Riki200

Posted by lkcl

|

Re: Riki200 July 25, 2017 12:00PM |

Registered: 7 years ago Posts: 249 |

Quote

lkcl

[www.professionalplastics.com]Quote

prot0typ1cal

How about G10/FR4 garolite?

Available in blue

niiice - you mean PCB fiberglass! that's actually a really interesting idea. it's easy to get hold of and strong as hell.

That's the stuff.

I get mine from McMaster-Carr. A tad more expensive than straight from the maker:

[www.mcmaster.com]

I like you re-named EtchXY to EdgeXY, makes more sense.

The only issue it doesn't address is that only one motor is actively driving the carriage at +/-45 degree moves.

Plus, the Ultimaker uses less belts to do the same thing, using the outer rods to spin two sets of pulleys/belts for each for the X and Y, making the optional outer CoreXY (EdgeXY) drive redundant.

Not saying it won't work, cause obviously it will. Your analysis appears correct, and as a concept appreciate the feedback.

|

Re: Riki200 July 25, 2017 12:40PM |

Registered: 8 years ago Posts: 5,232 |

Quote

lkcl

hi folks i was here over a year ago when designing and building the sandwich200 (based on the Fusebox) - i had to move and focus on a crowd-funding campaign, which i am now dealing with so i need to get back onto the 3D printer and make 10 of them, so as to have a small factory to make the parts for the crowd-funding campaign.

initially i was going to buy 10 cheap china-sourced 3D printers and have them shipped to where i am living in taiwan: turns out that the exact same printer i (mistakenly, naively) selected is one that people have actually had experience with here, so i've made a report: [forums.reprap.org] but the experience with that printer was so awful that i'm just going to have to return to a complete redesign of the Sandwich200.

So, instead of buying 10 printers with a known good reputation ( there must've been other options than the FLSUN i3 ) you decided to redesign an overly complicated printer, although you are on a tight budged and time-line?

If I'd been a supporter of your crowdfunding campaign, I'd be very nervous now...

|

Re: Riki200 July 25, 2017 02:34PM |

Registered: 6 years ago Posts: 6 |

I'm not convinced; it seems you only proved that the yellow blocks can't skew as long as the green blocks don't move, and vice versa. The way I see it:Quote

lkcl

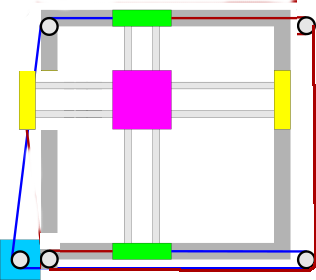

interestingly, prot0typ1cal, the same type of "shear" is simply not possible in the EdgeXY concept, in neither X nor Y (green or yellow blocks). let's go over it:

* push left yellow block "up", push right yellow block "down". this results in blue belt on left yellow idler trying to become LONGER (tension)... but *at the same time* because blue belt on right yellow idler is on the OPPOSITE side (top) it ALSO tries to become longer (tension, stretching). as BOTH parts of the belt cannot become longer, the result is that the twisting is RESISTED (i.e. cannot occur).

* likewise for left yellow block "down" and right yellow block "up" except now it is the red belt trying to stretch.

* similar for the green blocks except this time it is the belt fixing points doing the "resisting".

* Push left yellow block "up", push right yellow block "down". this results in blue belt on left yellow idler trying to become LONGER (tension), so it pulls lower green block left. At the same time, because blue belt on right yellow idler is on the OPPOSITE side (top) it ALSO tries to become longer, thus pulling upper green block right.

Can the green blocks actually move, or will the red belt save us?

* As the left yellow block goes up, the red belt on left yellow idler gets SHORTER (slack), allowing the upper green block to move right; the red belt on the lower right side also slackens, and permits the lower green block to move left.

And if you look at the actual ratios of belt pull/slack to block motion, all green attachments are 1x, while all yellow idlers are 2x -- thus for every 1mm the yellow blocks skew, the green blocks will skew 2mm. So it's kinda half rotating, half shear.

Also, as I mentioned on the mailing list, once you have a 4-rod/dual-gantry in your design, I just don't see what the benefit of these complicated drive schemes is. It seems easy to drive the green/yellow blocks directly and independently:\

For the X-axis, you put two shafts parallel to the Y-axis, at the left and right sides. They each have two timing belt pulleys (at the top/bottom ends), supporting one loop of timing belt for each green block. One shaft is coupled to the motor, the other is an idler. (The idler could be one long shaft, or two short shafts -- the drive shaft must be full length to drive both ends equally. Torsional wind-up should be negligible for reasonable shaft sizes and forces, but if you're worried about it, drive through a timing belt pulley at the drive shaft's midpoint, so both sides wind up equally.)

(I think what I just described is basically a Darwin Y-axis, FWIW.)

Then for the Y-axis, exactly the same thing, rotated 90 degrees. (And offset vertically some mm so the belts don't intersect, of course.)

|

Re: Riki200 July 25, 2017 02:36PM |

Registered: 8 years ago Posts: 776 |

Quote

prot0typ1cal

I like you re-named EtchXY to EdgeXY, makes more sense.

Quote

i didn't mean to! it was an accident, honest!one of the downsides of a 3000x1800 13in LCD, things are reaaally small...

Quote

The only issue it doesn't address is that only one motor is actively driving the carriage at +/-45 degree moves.

that's all in the fun of a CoreXY design. btw i rethought the pulley system: it *is* actually a doubling effect. the right-angle just before the attachment points had me confused.

Quote

Plus, the Ultimaker uses less belts to do the same thing, using the outer rods to spin two sets of pulleys/belts for each for the X and Y, making the optional outer CoreXY (EdgeXY) drive redundant.

... except the ultimaker-2, despite having the (small) closed loop drive belt which provides quite significant gearing (thus giving better precision and accuracy), the amount of force on the (long) belt loops is double that of the EtchXY, because the EtchXY has that double pulley system.

now, there's a trade-off here with having double the number of rods, but that's a design decision. because of the rigidity you _could_ actually knock out one set of rods and have the exact same carriage arrangement as in the ultimaker-2.

personally i'll be going with 4 6mm rods... because well... that's what i have right now, took me over a week to do the design work and printing the parts: i fink i will not throw that work and time away.

Quote

Not saying it won't work, cause obviously it will. Your analysis appears correct, and as a concept appreciate the feedback.

*thumbs*-up. well, i'm about to try it out. should take me about a week to do the CAD work. will keep you posted.

|

Re: Riki200 July 25, 2017 03:03PM |

Registered: 8 years ago Posts: 776 |

Quote

benson

I'm not convinced; it seems you only proved that the yellow blocks can't skew as long as the green blocks don't move, and vice versa. The way I see it:

* Push left yellow block "up", push right yellow block "down". this results in blue belt on left yellow idler trying to become LONGER (tension), so it pulls lower green block left. At the same time, because blue belt on right yellow idler is on the OPPOSITE side (top) it ALSO tries to become longer, thus pulling upper green block right.

ok let's think it through. scenario:

* all blocks try to move in a clockwise direction. yellow left: up, green top: right, yellow right: down, green bottom: left.

* both motors are locked solid (no chance of moving / turning).

what will happen is:

* red belt will go slack on the left yellow block's upper idler

* which also goes slack on the pair of red-belt idlers in the top left.

* first immediate effect is that the red pull-resistance on the top green block is now GONE. that PERMITS the green-top motion to the right.

* as this is rotation the same thing happens in the bottom left corner: red-belt also goes slack, that means bottom green block's no longer prevented from going left...

now for the blue belt, starting from the same left yellow block:

* that goes into TENSION on the left block's blue-idler.

* that in turn PULLS the lower green block to the left (motor is fixed/locked)

* likewise the right yellow block going down causes the same corresponding pull to the right of the green block.

o arse. you're right

will answer more (rest) tomorrow, thank you benson, this kind of analysis is absolutely invaluable to avoid making mistakes, it's really really appreciated.

|

Re: Riki200 July 25, 2017 03:17PM |

Registered: 8 years ago Posts: 776 |

Quote

o_lampe

So, instead of buying 10 printers with a known good reputation

none of which have been designed with maximising millimetres per second per dollar

Quote

( there must've been other options than the FLSUN i3 ) you decided to redesign an overly complicated printer,

no: i decided to write a report (to the 2,500 backers of the crowd-funded project as well as to the 450+ people on the free software mailing list that i run) saying that i was looking for ways to maximise the millimetres per second per dollar metric, with the expectation that if anyone wanted to either object or make any suggestions, they were free to do so, and that if they did not do so, then implicitly they were entrusting any decision-making to me and to me alone.

so that's the first misunderstanding that you've made.

the second misunderstanding that you've made is that i intend to just blithely plough ahead with this experiment regardless of consequences. that i will somehow attempt to lie to the backers about the results of what is a completely open exercise (or worse try to lie to myself), that if the experiment is a total failure i will go "hah, let's ignore that it's a failure and blithely demand that people buy 10 of these printers anyway".

can you see how that wouldn't work? the project that i'm running is pretty much 100% transparent. there's very little that i don't share with the backers. i've seen enough nightmare projects over the past 23 years i've been involved with free software to know that you just *do not* keep secrets and you *do not* try to disguise or hide failure.

Quote

although you are on a tight budget

correct

Quote

and time-line?

that's incorrect.

Quote

If I'd been a supporter of your crowdfunding campaign, I'd be very nervous now...

if i had made as many misunderstandings and assumptions as you have, instead of asking questions seeking clarification, which then forces people into the position of first having to contradict you, then work even harder to actually correct your errors of judgement, i would be pretty nervous too.

please do ask questions, o_lampe: it's generally considered to be much more polite, as it allows for the possibility that *you* are wrong. forcing people into the position of having to say, in either a direct or a roundabout route, "i'm sorry, but you're wrong", is, to put it diplomatically not generally considered acceptable behaviour on public forums.

i'm tired, it's 3:16am here right now so i'm taking the direct approach with you. please ask questions in future which allow the people you're engaging with the opportunity to be polite with you, ok?

|

Re: Riki200 July 26, 2017 03:22AM |

Registered: 8 years ago Posts: 776 |

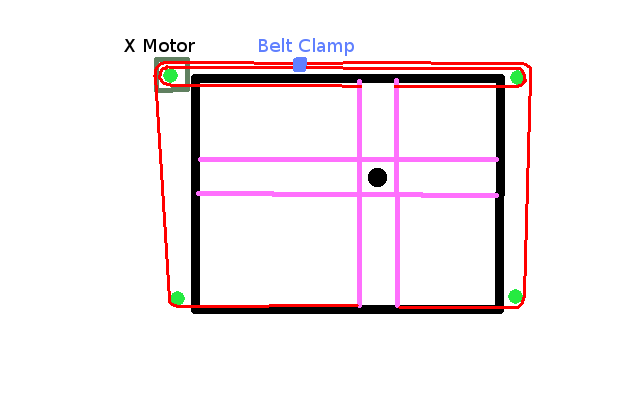

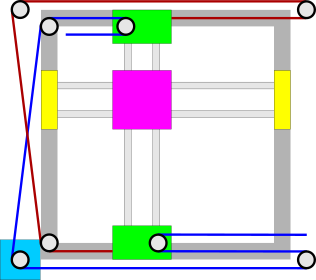

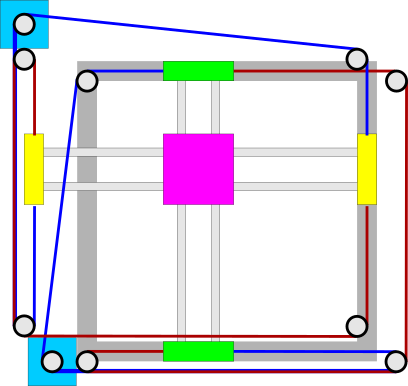

ok so benson this is equivalent to the ultimaker-2 style system that you were proposing, with the advantage that the BOM is greatly reduced and it's very very simple. thus helping move towards the "maximising mm/sec/$" criteria. the key bit is:

(1) you have to use the bottom edge of the belt loop in both cases: if you use the inner edge on both or the other edge attached on both idlers, the gantry will go in opposite directions at each end and rip the printer apart

(2) the outer belt yes it really can just go back-to-back round the inner belt, there's really nothing special about it: it could even not be a timing belt at all (just a thread/steel reinforced piece of rubber band).

now, there's a couple of things about it i don't like:

(1) the outer belt is much longer. this means it has a more "play" than the shorter one.

(2) if you try to "fix" that by making the two belts the same length then the X-Motor has to drive both, that means moving the X-motor into the middle, now you can't use the "belt clamp" trick, you have to put 2 GT2-20 gears onto the same motor shaft or come up with some other arrangement.... it gets complicated really quite quickly.

(3) there's no pulley system: this is theoretically possible but is also a lot more redesign work and also i would have to order some more 2020 extrusion, resize the entire frame, and i really don't want to do that.

so, not perfect but it has the advantage of being really *really* simple. six idler bearings total for both axes: that's all. thoughts appreciated.

Edited 2 time(s). Last edit at 07/26/2017 03:23AM by lkcl.

|

Re: Riki200 July 26, 2017 07:24AM |

Registered: 6 years ago Posts: 6 |

Yeah, where have I seen that mechanism before...

https://commons.wikimedia.org/wiki/File:Etchasketch.jpg

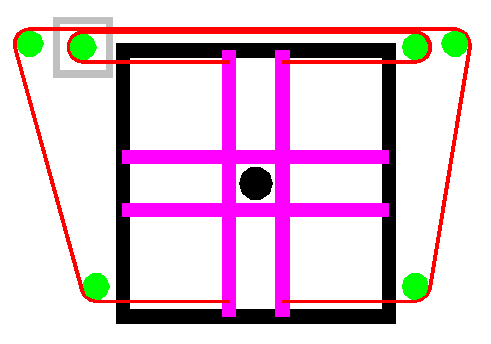

Note that if you actually wrap the outer belt around the inner belt on the pulleys, there's gonna be some slip as they go around the corner -- may or may not be a problem. You can of course avoid this by using two pulleys, one above the other, but that's got obvious downsides. Better, you can just add two more idlers top left and right, and keep it all in the same plane. Like this:

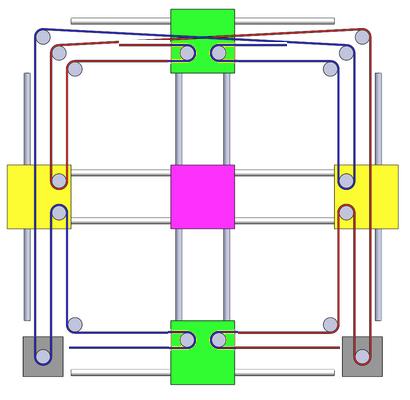

As for my (apparently) Ultimaker-2-style suggestion -- I've drawn two versions of it with pulleys set up for 2:1 mechanical advantage. The top version is a little more compact, but requires two sizes of idlers; the bottom is more straightforward, and could use the same idlers everywhere. These are side views of one axis -- there's of course an identical belt at the other end, and there's also 2 crossing belts for the other axis. As drawn, there's no effort to ensure clearance for the other axis, it's just a rough sketch:

https://commons.wikimedia.org/wiki/File:Etchasketch.jpg

Note that if you actually wrap the outer belt around the inner belt on the pulleys, there's gonna be some slip as they go around the corner -- may or may not be a problem. You can of course avoid this by using two pulleys, one above the other, but that's got obvious downsides. Better, you can just add two more idlers top left and right, and keep it all in the same plane. Like this:

As for my (apparently) Ultimaker-2-style suggestion -- I've drawn two versions of it with pulleys set up for 2:1 mechanical advantage. The top version is a little more compact, but requires two sizes of idlers; the bottom is more straightforward, and could use the same idlers everywhere. These are side views of one axis -- there's of course an identical belt at the other end, and there's also 2 crossing belts for the other axis. As drawn, there's no effort to ensure clearance for the other axis, it's just a rough sketch:

|

Re: Riki200 July 26, 2017 12:46PM |

Registered: 7 years ago Posts: 249 |

I have to disagree and agree with benson's analysis of the edgeXY.

1. Belts don't "push", they pull. Plus if tensioned properly do not produce "slack".

2. As in any CoreXY system, forces are balanced per individual axis, preventing misalignment between opposing blocks, plus the tie rods will also keep opposing blocks square.

3. The 2x belt ratio on the yellow, and 1x on the green blocks is a minor issue, which can be compensated for via firmware. However, opposing forces are still balanced. This can be a benefit if your design is not square, and one axis is longer than the other. Use the 2x on the longer axis.

4. True, as I stated earlier, there are easier methods to drive Ultimaker style mechanisms. EdgeXY is unique, and can be percieved as "overly complicated", as I'm sure delta printers are also viewed. At the end of the day, it will work as intended. If you want something different, EdgeXY delivers. If you want safe and simple, copy and paste.

Note: abandoned this design because decided to implement dual extruders, with different nozzle sizes and block temps. And the only reliable way was to have independent heads. CoreXYU !!!

1. Belts don't "push", they pull. Plus if tensioned properly do not produce "slack".

2. As in any CoreXY system, forces are balanced per individual axis, preventing misalignment between opposing blocks, plus the tie rods will also keep opposing blocks square.

3. The 2x belt ratio on the yellow, and 1x on the green blocks is a minor issue, which can be compensated for via firmware. However, opposing forces are still balanced. This can be a benefit if your design is not square, and one axis is longer than the other. Use the 2x on the longer axis.

4. True, as I stated earlier, there are easier methods to drive Ultimaker style mechanisms. EdgeXY is unique, and can be percieved as "overly complicated", as I'm sure delta printers are also viewed. At the end of the day, it will work as intended. If you want something different, EdgeXY delivers. If you want safe and simple, copy and paste.

Note: abandoned this design because decided to implement dual extruders, with different nozzle sizes and block temps. And the only reliable way was to have independent heads. CoreXYU !!!

|

Re: Riki200 July 27, 2017 07:33AM |

Registered: 6 years ago Posts: 14 |

Quote

lkcl

the problem is: the 2x pulley and the 4x pulley are on opposite sides (separated by 320mm). what happens, therefore, is that when the motor turns you get *twice* the force pulling on one side than on the other. what that does is create "lag" on the x/y-ends, and the whole assembly shears sideways. one x/y-end is pulled harder, that causes shear, and it's only when the force of the rods twisting in the plastic joints is builds up high enough that the *other* x/y-end starts to move.

Hmmm... if I understand this correctly, this can be re-worded as follows: Because there's a *single* belt pulling *both* upper and lower ends of the Y rods, there is no reason for this belt pulling both sides exactly symmetrically. Any difference in force or friction between the upper and lower carriages will pull the "easier target" more than the other and cause shearing. And the belt on the opposite sides of the carriages won't do anything to stop this either.

So here is my take on the EdgeXY concept. Keep in mind that I'm not a mechanical engineer, so take my analyses with a big grain of salt.

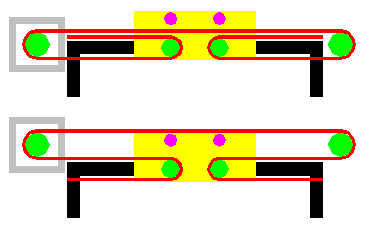

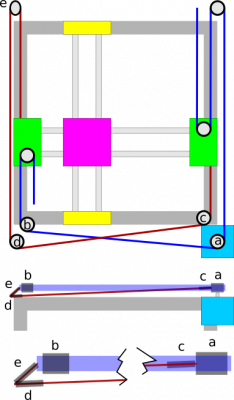

I started off by trying to explain to myself how the EdgeXY concept works by simplifying it to remove the 2x belt ratio. Doing this I found that I could use a similar cross-belt configuration where there is - as in CoreXY - only one motor per axis:

Note that there are now two belts, though there is no real need for having them separate as we could use just a single one clamped to the carriages. But it helps to understand the modification that follows.

While the blue belt is driven by the motor, the red belt makes sure the "slacking" part of the blue belt is kept tensioned by pulling the carriages in the other direction. This should take care of the rotating/shearing problem of the gantry, I hope.

(Note that I tried to get the motor to be "belt-centric" but not really sure that is the ideal location, maybe someone more experienced could help here.)

Now this concept can simply be modified for a 2x pulley ratio as follows:

Note that I kept the red belt as it was - since it only pulls the one carriage currently not being pulled by the motor, there appears no need to introduce more pulleys (or a 2x ratio) there. I wonder if this is actually better as I imagine it having less belt stretch/bearing play that way.

Of course, both pictures show only a single axis, so this setup would need to be duplicated and rotated by 90° for the other.

Alternatively of course, the Y axis concept could be copied from the Rikadenki plotter which to me seems to have the definite advantage in that it doesn't need the cost and weight of

* the two horizontal rods as well as

* the yellow Y carriages and

* associated rails.

But the disadvantage is obviously having a mass difference between the axes, and a major re-design I'd imagine.

|

Re: Riki200 July 27, 2017 09:30AM |

Registered: 8 years ago Posts: 776 |

Quote

prot0typ1cal

I have to disagree and agree with benson's analysis of the edgeXY.

3. The 2x belt ratio on the yellow, and 1x on the green blocks is a minor issue, which can be compensated for via firmware.

but not from the perspective of having actual 2x multipliers (pulley systems) which is a significant advantage in its own right. btw sorry prot0typ1cal, there was an off-forum discussion on the arm-netbooks mailing list where i double-checked benson's analysis, and concluded that he was right, unfortunately.

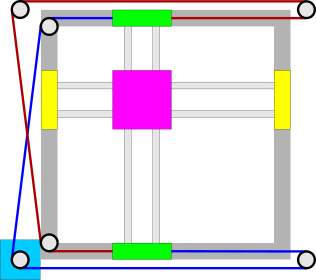

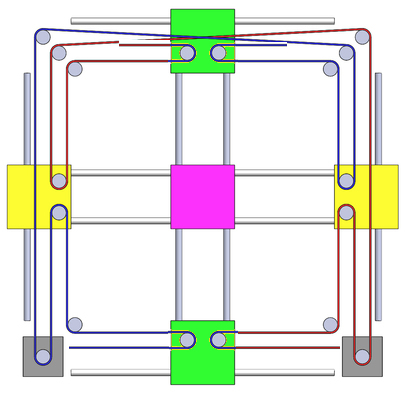

anyway just for completeness - and in case it turns out to not have the same flaw as the original, here is a corrected variant of EtchXY which does *not* have the mis-matched pulley system, this should actually have 2x on X and 2x on Y:

now, i haven't finished the belt layout at the top because it overlaps (in the drawing) and that's too complicated for gimp to cope with using cut/paste

but, basically, you can see the design flaw i think more clearly in this illustration. basically you "fix" the motors (do not allow them to rotate). now grab the purple block and rotate it. that causes all 4 x/y-end blocks to rotate... and each belt section leading between the yellow-to-green and green-to-yellow blocks will shorten and lengthen equally.... meaning that there's absolutely nothing to prevent rotation.

which is unfortunate, because i really really like the EtchXY concept.

|

Re: Riki200 July 27, 2017 09:48AM |

Registered: 8 years ago Posts: 776 |

Quote

chrigel

I started off by trying to explain to myself how the EdgeXY concept works by simplifying it to remove the 2x belt ratio. Doing this I found that I could use a similar cross-belt configuration where there is - as in CoreXY - only one motor per axis:

[attachment 96604 counterbelt1-1.png]

okaay.. sooo... let's go over it. let's make the motor spin anti-clockwise. that results in a "pull" on the blue belt leading to the upper green block. that in turn results in a "pull" on the red belt leading out of the upper green block... which in turn results in... follow the red-rabbit... a corresponding "pull" on the lower green block, left side, yay!

dude that's awesome, i love it.

ok briefly (tired, up early tomorrow), about the idea of leaving the red belt without an extra pulley, it's 6 of 1 1/2 a dozen of the other: longer belts means more stretch, but the force applied on a non-pulleyed belt is double that of a pulley'd one, so i'd be concerned about that.

btw apologies to benson i'm still reviewing and mulling, i really like what you came up with, i actually really want to implement it but i haven't the parts here and don't want to bug the person who's helping me here in china, ordering more bits from him (aside from anything it would be a 2 week delay).

back to you, chrigel: i love the idea you came up with. it's not actually a CoreXY it's a standard Cartesian. you can tell it's Cartesian because it operates perfectly with only a single belt. CoreXY critically depends on having both belts (and both belts at equal tension, as well). also on the face of it it looks like there's belt-crossing (red and blue) buuuut if you offset the red by 10-12mm (stacked) over the blue, they don't cross! this is very important. my only concern would be: can you then get a Y-axis set of (stacked!!) belts in there without any of them tangling up.. and i *think* the answer's "yes" if you put the Y motor in the top right then move that top right X-idler in-board a bit...

|

Re: Riki200 July 27, 2017 01:13PM |

Registered: 7 years ago Posts: 249 |

Hmm... bad.

You just unconstrained the X, basically making both axis free floating. Rotating the steppers can effect either axis.

The imaginary twist about the carriage is just as much true for a standard coreXY as the EdgeXY.

The advantage the EdgeXY is that to twist the carriage you torque on 4 rods and 4 blocks, not just 2 and 2. Simple physics.

And if you're using linear guide rails on the frame, rather than rods, even the smallest of rails will provide more than adequate perpendicular stability with only one truck (bearing block) opposed to 2x bushings on a rod. Fail to see how this twist occurs, as there isn't any force acting on the carriage, other than linear loads from the crossing rods. The coreXY drive isn't trying to twist the outside blocks either, again fail to see where the twist occurs. If you're talking unequal drag on the rails, that's just stupid conjecture and considered a component failure, not true operating conditions. Like saying cars can't drive straight because one wheel may go flat.

chrigel's examples are interesting, only they naturally impart twist (aka "racking"), as forces acting on the outer blocks are not equal, and rely on force transfer through a fixed short length of belting to tie opposing blocks together.

Edited 2 time(s). Last edit at 07/27/2017 01:15PM by prot0typ1cal.

|

Re: Riki200 July 27, 2017 01:44PM |

Registered: 8 years ago Posts: 776 |

Quote

prot0typ1cal

[attachment 96609 addon.jpg]

Hmm... bad.

You just unconstrained the X, basically making both axis free floating. Rotating the steppers can effect either axis.

The imaginary twist about the carriage is just as much true for a standard coreXY as the EdgeXY.

in a separate forum thread i made the mistake of believing that corexy is unconstrained: someone quickly pointed out my mistake. they pointed to corexy.com where it's noted that the design comes from an engineer's drafting table. engineers down the decades would not make the mistake of having a free-floating cross-bar

no the modifications i made simply *highlight* that the entire xy assembly in EtchXY is free-floating. more tomorrow (rest of message). really appreciate the discussion.

|

Re: Riki200 July 27, 2017 01:59PM |

Registered: 8 years ago Posts: 776 |

topologically equivalent. red belt goes round in the opposite direction to original sketch, no change in functionality. assuming red belt is offset by 12mm from blue. however it makes a 3D red-blue barrier only on one side (at the bottom).

left yellow block shifted out a bit. for Y axis belts rotate by 90 degrees then stretch outwards a bit to fit *around* X belts. red of Y fits *underneath* blue of X and vice-versa except on that one side where there's a 3D red-blue barrier, and for that you can connect to the slightly-shifted-outwards yellow block.

sorry for note-form.

|

Re: Riki200 July 27, 2017 02:08PM |

Registered: 6 years ago Posts: 6 |

Inertia. Consider when the extruder is at, say, X+ limit of travel, and you're accelerating in the Y+ direction. The whole mess wants to rotate clockwise. How much a problem this is depends on how crazy you get with accelerations.Quote

prot0typ1cal

Fail to see how this twist occurs, as there isn't any force acting on the carriage, other than linear loads from the crossing rods.

lkcl is trying to achieve rather extreme accelerations (I don't remember the numbers right off, he'll have to tell you), and trying to do it with cheap components too -- hence his quest for a cable/belt system that not only doesn't impart torque of its own, but actually resists torque, rather than leaving that to the rods and rails. Also explains the pursuit of mechanical advantage to reduce the belt tension for a given acceleration.

|

Re: Riki200 July 27, 2017 05:04PM |

Registered: 7 years ago Posts: 249 |

Quote

benson

Inertia. Consider when the extruder is at, say, X+ limit of travel, and you're accelerating in the Y+ direction. The whole mess wants to rotate clockwise. How much a problem this is depends on how crazy you get with accelerations...Quote

prot0typ1cal

Fail to see how this twist occurs, as there isn't any force acting on the carriage, other than linear loads from the crossing rods.

This is where the coreXY drive saves the day. Even with off center loads (offset moment of inertia) the dual belt loop system inhibits this behavior. Change in axis position is translated equally across, so center of gravity of the axis is no longer an issue, while is an issue with H-bot or IDEX (makerbot, FT-5, etc.). Doesn't matter if the axis is driven by pulleys or end of belts, coreXY achieves balance.

Which is why greater accelerations and print speeds are achievable with coreXY over other configurations. If you're implying belt stretch/slack, then the belts are either not properly tensioned, or sized for the applied forces. For my CoreXYU used 6mm PU steel core, each run close to 2.5 meters. Even with 5 N-M steppers belted 2:1, could not stretch these puppies measurably according to the specs.

If acceleration is set too high, as with any printer, you will skip steps. However, coreXY will remain square with the expected shifted print layer. If you want higher accelerations, use a belt ratio or larger stepper.

This whole off-center load is true regardless the cartesian system you decide on. IMO, with EdgeXY, you get more resistance to "twist" with a double cross beam than any other system using equal components. Inertia/momentum will always be there, how you deal with it is up to you.

|

Re: Riki200 July 28, 2017 02:10AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Riki200 July 28, 2017 05:52PM |

Registered: 6 years ago Posts: 14 |

Nice, I like that left and right edges now only use a single colour so we can cross the respective other easily.

Quote

lkcl

however it makes a 3D red-blue barrier only on one side (at the bottom).

Hm, I have to disagree somewhat here: Since the carriages have to be connected to red on one side and to blue on the other, we unfortunately have, for most of the rails' lengths, a 3D red-blue barrier there as well.

Quote

lkcl

left yellow block shifted out a bit. for Y axis belts rotate by 90 degrees then stretch outwards a bit to fit *around* X belts. red of Y fits *underneath* blue of X and vice-versa except on that one side where there's a 3D red-blue barrier, and for that you can connect to the slightly-shifted-outwards yellow block.

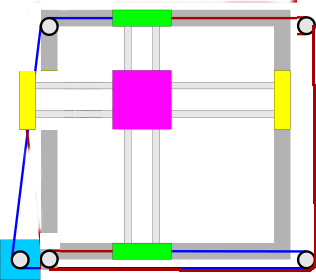

Ok, here is me trying to draw what you said:

Note that I haven't yet found a way to avoid the belts crossing the rods, next to the left and bottom carriages... my gut feeling tells me this isn't good, what do you think?

Edited 2 time(s). Last edit at 07/28/2017 05:53PM by chrigel.

|

Re: Riki200 July 29, 2017 02:02AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Riki200 July 29, 2017 02:07AM |

Registered: 8 years ago Posts: 776 |

Quote

chrigel

Hm, I have to disagree somewhat here: Since the carriages have to be connected to red on one side and to blue on the other, we unfortunately have, for most of the rails' lengths, a 3D red-blue barrier there as well.

no, sorry, i should have been more clear (one of the disadvantages of note-form when you're tired...) only a *partial* barrier. i.e. only a red barrier *or* a blue barrier but not both. only the bottom is a *full* red-blue barrier. thus it becomes possible to interlace the X and Y belts... as you managed to do, yay!

Quote

Ok, here is me trying to draw what you said:

Note that I haven't yet found a way to avoid the belts crossing the rods, next to the left and bottom carriages... my gut feeling tells me this isn't good, what do you think?

yep that's it! that's exactly it. regarding the blue belt crossing the rods, you can instead make the red belt attach to the far left of the yellow (left) block, and also make it the *bottom* belt. then the blue belt can run through a channel in and *over* the left yellow block.

now the only thing is, as prot0typ1cal mentioned (sorry i haven't caught up and acknowledged what you said man!) this design relies critically on pulling one block with one belt section but that the other belt section has to handle the load of *both* blocks (it's a train/carriages effect in other words). now, i honestly don't know enough about the materials properties of these GT2 timing belts (not the steel ones, the fibre-reinforced ones) to say if they'll stretch significantly, but given the kinds of accelerations and speeds i want to subject this design to i don't feel confident taking a risk.

now, i do actually have some GT2 steel-reinforced belt here, i wanted to see what it's like, and it's... really really stiff. trying to get it round even a GT2-20-tooth... i'd be concerned about how much tension it would need to be under. so... *sigh* overall it's all pointing towards the low-risk etch-a-sketch layout.

|

Re: Riki200 July 29, 2017 04:43AM |

Registered: 8 years ago Posts: 776 |

Quote

o_lampe

What bothers me in the last pic is, that you now have to tension 4 belts just right.

let's think this through... each blue-red belt is free (unconstrained) relative to each other, so they will try to even out the load between each other. that means that... yyeahhh unless you get the lengths (with belt tensioners) exactly right... yes, if you say try to tighten one end of the red belt it will pull *both* blocks... but in opposite directions! you'd then have to try to tension up the blue belt by a corresponding amount. it would be a bit of a pain, basically

now, in the etch-a-sketch design i'm proposing, you would *partly* avoid that problem by taking off the belt-clamp. tighten each belt section separately, then fit the belt-clamp back on. except... i was considering using the two belts with teeth back-to-back so that a clamp would go over them with teeth-interlocks.... and that would mean that the "resolution" of the clamp would be.... 2mm.

argh. i could conceivably make the clamp more complicated by allowing a part of it to be a "slider" with a screw that pushes it on and locks the two belts together that way.... complex but doable.

|

Re: Riki200 July 29, 2017 05:40AM |

Registered: 6 years ago Posts: 14 |

Quote

lkcl

yep that's it! that's exactly it. regarding the blue belt crossing the rods, you can instead make the red belt attach to the far left of the yellow (left) block, and also make it the *bottom* belt. then the blue belt can run through a channel in and *over* the left yellow block.

Great idea.

Quote

lkcl

now the only thing is, as prot0typ1cal mentioned (sorry i haven't caught up and acknowledged what you said man!) this design relies critically on pulling one block with one belt section but that the other belt section has to handle the load of *both* blocks (it's a train/carriages effect in other words).

Hmmm... so initially I didn't quite understand (or where prot0typ1cal mentioned it), but I think I got it now:

The blue belt (when driven by the motor) pulls one carriage, plus the red belt which pulls the other, i.e. 2:1, right?. Well, my initial way of thinking was to use a 2:1 pulley system for the blue belts anyway, would that make a difference? I think it could easily be added to the latest picture without upsetting anything.

Still, there is the concern o_lampe raised:

Quote

o_lampe

What bothers me in the last pic is, that you now have to tension 4 belts just right. It's difficult enough to equally tension two belts of a coreXY.

Quote

lkcl

now, i honestly don't know enough about the materials properties of these GT2 timing belts (not the steel ones, the fibre-reinforced ones) to say if they'll stretch significantly, but given the kinds of accelerations and speeds i want to subject this design to i don't feel confident taking a risk.

now, i do actually have some GT2 steel-reinforced belt here, i wanted to see what it's like, and it's... really really stiff. trying to get it round even a GT2-20-tooth... i'd be concerned about how much tension it would need to be under. so... *sigh* overall it's all pointing towards the low-risk etch-a-sketch layout.

Fair enough. I had some ideas for the etch-a-sketch layout as well, but before we leave this design behind (maybe we could call it cartesian-counter-cross), I wanted to share with you one more thought I had on it:

Since the red belt doesn't get driven by anything, it *doesn't need to be a belt*. I had this idea before lkcl figured out how to cross the belts nicely, so I naturally wanted to avoid having to use a design with a "belt stack" that is 4 belts tall using a different approach.

So if we replace the red belt with something like a cable or wire, it can change direction not only in a single plane (as a belt ideally should), but in, say, the Z axis direction as well:

The upper part shows the original belt layout from the top, in the middle is the view on the same thing from the front and the bottom shows details thereof.

So we can go with a single (blue, horizontal) belt per axis. Through some tilting and vertical shifting of the pulleys for the red cable, it can cross the blue belt between pulleys a and b, via pulleys c and d, then going straight up parallel to the Y axis from d to e which brings it back into the same plane as the blue belt before it attaches to the left green Y carriage.

The X axis can then be added using a stacked "blue" belt and another "red" cable going upwards instead of downwards if required to avoid tangling.

I imagine this would add quite a bit of design complexity though and I am unsure what adding a cable/wire would mean in terms of stretch or other non-ideal behaviour, let alone having to use different pulleys for cables vs. belts... so I'll leave it there for now, just had to get it out of my system :-) ...I am honestly sorry if I wasted anyone's time!

Edited 2 time(s). Last edit at 07/29/2017 06:38AM by chrigel.

|

Re: Riki200 July 29, 2017 06:17AM |

Registered: 8 years ago Posts: 776 |

Quote

chrigel

Quote

lkcl

now the only thing is, as prot0typ1cal mentioned (sorry i haven't caught up and acknowledged what you said man!) this design relies critically on pulling one block with one belt section but that the other belt section has to handle the load of *both* blocks (it's a train/carriages effect in other words).

Hmmm... so initially I didn't quite understand (or where prot0typ1cal mentioned it), but I think I got it now:

The blue belt (when driven by the motor) pulls one carriage, plus the red belt which pulls the other, i.e. 2:1, right?. Well, my initial way of thinking was to use a 2:1 pulley system for the blue belts anyway, would that make a difference? I think it could easily be added to the latest picture without upsetting anything.

short answer: sadly it wouldn't.

[lots snipped.... sorry!]

Quote

So if we replace the red belt with something like a cable or wire, it can change direction not only in a single plane (as a belt ideally should), but in, say, the Z axis direction as well:

aa... aa... yyyeahhh you could! good point! so if you could find a material that had greatly-reduced elasticity but was also malleable enough (several multi-strand steel cables?) then that would certainly get rid of the problems identified. ha. cool!

the only thing is: i am *reaally* not a fan of non-planar belt/cable arrangements. whatever you try to do, you *will* end up with cables/belts riding up/down the pulleys, no matter what you try to do, and you also end up with top strands in GT2 belts being stretched different amounts from bottom strands... it's all very very bad

fortunately we devised a scheme for this cartesian-counter-cross arrangement where the belts/cables can always be in-plane. offset and stacked in a horrendously complex-to-work-out way, but doable

also, one other point: the red (assuming it's a very-very-very-very-strong totally-non-elastic cable) thing in the diagram, yes, you would not need a pulley on it. it's "passive" in effect. it takes twice the load as the blue (belt), also bear in mind that the idlers c d and e for the red would also have twice the load of the blue...

|

Re: Riki200 July 30, 2017 03:15AM |

Registered: 8 years ago Posts: 5,232 |

@chrisgels idea to use wire instead of belt:

What happens when the critical portions of our classic CoreXY belts aren't parallel/rectingular to each other?

The belts change tension, which adds inaccuracy.

My gut feeling tells me, that the red wire not running parallel to the blue belt will cause the same inaccuracy? ( at least between idlers "d" and "c" )

Edited 1 time(s). Last edit at 07/30/2017 03:17AM by o_lampe.

What happens when the critical portions of our classic CoreXY belts aren't parallel/rectingular to each other?

The belts change tension, which adds inaccuracy.

My gut feeling tells me, that the red wire not running parallel to the blue belt will cause the same inaccuracy? ( at least between idlers "d" and "c" )

Edited 1 time(s). Last edit at 07/30/2017 03:17AM by o_lampe.

|

Re: Riki200 July 30, 2017 04:50AM |

Registered: 8 years ago Posts: 776 |

Quote

o_lampe

@chrisgels idea to use wire instead of belt:

What happens when the critical portions of our classic CoreXY belts aren't parallel/rectingular to each other?

you get a completely warped shape. it is *critical* to have the belts coming off the X-gantry at right-angles. ALL of them. otherwise you get non-linear printing. there was a horror-story recently on this forum about that.

Quote

The belts change tension, which adds inaccuracy.

it's much, much worse than that: the change in angle of the belt coming off the X-gantry and leading to the motor results in non-linear printing. even just 1mm of misalignment can result in a huge and noticeable amount of distortion.

Quote

My gut feeling tells me, that the red wire not running parallel to the blue belt will cause the same inaccuracy? ( at least between idlers "d" and "c" )

in the last drawing above this post, the critical bits are right: all the bits that are vertical (coming off the idlers, onto the gantry, fixed poses) are all correct. in the bit where he says "ok here is me trying to draw what you said" it is *also* correct: the bits that are at angles do not matter, it is only the bits that are square that matter. put your imagination at work: move the "carriage" (purple). if any belt sections change angle (even by the tiniest bit) then you've made a mistake. if the angles remain constant no matter what position the carriage is in, you've done it right. that applies to CoreXY, Cartesian - pretty much every single printer.

|

Re: Riki200 July 31, 2017 02:09AM |

Registered: 6 years ago Posts: 14 |

Quote

lkcl

it's much, much worse than that: the change in angle of the belt coming off the X-gantry and leading to the motor results in non-linear printing. even just 1mm of misalignment can result in a huge and noticeable amount of distortion.

I agree. If that was the case, it would be really horrible.

Quote

o_lampe

My gut feeling tells me, that the red wire not running parallel to the blue belt will cause the same inaccuracy? ( at least between idlers "d" and "c" )

I don't think so but am open to be corrected. Conceptually you could also replace idlers c, d and e with a different setup that change the red belts' direction only in right angles:

1. Make idler c vertical, (i.e. its rotation axis parallel to the X axis), so red goes down parallel to the Z axis.

2. Add another idler with its axis parallel to Y, so red goes now parallel to X towards idler d.

3. Make d lie flat in the X/Y plane, i.e. its axis parallel to Z. This will make red go parallel to Y towards idler e.

4. Make e's axis parallel to X, so red goes up, parallel to Z.

5. Add another idler with its axis parallel to Y that brings red parallel to X and

6. finally add yet another idler with its axis parallel to Z that makes red go down (parallel to Y) to attach to the left green carriage.

Anyway, I thought lkcl had already left this idea behind anyway, so maybe we should concentrate on the designs he's still considering? As far as I understand, they are currently the ones benson drew in most recent post.

Edited 3 time(s). Last edit at 07/31/2017 03:02AM by chrigel.

|

Re: Riki200 July 31, 2017 02:49AM |

Registered: 8 years ago Posts: 776 |

Quote

chrigel

Anyway, I thought lkcl had already left this idea behind anyway, so maybe we should concentrate on the designs he's still considering?

hey if people want to discuss this it's a public forum, it might prove useful to someone.

*sigh* i am going to have to go with the simpler etch-a-sketch for now, which will be temporary. to do the ultimaker-2 style design i will need to order some parts (rods, large GT2-50s, closed-loop belts) and maybe adjust the frame as well so that the rods are fully supported.... none of which i want to do immediately.

ssooo... we go with the flow...

|

Re: Riki200 August 01, 2017 01:05AM |

Registered: 7 years ago Posts: 249 |

Problem with the etch-a-sketch is it uses closed loops, both of different lengths on the same axis, so stretch/acceleration/harmonics will be different on both loops.

Inherently, the etch-a-sketch isn't square or parallel, not really required for a child's toy, close is good enough. Will require some degree of tuning for a 3d printer, with pulleys free to offset perpendicular to the axis to dial it in, then lock in place.

All pulleys will need to be toothed, or at least should be. Not really a big problem if you can buy machined lengths of pulley stock and slice/bore it yourself (I have).

Cool project.

Inherently, the etch-a-sketch isn't square or parallel, not really required for a child's toy, close is good enough. Will require some degree of tuning for a 3d printer, with pulleys free to offset perpendicular to the axis to dial it in, then lock in place.

All pulleys will need to be toothed, or at least should be. Not really a big problem if you can buy machined lengths of pulley stock and slice/bore it yourself (I have).

Cool project.

|

Re: Riki200 August 01, 2017 01:21AM |

Registered: 8 years ago Posts: 776 |

Quote

prot0typ1cal

Problem with the etch-a-sketch is it uses closed loops, both of different lengths on the same axis, so stretch/acceleration/harmonics will be different on both loops.

yyeahh if i had time i would put in twin motor gears (on a single shaft mounted with bearings above and below) just like in the original etch-a-sketch, then put the motor in the *middle* of the extrusion so that the belts are of equal length. but... this is a temporary job / experiment.

Quote

Inherently, the etch-a-sketch isn't square or parallel, not really required for a child's toy, close is good enough. Will require some degree of tuning for a 3d printer, with pulleys free to offset perpendicular to the axis to dial it in, then lock in place.

yep spotted that one

i will be taking it into account. does actually have to be true. and the frame as well. dang.

i will be taking it into account. does actually have to be true. and the frame as well. dang.

Sorry, only registered users may post in this forum.