[BuildLog] HexRap | Extrusion based 3D-Printer

Posted by TheHexaCube

|

[BuildLog] HexRap | Extrusion based 3D-Printer May 25, 2016 05:04PM |

Registered: 8 years ago Posts: 6 |

Hey guys, it's Hexa here.

Over the last ~2 months I have been designing and planning my own design, which I've decided to call HexRap for now.

The real reason I've decided to make my very own printer is that I wasn't happy with the prints I was getting from my Hephestos I3,

though I'm not saying the printer is bad, but rather I did something wrong while assembling it.

My main goal was to design a printer that is much more rigid than the typical plate-style I3, while still being cheap to build (as I'm a pupil and don't earn alot of money).

While still being affordable for me, I didn't want to sacrifice quality so I mostly tried to get parts as cheap as possible, while still having a good quality.

Over the next few weeks I plan to document the build aswell as to share all parts and files necessary for anyone that wants to build a 'HexRap'

Though I'm pretty much finished with my design, I'm still open to any constructive criticism and comments on it.

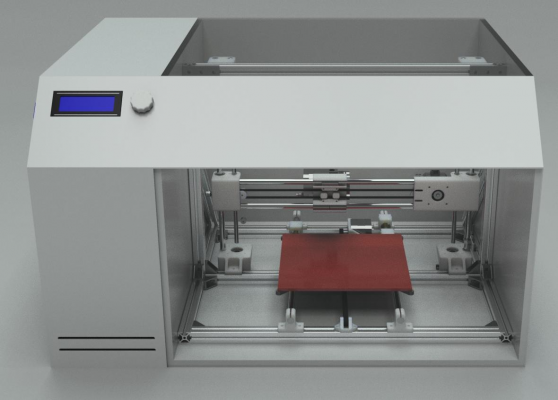

For today, I'll simply share a basic render of what the printer is supposed to look like one day.

// Updates soon \\

Over the last ~2 months I have been designing and planning my own design, which I've decided to call HexRap for now.

The real reason I've decided to make my very own printer is that I wasn't happy with the prints I was getting from my Hephestos I3,

though I'm not saying the printer is bad, but rather I did something wrong while assembling it.

My main goal was to design a printer that is much more rigid than the typical plate-style I3, while still being cheap to build (as I'm a pupil and don't earn alot of money).

While still being affordable for me, I didn't want to sacrifice quality so I mostly tried to get parts as cheap as possible, while still having a good quality.

Over the next few weeks I plan to document the build aswell as to share all parts and files necessary for anyone that wants to build a 'HexRap'

Though I'm pretty much finished with my design, I'm still open to any constructive criticism and comments on it.

For today, I'll simply share a basic render of what the printer is supposed to look like one day.

// Updates soon \\

|

Re: [BuildLog] HexRap | Extrusion based 3D-Printer May 26, 2016 05:38AM |

Registered: 8 years ago Posts: 601 |

Is it just a prusa with an enclosure? Will the frame be attached to the enclosure for added rigidity? What's in the electronics compartment on the left? You could place the filament spool in there to make the design neater and save a bit more space. Will the enclosure be heated? Have you considered improving any other aspects of the prusa design? it's well worth looking into a single motor z axis design, which only costs a little bit extra for the pulleys and belt

I've got a v-slot prusa style machine and it's a great printer, It might be worth looking into v-slot to save some space in there? Seems a shame to have such a large printer with a small bed. what are the overall measurements on this? just eyeballing it, it must be around 800mm wide at least

I look forward to seeing your progress though, keep us updated

I've got a v-slot prusa style machine and it's a great printer, It might be worth looking into v-slot to save some space in there? Seems a shame to have such a large printer with a small bed. what are the overall measurements on this? just eyeballing it, it must be around 800mm wide at least

I look forward to seeing your progress though, keep us updated

|

Re: [BuildLog] HexRap | Extrusion based 3D-Printer May 26, 2016 06:57AM |

Registered: 8 years ago Posts: 6 |

Well, to be honest, yes and no.

It really depends on what a Prusa I3 is to you, it uses the same principle though, I just like to call it an upgrade to a prusa or just my own design as all parts are made by me.

Yes, the printer will be attached to the Frame.

In the electronics compartment are 2 PSUs (because each one doesn't have enough power, and I don't want to buy a new one), a RAMPS (or any other board you want) aswell as any additional wiring needed plus the LCD controller.

I also have thought about putting filament in there, yes.

I did not plan on actively heating the enclosure as I w

as told the heat of the heatbed would be enough, though it should not be that hard to add that.

The reason I've stuck with the basic prusa i3 priciple is that I know how it works, and it's my "first" complete rebuild, so I'll probably stick with that, thanks for the tip though, I might look into that.

The printer indeed is quite large for it's 200x200mm print size, though it doesn't really matter to me, as extrusions are dirt cheap here in germany (~3€/m already cut)

With the enclosure, the printer is about 720x540x420mm.

I've chosen not to use anything like vslot, as it is more expensive than my solution, while maybe being a bit more compact.

You could after all, extend the 4 x-extrusions and fit a 200x300mm bed in there, that way it would be a bit less wasting I think.

After all, thank you very much for your comment, I value that alot.

I'll also update my first post, so stay tuned.

~Hexa

Edited 1 time(s). Last edit at 05/26/2016 06:58AM by TheHexaCube.

It really depends on what a Prusa I3 is to you, it uses the same principle though, I just like to call it an upgrade to a prusa or just my own design as all parts are made by me.

Yes, the printer will be attached to the Frame.

In the electronics compartment are 2 PSUs (because each one doesn't have enough power, and I don't want to buy a new one), a RAMPS (or any other board you want) aswell as any additional wiring needed plus the LCD controller.

I also have thought about putting filament in there, yes.

I did not plan on actively heating the enclosure as I w

as told the heat of the heatbed would be enough, though it should not be that hard to add that.

The reason I've stuck with the basic prusa i3 priciple is that I know how it works, and it's my "first" complete rebuild, so I'll probably stick with that, thanks for the tip though, I might look into that.

The printer indeed is quite large for it's 200x200mm print size, though it doesn't really matter to me, as extrusions are dirt cheap here in germany (~3€/m already cut)

With the enclosure, the printer is about 720x540x420mm.

I've chosen not to use anything like vslot, as it is more expensive than my solution, while maybe being a bit more compact.

You could after all, extend the 4 x-extrusions and fit a 200x300mm bed in there, that way it would be a bit less wasting I think.

After all, thank you very much for your comment, I value that alot.

I'll also update my first post, so stay tuned.

~Hexa

Edited 1 time(s). Last edit at 05/26/2016 06:58AM by TheHexaCube.

|

Re: [BuildLog] HexRap | Extrusion based 3D-Printer May 26, 2016 07:42AM |

Registered: 11 years ago Posts: 5,780 |

When you set out to improve something, you have to look at the thing you're trying to improve and figure out what's wrong with it, then make your design corrections. In the case of a flat plate i3, the flat plate isn't rigid, and it is a little difficult to enclose without building a large box to enclose the whole thing.

Your goal was to make something better than your flat-plate i3, but you've used a single, vertical piece of 2020 for the Z axis. How will that be an improvement? 2020 seems pretty stiff, but it isn't that stiff. Since you're going to enclose the whole thing, it would be much better to make a more cubic structure with the 2020. THAT would be a big increase in rigidity over the flat plate design you have now. For an even bigger improvement, use 40 mm square t-slot. THAT will be rock solid and won't require any additional bracing.

You've set the electronics off to one side of the printer. That increases the footprint considerably over the already large footprint required due to the bed moving in the Y axis. If you put the electronics over or under the mechanism the printer gets taller instead of wider. Taller is usually more acceptable than wider.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Your goal was to make something better than your flat-plate i3, but you've used a single, vertical piece of 2020 for the Z axis. How will that be an improvement? 2020 seems pretty stiff, but it isn't that stiff. Since you're going to enclose the whole thing, it would be much better to make a more cubic structure with the 2020. THAT would be a big increase in rigidity over the flat plate design you have now. For an even bigger improvement, use 40 mm square t-slot. THAT will be rock solid and won't require any additional bracing.

You've set the electronics off to one side of the printer. That increases the footprint considerably over the already large footprint required due to the bed moving in the Y axis. If you put the electronics over or under the mechanism the printer gets taller instead of wider. Taller is usually more acceptable than wider.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: [BuildLog] HexRap | Extrusion based 3D-Printer May 26, 2016 10:15AM |

Registered: 8 years ago Posts: 6 |

In fact, I did not use just a single piece of 2020, I've also braced it, which isn't seen in the Render, I will provide more pictures later though.

What makes the prusa i3 not rigid isn't the plate itself, but the way it is mounted to the y-axis (nuts, that is).

Compared to that method, properly screwing extrusions with corners onto each other seems at least some better.

I'm quite sure that this will be an improvement, maybe not as big as other solutions, but certainly more rigid.

With cubic, I know there is the wilson II, but I didn't like how much plastic parts it needed for mounting it, and I also enjoy CAD.

Of course I also could use 4040, or 8080 or a one piece cast frame, but I do have a certain budget and bigger stuff means I would have to spend money I don't have.

One reason i put electronics and the spool on the printer's side is that I am less limited horziontally than I am vertically, so I longer printer is better for my needs.

Also, I could imagine the integrated lcd would not be as acessible as it is right now.

~Hexa

What makes the prusa i3 not rigid isn't the plate itself, but the way it is mounted to the y-axis (nuts, that is).

Compared to that method, properly screwing extrusions with corners onto each other seems at least some better.

I'm quite sure that this will be an improvement, maybe not as big as other solutions, but certainly more rigid.

With cubic, I know there is the wilson II, but I didn't like how much plastic parts it needed for mounting it, and I also enjoy CAD.

Of course I also could use 4040, or 8080 or a one piece cast frame, but I do have a certain budget and bigger stuff means I would have to spend money I don't have.

One reason i put electronics and the spool on the printer's side is that I am less limited horziontally than I am vertically, so I longer printer is better for my needs.

Also, I could imagine the integrated lcd would not be as acessible as it is right now.

~Hexa

|

Re: [BuildLog] HexRap | Extrusion based 3D-Printer June 06, 2016 07:45PM |

Registered: 8 years ago Posts: 601 |

I feel that in that space, you could probably get a 300x200mm bed in at least, just by re-arranging the X axis a bit from the standard prusa design. you could keep the same footprint, but have a bigger bed. Or if you are content with a 200x200mm bed, than you can reduce the footprint of the entire machine. I used v slot as an example, but I'm sure I've seen designs use rods and be more compact. Of course, if footprint of the machine is not an issue than this is fine, but for the sake of good design I hate to see wasted space personally.

As for rigidity, if the extrusions are attached to the case I don't see a problem? Maybe DigitalDentist has missed this?

As for rigidity, if the extrusions are attached to the case I don't see a problem? Maybe DigitalDentist has missed this?

Sorry, only registered users may post in this forum.