Rostock mini pro, problem with movements

Posted by Fz0077

|

Rostock mini pro, problem with movements June 14, 2014 07:27AM |

Registered: 9 years ago Posts: 9 |

Hello, I'm new here and also new to 3d printers.

I built a rostock mini pro with ramps 1.4.

for the software configuration i used these instructions: [onedrive.live.com]

after configurating the printer in repetier host i press the home symbol.

The carriages should move up until they hit the endstoppers, but that doesnt happen.

Instead the carriages just jump a few mm in some direction.

I hope you can help me out here, i checked the internet but couldn find anything...

I built a rostock mini pro with ramps 1.4.

for the software configuration i used these instructions: [onedrive.live.com]

after configurating the printer in repetier host i press the home symbol.

The carriages should move up until they hit the endstoppers, but that doesnt happen.

Instead the carriages just jump a few mm in some direction.

I hope you can help me out here, i checked the internet but couldn find anything...

|

Re: Rostock mini pro, problem with movements June 14, 2014 08:15AM |

Registered: 10 years ago Posts: 17 |

Hi

welcome to an amazing world

i faced same problem first time homing

this is my post:

[forums.reprap.org]

in the 5th reply ANDY wrote:

You have your micro stepping set at 1/16. For your A4988 drivers that would mean all three jumpers under the driver on RAMPS being populated. Are they?

be sure your endstops are wired the right way (dont shorten + and -)

regards

Edited 1 time(s). Last edit at 06/14/2014 08:17AM by LB-3D.

welcome to an amazing world

i faced same problem first time homing

this is my post:

[forums.reprap.org]

in the 5th reply ANDY wrote:

Your endstop configuration is working o.k although you seem to have your switches wired NO I.e they go closed circuit when you operate them. That's o.k though because you have the logic set to 'true'. The acid test is what happens when you send M119. As per your post all seems o.k. So it's not your endstop configuration causing the issue. You have your micro stepping set at 1/16. For your A4988 drivers that would mean all three jumpers under the driver on RAMPS being populated. Are they? Given that your end stops are operating correctly it must be something else. I would go back to a fresh copy of Marlin and just comment out #define ENABLE_AUTO_BED_LEVELING and #define ACCURATE_BED_LEVELLING and recompile Andy

You have your micro stepping set at 1/16. For your A4988 drivers that would mean all three jumpers under the driver on RAMPS being populated. Are they?

be sure your endstops are wired the right way (dont shorten + and -)

regards

Edited 1 time(s). Last edit at 06/14/2014 08:17AM by LB-3D.

|

Re: Rostock mini pro, problem with movements June 14, 2014 08:24AM |

Registered: 10 years ago Posts: 903 |

Start with the M119 command to check your endstop wiring. If the switches are reading triggered when the carriages are not touching them, the printer will think that it is already homed and not move the carriages (or in some cases only move them in one direction). You can either move the "NC" wire to "NO" (or vise versa) on the switch, or invert the endstops in firmware.....

|

Re: Rostock mini pro, problem with movements June 14, 2014 01:38PM |

Registered: 9 years ago Posts: 9 |

okay i have done this, i really forgot to put in the jumpers  ... thanks for that!

... thanks for that!

but now when i try to home it, the carriage Z goes down crashing the bottom lol, what could be the reason for that? no other carriage moves

when i try the m119 command i get the following:

x_max:H y_max:H z_max:L

... thanks for that!

... thanks for that!but now when i try to home it, the carriage Z goes down crashing the bottom lol, what could be the reason for that? no other carriage moves

when i try the m119 command i get the following:

x_max:H y_max:H z_max:L

|

Re: Rostock mini pro, problem with movements June 14, 2014 05:06PM |

Registered: 10 years ago Posts: 903 |

Z moves, and the Z-max endstop is low. If they are all wired the same, my guess is that your firmware still has remnants of a Cartesian configuration in the Z-tower configuration that need to be corrected to match the X and Y towers. The usual suspects are that the Z speeds are set to 10% of the X and Y, one or more endstop settings are inverted, the travel direction setting on one or more axis is inverted, etc. Fix this first, and upload a new image to your board.

Once you get the new firmware loaded and with the printer powered off, disconnect the stepper motors (or remove the belts), move the carriages to mid-point on the verticals, and power up the board. With nothing touching the endstops, they should all read L when you do an M119. Now, press/hold the X endstop, and type M119 with your other hand. Did X-max change to H? If so, repeat for Y and Z. If an endstop starts out H and changes to L when you press it, you need to invert the endstop in firmware or else swap the wire on the switch from the NC terminal to the NO terminal (or vice versa). When all three are L when not triggered and change to H when you touch them, then your endstops are set.

With the endstops sorted out, power down the printer, and put the belts back on or plug the stepper motors back in. With the carriages still set at mid-point and a hand near the power plug, power up the printer and send it a home command if it doesn't auto-home. All three carriages should travel upwards to the endstops, "bump" off of them and move down a bit, and then move back up to the endstop again. If any carriage starts to move downward when you power on or send the home command, yank the power plug and either invert the direction of travel in firmware or pull the stepper motor plug from the board and turn it around 180 degrees (if it doesn't have a one-way keyed Molex connector that prevents it from going on backwards).

When you have the hotend mounted and are ready for calibration, Jay's video for manually calibrating a Delta printer on YouTube will show you everything.....

Once you get the new firmware loaded and with the printer powered off, disconnect the stepper motors (or remove the belts), move the carriages to mid-point on the verticals, and power up the board. With nothing touching the endstops, they should all read L when you do an M119. Now, press/hold the X endstop, and type M119 with your other hand. Did X-max change to H? If so, repeat for Y and Z. If an endstop starts out H and changes to L when you press it, you need to invert the endstop in firmware or else swap the wire on the switch from the NC terminal to the NO terminal (or vice versa). When all three are L when not triggered and change to H when you touch them, then your endstops are set.

With the endstops sorted out, power down the printer, and put the belts back on or plug the stepper motors back in. With the carriages still set at mid-point and a hand near the power plug, power up the printer and send it a home command if it doesn't auto-home. All three carriages should travel upwards to the endstops, "bump" off of them and move down a bit, and then move back up to the endstop again. If any carriage starts to move downward when you power on or send the home command, yank the power plug and either invert the direction of travel in firmware or pull the stepper motor plug from the board and turn it around 180 degrees (if it doesn't have a one-way keyed Molex connector that prevents it from going on backwards).

When you have the hotend mounted and are ready for calibration, Jay's video for manually calibrating a Delta printer on YouTube will show you everything.....

|

Re: Rostock mini pro, problem with movements June 15, 2014 06:47AM |

Registered: 9 years ago Posts: 9 |

thanks for the reply vreihen!

It helped me finding the problem.

The endstops X and Y seem not to work.

I testet the connection of the wire and the mechanism of the endstops with a multimeter, they seem to be fine, but i dont get a signal to the program.

when i press the endstops and type m119, they stay the same.

Only Z seems to work correctly...

I did invert the endstops so all of them now get L when i do the m119 command, when i try to home it now all 3 carriages move.

Looks like i need a new ramps board...

Edited 2 time(s). Last edit at 06/15/2014 07:37AM by Fz0077.

It helped me finding the problem.

The endstops X and Y seem not to work.

I testet the connection of the wire and the mechanism of the endstops with a multimeter, they seem to be fine, but i dont get a signal to the program.

when i press the endstops and type m119, they stay the same.

Only Z seems to work correctly...

I did invert the endstops so all of them now get L when i do the m119 command, when i try to home it now all 3 carriages move.

Looks like i need a new ramps board...

Edited 2 time(s). Last edit at 06/15/2014 07:37AM by Fz0077.

|

Re: Rostock mini pro, problem with movements June 15, 2014 05:34PM |

Registered: 10 years ago Posts: 515 |

Quote

Fz0077

thanks for the reply vreihen!

It helped me finding the problem.

The endstops X and Y seem not to work.

I testet the connection of the wire and the mechanism of the endstops with a multimeter, they seem to be fine, but i dont get a signal to the program.

when i press the endstops and type m119, they stay the same.

Only Z seems to work correctly...

I did invert the endstops so all of them now get L when i do the m119 command, when i try to home it now all 3 carriages move.

Looks like i need a new ramps board...

Unless you have shorted something out I doubt your RAMPS is the issue. Have you got a photo of your endstop connections at the RAMPS end you could post?

|

Re: Rostock mini pro, problem with movements June 20, 2014 06:05AM |

Registered: 9 years ago Posts: 9 |

yes i had shorted something..., that was my fault, but i got a new RAMPS, now the same issue as before.

EDIT: I found the problem and solved it!

yyou were right i just used the wrong pins, now it all works fine and i managed to do the first dry run with success!

I only have 1 little question:

Where do i connect the small cooling fan to?

on the RAMPS board?

Edited 1 time(s). Last edit at 06/20/2014 06:55AM by Fz0077.

EDIT: I found the problem and solved it!

yyou were right i just used the wrong pins, now it all works fine and i managed to do the first dry run with success!

I only have 1 little question:

Where do i connect the small cooling fan to?

on the RAMPS board?

Edited 1 time(s). Last edit at 06/20/2014 06:55AM by Fz0077.

|

Re: Rostock mini pro, problem with movements June 20, 2014 07:29AM |

Registered: 10 years ago Posts: 515 |

It depends ....

As with all things Marlin lol. If you have configured your RAMPS in Configuration.h as 33 this tells Marlin that you, potentially, want a hot end heater, heated bed and one fan. If you chose 35 then you could have hot end heater and two fans. Let's assume you used MOTHERBOARD == 33. D9 would be the fan output (it supplies 12V when activated and you need to be conscious of the +ve & -ve polarity) D10 would be your hot end, polarity doesn't matter and D8 would be your heated bed, again polarity doesn't matter.

Andy

As with all things Marlin lol. If you have configured your RAMPS in Configuration.h as 33 this tells Marlin that you, potentially, want a hot end heater, heated bed and one fan. If you chose 35 then you could have hot end heater and two fans. Let's assume you used MOTHERBOARD == 33. D9 would be the fan output (it supplies 12V when activated and you need to be conscious of the +ve & -ve polarity) D10 would be your hot end, polarity doesn't matter and D8 would be your heated bed, again polarity doesn't matter.

Andy

|

Re: Rostock mini pro, problem with movements June 20, 2014 09:59AM |

Registered: 9 years ago Posts: 56 |

As AndyCart said, the default fan(D9) is connected just bellow HotEnd Power(D10), see attached image.

I also have Rostock Mini Pro by 3dPrinterCzar and spent first month calibrating and tweaking so don't be afraid to ask if you have any more problems.

I have acumulated a lot of tutorials and advice that is scatered on the web.

I also have Rostock Mini Pro by 3dPrinterCzar and spent first month calibrating and tweaking so don't be afraid to ask if you have any more problems.

I have acumulated a lot of tutorials and advice that is scatered on the web.

|

Re: Rostock mini pro, problem with movements June 20, 2014 11:49AM |

Registered: 9 years ago Posts: 9 |

Quote

DinoK

As AndyCart said, the default fan(D9) is connected just bellow HotEnd Power(D10), see attached image.

I also have Rostock Mini Pro by 3dPrinterCzar and spent first month calibrating and tweaking so don't be afraid to ask if you have any more problems.

I have acumulated a lot of tutorials and advice that is scatered on the web.

thank you, i already managed to find out how to connect it.

everything seems to work now, but i managed to clog up the hot end with a piece of PLA, cant get it out, heating it up doesnt solve the problem, when i tried to pull it out it just snapped...

I feel like an complete idiot right now, but is it possible to disassemble the hot end so i can get this stuff out?

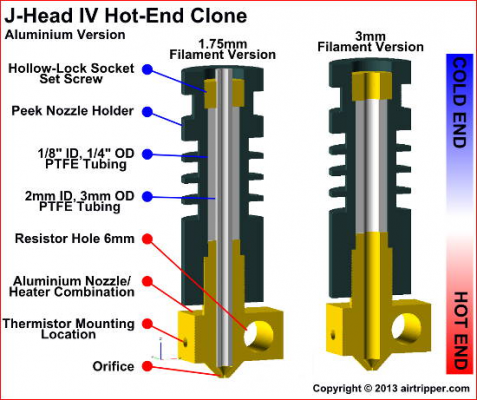

The hotend is a J-head MKIV.

|

Re: Rostock mini pro, problem with movements June 20, 2014 01:51PM |

Registered: 10 years ago Posts: 515 |

|

Re: Rostock mini pro, problem with movements June 21, 2014 05:04AM |

Registered: 9 years ago Posts: 56 |

I had to disassemble the hotend also at the begining since they are cheap clones of J-head MK-IV and also poorly assembled.

More about the clones :

http://airtripper.com/1236/j-head-mk-iv-hot-end-clone-design-quick-review/

But since I took the hotend apart and assembled it properly it works great.

Be careful with termistor wires , I broke them off and had to solder them back on. But it was a lesson not to bend them so much next time as they easily break off.

Here is the post from Solidoodle about cleaning out a clogged nozzle :

http://www.soliforum.com/topic/255/cleaning-out-a-clogged-nozzle-with-poking-it-with-a-wire-doesnt-work/

More about the clones :

Quote

... has 4 cooling vents, a push-to-fit connector that could be nice for a bowden extruder, an over-sized nozzle, and the vents are not milled to the rounded contour of the core. (This will negatively affect cooling.) ....

http://airtripper.com/1236/j-head-mk-iv-hot-end-clone-design-quick-review/

But since I took the hotend apart and assembled it properly it works great.

Be careful with termistor wires , I broke them off and had to solder them back on. But it was a lesson not to bend them so much next time as they easily break off.

Here is the post from Solidoodle about cleaning out a clogged nozzle :

http://www.soliforum.com/topic/255/cleaning-out-a-clogged-nozzle-with-poking-it-with-a-wire-doesnt-work/

|

Re: Rostock mini pro, problem with movements June 22, 2014 11:22PM |

Registered: 10 years ago Posts: 515 |

I've used a few clone j heads in the past and as long as you set them up right they are o.k. The main issue with the ones I have tried is that they don't have the lock nut holding the PTFE liner tight to the aluminium part. I solved this by cutting a 6mm piece of 8mm OD, 5mm ID aluminium tube and putting it on top of the liner. The pneumatic connector then presses against this when tightened and, therefore, also keeps the liner tight against the block. If the liner moves away from the block PLA will pool in the gap and as soon as the hotend cools you have a clog. This maybe what's happened in your case

Andy

Andy

|

Re: Rostock mini pro, problem with movements June 24, 2014 02:28PM |

Registered: 9 years ago Posts: 4 |

Hello new here and with a rostock mini pro from czar.

im having the same problem,all my endstops show h when pressed but my z axis is backwards,i also get a long beep sound when trying to home.

any ideas or can some one upload thier firmware? i would be mucho happy if someone could.

edit,i forgot to fit the jumpers,but when trying to home all carriages move to the bottom

Edited 1 time(s). Last edit at 06/24/2014 03:02PM by Nostromo.

im having the same problem,all my endstops show h when pressed but my z axis is backwards,i also get a long beep sound when trying to home.

any ideas or can some one upload thier firmware? i would be mucho happy if someone could.

edit,i forgot to fit the jumpers,but when trying to home all carriages move to the bottom

Edited 1 time(s). Last edit at 06/24/2014 03:02PM by Nostromo.

|

Re: Rostock mini pro, problem with movements June 25, 2014 02:30PM |

Registered: 9 years ago Posts: 4 |

|

Re: Rostock mini pro, problem with movements June 25, 2014 03:27PM |

Registered: 10 years ago Posts: 732 |

|

Re: Rostock mini pro, problem with movements June 25, 2014 03:47PM |

Registered: 9 years ago Posts: 4 |

|

Re: Rostock mini pro, problem with movements June 25, 2014 04:03PM |

Registered: 9 years ago Posts: 569 |

One of the issues I encountered was with my end connections. Appearently I suck at terminating wires. Once I picked up a racheting crimping tool, all of my connections were a lot smoother. I think this also caused my motors to "malfunction" at times as a result which made troubleshooting more difficult.

I realized the issue with my end stops using the M119 command to give their current state. You either want them all high (NC?) or all low (NO?), and in my case, my Z endstop was reading as high (NO?) do to bad wiring on my part, so it never moved up.

Another issue I had, though I don't believe it is related to this thread, was that the voltages on my motors were to low. Using a multimeter, I adjusted the voltages to 0.4 V each (found it online somewhere). Be real careful adjusting the voltages though, as it is easy to slip and short the A4988.

EDIT: Oh, and I did have to take my J-Head apart do to a leak between the aluminium block and the PTFE, which I read was a common issue with J-Heads...more so with the clones. Took it apart cold which might have been an issue, but was pretty easy to do. Cleaned off all the leaked PLA and seemed to get it back together again and working, with a little plumbers tape to hopefully prevent future leaks. I will admit that I encountered a jam after re-leveling my bed and have since given up. I believe I failed to load the PLA correctly at the time, but have been to frustrated to trouble shoot it yet.

Edited 1 time(s). Last edit at 06/25/2014 04:09PM by Kurzaa.

I realized the issue with my end stops using the M119 command to give their current state. You either want them all high (NC?) or all low (NO?), and in my case, my Z endstop was reading as high (NO?) do to bad wiring on my part, so it never moved up.

Another issue I had, though I don't believe it is related to this thread, was that the voltages on my motors were to low. Using a multimeter, I adjusted the voltages to 0.4 V each (found it online somewhere). Be real careful adjusting the voltages though, as it is easy to slip and short the A4988.

EDIT: Oh, and I did have to take my J-Head apart do to a leak between the aluminium block and the PTFE, which I read was a common issue with J-Heads...more so with the clones. Took it apart cold which might have been an issue, but was pretty easy to do. Cleaned off all the leaked PLA and seemed to get it back together again and working, with a little plumbers tape to hopefully prevent future leaks. I will admit that I encountered a jam after re-leveling my bed and have since given up. I believe I failed to load the PLA correctly at the time, but have been to frustrated to trouble shoot it yet.

Edited 1 time(s). Last edit at 06/25/2014 04:09PM by Kurzaa.

|

Re: Rostock mini pro, problem with movements June 25, 2014 04:30PM |

Registered: 9 years ago Posts: 4 |

Quote

Kurzaa

One of the issues I encountered was with my end connections. Appearently I suck at terminating wires. Once I picked up a racheting crimping tool, all of my connections were a lot smoother. I think this also caused my motors to "malfunction" at times as a result which made troubleshooting more difficult.

I realized the issue with my end stops using the M119 command to give their current state. You either want them all high (NC?) or all low (NO?), and in my case, my Z endstop was reading as high (NO?) do to bad wiring on my part, so it never moved up.

Another issue I had, though I don't believe it is related to this thread, was that the voltages on my motors were to low. Using a multimeter, I adjusted the voltages to 0.4 V each (found it online somewhere). Be real careful adjusting the voltages though, as it is easy to slip and short the A4988.

EDIT: Oh, and I did have to take my J-Head apart do to a leak between the aluminium block and the PTFE, which I read was a common issue with J-Heads...more so with the clones. Took it apart cold which might have been an issue, but was pretty easy to do. Cleaned off all the leaked PLA and seemed to get it back together again and working, with a little plumbers tape to hopefully prevent future leaks. I will admit that I encountered a jam after re-leveling my bed and have since given up. I believe I failed to load the PLA correctly at the time, but have been to frustrated to trouble shoot it yet.

Thanks for your reply,i dont have the j head wired up yet as i want to get the homing right,i will try and get a crimping tool tomorrow and redo my connectors tomorrow night.

my axis dont seem to be moving correctly now,only z is behaving normally.

On another note i stumbled across this

[github.com]

|

Re: Rostock mini pro, problem with movements June 28, 2014 06:15AM |

Registered: 9 years ago Posts: 9 |

well i try to disassemble the hotend, but i dont know how...

to what temperature do i have to heat it?

well... i think i'm going to buy a new hotend just to be sure and leave the clone as a reserve anyway.

Does the MkV j-head work well with the rostock?

next edit:

I now got rid of all the kopten tape around the hotend and it looks like the PEEK around the threads melted severely, thats why i couldnt take it off...

I dont know if i damaged it to that way or if it came like this but damn! I'll just order a new one lol!

ALSO: I didnt know before: The PEEK melted over the termistor and now i cant get it out of there (*hardcore facepalming)

Edited 3 time(s). Last edit at 06/28/2014 07:53AM by Fz0077.

to what temperature do i have to heat it?

well... i think i'm going to buy a new hotend just to be sure and leave the clone as a reserve anyway.

Does the MkV j-head work well with the rostock?

next edit:

I now got rid of all the kopten tape around the hotend and it looks like the PEEK around the threads melted severely, thats why i couldnt take it off...

I dont know if i damaged it to that way or if it came like this but damn! I'll just order a new one lol!

ALSO: I didnt know before: The PEEK melted over the termistor and now i cant get it out of there (*hardcore facepalming)

Edited 3 time(s). Last edit at 06/28/2014 07:53AM by Fz0077.

|

Re: Rostock mini pro, problem with movements June 28, 2014 10:44AM |

Registered: 10 years ago Posts: 903 |

In the age of digital photography, I am at a loss to explain why some people insist on buying camera film. (Professional photographers and legal requirement photo reasons aside.) Ditto for the J-head. It is a ticking time bomb, waiting for a PEEK meltdown due to a firmware crash, thermistor failure, or attempt to print ABS. My genuine J-head melted down before it even printed its first item, but I learned from my mistake and didn't buy another one to repeat the cycle. Just say no to PEEK.....

|

Re: Rostock mini pro, problem with movements June 30, 2014 08:33AM |

Registered: 9 years ago Posts: 56 |

Quote

Nostromo

Hello new here and with a rostock mini pro from czar.

im having the same problem,all my endstops show h when pressed but my z axis is backwards,i also get a long beep sound when trying to home.

any ideas or can some one upload thier firmware? i would be mucho happy if someone could.

(

It took me some time but I finally managed to upload my firmware to my blog. You can get it there but please read the warnings at the end, I don't want your head to crash and ruin your bed because of me.

I plan to write detailed tutorials and how-to's about Rostock Mini Pro but the days are too short to get everything on paper and my head is full of possible topics .

All about delta 3d printers in one place [www.deltarap.org]

|

Re: Rostock mini pro, problem with movements July 05, 2014 09:36AM |

Registered: 9 years ago Posts: 9 |

hey there its me again!

the printer now works! thank you guys for your help!

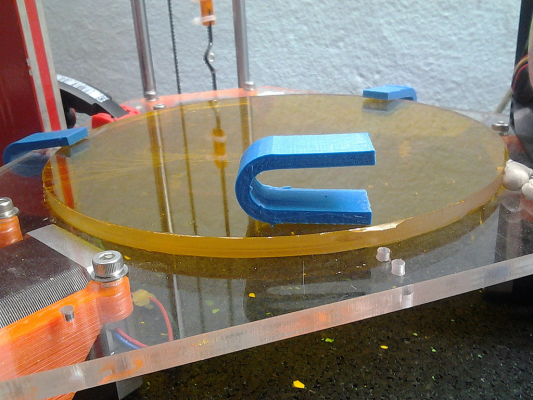

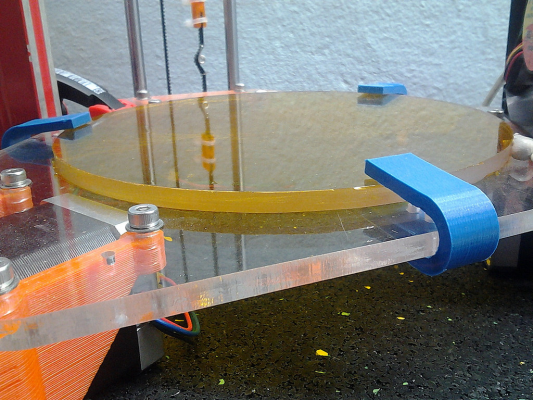

i only need to calibrate some stuff... any tips on fixing the printing base plate?

i use printers tape and the pla seems to stick on it perfectly.

but the printer starts to push the plate around while printing on higher layers, also it jumps from one point to the other very fast...

any configuration tips regarding slic3r and the plate?

the printer now works! thank you guys for your help!

i only need to calibrate some stuff... any tips on fixing the printing base plate?

i use printers tape and the pla seems to stick on it perfectly.

but the printer starts to push the plate around while printing on higher layers, also it jumps from one point to the other very fast...

any configuration tips regarding slic3r and the plate?

|

Re: Rostock mini pro, problem with movements July 05, 2014 01:32PM |

Registered: 9 years ago Posts: 569 |

I used two large binder clips on my build plate, though it reduces the size of the print area...fan was hitting one of the clips, hence only using two clips.

Still trying to get my printer working consistently, but I don't recall any printer specific slic3r settings. At least none that weren't obvious. Of course filament temperatures and retraction speeds all need to be figured out as part of the calibration process and I believe for each type of filament.

Still trying to get my printer working consistently, but I don't recall any printer specific slic3r settings. At least none that weren't obvious. Of course filament temperatures and retraction speeds all need to be figured out as part of the calibration process and I believe for each type of filament.

|

Re: Rostock mini pro, problem with movements August 05, 2014 02:27PM |

Registered: 9 years ago Posts: 56 |

I ditched the rubber legs and also use clips to hold the bed. Had the same problem at the beginning-the plate was tilting when printing larger objects.

It is very stable now except the head hitting clips sometimes when printing very large objects. I will buy a bigger piece of acryl and attach it with the same

screws that hold the motors to solve that, but for now I just have to position the object the right way before slicing.

Almost forgot....you can get my Slic3r and other settings on my blog. That is the thing I wish I had at

the beginning, it would be a great time saver.

Edited 1 time(s). Last edit at 08/05/2014 02:36PM by DinoK.

All about delta 3d printers in one place [www.deltarap.org]

It is very stable now except the head hitting clips sometimes when printing very large objects. I will buy a bigger piece of acryl and attach it with the same

screws that hold the motors to solve that, but for now I just have to position the object the right way before slicing.

Almost forgot....you can get my Slic3r and other settings on my blog. That is the thing I wish I had at

the beginning, it would be a great time saver.

Edited 1 time(s). Last edit at 08/05/2014 02:36PM by DinoK.

All about delta 3d printers in one place [www.deltarap.org]

Sorry, only registered users may post in this forum.