This is a tank

Posted by cwaa

|

This is a tank August 21, 2016 03:28PM |

Registered: 7 years ago Posts: 257 |

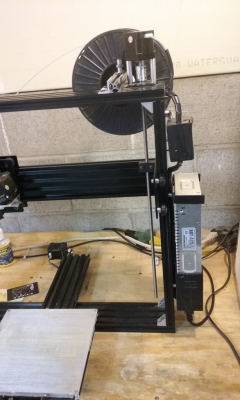

When I decided to build my own printer, one thing I wanted was to avoid the polished rods and sliding bushings most printers are made with. They flex and can pass vibrations to the print head. This design uses two ball bearings on each rubber tired wheel. I can stand on the frame and it can be used for light CNC work.

This frame is available through a company called "Open Builds". My frame is based on several models from Open Builds. The controller, extruder, heated bed and hot end were selections I made after deciding on the frame and linear movement methods. As to how fast it will print, I am still learning. There is quite a lot of inertia in the X and Y axis. But the movements are rock solid. I am using an aluminum printing surface, over an aluminum heating plate. They are insulated from the aluminum build plate and carriage. I use a proximity sensor to level the bed automatically.

I think a lot of Open Builds............Take a look.

[www.openbuilds.com]

This machine has a double carriage and two screws on the Z axis. I explored a single stepper with a belt for the Z axis and found the double motor and screw a very inexpensive alternative to a belt.

Oh, something else about that frame. The carriage plates can be purchased or made, but the purchased plates come pre-drilled to accept the rubber tired wheels, and one side has an eccentric to tighten the wheels into the slot. Very clever design .

This frame is available through a company called "Open Builds". My frame is based on several models from Open Builds. The controller, extruder, heated bed and hot end were selections I made after deciding on the frame and linear movement methods. As to how fast it will print, I am still learning. There is quite a lot of inertia in the X and Y axis. But the movements are rock solid. I am using an aluminum printing surface, over an aluminum heating plate. They are insulated from the aluminum build plate and carriage. I use a proximity sensor to level the bed automatically.

I think a lot of Open Builds............Take a look.

[www.openbuilds.com]

This machine has a double carriage and two screws on the Z axis. I explored a single stepper with a belt for the Z axis and found the double motor and screw a very inexpensive alternative to a belt.

Oh, something else about that frame. The carriage plates can be purchased or made, but the purchased plates come pre-drilled to accept the rubber tired wheels, and one side has an eccentric to tighten the wheels into the slot. Very clever design .

|

Re: This is a tank August 22, 2016 11:02AM |

Registered: 8 years ago Posts: 601 |

Ahh nice, the Voxel Ox by Marshall Peck. I've made one of these as well but over the past year it has taken on many modifications!

-- Highly modified X axis and gantry to be lighter, and more space efficient in both X and Z planes. I've knocked at least 400/500 grams off the extruder carriage.

-- New bottom frame to store electronics. Makes the machine look like an absolute beast, yet it's still the same size....

-- Larger machined aluminium bed, 280x280mm with 240v heater. (not pictured)

-- Single motor Z axis. Easily the best upgrade. Actually pretty cheap. I used 2 more openbuilds plates for simplicity, but a printed alternative would work well here making it cheaper than a 2x motor configuration.

-- New titan extruder.

Next up will be a full heated enclosure, and possibly water cooling for the motors

-- Highly modified X axis and gantry to be lighter, and more space efficient in both X and Z planes. I've knocked at least 400/500 grams off the extruder carriage.

-- New bottom frame to store electronics. Makes the machine look like an absolute beast, yet it's still the same size....

-- Larger machined aluminium bed, 280x280mm with 240v heater. (not pictured)

-- Single motor Z axis. Easily the best upgrade. Actually pretty cheap. I used 2 more openbuilds plates for simplicity, but a printed alternative would work well here making it cheaper than a 2x motor configuration.

-- New titan extruder.

Next up will be a full heated enclosure, and possibly water cooling for the motors

|

Re: This is a tank August 24, 2016 11:54AM |

Registered: 7 years ago Posts: 257 |

|

Re: This is a tank August 24, 2016 01:54PM |

Registered: 11 years ago Posts: 5,780 |

Cheapness is why you see so many machines with two motors in the Z axis. The kit seller knows you won't think through the problems of two motors because that shiny, sparkly low price has you mezmerized, and besides, most of the machines out there have dual z motors, so it must be good, right?. The problem is that the motors and screws can easily get out of sync, causing the X axis to tilt relative to the Z axis.

How do they get out of sync? let's see...

1) someone (maybe even a small child) turns one of the screws manually- it's very easy to do without tools when the motors have no current.

2) microstepping drivers power off with motors that are not at full step positions. The motors jump to their respective nearest full step points sometimes in opposite directions.

3) some mechanical misalignment causes one screw to bind and the motor skips.

4) a wiring problem- a motor connector or wire comes loose on one motor or the other

5) a shaft coupler screw loosens due to vibration

6) a driver problem- if using separate drivers for the motors, one or the other may fail

If you want to get the X axis out of the way for doing maintenance on the bed or extruder, you have to either power up the host computer and printer, then open the host software and command the Z axis to jog, or you have to turn on the printer and step through multiple menus to jog the Z axis using the LCD control panel. Leveling and zeroing the bed is also a PITA with dual motors, again because you must drive them from the controller.

A single motor/loop belt system locks the Z axis screws together and they never get out of sync (well, OK, if a grub screw on one pulley comes loose they can). If you want to raise the X axis to work on the extruder or bed, you simply grab the belt and pull it until the X axis is a high as you need. Nothing has to be powered up, you don't have to step through menus, and when you let go of the belt, the screws will still be synced perfectly. You'll never waste time trying to realign the X and Z axes, and maintenance is much faster and easier, as is leveling and zeroing the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

How do they get out of sync? let's see...

1) someone (maybe even a small child) turns one of the screws manually- it's very easy to do without tools when the motors have no current.

2) microstepping drivers power off with motors that are not at full step positions. The motors jump to their respective nearest full step points sometimes in opposite directions.

3) some mechanical misalignment causes one screw to bind and the motor skips.

4) a wiring problem- a motor connector or wire comes loose on one motor or the other

5) a shaft coupler screw loosens due to vibration

6) a driver problem- if using separate drivers for the motors, one or the other may fail

If you want to get the X axis out of the way for doing maintenance on the bed or extruder, you have to either power up the host computer and printer, then open the host software and command the Z axis to jog, or you have to turn on the printer and step through multiple menus to jog the Z axis using the LCD control panel. Leveling and zeroing the bed is also a PITA with dual motors, again because you must drive them from the controller.

A single motor/loop belt system locks the Z axis screws together and they never get out of sync (well, OK, if a grub screw on one pulley comes loose they can). If you want to raise the X axis to work on the extruder or bed, you simply grab the belt and pull it until the X axis is a high as you need. Nothing has to be powered up, you don't have to step through menus, and when you let go of the belt, the screws will still be synced perfectly. You'll never waste time trying to realign the X and Z axes, and maintenance is much faster and easier, as is leveling and zeroing the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: This is a tank August 24, 2016 03:26PM |

Registered: 8 years ago Posts: 601 |

I can't remember how much the belt cost, but it was in the range of normally priced GT2 belt. I searched aliexpress and ordered a batch of 5, and I remember it being less than £10 at least. Considering the cost of the rest of the machine, it really wasn't a problem. Other parts needed? a 'standard' nema 17 bracket mount (£1-2) and whatever bearings you have lying around, and also some of the openbuilds mounts. You could print these though, they don't need to be particularly strong. The total cost for me to do the whole single motor Z upgrade probably cost around £40, but I could easily have done it for less than £10-15.

Bed levelling was something I had to do very regularly, but now I never have to do it. A single Z motor and an opto endstop are the upgrades that did this, and I attribute most of the success to the single Z motor. You may not see the benefits of a single Z screw as you have auto bed levelling, but the longevity of your machine will notice it. An uneven gantry will put unnecessarily stress on one side of your machine, wearing down bearings, nuts, lead screws, motors etc.

Bed levelling was something I had to do very regularly, but now I never have to do it. A single Z motor and an opto endstop are the upgrades that did this, and I attribute most of the success to the single Z motor. You may not see the benefits of a single Z screw as you have auto bed levelling, but the longevity of your machine will notice it. An uneven gantry will put unnecessarily stress on one side of your machine, wearing down bearings, nuts, lead screws, motors etc.

|

Re: This is a tank April 19, 2017 05:31PM |

Registered: 7 years ago Posts: 257 |

|

Re: This is a tank April 19, 2017 08:55PM |

Registered: 11 years ago Posts: 5,780 |

Vibrating belt?

Whether you experience the problems (or even recognize them) doesn't mean they aren't real. You're confusing your personal experience with common experience. A quick perusal of these forums will bring up plenty of posts from people who have had the very real problem of Z axis screws losing sync. A vibrating belt is no more of a problem in the Z axis than it is in X or Y, except that the Z axis moves much less than X or Y. You could say that the "problem" of a vibrating Z belt is so rare that it's imaginary.

The majority of people who have the Z screws losing sync problem think that releveling the bed or autoleveling will fix it. It doesn't. Autoleveling will get the first layer to stick, but if the screws have lost sync the X axis will be tilted and prints will be skewed. That means you won't be able to print accurately shaped parts so things like gears that mesh or screw-together parts won't work as designed/intended.

There are a lot of people out there who never print anything but yoda heads and tug boats and will never recognize the problem until the X axis tilt gets so bad that the Z axis binds and stops moving. That may take a while.

Edited 1 time(s). Last edit at 04/19/2017 08:56PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Whether you experience the problems (or even recognize them) doesn't mean they aren't real. You're confusing your personal experience with common experience. A quick perusal of these forums will bring up plenty of posts from people who have had the very real problem of Z axis screws losing sync. A vibrating belt is no more of a problem in the Z axis than it is in X or Y, except that the Z axis moves much less than X or Y. You could say that the "problem" of a vibrating Z belt is so rare that it's imaginary.

The majority of people who have the Z screws losing sync problem think that releveling the bed or autoleveling will fix it. It doesn't. Autoleveling will get the first layer to stick, but if the screws have lost sync the X axis will be tilted and prints will be skewed. That means you won't be able to print accurately shaped parts so things like gears that mesh or screw-together parts won't work as designed/intended.

There are a lot of people out there who never print anything but yoda heads and tug boats and will never recognize the problem until the X axis tilt gets so bad that the Z axis binds and stops moving. That may take a while.

Edited 1 time(s). Last edit at 04/19/2017 08:56PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: This is a tank April 24, 2017 10:27AM |

Registered: 7 years ago Posts: 257 |

|

Re: This is a tank May 13, 2017 10:38AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Cheapness is why you see so many machines with two motors in the Z axis. The kit seller knows you won't think through the problems of two motors because that shiny, sparkly low price has you mezmerized, and besides, most of the machines out there have dual z motors, so it must be good, right?. The problem is that the motors and screws can easily get out of sync, causing the X axis to tilt relative to the Z axis.

chris (nophead) had an idea which he provided with the mendel90, which helped with this: a couple of "pointy arrows" which you put on the lead screws, along-side some pointy-pointed things that are attached to the base, at which the pointy-arrows can point.

once you have the printbed aligned and all happy... *at z-level 0*... you simply adjust the arrows to point at their pointy-pointed things, and you can *instantly* tell if (a) the z-home didn't actually work (b) one of the z-screws has got out of sync for *any* reason, even during the operation of the printer. i used to watch them, mesmerised, to make sure that they rotated by the exact same amount on each Z-lift, and i got a pretty good visual indication of how much they would turn for a given 0.15, 0.2 or 0.3mm z-lift.

what's nice about this, dd, is that it works even if you had a single z-screw (and belt) like in this design: you could still conceivably have a grub screw come looes on a single-z-motor design, and nophead's arrows idea would help with that just as well as if you had dual separate z-motors.

|

Re: This is a tank May 15, 2017 10:58AM |

Registered: 7 years ago Posts: 257 |

Sorry, only registered users may post in this forum.