MechaBits KraftWerk'r

Posted by MechaBits

|

Re: MechaBits KraftWerk'r February 06, 2020 10:04PM |

Registered: 8 years ago Posts: 1,671 |

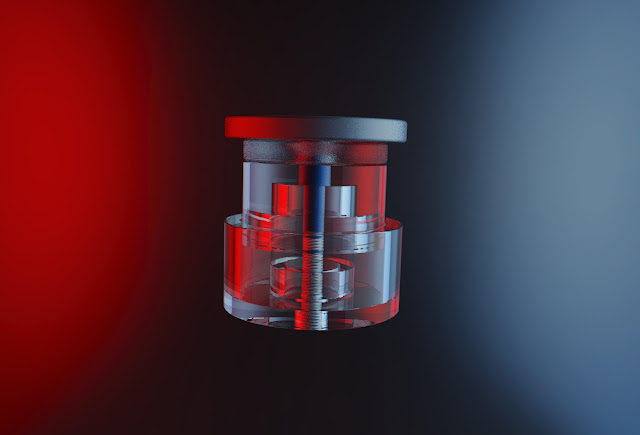

Thinking of next print, something small, maybe for use on the cube, and also the new bed re-jig

it makes more sense on the cube at the moment, but could end up on others. MagMounts on the cube makes sense because I have the large glass plate and I could save either on a top plate, or on extra bed profile purchase....maybe?

I was thinking of gluing the 20-25mm disc mags to the bed, which attaches to the smaller countersunk magnet 15-20mm or a steel disk? but the magnet probably easier to source & cheaper than ideal steel spacer. Maybe i could go smaller on the mags but didnt want any slippage.

Printed first time, was tempted to do 0.1 layers but as I hadnt tested fit, I thought .28 will do, clearance just about ok, a nice vapor smooth it would be perfect, but it works as is. Really didnt need the flutes on the sides, or spring retainer in bottom but wanted to try out the idea.

I was wondering when a new page would start.

Edited 2 time(s). Last edit at 02/07/2020 05:01AM by MechaBits.

|

Re: MechaBits KraftWerk'r February 17, 2020 02:38AM |

Registered: 8 years ago Posts: 1,671 |

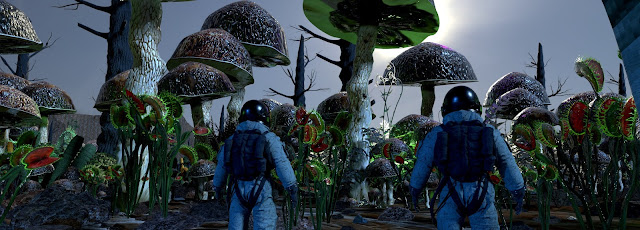

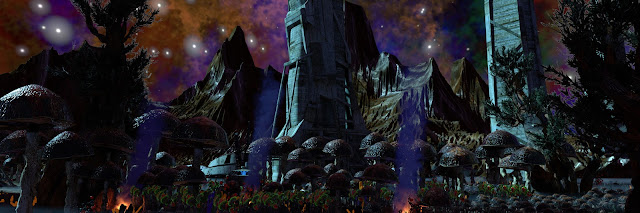

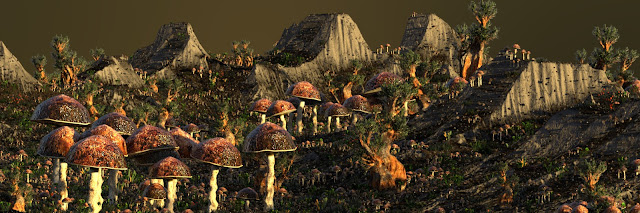

The Mission to Terraform Planet-M has begun. Many assets still need transporting & assembly, delivery of the Modular 3D Habitat Printer is imminent, and work is ongoing to clear space in the Shroom patch, weed out the deadly man eating plants, & setup protection for the giant entheogenic Shrooms.

|

Re: MechaBits KraftWerk'r February 17, 2020 05:49AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: MechaBits KraftWerk'r February 18, 2020 09:24AM |

Registered: 8 years ago Posts: 1,671 |

A Chance to Escape or Confront Ideology

Any Psychonauts wishing to relocate to Planet-M need to furnish designs for their 3D Printed Habitat before embarking on Musk's 2020 Shuttle, unless your Glamping in which case remember to pack your tent.

Edited 2 time(s). Last edit at 02/19/2020 12:33PM by MechaBits.

|

Re: MechaBits KraftWerk'r February 24, 2020 02:19PM |

Registered: 8 years ago Posts: 1,671 |

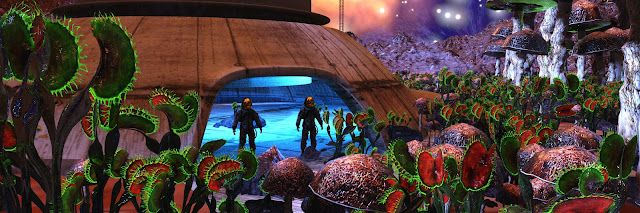

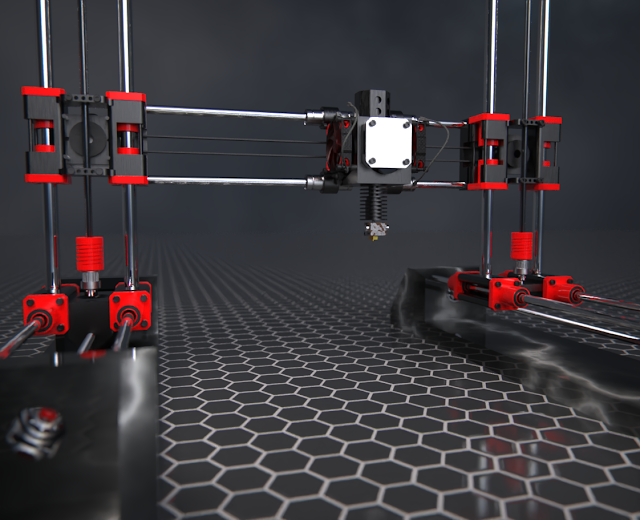

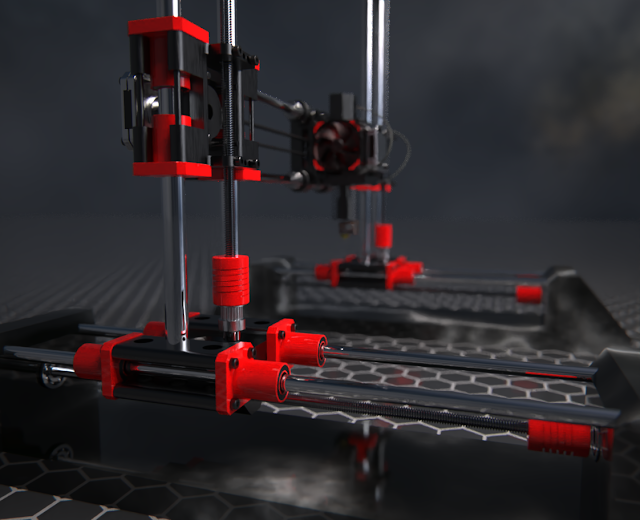

Someone teleported the wrong printer, but while waiting for new ones to be designed & constructed and the world wide quarantine to be lifted, maybe this one can be used for some moulds or components, once the protective coating is removed. Obviously a concrete printer doesnt need fans, (unless they could be used for motion) or Jheads, leadscrews with springy couplers in H, most resemble a small movable crane or robot arm, though gantry types are out there, this one would need build platforms on the back of moon buggy's & a crane to lift it off & place the building or sections.

As the different designs for habitats evolve on earth, new tools & process machinery will be created to streamline the production process. Tune in the next time the planet broadcasts arent obscured by the authorities 10G Deep Think Ideology Protection Field.

|

Re: MechaBits KraftWerk'r March 27, 2020 11:54AM |

Registered: 8 years ago Posts: 1,671 |

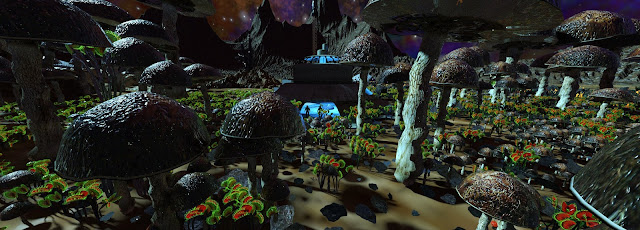

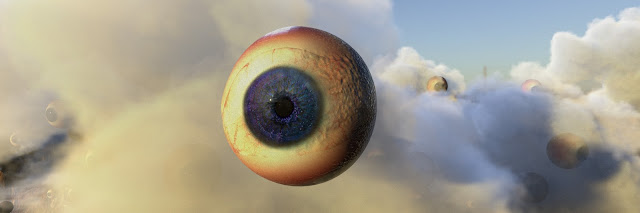

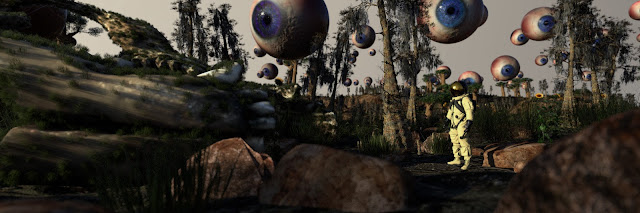

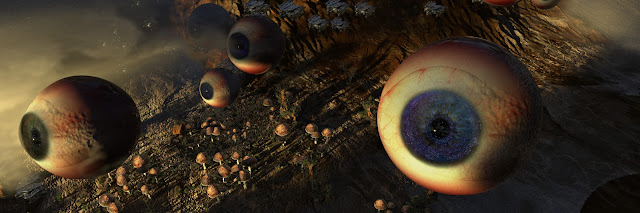

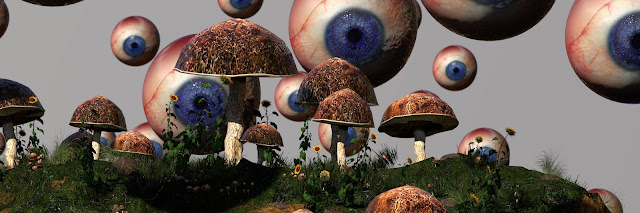

As Earth continues to be Devastated by the Global Pandemic, the Mutated CoronaVirus of 2020, demand for off world retirement homes has increased Exponentially. Fleets of Dropships arrive with new Citizens every day, escorted by i-ball drones scanning for infected cargo while guiding the fleet to the restricted Quarantine Zone. This Planet has already suffered with Extinction Events, the last thing it needs is for the fragile ecosystem to be infected with anything that changes the delicate symbiotic balance between the Empathogens & the living inhabitants. These Pioneering Psychonauts are convinced the Shrooms hold the answer to many of the Earths problems, especially whilst in lockdown in Social Isolation or on Life Support in an induced coma, or if you have been selected for the Mandatory Decontamination Camps.

Meanwhile with stocks of 3D Printing Filament running at a reduced capacity of 0.5kg, we have decided to ring fence the roll until it can be used for something useful, our top minds are working on the issue and will report back as soon as is humanly possible

|

Re: MechaBits KraftWerk'r April 04, 2020 04:49PM |

Registered: 8 years ago Posts: 1,671 |

All over the world people are 3D Printing Face Shields, many are jumping

on the bandwagon and copying the First design made popular by Joseph

Prusa, some with minor variations, all with one basic design flaw, they

only cover 120 - 180 degrees, easy for particulants to still reach your

face. They can also take a few hours to make. I propose an alternative

which requires no printer, just a suitably long piece of clear

Polypropylene or similar & a pair of scissors & some good tape

for the seam. the other pictures are examples of the design most people

are following. #covid-19 #PPE #virus #mask

Tape a poly bag on the top for extra protection

Edited 1 time(s). Last edit at 04/04/2020 04:50PM by MechaBits.

|

Re: MechaBits KraftWerk'r April 04, 2020 06:07PM |

Registered: 11 years ago Posts: 5,780 |

How are they going to breathe? What keeps it from fogging up?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MechaBits KraftWerk'r April 04, 2020 08:21PM |

Registered: 8 years ago Posts: 1,671 |

How they Breath, as normal, obviously paper masks & goggles underneath.

The masks/goggles that have breathing holes and a little plastic filter thing would be underneath, this has huge hole in the top how would it steam up, also when I has a kid I was into magic

and I used to have this stuff that I could put on plastic to stop it steaming up.

Maybe you need to mod it, but I think i'd be safe going to the shops in it without looking like a t##t

it could have slits in it in addition to tape(for interlocking ends) Mark

my words, if they ever have a Paris/Milan fashion show again i'm sure they be all the rage.

Why would it steam up any more than any other with the big hole at top?

I had a motorbike once and sometimes visor would steam up but probably due to the difference in heat & cold, but they never stopped selling bike helmets.

Edited 4 time(s). Last edit at 04/04/2020 08:43PM by MechaBits.

The masks/goggles that have breathing holes and a little plastic filter thing would be underneath, this has huge hole in the top how would it steam up, also when I has a kid I was into magic

and I used to have this stuff that I could put on plastic to stop it steaming up.

Maybe you need to mod it, but I think i'd be safe going to the shops in it without looking like a t##t

it could have slits in it in addition to tape(for interlocking ends) Mark

my words, if they ever have a Paris/Milan fashion show again i'm sure they be all the rage.

Why would it steam up any more than any other with the big hole at top?

I had a motorbike once and sometimes visor would steam up but probably due to the difference in heat & cold, but they never stopped selling bike helmets.

Edited 4 time(s). Last edit at 04/04/2020 08:43PM by MechaBits.

|

Re: MechaBits KraftWerk'r April 04, 2020 11:12PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r April 05, 2020 01:20AM |

Registered: 6 years ago Posts: 1,007 |

I stay with my goggles and FFP2 mask (I discovered they were FFP2 and suitable here) I use when I work with anything that produces dust like sanding, fiber glass cutting....

With this Wuhan virus, the masks are not clogged and can be sterilized with 70° alcohol.

Lets hope their virus is as long lasting as their bearings

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

With this Wuhan virus, the masks are not clogged and can be sterilized with 70° alcohol.

Lets hope their virus is as long lasting as their bearings

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: MechaBits KraftWerk'r April 05, 2020 01:44AM |

Registered: 8 years ago Posts: 1,671 |

I'm working on the assumption they will never put it back in the bottle, it will be around until a vaccine, just have to hope that what I & mother had in December was it, she was xray'd they said pneumonia(hadnt had a cold in 20yrs), when she had follow up & asked what type it was....they had no record(first hospital in UK where they imported people from china, we live on a peninsular which could have been sealed off but nah. So just have to hope your in the 99% that will not die, and as I've been in social isolation as long as I can remember so no change there.

They talk of the anti-viral mushrooms in this video [www.youtube.com]

Edited 1 time(s). Last edit at 04/06/2020 05:44AM by MechaBits.

They talk of the anti-viral mushrooms in this video [www.youtube.com]

Edited 1 time(s). Last edit at 04/06/2020 05:44AM by MechaBits.

|

Re: MechaBits KraftWerk'r April 05, 2020 03:25AM |

Registered: 6 years ago Posts: 1,007 |

Quote

MechaBits

I'm working on the assumption they will never put it back in the bottle, it will be around until a vaccine, just have to hope that what I & mother had in December was it, she was xray'd they said pneumonia(hadnt had a cold in 20yrs), when she had follow up & asked what type it was....they had no record(first hospital in UK where they imported people from china, we live on a peninsular which could have been sealed off but nah. So just have to hope your in the 99% that will not die, and as I've been in social isolation as long as I can remember so no change there.

From what I read and it makes sense, it will spread, no way to prevent it. Just slow it down to allow hospitals to be able to cope with the emergencies, develop medication, vaccine....

A majority will develop immunity, hope we are.

On the plus side, now we can see who and what are really useful in our society. The banksters, their politician puppets, the lawyers ... or the scientists, MDs, engineers, farmers, technicians, workers, truckers ....who built, keep running this modern society and will save it. Our society will have to change accordingly.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: MechaBits KraftWerk'r April 05, 2020 03:51AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r April 05, 2020 05:17PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r June 22, 2020 09:04AM |

Registered: 8 years ago Posts: 1,671 |

Imagine being locked down for months and not printing anything, the printers just been sitting there with half a roll in, waiting to be useful. (YS PLA turned out to be hassle free if the roll ever runs out I'll try them again) So I expected a problem when I tried to print something, usually the pressure on the filament from the extruder pinch wheel is enough to make it break at that spot if left for a while, but everything went smooth no leveling needed, except the thing that was printed proved a negative.

it didnt work, but now I know for sure.

The last few months have mainly been taken up trying to recreate a floating island, but not the green energy haven built from ocean waste I'd like to have a stab at, or a model/maquette that I could print a scale model of...maybe next time, but i'm starting to think a land based resort project maybe a better use of time, but the idea or dream of ever actually building even the most simplest modest passive/eco land based dwelling is evaporating as the world re-aligns, it will be interesting to see how they attempt to make us pay for the recent spending....not everyone received money but we are all going to pay for it.

Edited 2 time(s). Last edit at 06/22/2020 12:00PM by MechaBits.

it didnt work, but now I know for sure.

The last few months have mainly been taken up trying to recreate a floating island, but not the green energy haven built from ocean waste I'd like to have a stab at, or a model/maquette that I could print a scale model of...maybe next time, but i'm starting to think a land based resort project maybe a better use of time, but the idea or dream of ever actually building even the most simplest modest passive/eco land based dwelling is evaporating as the world re-aligns, it will be interesting to see how they attempt to make us pay for the recent spending....not everyone received money but we are all going to pay for it.

Edited 2 time(s). Last edit at 06/22/2020 12:00PM by MechaBits.

|

Re: MechaBits KraftWerk'r June 30, 2020 09:29PM |

Registered: 8 years ago Posts: 1,671 |

Something a little more useful, Zzz Axis parts for 12mm long bearing, sometimes I wish i was printing with something I could slim the parts down further with, I didnt want print to take forever so didnt print the z nut half of initial part. Having the motor at the bottom means it might not go low enough for some bed designs but plenty of room for either of my bed arrangements, though I'm thinking this right side actuator may end up being driven from the other side with a belt. Thinking of running a piece of 2020 across the top just to drive this side, and if I go that route I will probably swap out the current x axis for another piece of 2020, as the current x axis has only 2 mounting points either end but 90 degrees difference so each Z end needs to be different, the left one needs the x motor on it, but if I went the 2020 route i'd mount it to the profile instead. Then I wonder about a third piece of 2020 just to make z alignment easy at the base....maybe running the belt on the bottom will work out better...think I have a dual shaft 17 i can use.

had the printer printing too slow in the beginning as I was printing .28 and thought I wanted better layer adhesion, but even with the second part just for cooling purposes I was putting too much heat into the part with the slower print, lucky it's only a slight camber on a surface i dont need.

Edited 1 time(s). Last edit at 06/30/2020 11:11PM by MechaBits.

|

Re: MechaBits KraftWerk'r July 02, 2020 11:42AM |

Registered: 8 years ago Posts: 1,671 |

It was all going so well and then the curl at the top of the hole made the head catch and mis steps, & knowing I needed the motor holes in the right place I had to give it a magic tap...to get things back in sync. Couldnt be sure I had measured enough times, but everything went together fine, though if I ever print them again there's a couple of changes I could make. i decided to move the motor thru 90 deg' which now throws the idea of a synced Z's out until I redesign the first side to match...not sure....something for the future...and as much as I like having more metal parts in the machines....I could remove 5 metal parts with the addition of 2 custom plastic parts...but If i ever print more parts for it, i'd probably just use some black 2020.

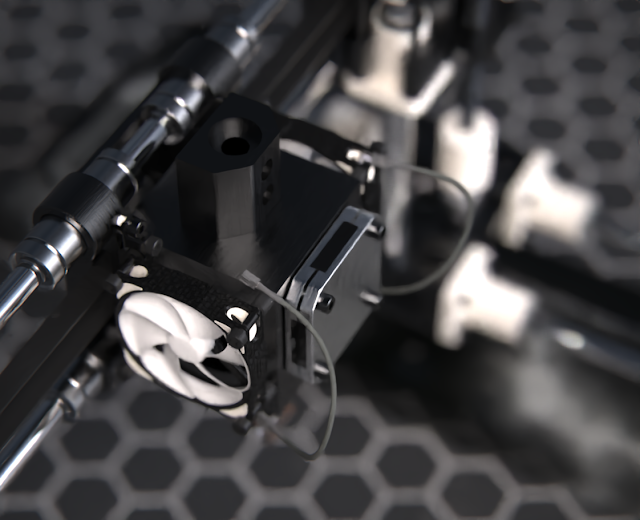

Now here we go again with another hotend mount design needed, though I think to keep the enthusiasm for it, i've mounted the rail behind the support bar, having it on the front adds distance from the belt, and while it may prove a tight squeeze, maybe impossible by the time the fan comes into the mix??? worth a try, creating a cleaner look from the front but trickier to dismantle...only time will tell if it's do-able.

Edited 1 time(s). Last edit at 07/02/2020 10:29PM by MechaBits.

|

Re: MechaBits KraftWerk'r July 04, 2020 10:53PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r July 05, 2020 03:30AM |

Registered: 6 years ago Posts: 1,007 |

Quote

MechaBits

A word you have used in your post has been banned from use. Please use a different word or contact the forum administrators.

Sh... I missed the post AND this "gem" I collect. Anyway .. Or is it a trick to see who reads this thread ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: MechaBits KraftWerk'r July 05, 2020 04:20AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r July 09, 2020 01:49AM |

Registered: 8 years ago Posts: 1,671 |

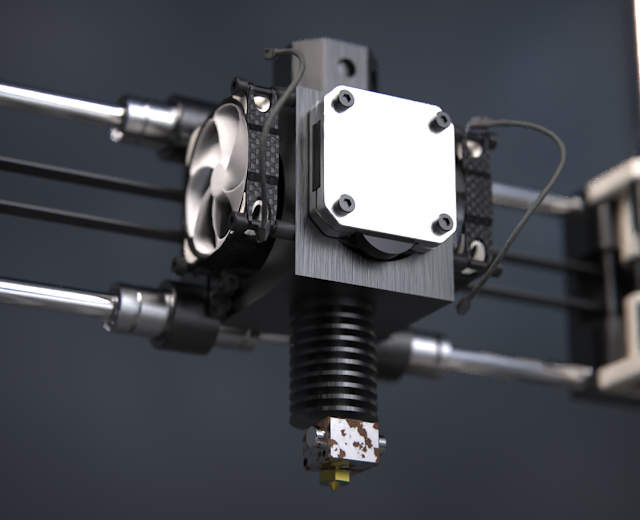

Probably won't use this hotend, but if I do it will need a silicone sock or two, just wanted to see how things panned out, that little heatsink must run too warm for pla mounts, but the 40mm might push enough...right over that heatblock... These parts finish of the printer, i'm out of mega's though it's all plugged into a ramps. I need a pair of 400mm leadscrews, as the temp ones are too short, though plenty for most parts. to do this justice it needs to go inside the black tube frame but that means furloughing the other....and then after a period of time, made redundant...or Assimilated by the other machines that are spawning.

|

Re: MechaBits KraftWerk'r July 12, 2020 07:47AM |

Registered: 8 years ago Posts: 1,671 |

Out with the old in with the new...re-jig complete, feng shui restored in one small corner of the room. Maybe next year i'll remove the alu profile & bolt it to the worksurface but at the moment it's easier to move as is. Arduino came out of the mill which was used to test that, but obviously another controllers needed for that, have the Uno & some BOBs but still mulling over spending the money need to finish it...& if I really want the trouble & mess, but it is good to have machines to tinker with, can't wait for government to enable access to the means of production.

Edited 2 time(s). Last edit at 07/12/2020 09:42PM by MechaBits.

|

Re: MechaBits KraftWerk'r July 26, 2020 05:01PM |

Registered: 8 years ago Posts: 1,671 |

With the roll almost at an end, figuring out what to squeeze out of the last few meters...I decide on a box for slider stepper controller, some cable tidy's(i'll keep these in mind for future end of rolls), & Z-nut trap thing(i did 5p & 5 T&B with 30% on that), hopefully good enough for a spindle, i've seen worse doing ok jobs. I'm not looking for much travel on Z, so spread bearings out as wide as the plate allows. Maybe a custom metal plate will be better to use all the holes & allow mounting on X...but getting that part made local, i'd be better just getting some Petg, my next roll is a PLA+ so will be interesting to see how good that is.

Though still deciding which config for the mill's is the most do-able...with the parts at hand, though ideally would love a short pair of 25 or 30's linear rails....those things have 10mm mount holes would make things much easier but the price is too far to go at the mo', ie alternate cheaper solutions.

Need a better river for the slider, but just wanted something quick & simple to get things moving, but it's far to loud, & jerky on slow speeds, but could be made a little better with geared drive rather than the belt, but I would really like a single 32bit gumstick with one driver on it....or something else...maybe to get the best out of the slider I need the extra 2 axis, but i'm using the gimbal on there for now.

Edited 2 time(s). Last edit at 07/26/2020 06:44PM by MechaBits.

|

Re: MechaBits KraftWerk'r July 27, 2020 02:40PM |

Registered: 8 years ago Posts: 1,671 |

Another little gizmo, converting the manual manfrotto 454 macro focus slider into another motorized axis, one of those things I never got around to doing turned out to be a ten minute job, there was a video recently on YT where some guys in lockdown where making a similar slider but because of the lockdown they couldnt get together to add the 3D printed gears to make it all work how they designed it, I wasnt sure this belt driven one would have enough power to turn the very fine unlubed brass screw with only a little knurling for grip, but it all moves with no issues, cool for slow moving macro, and maybe some other uses in some other machine.

|

Re: MechaBits KraftWerk'r August 02, 2020 10:20PM |

Registered: 8 years ago Posts: 1,671 |

PLA+ first print on 3m tape, no change in settings(which I was dreading changing FW as my max temps set at 210), came off without peeling tape, slight curl on the thin part which I was expecting because of the chamfers but it slid into place perfect, model not off thingverse, I had a look at a few but didnt even dl one for size, maybe I should have because shutter button isnt in perfect position but the case was more about the tripod mount, there's a few cnc'd cases to choose from but none where screaming buy me, so 50g's later a solution to the problem of holding the camera that has no butthole.

Edited 1 time(s). Last edit at 08/02/2020 10:21PM by MechaBits.

|

Re: MechaBits KraftWerk'r August 04, 2020 08:01PM |

Registered: 8 years ago Posts: 1,671 |

Now remember kids always return printer to Zero before turning off...

Unless daddy bought or built a real smart one.

It was all on course to be a smooth print, maybe i should have spent more time re leveling, first few perim's where loose so stopped a couple of times, but also this filaments min temp is 205 I have it on 206, not done any heat tests or altered settings(for a few years) but on this I decided to try printing a little slower 0.9, too cocky perhaps without part cooling, it looked fine for first layers then I noticed a little curl so bumped speed up to 1.1 and went for a kip...returned to the flaw in the layer more curling, but not to worry it's a non mating surface under the 3030, apart from that I just hope there enough lamination in that layer, though the part may still function even if it was split at that point.

Edited 5 time(s). Last edit at 08/05/2020 10:12PM by MechaBits.

Unless daddy bought or built a real smart one.

It was all on course to be a smooth print, maybe i should have spent more time re leveling, first few perim's where loose so stopped a couple of times, but also this filaments min temp is 205 I have it on 206, not done any heat tests or altered settings(for a few years) but on this I decided to try printing a little slower 0.9, too cocky perhaps without part cooling, it looked fine for first layers then I noticed a little curl so bumped speed up to 1.1 and went for a kip...returned to the flaw in the layer more curling, but not to worry it's a non mating surface under the 3030, apart from that I just hope there enough lamination in that layer, though the part may still function even if it was split at that point.

Edited 5 time(s). Last edit at 08/05/2020 10:12PM by MechaBits.

|

Re: MechaBits KraftWerk'r August 20, 2020 09:25AM |

Registered: 8 years ago Posts: 1,671 |

The first printer was made homeless by a younger sleeker upstart, so I found a plinth for Numero Uno to stand on, but it throws up a dilemma of which direction to take the new parts. Do I split the 4 rod Z column and have 2 either end of gantry(2 dif' directions) or keep the 4 and have 2 at other end, or ditch the 2 at the end and use a 12mm rod. Top bracing the rods would be tricky for maybe a little improvement. The hotend sticks out way too far & ideally would like the gantry in the middle of the Z rods, but repeating the other design with single 12mm Z rods, isn't what I feel like doing with these parts. Spare parts are dwindling as things get tidier, with at least 2 directions I could take for the bed, the mulling over what the most important thing to print first can take days. A new base is needed for the 4 rod Z as this was the first printed part used in the printer, printed in the FabLab with settings I didnt get to choose, they went for speed. The Profile is 90mm wide and the base is 2 parts, and as it's going to take hours for each(including 2 other parts for cooling) so I have to be really sure I want them, as this profile is a little overfill for the base and better for a mill gantry, I have some thinner 90x45mm profile but it needs cutting to length. I've reprinted the parts on Z where perspex was used, though keeping some of it adds to the stiffness I might just retire those as the base shape is now a simple square???

As i've said before hotend extends out far too much, and i'm thinking about bringing it more inlive with the center of the base but having done it recently on the other printer, I know i'd want to try another way, but not quite decided yet.

The 3030 arm in the making with my last 400mm piece(maybe also a spare 3030 piece on the bed rails,) also has me wondering if it should be an arm or a bed rail support, as I already have a 3030 arm on the other printer, and already designed the parts for it, though I suppose the new goal would be to standardize this design with the other printer, reduce parts, make Z single motor, hide the belt in the profile...though on this printer i'm just about to move the feeder from rear of frame to the right of the arm, to balance things out and decrease the bowden tube length, this arm setup is rock solid a little more weight a breeze for it, will probably add fixed couplers to it as there's a little mismatch at the moment.

|

Re: MechaBits KraftWerk'r August 24, 2020 08:17AM |

Registered: 8 years ago Posts: 1,671 |

Hot off the Presstidigitizer, bustin out some new shapes & some old. New left Z Base Part 1, bottom part 2 will be the last part needed, and a smaller Z base for the right side, right side needed an extra part for the motor but decided to use the parts from the left side for now to save time on printing but will probably update it at some point, so take a look at the previous beauty before it's reduced to robot parts. While deciding if I should pull things apart to re-imagine, I realized I could put together the new arm without dismantling the other, and it went together quick & easy, I managed to get the rail hidden in the recess of the gantry, I didnt exactly calculate how far down I wanted the print head, just designed a part to do the job simply, for a moment i wasnt sure i'd get the clearance where I need it, will have to make sure bed get's raised to meet it, clearance with the gantry & carriage is as tight as the vickers new choir boy, 8mm rods in a 8.3 hole ohh such a tight squeeze, send me a new part this one's split...those hairline cracks on the 3mm hole layer changes proved to be fatal for the part after hammering home the rods, also because the internals of the hole would be messed up...with over shoots/ cornering of the 3mm holes intruding into the 8mm space. With one last big-ish part the left Z base the machine will be free standing again...I was holding back on this part because I thought I needed extra material for bolt ears, but I managed to fit them underneath Z motor...had to build up the base enough, really should have got some 8mm bolts with flatter heads so I dont loose anymore Z than necessary. Rather than having to print an extra sacrificial part I decided to split the base into 2 parts.

|

Re: MechaBits KraftWerk'r August 24, 2020 09:53AM |

Registered: 8 years ago Posts: 1,671 |

Looked out the window and saw this bright disk in the sky...what is that mystical orb... I thought i'd show it to the printer, but I think this dark beast is like myself a creature of the night...the light...it burns....pla+

I think it's time to get the last rays of summer or stay in & polish those bearings

Edited 2 time(s). Last edit at 08/24/2020 12:45PM by MechaBits.

Sorry, only registered users may post in this forum.