1 or 2 motor for z-axis

Posted by chaoscrack

|

1 or 2 motor for z-axis July 22, 2015 09:54AM |

Registered: 8 years ago Posts: 65 |

Hello

I want to build my own printer. Now I'm asking myself should I use one or two stepper motor for the z-axis.

From my point of view it should be stiff enough to use a linear guide at one side and at the other side a linear guide with a ball screw. The two linear guides I would connect with a extruded aluminium.

What do you think, is it stiff enough and would be work proper, or should I use two ball screws? I'm a bit uncertain whether is the system overdimensioned with two ball screws.

Thank you for your feedback

Patrick

I want to build my own printer. Now I'm asking myself should I use one or two stepper motor for the z-axis.

From my point of view it should be stiff enough to use a linear guide at one side and at the other side a linear guide with a ball screw. The two linear guides I would connect with a extruded aluminium.

What do you think, is it stiff enough and would be work proper, or should I use two ball screws? I'm a bit uncertain whether is the system overdimensioned with two ball screws.

Thank you for your feedback

Patrick

|

Re: 1 or 2 motor for z-axis July 22, 2015 10:42AM |

Registered: 10 years ago Posts: 814 |

|

Re: 1 or 2 motor for z-axis July 22, 2015 02:45PM |

Registered: 11 years ago Posts: 5,780 |

Linear guides are very unforgiving of misalignment. If your machine's frame or the aluminum piece joining the two bearing blocks has any flex, you may have problems with binding if you use a single screw on one side. I like the use of linear guides, but I think you should also have leads screws on both sides, driven by a belt and a single motor. If you're going to the trouble and expense of using linear guides, you won't want the alignment of the axes to depend on two motors remaining in sync or screws that can be turned independently by hand.

|

Re: 1 or 2 motor for z-axis July 22, 2015 03:14PM |

Registered: 8 years ago Posts: 65 |

Thank you for your response

@madmike8

The idea is to build a Mendel90. Instead of sheets I want to use extruded aluminium and for the guides the linear one. The build area should be 200/200/200 to 250/250/250.

@the_digital_dentist

I have access to a lot of alignment tools. To alignment the printer is not the problem. My goal is to make an stiff and precise basement, but with as less parts as possible. So if it is possible to use only a ball screws and two guides, it would be nice.

@madmike8

The idea is to build a Mendel90. Instead of sheets I want to use extruded aluminium and for the guides the linear one. The build area should be 200/200/200 to 250/250/250.

@the_digital_dentist

I have access to a lot of alignment tools. To alignment the printer is not the problem. My goal is to make an stiff and precise basement, but with as less parts as possible. So if it is possible to use only a ball screws and two guides, it would be nice.

|

Re: 1 or 2 motor for z-axis July 22, 2015 04:35PM |

Registered: 11 years ago Posts: 5,780 |

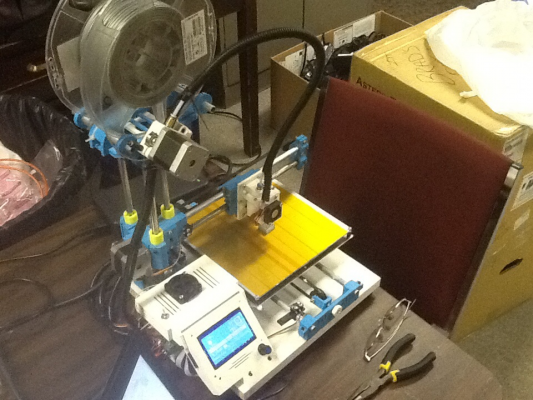

My printer has 305 x 317x 280 mm print envelope and is very rigidly constructed. The frame is built from 1.5" square 8020 aluminum extrusion and uses dual Z axis lead screws with one drive motor and belt, and with fully supported guide rails. I used linear guides in the X and Y axes, and the Y axis is driven by a ball screw. You can see it by following the link in my signature, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1 or 2 motor for z-axis July 23, 2015 01:14PM |

Registered: 11 years ago Posts: 1,049 |

Why do you need the second guide (one without leadscrew)

Is your extruder exceedingly heavy that it will make gantry droop?

Is the linear guide NOT capable of supporting gantry out to 300mm?

Will your X axis linear guide on Z-gantry be so heavy and loose it needs to be supported?

You are not driving around a router/ spindle cutting steel --- just laying down PLA/ABS.

Ordbot Hadron uses TWO leadscrews / motors for Z-axis (driven by one stepper driver)

and it works very well with just maker slides

Is your extruder exceedingly heavy that it will make gantry droop?

Is the linear guide NOT capable of supporting gantry out to 300mm?

Will your X axis linear guide on Z-gantry be so heavy and loose it needs to be supported?

You are not driving around a router/ spindle cutting steel --- just laying down PLA/ABS.

Ordbot Hadron uses TWO leadscrews / motors for Z-axis (driven by one stepper driver)

and it works very well with just maker slides

Sorry, only registered users may post in this forum.