Success!

Posted by Freebird01

|

Success! August 29, 2015 11:24AM |

Registered: 9 years ago Posts: 70 |

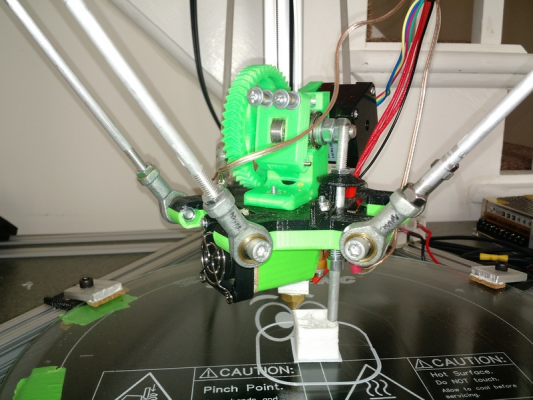

Finally after multiple build iterations and changing directions a few times I'm finally starting to see some successful prints. Thanks DC42 and anyone else who endured my ramblings and stupid questions.

the biggest lesson ive learned is WATCH OUT FOR GARBAGE CHINESE COMPONENTS!!!!!

that has been the biggest hurdle. now that i spent some money and bought a budaschnozzle my printer is extruding reliably and i can actually tweak settings to get what want. Next step is to get rid of the seemecnc knockoff heated plate and find something a little stronger (dont get hot enough for my liking)

biggest issue im fighting at the moment is bed adhesion. I've tried abs slurry and hair spray and its only been marginally effective. I have a roll of kapton tape on its way.

i still have more cleanup to do on the build with hiding wiring and re-routing some of the cables.. and eventually i want to add a paneldue to it...

https://www.youtube.com/watch?v=u6uJ76Meuyo

the biggest lesson ive learned is WATCH OUT FOR GARBAGE CHINESE COMPONENTS!!!!!

that has been the biggest hurdle. now that i spent some money and bought a budaschnozzle my printer is extruding reliably and i can actually tweak settings to get what want. Next step is to get rid of the seemecnc knockoff heated plate and find something a little stronger (dont get hot enough for my liking)

biggest issue im fighting at the moment is bed adhesion. I've tried abs slurry and hair spray and its only been marginally effective. I have a roll of kapton tape on its way.

i still have more cleanup to do on the build with hiding wiring and re-routing some of the cables.. and eventually i want to add a paneldue to it...

https://www.youtube.com/watch?v=u6uJ76Meuyo

|

Re: Success! August 29, 2015 12:43PM |

Registered: 8 years ago Posts: 150 |

Quote

Freebird01

Finally after multiple build iterations and changing directions a few times I'm finally starting to see some successful prints. Thanks DC42 and anyone else who endured my ramblings and stupid questions.

the biggest lesson ive learned is WATCH OUT FOR GARBAGE CHINESE COMPONENTS!!!!!

that has been the biggest hurdle. now that i spent some money and bought a budaschnozzle my printer is extruding reliably and i can actually tweak settings to get what want. Next step is to get rid of the seemecnc knockoff heated plate and find something a little stronger (dont get hot enough for my liking)

biggest issue im fighting at the moment is bed adhesion. I've tried abs slurry and hair spray and its only been marginally effective. I have a roll of kapton tape on its way.

i still have more cleanup to do on the build with hiding wiring and re-routing some of the cables.. and eventually i want to add a paneldue to it...

Congrats!

What motor do you use for the extruder?

|

Re: Success! August 29, 2015 01:04PM |

Registered: 9 years ago Posts: 70 |

|

Re: Success! August 29, 2015 03:41PM |

Registered: 10 years ago Posts: 732 |

|

Re: Success! August 29, 2015 04:07PM |

Registered: 9 years ago Posts: 70 |

|

Re: Success! August 30, 2015 04:17PM |

Registered: 9 years ago Posts: 70 |

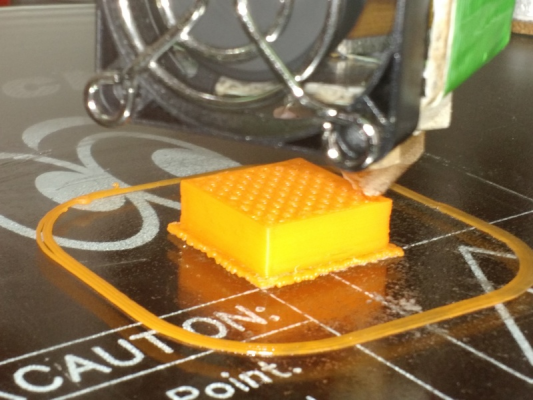

what would be a good cause for mid layer adhesion issues?

PLA nozzle temp 210c

bed temp 50c

pronterface and slic3r for my software...

anything i should be looking for? anymore info you would like?

PLA nozzle temp 210c

bed temp 50c

pronterface and slic3r for my software...

anything i should be looking for? anymore info you would like?

|

Re: Success! August 31, 2015 07:46AM |

Registered: 10 years ago Posts: 16 |

|

Re: Success! August 31, 2015 08:31AM |

Registered: 9 years ago Posts: 70 |

|

Re: Success! August 31, 2015 08:51AM |

Registered: 10 years ago Posts: 16 |

Try lowering your retraction from the range 0.1 to 0.5mm (not the lifting, that's not an issue I believe), start low and find the sweet spot so your hotend won't leak and your filament won't cool down.

All you want is to release a bit of pressure from your hotend but you don't want the warm filament to cool down.

You might also want to play with lowering retraction speed, that could also be a factor.

All you want is to release a bit of pressure from your hotend but you don't want the warm filament to cool down.

You might also want to play with lowering retraction speed, that could also be a factor.

|

Re: Success! August 31, 2015 09:34AM |

Registered: 9 years ago Posts: 70 |

|

Re: Success! August 31, 2015 12:02PM |

Registered: 8 years ago Posts: 150 |

Quote

Freebird01

what would be a good cause for mid layer adhesion issues?

PLA nozzle temp 210c

bed temp 50c

pronterface and slic3r for my software...

anything i should be looking for? anymore info you would like?

When I get that first suspect is the filament not coming of the spool smoothly. Second check is variation in filament diameter (I use cheep stuff).

|

Re: Success! August 31, 2015 12:27PM |

Registered: 9 years ago Posts: 70 |

|

Re: Success! August 31, 2015 02:36PM |

Registered: 9 years ago Posts: 70 |

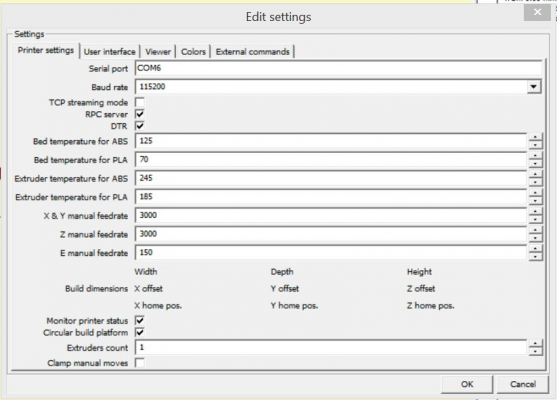

ok...this is a quirk thats really bugging me with pronterface. I have it set for circular build platform... and in slic3r my parts are in the middle of the build plate..

pronterface has them out in left field. ive done some internet searching and come to the conclusion that i should be able to update it in the settings... however those areas are gray'ed out and there is no where to adjust...

pronterface has them out in left field. ive done some internet searching and come to the conclusion that i should be able to update it in the settings... however those areas are gray'ed out and there is no where to adjust...

|

Re: Success! September 01, 2015 01:57PM |

Registered: 8 years ago Posts: 4 |

I had this issue last night using Pronterface for the first time. My XYZ offsets and home positions were not grayed out and I was able to put in an X/Y offset of -75 with X/Y home pos. of 75. This centered my print. Not too helpful for figuring out why you don't have that option, but that is how I solved the offset.

Sorry, only registered users may post in this forum.