. A full delrin wheel set is like $2.

[openbuildspartstore.com]

Edited 2 time(s). Last edit at 11/06/2014 06:28AM by ledaero.

[openbuildspartstore.com]

Edited 2 time(s). Last edit at 11/06/2014 06:28AM by ledaero.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? December 14, 2015 01:03PM |

Registered: 8 years ago Posts: 9 |

Quote

Dejay

I want to build a larger scale coreXY printer sometimes in the future (about 600 to 1000mm width, depending on feasibility) and would like to use aluminium extrusions for the carriage because of reduced weight, costs and increased stiffness compared to steel rods.

I'm currently in the process of building my own 2ft x 2ft (about 600mm x 600mm) custom 3D printer from scratch. I've never built one before, but i'm making great progress. I've got most of the files in solidworks, and designing more on the fly as i build more and more. I'm using 1" t-slot to simplify the design and using t-slot linear bearings as well. I'm somewhat surprised that only a few have used them before, but they do get expensive if they are commercial aluminum ones.

Here are the thingiverse design files for the 3D printed replicas i made:

http://www.thingiverse.com/thing:1113348

Edited 1 time(s). Last edit at 12/14/2015 01:05PM by BioLumo.

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? December 14, 2015 03:37PM |

Registered: 9 years ago Posts: 210 |

|

Re: Printed slides or wheels for T-Slot aluminium extrusions? December 14, 2015 08:32PM |

Registered: 11 years ago Posts: 5,780 |

You can get good, used linear guides 600mm long with bearing blocks via ebay for about $30-60 each. You can't get better bearings- no play whatsoever. They will outperfrom and last a lot longer than bushings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.