Printer Design with Bearings on Extrusions

Posted by gmedlicott

|

Printer Design with Bearings on Extrusions November 26, 2018 01:06AM |

Registered: 5 years ago Posts: 71 |

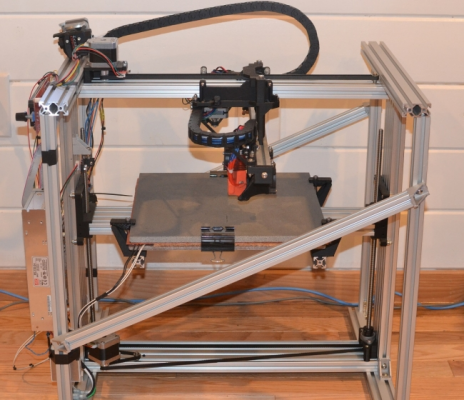

A while back I designed a printer that was to be the base for a printer farm after trying to use a upgraded Folger FT5 for that purpose. The printer is designed to be easily extendable in the X (or Y) dimension. It uses 623zz bearings that ride on the extrusions for all motion constrain.

I finally wrote up a blog post here:

https://www.tolen3d.com/blog/designing-a-printer-farm-unit

I'm in the middle of a complete redesign, so comments welcome!

I finally wrote up a blog post here:

https://www.tolen3d.com/blog/designing-a-printer-farm-unit

I'm in the middle of a complete redesign, so comments welcome!

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 02:11AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 10:20AM |

Registered: 10 years ago Posts: 651 |

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 12:30PM |

Registered: 5 years ago Posts: 71 |

Quote

o_lampe

How do you adjust the bearing clearance? Using eccentric screw posts or do you add some tensioners in the brackets?

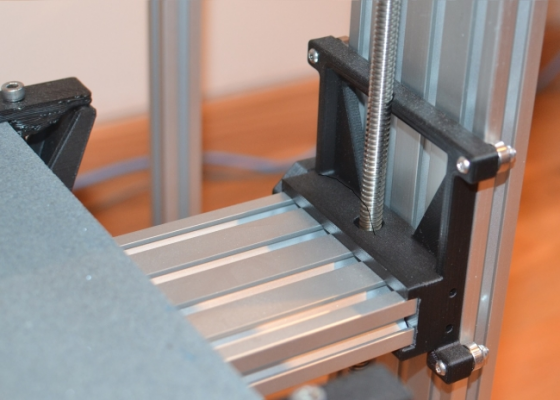

The printed parts are very rigid, and are designed so the bearings have a light pre-load. It takes an accurate printer, and measuring the extrusion dimension to make it work.

Quote

o_lampe

Most people would be afraid of the noise coming from naked bearings on extrusion.

I was worried about the noise too, but it actually isn't that loud. The Nema 17 motors are much louder using a 16/32 microstep driver. It may be more audible with Trinamic drivers.

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 12:58PM |

Registered: 5 years ago Posts: 71 |

Quote

FA-MAS

Those steel bearings are going to start eating away at the softer aluminum they’re riding on.

Another concern I'm looking into, though the bearings in this setup have a light preload (20N maybe for the X&Y, 50N for the Z) and have purely rolling motion vs rolling-sliding as found in V-wheels. Also aluminum extrusion is anodized which increases hardness. Even so, I'm working on a preload vs wear test to determine a max acceptable preload.

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 03:26PM |

Registered: 11 years ago Posts: 5,780 |

If I were contemplating enough production to justify a printer farm, I don't think I would rely on bearings held in printed plastic mounts. I think I'd end up spending more time repairing the machines than printing. Would it really be difficult to make the part from a drilled piece of metal?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer Design with Bearings on Extrusions November 28, 2018 03:53PM |

Registered: 5 years ago Posts: 71 |

Quote

the_digital_dentist

If I were contemplating enough production to justify a printer farm, I don't think I would rely on bearings held in printed plastic mounts. I think I'd end up spending more time repairing the machines than printing. Would it really be difficult to make the part from a drilled piece of metal?

Having come from a background of designing parts for CNC machining, plastic (printed or other) is amazing, I can design semi-complex parts and added features are free! That said, 3d printing parts can be a bit weak, and are not always dimensional accurate. Now injection molding on the other hand...

|

Re: Printer Design with Bearings on Extrusions November 29, 2018 03:53AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Printer Design with Bearings on Extrusions November 29, 2018 06:39AM |

Registered: 5 years ago Posts: 62 |

Quote

the_digital_dentist

If I were contemplating enough production to justify a printer farm, I don't think I would rely on bearings held in printed plastic mounts. I think I'd end up spending more time repairing the machines than printing. Would it really be difficult to make the part from a drilled piece of metal?

Of course you would.

Why does it matter?

|

Re: Printer Design with Bearings on Extrusions November 29, 2018 06:58AM |

Registered: 6 years ago Posts: 1,007 |

Quote

gmedlicott

The printed parts are very rigid, and are designed so the bearings have a light pre-load. It takes an accurate printer, and measuring the extrusion dimension to make it work.

.

They don't look rigid at all and in fact luckily they are not as the whole set up would have the bearings eat in the Al extrusion or bind. The X, Y connecting part is particularly flimsy.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Printer Design with Bearings on Extrusions November 29, 2018 09:24AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Number_5

Quote

the_digital_dentist

If I were contemplating enough production to justify a printer farm, I don't think I would rely on bearings held in printed plastic mounts. I think I'd end up spending more time repairing the machines than printing. Would it really be difficult to make the part from a drilled piece of metal?

Of course you would.

Why does it matter?

Of course I would what? Why does anything matter?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer Design with Bearings on Extrusions November 29, 2018 01:20PM |

Registered: 5 years ago Posts: 71 |

Quote

MKSA

Quote

gmedlicott

The printed parts are very rigid, and are designed so the bearings have a light pre-load. It takes an accurate printer, and measuring the extrusion dimension to make it work.

.

They don't look rigid at all and in fact luckily they are not as the whole set up would have the bearings eat in the Al extrusion or bind. The X, Y connecting part is particularly flimsy.

The carriage parts are rigid in design (relative, 3d printing vs. CNC machining) as there is always material directly connecting opposing bearings, with the bearing preload set by elastic deformation. The Z for instance has a preload of 50N, enough so the bearings ride smoothly on the extrusion, yet stiff enough for the bed to tolerate a lopsided print at large volume.

The X-Y interface does look weak, but it has M6 x 120mm through bolts with the side carriage parts having locking tabs to prevent rotation. I can grab the ends of the lower Y rail and barely rock it, with much more force than the print head would exert. This design is simple but has its downsides as described in the blog post at the top of the thread.

https://www.tolen3d.com/blog/designing-a-printer-farm-unit

This build was more an exercise in seeing what worked and what didn't. Many lessons learned as all of us can probably attest to when building our printers!

Sorry, only registered users may post in this forum.