Benefits / Drawbacks of Metal Effector Plates

Posted by Kurzaa

|

Benefits / Drawbacks of Metal Effector Plates September 17, 2015 04:19PM |

Registered: 9 years ago Posts: 569 |

Just received an email today from Utlibots that they are now carrying metal kossel parts, including the effector plate and a groove plate for the hotend.

While I understand the benefits of metal corners from the frames, I would think the added weight of a metal effector plate over a laser cut or printed plate would be detrimental to the printer. Is this something I should look into for my Rostock Mini, assuming the arm widths are similar?

While I understand the benefits of metal corners from the frames, I would think the added weight of a metal effector plate over a laser cut or printed plate would be detrimental to the printer. Is this something I should look into for my Rostock Mini, assuming the arm widths are similar?

|

Re: Benefits / Drawbacks of Metal Effector Plates September 17, 2015 05:05PM |

Registered: 9 years ago Posts: 445 |

First thing that comes to my mind is you get better stability of the hotend at higher speeds/accelerations.

Might be wrong about this though.

Gonna try for my self, ordered a metal effector from robotdigg a couple of days ago.

I would like to see a metal effector that goes with balls/magnets though, where you fasten the balls to the effector and have the magnet inside a PTFE-cone on the rod.

Edited 1 time(s). Last edit at 09/17/2015 05:08PM by Koenig.

Might be wrong about this though.

Gonna try for my self, ordered a metal effector from robotdigg a couple of days ago.

I would like to see a metal effector that goes with balls/magnets though, where you fasten the balls to the effector and have the magnet inside a PTFE-cone on the rod.

Edited 1 time(s). Last edit at 09/17/2015 05:08PM by Koenig.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 17, 2015 06:41PM |

Registered: 8 years ago Posts: 396 |

Watch this video and pay close attention to the effector an extruder..

[m.youtube.com]

I dont think the weight you are referring to is detrimental.

It may even improve print quality.

[m.youtube.com]

I dont think the weight you are referring to is detrimental.

It may even improve print quality.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 17, 2015 10:19PM |

Registered: 9 years ago Posts: 127 |

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 03:46AM |

Registered: 9 years ago Posts: 483 |

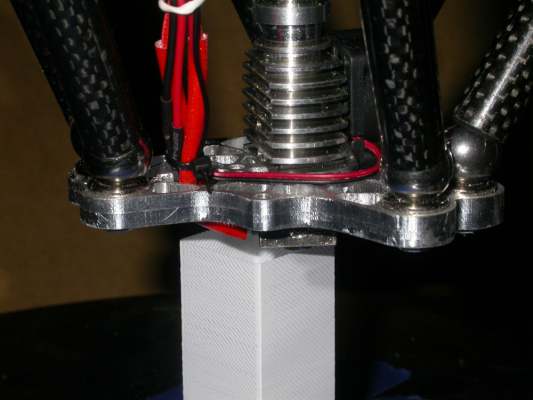

My aluminum effector weighs 22 grams by itself. Adding the ball bearings (14mm) and magnets bring the weight up to 110 grams. It's more than rigid enough, so I could probably shave a couple more grams from the effector, but it wouldn't change the overall weight enough to make it worth the effort.

Here's a shot of it with a Prometheus hot end attached.

Here's a shot of it with a Prometheus hot end attached.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 04:40AM |

Registered: 10 years ago Posts: 732 |

I looked at the video and I do not see your point. The print speed is extremely low for a delta printer. What they are showing is not what we would like to see.Quote

thetazzbot

Watch this video and pay close attention to the effector an extruder..

[m.youtube.com]

I dont think the weight you are referring to is detrimental.

It may even improve print quality.

The bowden tube is nicely short. There should be less problems with retraction setup. And the bowden still isolates the stepper from high frequency speed changes which do not span a big distance. That is good. It should be able to print pretty fast at least the small infill areas. But it is not shown on the video.

What we would like to see how it behaves when it is doing:

- high speed and high acceleration infill of small areas

- long and fast non-printing moves (about 200 mm long at about 250-300 mm/s and at least 7000 mm/s²

I doubt that platform rigidity is a problem compared to the ones I mentioned above. I can tell that the traditional rostock has the biggest problems with:

- diagonal rods (we need proper tight angle (ball) joints)

- frame is not stiff enough

- smooth rods are not stiff enough (they should be at least Ø12 mm)

- betls have too low young's modulus (they are too springy); and this is the original T2.5 steel core belts, GT2 glass core belts are much worse; spectra is better than glass but worse than steel

- I did not evaluate the stepper dynamic moment, there may be a problem there too, for now I just run them at as high current as I can

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 04:43AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Ezrec

I see them on Ultibots and Aliexpress, and other places.

But I have yet to find a CAD drawing - it's hard to order something if I don't know it's going to fit!

The Robotdigg Alluminium effector weighs 36 grammes and is 39.7 mm accros the ball mounting points and follows the Mini Kossel printed one almost exactly the centre hole is 16mm same ad a J-Head or E3D Hotend mounting and at $15 it is a snip especially if you use there Robotdigg Alloy carriages (at $30 a set for open ended belts or $28 if you want the closed belt ones) carriages as well

Doug

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 09:18AM |

Registered: 8 years ago Posts: 396 |

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 03:54PM |

Registered: 10 years ago Posts: 732 |

Well, the extruder stepper is connected through the flexible bowden and the rubber bands. It will always experience lower accelerations and therefore its weight should not be counted in full.

I would really like to see how can it cope with long quick moves and whether it would not catch some crazy oscillations (resonance) for some "unfortunate" gcode.

But yes, a slightly heavier platform will work too. The only consequence is a slightly smaller maximum accelerations.

I would really like to see how can it cope with long quick moves and whether it would not catch some crazy oscillations (resonance) for some "unfortunate" gcode.

But yes, a slightly heavier platform will work too. The only consequence is a slightly smaller maximum accelerations.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 04:39PM |

Registered: 9 years ago Posts: 569 |

|

Re: Benefits / Drawbacks of Metal Effector Plates September 18, 2015 07:09PM |

Registered: 9 years ago Posts: 483 |

Positioning a print cooling fan is easier with the hotend below the effector. I don't think this is much of a benefit though. The heat sink above the effector gives makes more vertical space available for the print. It also lessens the effects of a tilted effector (for example:if your arms aren't exactly the same length). The effector definitely increases the cooling area.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 24, 2015 04:09PM |

Registered: 10 years ago Posts: 469 |

I just ordered a kossel effector in metal. 13bux shipped. Not a bad deal. I am hoping to use it as part of the heatsink and remove the fan altogether.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Benefits / Drawbacks of Metal Effector Plates September 24, 2015 04:39PM |

Registered: 9 years ago Posts: 445 |

Quote

jaguarking11

I just ordered a kossel effector in metal. 13bux shipped. Not a bad deal. I am hoping to use it as part of the heatsink and remove the fan altogether.

Don't know what hotend you are using, but with an E3D v6 I don't think the cooling will be sufficient, I think the heat will creep to far up the heatbreak to cause blockage.

The contact surface between the effector and the heatsink is at the highest point and rather small.

|

Re: Benefits / Drawbacks of Metal Effector Plates September 25, 2015 12:07AM |

Registered: 9 years ago Posts: 483 |

|

Re: Benefits / Drawbacks of Metal Effector Plates October 26, 2015 03:14PM |

Registered: 10 years ago Posts: 469 |

To follow up with this. I got the metal effector in the mail. Its definitely way too heavy. Its also has a very small hole for the hot end. I am hoping to bore the effector out in the middle to atach the heat sink. I only print with abs, my retraction is less than 4mm, there is no problem in printing with no fan if the machine is not closed. Now that I have a heated chamber I installed a cheap very weak fan to the heatsink with no shrouding as I was getting the ocasional clog without it.

For me the plan is as follows.

1 - Bore out the center hole to almost the same size as the heatsink, This will reduce both weight and provide a contact point for the bottom fin to conduct heat to the body.

2 - Bore out lightening holes all around the metal plate to lighten it up as much as possible while retaining its strength.

The final goal is to get the metal plate to weigh in around the same amount as its plastic counterpart and remove the fan altogether, while reducing the hardware count (read weight) I will be installing spacers that are in the 10mm range, made of light antenna tubes to get the arm spacing proper.

All of this will not happen until at least December though.

Further thoughts.

Getting a cheap p4 era heatsink that is all aluminum and cut it into a triangle shape.

Cross drill the heatsink to reduce weight further.

Install spacers for arm mounting.

drill center hole in m6 format and install heatbreak. install bowden tube ontop.

Passive heatsink/effector combo with not too much weight. Being that most heat-sinks are extruded the quality would be superior to the cast parts I am seeing now.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

For me the plan is as follows.

1 - Bore out the center hole to almost the same size as the heatsink, This will reduce both weight and provide a contact point for the bottom fin to conduct heat to the body.

2 - Bore out lightening holes all around the metal plate to lighten it up as much as possible while retaining its strength.

The final goal is to get the metal plate to weigh in around the same amount as its plastic counterpart and remove the fan altogether, while reducing the hardware count (read weight) I will be installing spacers that are in the 10mm range, made of light antenna tubes to get the arm spacing proper.

All of this will not happen until at least December though.

Further thoughts.

Getting a cheap p4 era heatsink that is all aluminum and cut it into a triangle shape.

Cross drill the heatsink to reduce weight further.

Install spacers for arm mounting.

drill center hole in m6 format and install heatbreak. install bowden tube ontop.

Passive heatsink/effector combo with not too much weight. Being that most heat-sinks are extruded the quality would be superior to the cast parts I am seeing now.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

Sorry, only registered users may post in this forum.