Z / X Design feedback request

Posted by Via

|

Z / X Design feedback request April 26, 2020 04:23PM |

Registered: 5 years ago Posts: 23 |

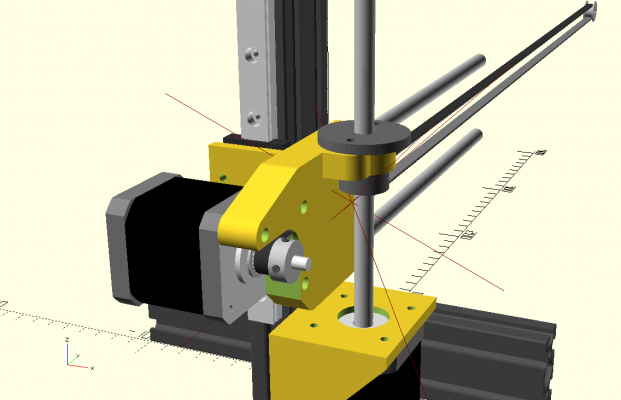

I am in process of building my first completely designed from scratch printer (but utilising some ideas from other printers). I currently have a scratch built AM8 and going for a similar design but with some improvements and larger build area.

I purchased some linear rails which were originally going to be used for Y axis but have instead gone for a VSlot gantry. So I was thinking of putting the linear rails to use replacing the smooth rods on Z Axis.

This is my draft idea and was wondering what people think and if there are any possible problems I have not thought about. Using similar design to current prusa i3 style, linear rails on side of 2040 extrusion because attaching from the front would be nightmare with belt and leadscrew in the way.

Opposite side will then match but with idler.

I purchased some linear rails which were originally going to be used for Y axis but have instead gone for a VSlot gantry. So I was thinking of putting the linear rails to use replacing the smooth rods on Z Axis.

This is my draft idea and was wondering what people think and if there are any possible problems I have not thought about. Using similar design to current prusa i3 style, linear rails on side of 2040 extrusion because attaching from the front would be nightmare with belt and leadscrew in the way.

Opposite side will then match but with idler.

|

Re: Z / X Design feedback request April 26, 2020 05:35PM |

Registered: 11 years ago Posts: 5,780 |

If you're going to use 2 Z axis motors, you'll have to sync them frequently because cycling power on the printer will cause the motors to jump. Resync is easy- run the X axis to just beyond the top of the Z axis. If you set the physical stops up so that the X axis is perpendicular to the Z axis when it's against the stops, the screws will synchronize and then you'll be able to print. The X axis motor mount is a complex shape to print. You might be better off splitting it into two or three pieces and screwing/gluing them together after printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z / X Design feedback request April 27, 2020 11:12AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Z / X Design feedback request April 27, 2020 11:48AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Z / X Design feedback request April 27, 2020 05:00PM |

Registered: 5 years ago Posts: 23 |

Thanks for feedback...

2 Z motors - take it this will be no different to current system using smooth rods, I currently occasionally resync them but most of the time difference is negliable and accounted for with mesh levelling.

3 Mounting holes - Mainly asthetics using all 4 made it look very blocky which seems to be increased because of no smooth rod bearing mount to break this up.

Tension - Not designed yet so not shown, other end will be pretty much similar to Prusa style with idler sitting in a fork which can then be tightened via bolt through mount.

2 Z motors - take it this will be no different to current system using smooth rods, I currently occasionally resync them but most of the time difference is negliable and accounted for with mesh levelling.

3 Mounting holes - Mainly asthetics using all 4 made it look very blocky which seems to be increased because of no smooth rod bearing mount to break this up.

Tension - Not designed yet so not shown, other end will be pretty much similar to Prusa style with idler sitting in a fork which can then be tightened via bolt through mount.

|

Re: Z / X Design feedback request April 28, 2020 03:17AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Z / X Design feedback request April 28, 2020 04:00PM |

Registered: 6 years ago Posts: 265 |

If you have separate drivers for each of the Z motors and a bed leveling probe you can use Marlin's Z auto-alignment feature to sync the Z motors. You use the G34 gcode and Marlin will probe either side of the bed and adjust the Z motors until the difference in the measurements is below a set threshold (I have mine set to 0.02mm).

|

Re: Z / X Design feedback request April 29, 2020 03:25AM |

Registered: 6 years ago Posts: 1,007 |

Quote

MMcLure

If you have separate drivers for each of the Z motors and a bed leveling probe you can use Marlin's Z auto-alignment feature to sync the Z motors. You use the G34 gcode and Marlin will probe either side of the bed and adjust the Z motors until the difference in the measurements is below a set threshold (I have mine set to 0.02mm).

You do realize that by doing that with a somewhat rigid frame and guides you force them ? Of course if there is enough play and flexibility as most hobby machines have, it usually doesn't bind.

That is the big difference with a Delta where ABL is a must and mechanically sound due to its articulations.

Edited 1 time(s). Last edit at 04/29/2020 03:40AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Z / X Design feedback request April 30, 2020 12:55PM |

Registered: 6 years ago Posts: 265 |

The axis will always have a little play if the motors aren't physically synced. Yes, while the axis isn't in sync there might be some binding, but it shouldn't be any worse than what you'd get if you were manually syncing or doing what I saw earlier in this thread (forcing both motors to the top of the gantry).

|

Re: Z / X Design feedback request April 30, 2020 07:25PM |

Registered: 11 years ago Posts: 5,780 |

Using a probe to check the X axis angle is using the bed as a reference. The bed may not be flat and it's Z position may change if it is poorly designed or made (most are, or you wouldn't need a sensor on the extruder carriage to try to compensate for it). The Z axis doesn't normally change position so it's a good reference. The X axis needs to be perpendicular to Z to ensure smooth motion as it goes up the Z axis. Syncing by running to the top of the Z axis forces X to be perpendicular to Z (as long as you position the stops so it will be). If you reference the bed, and the bed is out of whack, the X axis will also be out of alignment with Z.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z / X Design feedback request May 01, 2020 02:08AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Z / X Design feedback request May 01, 2020 06:55AM |

Registered: 11 years ago Posts: 5,780 |

We had a Taz printer at the makerspace several years ago. It had two Z motors and a glass bed with 4 leveling screws on a flexible plate on top of flexible Y axis guide rails held in place by printed parts. It used to require releveling the bed for literally every print and then the prints wouldn't stick reliably because the bed was glass with a heater glued directly to it. People would be using the printer for a while then come to me for help with it because they couldn't get the bed leveled. I'd take one look at the machine and see that the X axis was obviously tilted relative to the Z axis, and they had attempted to adjust the bed to match the X axis tilt. Doh!

The bed surface is NOT the XY plane of the printer but it should be parallel to it. The XY plane is established by the guide rails (as are the XZ and YZ planes).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The bed surface is NOT the XY plane of the printer but it should be parallel to it. The XY plane is established by the guide rails (as are the XZ and YZ planes).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z / X Design feedback request May 01, 2020 07:03AM |

Registered: 11 years ago Posts: 5,780 |

Quote

MKSA

Conclusion, one motor plus belt driving the two leadscrews !

Better, simpler, cheaper ! Just requires a bit more thinking and ability to make properly.

But, but, but.... then you can't make cool youtube videos of screws spinning and the axis leveling itself! No one wants to watch a youtube video of a printer that just prints every time you turn it on, like some sort of - ugh! - household appliance. Boring!!!

I'm going to make a printer that mounts the extruder on a quadcopter. It'll have sensors and cameras and AI software (no, QUANTUM AI software!) that locates the print surface and it will hover over it as it extrudes plastic. I'll have it printing on roofs of houses and even cars while they're in motion! My videos will go viral! I'll be a youtube star!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.