Belt z axis - which gears?

Posted by witor

|

Belt z axis - which gears? December 14, 2018 04:52PM |

Registered: 6 years ago Posts: 63 |

After bad experience with my Anet A6 in which I had to mechanically (with belt) link both z axis screw leads to stop them getting out of sync I am thinking about a new way of driving z axis in my new printer.

I plan to use rails on all axis. I would like to have a horizontal rotating rod with timing pulleys on both ends driving belts on both sides lifting the z axis. Some think like in this video:

[www.youtube.com]

The question is how to link a motor to the rod. I have the following ideas:

1) Simple gears like in the video above. Advantages: Simple. Disadvantages: play on the gears. Z axis falling down under gravity. Printed gears wearing out and not being precise enough

2) Worm on the steper shaft and worm gear on the shaft (worm gearbox). Advantages: large gear ratio and resolution on z axis. Z axis will not fall under gravity. Disadvantage difficult to build using diy methods or expensive to buy.

3) Belt drive - small timing pulley on the stepper shaft large pulley on the rod. Advantages - simplicity. Disadvantage fall under gravity, small gear ratio, too many belts resulting in lower precision and play... but i really like this solution:

[www.youtube.com]

Simple and should have enougr resolution and precision for z axis.

What are you thoughts about the above 3 solutions?

Edited 1 time(s). Last edit at 12/14/2018 07:58PM by witor.

I plan to use rails on all axis. I would like to have a horizontal rotating rod with timing pulleys on both ends driving belts on both sides lifting the z axis. Some think like in this video:

[www.youtube.com]

The question is how to link a motor to the rod. I have the following ideas:

1) Simple gears like in the video above. Advantages: Simple. Disadvantages: play on the gears. Z axis falling down under gravity. Printed gears wearing out and not being precise enough

2) Worm on the steper shaft and worm gear on the shaft (worm gearbox). Advantages: large gear ratio and resolution on z axis. Z axis will not fall under gravity. Disadvantage difficult to build using diy methods or expensive to buy.

3) Belt drive - small timing pulley on the stepper shaft large pulley on the rod. Advantages - simplicity. Disadvantage fall under gravity, small gear ratio, too many belts resulting in lower precision and play... but i really like this solution:

[www.youtube.com]

Simple and should have enougr resolution and precision for z axis.

What are you thoughts about the above 3 solutions?

Edited 1 time(s). Last edit at 12/14/2018 07:58PM by witor.

|

Re: Belt z axis - which gears? December 14, 2018 11:06PM |

Registered: 11 years ago Posts: 5,780 |

I used option 2 and it works very well. The print quality is a direct function of the gear quality. I attempted to make a printable worm gear box using some cheap gears I bought from China and it failed miserably. I got all the torque multiplication needed, and the bed didn't drop when power was cut, but the gears introduced variation in layer thickness that cycled every time the worm made one rev (2mm in the prints). I would not trust printed plastic gears to deliver quality prints.

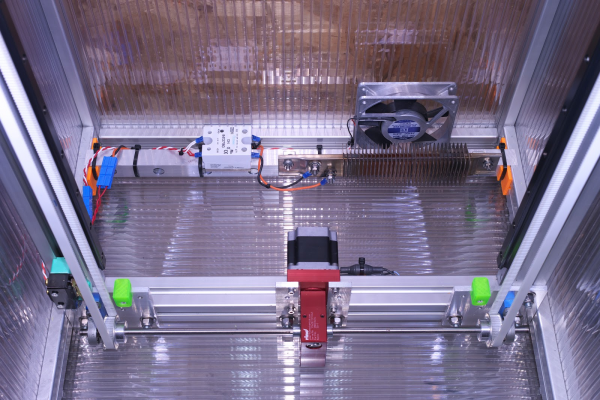

I used a Rino 30:1 worm gear reducer that I bought via ebay for $108. Not cheap, but it has quality gears, and it's cheaper than buying a set of quality gears, bearings, and a motor. Here's the bottom of the Z axis in my printer- you can see the worm gear box and Z axis motor at the center. There's an 8mm output shaft that turns two 60 tooth GT2 pulleys. It was actually very easy to build the Z axis. I recently had a belt failure due to the design of the Z axis belt clamps, so I wouldn't recommend my original design for the clamps. I have a new design that I believe will work better.

Belt drive is limited to ratios of about 4:1 using commonly available pulleys, so you'll need multiple stages to get a high enough gear ratio to keep the bed/X axis from dropping when power is cut. You don't have to worry about backlash because gravity will keep the system loaded in one direction at all times.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I used a Rino 30:1 worm gear reducer that I bought via ebay for $108. Not cheap, but it has quality gears, and it's cheaper than buying a set of quality gears, bearings, and a motor. Here's the bottom of the Z axis in my printer- you can see the worm gear box and Z axis motor at the center. There's an 8mm output shaft that turns two 60 tooth GT2 pulleys. It was actually very easy to build the Z axis. I recently had a belt failure due to the design of the Z axis belt clamps, so I wouldn't recommend my original design for the clamps. I have a new design that I believe will work better.

Belt drive is limited to ratios of about 4:1 using commonly available pulleys, so you'll need multiple stages to get a high enough gear ratio to keep the bed/X axis from dropping when power is cut. You don't have to worry about backlash because gravity will keep the system loaded in one direction at all times.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt z axis - which gears? December 15, 2018 10:58AM |

Registered: 6 years ago Posts: 63 |

Thank you for your reply. I have already studied your design which I consider to be a masterpiece. Belt driven z axis, 3 point support for the bed and other stuff you have done with your printer are amazing.

Thank you for your study of the Chinese worm gears and DIY gearbox. It will save me some wasted time and money because that was exactly what I was going to try before I saw your study.

Unfortunately living in the UK I find it difficult to source some of the components you have used especially linear rails. I will have settle for something like Robotdigg MGN 12 rails (I still need to do more research on them to see if they are any good). I have spent months waiting for decent rails to pop out on ebay - no luck so far. Rino gearbox would be ideal but it is quite expensive.

I am impressed by the quality of the print in this short video: [www.youtube.com] , which I believe was done on this printer: [www.youtube.com] On the video you can see quite simple Z drive.

Have you tried something like this before worm gearbox? I would love to know what you think about this solution.

I am not too much concerned about Z axis falling under gravity as this could be prevented by a anti reverse ratchet mechanism. I am however concerned if I will get the print quality I am after.

The main objective of my project is to have a relatively simple Cartesian printer, not necessarily super fast, but able to do high quality prints. That's why rails and synchronised Z axis belt drive which will stop both sides getting out of sync - the problem I had with my cheap 3d printer before I modified it.

Thank you for your study of the Chinese worm gears and DIY gearbox. It will save me some wasted time and money because that was exactly what I was going to try before I saw your study.

Unfortunately living in the UK I find it difficult to source some of the components you have used especially linear rails. I will have settle for something like Robotdigg MGN 12 rails (I still need to do more research on them to see if they are any good). I have spent months waiting for decent rails to pop out on ebay - no luck so far. Rino gearbox would be ideal but it is quite expensive.

I am impressed by the quality of the print in this short video: [www.youtube.com] , which I believe was done on this printer: [www.youtube.com] On the video you can see quite simple Z drive.

Have you tried something like this before worm gearbox? I would love to know what you think about this solution.

I am not too much concerned about Z axis falling under gravity as this could be prevented by a anti reverse ratchet mechanism. I am however concerned if I will get the print quality I am after.

The main objective of my project is to have a relatively simple Cartesian printer, not necessarily super fast, but able to do high quality prints. That's why rails and synchronised Z axis belt drive which will stop both sides getting out of sync - the problem I had with my cheap 3d printer before I modified it.

|

Re: Belt z axis - which gears? December 16, 2018 11:47AM |

Registered: 11 years ago Posts: 5,780 |

Thanks, but I think it's more like "OK".

I saw someone posted a belt driven Z axis design that used this set of gears and their prints had no repeating Z axis artifacts: [www.ebay.com]

I can't find the original article/post where I saw that. It may have been at hack-a-day or Make. The only problem I see is that the disc gear bore is 5 mm and a long 5mm shaft is going to tend to twist. The gear could probably be bored out to 8 mm easily enough if you need to use a long output shaft.

I wouldn't trust printed plastic pulleys to deliver quality prints, OTOH, it's cheap and probably worth trying. The Z axis is very sensitive to errors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I saw someone posted a belt driven Z axis design that used this set of gears and their prints had no repeating Z axis artifacts: [www.ebay.com]

I can't find the original article/post where I saw that. It may have been at hack-a-day or Make. The only problem I see is that the disc gear bore is 5 mm and a long 5mm shaft is going to tend to twist. The gear could probably be bored out to 8 mm easily enough if you need to use a long output shaft.

I wouldn't trust printed plastic pulleys to deliver quality prints, OTOH, it's cheap and probably worth trying. The Z axis is very sensitive to errors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt z axis - which gears? December 18, 2018 06:53AM |

Registered: 11 years ago Posts: 5,780 |

Several months ago I saw a post in another forum (?) where someone used this set of gears to lift the Z axis in their printer. The photos of the prints looked like they were free of artifacts in the Z axis. Both gears have 5 mm bore, and I wouldn't trust a 5mm output shaft not to twist if it were very long, but you could probably bore out the hole to 8mm or so without too much difficulty.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt z axis - which gears? December 19, 2018 10:57PM |

Registered: 5 years ago Posts: 50 |

I'd do 3 but use something like a solenoid with a rubber on the tip to brake the transmission rod to keep the gantry from falling down in case of power loss. I don't think it makes that much of a difference to have that much resolution on the z axis. Even SLA printers like the Forms2 only have just a 1 or 2mm pitch trapezoidal leadscrew so you're not gaining anything by having a huge reduction like 1:10

|

Re: Belt z axis - which gears? December 20, 2018 10:56AM |

Registered: 11 years ago Posts: 5,780 |

10:1 isn't a huge reduction compared to driving a 2mm pitch screw. Relatively speaking, it isn't a reduction at all.

A motor driving a 2mm pitch screw achieves a 1600 usteps/mm using conventional parts/driver (200 steps/rev, 16:1 ustepping).

The same motor with a 10:1 reduction driving a 16 tooth pulley with 2 mm pitch belt achieves only 1000 ustep/rev. You'd need a 16:1 reduction to match the 2 mm pitch screw steps/mm and torque multiplication.

That's one of the reasons a worm gear box is good for this purpose(assuming high quality gears)- it achieves a high gear reduction with just 2 gears without any concerns about backlash, and usually also prevents bed motion when motor power is cut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A motor driving a 2mm pitch screw achieves a 1600 usteps/mm using conventional parts/driver (200 steps/rev, 16:1 ustepping).

The same motor with a 10:1 reduction driving a 16 tooth pulley with 2 mm pitch belt achieves only 1000 ustep/rev. You'd need a 16:1 reduction to match the 2 mm pitch screw steps/mm and torque multiplication.

That's one of the reasons a worm gear box is good for this purpose(assuming high quality gears)- it achieves a high gear reduction with just 2 gears without any concerns about backlash, and usually also prevents bed motion when motor power is cut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt z axis - which gears? December 20, 2018 12:48PM |

Registered: 6 years ago Posts: 63 |

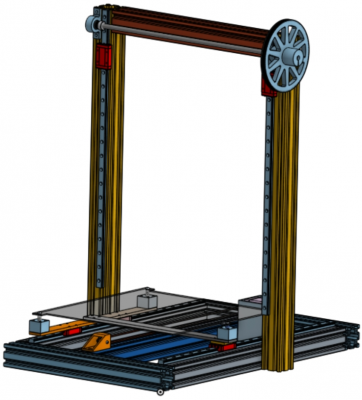

This is my current idea. The big wheel is a 200 teeth gt2 pulley (almost 130mm in diameter). There will be 20 teeth pulley on the motor and 20 on the rotating rod which is 8mm in diameter. Not sure if i will be able to print gt2. If not then gt3 will be used to link the big pulley with the motor.

Large pulley will be printed. It is not ideal but I hope that with this size of the wheel small inaccuracies in its print will have less effect on the quality of the printing of the new printer. Later I might even consider using a 400 teeth pulley (which I can't print with my current printer. 20 on motor + 20 on rod + 200 will give 0.02mm movement of z axis per motor step which is the same as on UMMD. With 400 that would be 0.01mm per step but the diameter of the wheel would be almost 260mm which is a bit too much.

I would prefer 10mm rods but it is hard to find 20 ght2 pulley with 10mm bore. I am still not sure if movement of the x axis will not produce too much z axis vibration due to elasticity of the 10mm belts. I could use a steel reinforced belt, but I would have to use bigger pulleys on the rod and smaller gear ratio. I will try to design my Z axis in such a way that if the whole thing does not work I will replace it with 2 lead screws driven by 1 motor and belt.

Large pulley will be printed. It is not ideal but I hope that with this size of the wheel small inaccuracies in its print will have less effect on the quality of the printing of the new printer. Later I might even consider using a 400 teeth pulley (which I can't print with my current printer. 20 on motor + 20 on rod + 200 will give 0.02mm movement of z axis per motor step which is the same as on UMMD. With 400 that would be 0.01mm per step but the diameter of the wheel would be almost 260mm which is a bit too much.

I would prefer 10mm rods but it is hard to find 20 ght2 pulley with 10mm bore. I am still not sure if movement of the x axis will not produce too much z axis vibration due to elasticity of the 10mm belts. I could use a steel reinforced belt, but I would have to use bigger pulleys on the rod and smaller gear ratio. I will try to design my Z axis in such a way that if the whole thing does not work I will replace it with 2 lead screws driven by 1 motor and belt.

|

Re: Belt z axis - which gears? April 07, 2019 02:43PM |

Registered: 10 years ago Posts: 87 |

|

Re: Belt z axis - which gears? April 07, 2019 03:20PM |

Registered: 6 years ago Posts: 63 |

Sorry, only registered users may post in this forum.