MiniMax: my experimental CoreXY

Posted by o_lampe

|

MiniMax: my experimental CoreXY September 16, 2018 06:12AM |

Registered: 8 years ago Posts: 5,232 |

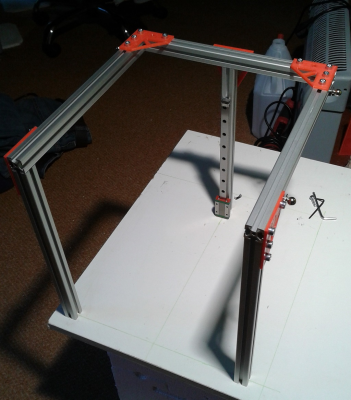

I wanted to build a test rig for my cloverleaf cable drive. A simple weightlifting platform.

I only had nine 2020 extrusion, 300mm long to play with. Not enough to build a cube and a bed frame. So I started to minimize extrusion count and came up with this:

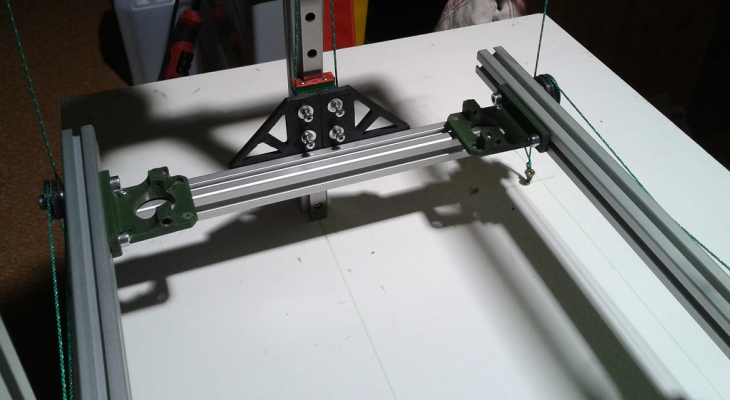

The single linear rail will lift the 'U'-shaped bed frame. The bed frame will be stabilized by 'parallel bar' cables. I believe, the extra friction will keep the bed from dropping or at least will slow it down.

I have to print some brackets before I can test it. But if it's halfway successive, I want to build a CoreXY printer with two more cloverleaf drives.

I only had nine 2020 extrusion, 300mm long to play with. Not enough to build a cube and a bed frame. So I started to minimize extrusion count and came up with this:

The single linear rail will lift the 'U'-shaped bed frame. The bed frame will be stabilized by 'parallel bar' cables. I believe, the extra friction will keep the bed from dropping or at least will slow it down.

I have to print some brackets before I can test it. But if it's halfway successive, I want to build a CoreXY printer with two more cloverleaf drives.

|

Re: MiniMax: my experimental CoreXY September 17, 2018 01:44PM |

Registered: 7 years ago Posts: 363 |

|

Re: MiniMax: my experimental CoreXY September 17, 2018 03:47PM |

Registered: 5 years ago Posts: 71 |

|

Re: MiniMax: my experimental CoreXY September 18, 2018 01:12AM |

Registered: 8 years ago Posts: 5,232 |

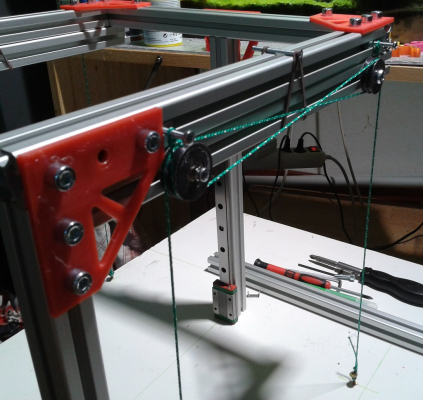

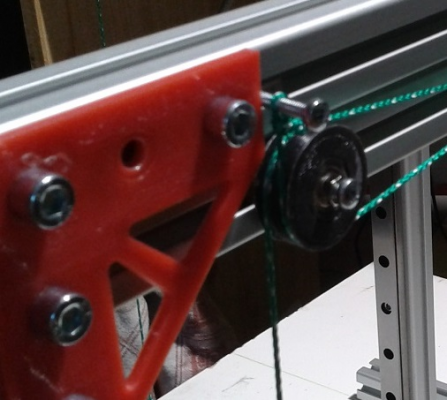

The material in the pic is silicone tube, but it's too soft. I try rubber tube now, but need a long run to confirm. A sandblasted aluminum idler pulley would be next on the list.

The pulleys are offset by M3 washers. The cable hasn't given me any headache yet, it's a 0.5mm Aramid fishing line.

I have a mocked up bed frame running with 1.3mm PP-cable for the parallel bars. That cable it too stretchy and I'll replace it with aramid.

But the parallel bar is a full success already. There's a significant difference with cables attached or just lifted by the linear rail.

There's a significant difference with cables attached or just lifted by the linear rail.

Maybe I have to add diagonal struts on top of the 'T-bar'. It doesn't deflect now, but the PP cable isn't very tight.

The pulleys are offset by M3 washers. The cable hasn't given me any headache yet, it's a 0.5mm Aramid fishing line.

I have a mocked up bed frame running with 1.3mm PP-cable for the parallel bars. That cable it too stretchy and I'll replace it with aramid.

But the parallel bar is a full success already.

There's a significant difference with cables attached or just lifted by the linear rail.

There's a significant difference with cables attached or just lifted by the linear rail.Maybe I have to add diagonal struts on top of the 'T-bar'. It doesn't deflect now, but the PP cable isn't very tight.

|

Re: MiniMax: my experimental CoreXY September 18, 2018 11:49AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: MiniMax: my experimental CoreXY September 19, 2018 12:55AM |

Registered: 8 years ago Posts: 5,232 |

It's either the Ramps_test firmware or slipping, but the bed frame looses position constanly.

I thought of wrapping the cable twice around the stepper shaft before wrapping around the next idler pulley. Have to add washers to increase offset.

Also have to write a code, that moves xx# steps up and down instead of the timed approach in Ramps_test.

I thought of wrapping the cable twice around the stepper shaft before wrapping around the next idler pulley. Have to add washers to increase offset.

Also have to write a code, that moves xx# steps up and down instead of the timed approach in Ramps_test.

|

Re: MiniMax: my experimental CoreXY September 19, 2018 02:36PM |

Registered: 5 years ago Posts: 71 |

If the cable is slipping on the rubber shaft, you could increase the rubber diameter for more cable wrap length (2x?). The shaft as shown is pretty small in diameter, smaller than a 12T GT2 pulley it looks like.

At the risk of making it over complicated, you could add a second set of idlers at the corners and replicate the setup for double the cable wrap. That could possibly be less conducive to cable binding than wrapping the cable twice?

At the risk of making it over complicated, you could add a second set of idlers at the corners and replicate the setup for double the cable wrap. That could possibly be less conducive to cable binding than wrapping the cable twice?

|

Re: MiniMax: my experimental CoreXY September 20, 2018 12:50AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: MiniMax: my experimental CoreXY September 23, 2018 02:14AM |

Registered: 8 years ago Posts: 5,232 |

What, if I replace one of the parallel bar pulleys with an encoder wheel?

Slip wouldn't be a problem with a closed loop stepper driver. ( here we go again )

)

Something like the mechaduinos?

Surely the resolution wouldn't be good enough. Maybe, if I fit it on the idler pulley? That would also work for the XY-gantry.

Slip wouldn't be a problem with a closed loop stepper driver. ( here we go again

)

)Something like the mechaduinos?

Surely the resolution wouldn't be good enough. Maybe, if I fit it on the idler pulley? That would also work for the XY-gantry.

Sorry, only registered users may post in this forum.