How to fix smooth rods to the frame

Posted by cristian

|

How to fix smooth rods to the frame August 23, 2015 05:15AM |

Registered: 9 years ago Posts: 344 |

I am starting a new printer build (cubic frame with coreXY), and I would like to avoid plastic as much as possible in the critical parts of the structure, so I was wondering: what is the best way to fix smooth rods to the frame with metal parts?

Online I found flanges (such as this one) and standings (for example this one).

Are there other ways to properly fix smooth rods? Besides their different geometry, do flanges have (dis)advantages wrt standings?

Online I found flanges (such as this one) and standings (for example this one).

Are there other ways to properly fix smooth rods? Besides their different geometry, do flanges have (dis)advantages wrt standings?

|

Re: How to fix smooth rods to the frame August 23, 2015 07:16AM |

Registered: 11 years ago Posts: 5,780 |

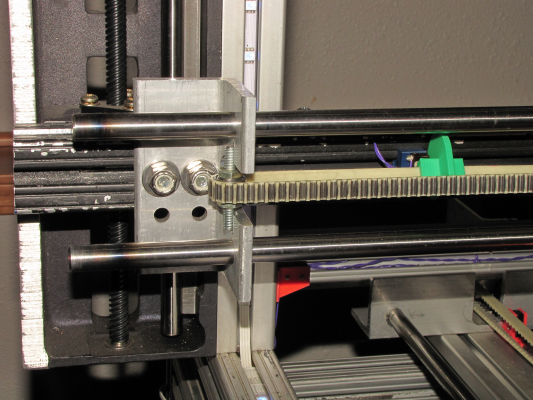

I used this for a couple years and it worked well:

There are more photos on my website here: [mark.rehorst.com]

I drilled holes to fit the rails on a milling machine (drilled all 4 in single piece of angle stock) then cut slots for the belt. Finally, I sawed the part in half and milled the sawed ends smooth. By drilling on the milling machine you can get the holes placed very accurately so you know the rails will be parallel when you put them into the brackets. I did this for the X and Y axes. If you want to be really anal about it, you could also mill the 8020 where the brackets are going to mount to ensure that it is flat and in the exact same plane at both bracket sites. You don't have to take off much metal for that- just enough to ensure flatness- maybe 1 mm.

Last year I got rid of the guide rails and replaced them with linear guides- much better performance, and more compact. See link below for the newer version of the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are more photos on my website here: [mark.rehorst.com]

I drilled holes to fit the rails on a milling machine (drilled all 4 in single piece of angle stock) then cut slots for the belt. Finally, I sawed the part in half and milled the sawed ends smooth. By drilling on the milling machine you can get the holes placed very accurately so you know the rails will be parallel when you put them into the brackets. I did this for the X and Y axes. If you want to be really anal about it, you could also mill the 8020 where the brackets are going to mount to ensure that it is flat and in the exact same plane at both bracket sites. You don't have to take off much metal for that- just enough to ensure flatness- maybe 1 mm.

Last year I got rid of the guide rails and replaced them with linear guides- much better performance, and more compact. See link below for the newer version of the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How to fix smooth rods to the frame August 23, 2015 09:04AM |

Registered: 9 years ago Posts: 344 |

That would be interesting for the X axis of the coreXY, although I have no direct access to a milling machine. How do you ensure that the diameter of the holes is correct and there is no play? And how do you fix the rods so that they do not slide through the holes?

Edited 1 time(s). Last edit at 08/23/2015 09:10AM by cristian.

Edited 1 time(s). Last edit at 08/23/2015 09:10AM by cristian.

|

Re: How to fix smooth rods to the frame August 23, 2015 09:30AM |

Registered: 11 years ago Posts: 5,780 |

IRIC, I used a mill to bore the holes for the guide rails. The rails fit very precisely- if I didn't hold them completely perpendicular to the bracket I couldn't get them into the holes.

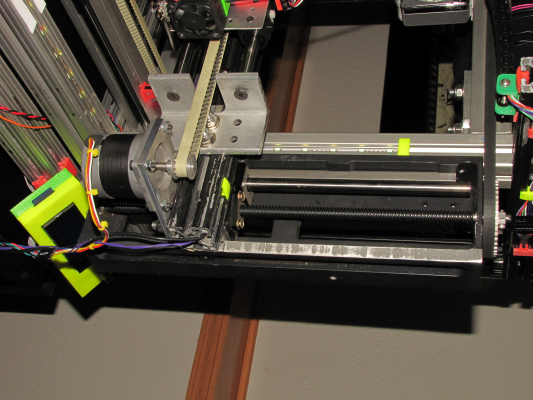

The guide rails I was using had tapped holes in the ends. The opposite end bracket had holes to fit countersunk screws so the countersink centered them:

Those holes were drilled on the milling machine into the single piece of angle bracket that was ultimately cut into the two pieces.

If you don't have tapped holes in the guide rails you're using, you can drill them on a lathe and tap them by hand. Guide rails are usually mild steel with a hardened outer surface to resist wear from bearings, so it isn't particularly difficult to drill or tap them. Otherwise you could just add grub screws to the brackets or even easier, print a plastic piece that straddles the rail and bracket and has screws that grab both.

Edited 1 time(s). Last edit at 08/23/2015 09:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The guide rails I was using had tapped holes in the ends. The opposite end bracket had holes to fit countersunk screws so the countersink centered them:

Those holes were drilled on the milling machine into the single piece of angle bracket that was ultimately cut into the two pieces.

If you don't have tapped holes in the guide rails you're using, you can drill them on a lathe and tap them by hand. Guide rails are usually mild steel with a hardened outer surface to resist wear from bearings, so it isn't particularly difficult to drill or tap them. Otherwise you could just add grub screws to the brackets or even easier, print a plastic piece that straddles the rail and bracket and has screws that grab both.

Edited 1 time(s). Last edit at 08/23/2015 09:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How to fix smooth rods to the frame August 23, 2015 05:23PM |

Registered: 9 years ago Posts: 344 |

|

Re: How to fix smooth rods to the frame September 05, 2015 05:25PM |

Registered: 10 years ago Posts: 20 |

As an alternative to smooth rod, you could try linear rails.

Perhaps something like this (http://www.zoro.com/redi-rail-guide-rail-6096mm-l-368-mm-w-102-mm-h-g-rrl34r-024000-r0/i/G0279255/?utm_source=google_shopping&utm_medium=cpc&utm_campaign=Google_Shopping_Feed&gclid=CK_l8O_p4McCFY6EaQodatIEUg) with the mount holes predrilled would work in an extruded frame?

Just thinking outside the box.

Perhaps something like this (http://www.zoro.com/redi-rail-guide-rail-6096mm-l-368-mm-w-102-mm-h-g-rrl34r-024000-r0/i/G0279255/?utm_source=google_shopping&utm_medium=cpc&utm_campaign=Google_Shopping_Feed&gclid=CK_l8O_p4McCFY6EaQodatIEUg) with the mount holes predrilled would work in an extruded frame?

Just thinking outside the box.

|

Re: How to fix smooth rods to the frame September 05, 2015 06:45PM |

Registered: 9 years ago Posts: 344 |

That may be an option too, yes. I wish they specified clearances and deflection in every product...

Now I bought a cheap linear guide like this one to get familiar with this kind of linear motion system and to measure the play of this low end stuff. I will post the results as soon as I receive it.

Now I bought a cheap linear guide like this one to get familiar with this kind of linear motion system and to measure the play of this low end stuff. I will post the results as soon as I receive it.

Sorry, only registered users may post in this forum.