265mm 12V/24V round heatbed feedbacks needed

Posted by darkoddio

|

265mm 12V/24V round heatbed feedbacks needed February 17, 2016 04:59AM |

Registered: 8 years ago Posts: 14 |

Hi all

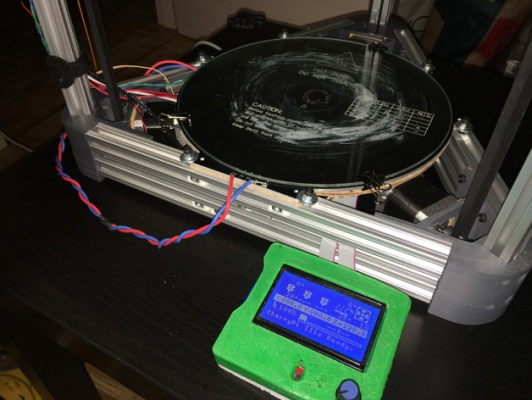

I'm building my new Delta printer based on Cherry Pi IIIs from AndyCart.

I bought the above heatbed from Aliexpress

I mounted it with the black surface up, with glass on top.

Afterwards I red that I can also print directly on the alluminium side (this means black side down). Maybe I will give it a try.

The heatbed is currently connected to D8 on RAMPS 1.4

I had to change the MOSFET on the RAMPS because the original one was getting too hot and cutting the power to the heatbed.

Voltage on the bed itself is around 11.20V.

After some test I can now heat the bed (without glass) to 90° in 20 minutes (putting some cork also over the glass while heating)

If I add the glass over the black side, I can heat the bed up to 87° in 25 minutes.

Isn't it too much time?

I'm searching for other users that have the same heatbed to share some experience

I would like to have some info like:

- how do you power it? 12V or 24V?

- does heating with 24V speed the process?

- do you use 12V/24V booster connected to RAMPS D8?

- how much does it take to heat the bed? can you reach 100°?

- are you printing directly on aluminium side or on the glass?

Edited 1 time(s). Last edit at 02/17/2016 05:00AM by darkoddio.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 17, 2016 08:12AM |

Registered: 10 years ago Posts: 14,672 |

Unfortunately you've chosen both the bed heater and the electronics poorly IMO. PCB heaters are notorious for being under powered, and Arduino/RAMPS has the most limitations and drawbacks of all the common electronics.

You are losing 13% of your heating power because the bed heater voltage is 11.2V instead of 12V. So using thicker wires form the PSU and to the bed heater may help.

If you are using a Chinese LED/CCTV supply, then by turning up the voltage adjustment pot to 14V you can get 36% more heating power than with 12v, which might be enough. But Arduino/RAMPS doesn't really like more than 12V, especially if you are powering an LCD from it as well. You can overcome this by adding an external 5V regulator to the RAMPS, however your bed heater may be drawing more than 10A with the voltage turned up to 14V. So you will need to replace the 11A fuse as well.

If you were starting again, I would recommend you use 28V-capable electronics. Deltas benefit form 32-bit electronics.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You are losing 13% of your heating power because the bed heater voltage is 11.2V instead of 12V. So using thicker wires form the PSU and to the bed heater may help.

If you are using a Chinese LED/CCTV supply, then by turning up the voltage adjustment pot to 14V you can get 36% more heating power than with 12v, which might be enough. But Arduino/RAMPS doesn't really like more than 12V, especially if you are powering an LCD from it as well. You can overcome this by adding an external 5V regulator to the RAMPS, however your bed heater may be drawing more than 10A with the voltage turned up to 14V. So you will need to replace the 11A fuse as well.

If you were starting again, I would recommend you use 28V-capable electronics. Deltas benefit form 32-bit electronics.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 17, 2016 01:19PM |

Registered: 10 years ago Posts: 293 |

I'd recommend one of the below SSR's and a separate supply for the heated bed.

[www.auberins.com]

The RAMPS FET will then only need to drive the SSR (which it can easily do) the SSR will isolate your heated bed from the RAMPS board which would allow you to pump a bit more power into the bed (within reason). For instance you could go 15V or so for the bed (at 12V terminals) while still running the RAMPS board at 12V, the limit here is to not overload the traces with too much current.

I'm assuming you don't want to replace either the RAMPS board or the heated bed.

Edited 1 time(s). Last edit at 02/17/2016 01:22PM by WZ9V.

[www.auberins.com]

The RAMPS FET will then only need to drive the SSR (which it can easily do) the SSR will isolate your heated bed from the RAMPS board which would allow you to pump a bit more power into the bed (within reason). For instance you could go 15V or so for the bed (at 12V terminals) while still running the RAMPS board at 12V, the limit here is to not overload the traces with too much current.

I'm assuming you don't want to replace either the RAMPS board or the heated bed.

Edited 1 time(s). Last edit at 02/17/2016 01:22PM by WZ9V.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 17, 2016 04:52PM |

Registered: 8 years ago Posts: 14 |

yes, SSR was already an option: I'm about to buy this one [www.amazon.it]

even if I need to buy another power supply: any suggestion? how many amps should have it? I guess at least 10A, right?

EDIT

since the heatbed is 120W, if I want 15V it should have 8A, if I'm right

What about something like this? [www.ebay.it]

Edited 2 time(s). Last edit at 02/17/2016 06:53PM by darkoddio.

even if I need to buy another power supply: any suggestion? how many amps should have it? I guess at least 10A, right?

EDIT

since the heatbed is 120W, if I want 15V it should have 8A, if I'm right

What about something like this? [www.ebay.it]

Edited 2 time(s). Last edit at 02/17/2016 06:53PM by darkoddio.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 17, 2016 09:04PM |

Registered: 10 years ago Posts: 293 |

I would not risk it on an Amazon SSR. The one I posted has a proper FET design with a low on resistance. There are a lot of cheap ones using a BJT that will get VERY HOT. I tested one that at 17A load was reaching close to 70C with the huge heatsink. Even with the heatsink and a fan it was still around 40C. The one I posted barely gets warm at similar loads.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 03:19AM |

Registered: 10 years ago Posts: 14,672 |

Quote

WZ9V

I would not risk it on an Amazon SSR. The one I posted has a proper FET design with a low on resistance. There are a lot of cheap ones using a BJT that will get VERY HOT. I tested one that at 17A load was reaching close to 70C with the huge heatsink. Even with the heatsink and a fan it was still around 40C. The one I posted barely gets warm at similar loads.

Seconded, that Amazon one is a SSR-25DD which is useless for this application because of its high voltage drop.

Edited 1 time(s). Last edit at 02/18/2016 03:20AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 05:49AM |

Registered: 8 years ago Posts: 14 |

please help, how to identify the voltage drop?

what about this SSR-60DD [www.amazon.it] ?

I'm a bit unwilling to buy from US, I would like to find an alternative in Europe

what about this SSR-60DD [www.amazon.it] ?

I'm a bit unwilling to buy from US, I would like to find an alternative in Europe

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 06:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

darkoddio

please help, how to identify the voltage drop?

what about this SSR-60DD [www.amazon.it] ?

I'm a bit unwilling to buy from US, I would like to find an alternative in Europe

Read the reviews, you will see that it gets very hot, indicating it has high voltage drop.

I've not used one, but the Power Expander from reprap.me in Denmark should be up to the job.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 08:29AM |

Registered: 8 years ago Posts: 14 |

Hi dc42

I somehow missed the Power Expander [reprap.me]

It seems that it is actually exactly what I'm searching for

Do you have any suggestion about the additional power supply?

Do you think the one I link here is enough? [www.ebay.it]

regards

I somehow missed the Power Expander [reprap.me]

It seems that it is actually exactly what I'm searching for

Do you have any suggestion about the additional power supply?

Do you think the one I link here is enough? [www.ebay.it]

regards

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 01:10PM |

Registered: 10 years ago Posts: 293 |

Unfortunately most DC SSR listings hide the one piece of information that would help which is the on resistance. If it's around 0.1 ohm it's a design using a bipolar transistor or really crappy FET, if it's around 0.006 ohms it's a much better FET design.

I have one of each, using ohms laws

Crappy SSR at 17A = 28.9W lost to waste power (Heat) - 10% power loss in SSR

Good SSR at 17A = 1.7W lost to waste power (Heat) - 0.6% power loss in SSR

In my 17A test setup, Crappy SSR got to 70C with the big honking heat sink. Good SSR barely gets warm.

I have one of each, using ohms laws

Crappy SSR at 17A = 28.9W lost to waste power (Heat) - 10% power loss in SSR

Good SSR at 17A = 1.7W lost to waste power (Heat) - 0.6% power loss in SSR

In my 17A test setup, Crappy SSR got to 70C with the big honking heat sink. Good SSR barely gets warm.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 06:47PM |

Registered: 10 years ago Posts: 14,672 |

Quote

darkoddio

Hi dc42

I somehow missed the Power Expander [reprap.me]

It seems that it is actually exactly what I'm searching for

Do you have any suggestion about the additional power supply?

Do you think the one I link here is enough? [www.ebay.it]

regards

I would use a single 12V 300W LED/CCTV power supply, and replace the crappy RAMPS by 32-bit electronics more suited to running a delta and not limited to 12V. No relay will be needed if you choose electronics capable of switching 12 or 13A to the bed.

Edited 2 time(s). Last edit at 02/18/2016 06:49PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 07:31PM |

Registered: 8 years ago Posts: 14 |

Well, I'm currently using an HP DPS-600PB (575W 12.15V 47A) server power supply that should be more than enough to power whatever is connected to it

I'm a bit confused: why are you suggesting to use a 12V power supply and at the same time to switch to 32bit electronics (please provide an example) because it has no 12V limit?

What's the advantage then?

If I'm right, many delta kits are provided with same RAMPS as mine (maybe not from china? )

)

BTW I did one more test: I can reach 90° in 13 minutes and 100° in 20 minutes

Actually, even with my crappy RAMPS and quite big aluminium heatbed, I'm getting better results than other users on this forum

We must keep in consideration that this heatbed is 20% bigger than the "standard" square 214x214 ones

FYI, these are voltage readings:

in stand by:

12.67V input in both 5A and 11A RAMPS connectors

when heating bed:

12.37V input in 5A RAMPS connector

11.85V input in 11A RAMPS connector (I've recently connected here also a 12V 60x60 fan for electronics, is it right?)

11.22V out of D8

11.07V on bed pads

Edited 1 time(s). Last edit at 02/18/2016 07:31PM by darkoddio.

I'm a bit confused: why are you suggesting to use a 12V power supply and at the same time to switch to 32bit electronics (please provide an example) because it has no 12V limit?

What's the advantage then?

If I'm right, many delta kits are provided with same RAMPS as mine (maybe not from china?

)

)BTW I did one more test: I can reach 90° in 13 minutes and 100° in 20 minutes

Actually, even with my crappy RAMPS and quite big aluminium heatbed, I'm getting better results than other users on this forum

We must keep in consideration that this heatbed is 20% bigger than the "standard" square 214x214 ones

FYI, these are voltage readings:

in stand by:

12.67V input in both 5A and 11A RAMPS connectors

when heating bed:

12.37V input in 5A RAMPS connector

11.85V input in 11A RAMPS connector (I've recently connected here also a 12V 60x60 fan for electronics, is it right?)

11.22V out of D8

11.07V on bed pads

Edited 1 time(s). Last edit at 02/18/2016 07:31PM by darkoddio.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 18, 2016 07:52PM |

Registered: 10 years ago Posts: 14,672 |

I am suggesting you use a 12V LED supply turned up to about 14V using the voltage adjustment pot that these supplies have. I think I mentioned before that turning up the supply voltage beyond 12V is not a good idea if you are using RAMPS.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 05:45AM |

Registered: 8 years ago Posts: 14 |

Yes, you suggested to turn up the voltage

I missed the reference in your first post to the power supply having the voltage pot, sorry

What 32bit board were you referring to?

So I see 3 options to improve my heatbed performance (in order of preference):

1) replace power supply with LED having voltage pot and increasing it to 14V, keeping existing electronics

2) SSR + dedicated power supply

3) replace electronics and keep current power supply

Am I right? Anything else?

I missed the reference in your first post to the power supply having the voltage pot, sorry

What 32bit board were you referring to?

So I see 3 options to improve my heatbed performance (in order of preference):

1) replace power supply with LED having voltage pot and increasing it to 14V, keeping existing electronics

2) SSR + dedicated power supply

3) replace electronics and keep current power supply

Am I right? Anything else?

|

Anonymous User

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 07:11AM |

You can go the expensive way, of SSRs, 32bit electronic, ....

I'd recommend to:

1.) get a cheap 180W 12V Powersupply from China, where you can increase the voltage to about 14-15V like this: ebay --> on the right side of the terminals is a turnable resistor for changing the voltage...

--> Separate Powersupply, so the RAMPS can stil have its needed 12V...

ATTENTION! If your Heatbed has 120W at 12V, it means at 15V it has 187.5W! - The Current increases the same ammount, the voltage is increased, because the resisstance is stable!

2.) get a MOSFET like IRF540Z - has a very low RDSon and is perfect to be driven by 5V electronics like RAMPS.

3.) Solder one Wire to the Gate (left pin) of the Heatbed FET on the RAMPS, and solder it to the new IRF540Z

4.) Connect the "-" of the both powersupplies

5.) connect the "+" of the new powersuplly to the Heatbed

6.) Connect the '-' of the Heatbed to the new IRF540Z (middle Pin)

7.) Connect the right Pin of the new IRF540Z to the '-' of the Powersupply

Wires for steps 5,6,7 should have higher diameter/cross section (As you are from Europe I'd recommend 2,5mm²-Wire)

Eventually attach small cooling fins to IRF540Z - I have None and it still stays cool...

Edited 1 time(s). Last edit at 02/19/2016 07:12AM by Sir_Death.

I'd recommend to:

1.) get a cheap 180W 12V Powersupply from China, where you can increase the voltage to about 14-15V like this: ebay --> on the right side of the terminals is a turnable resistor for changing the voltage...

--> Separate Powersupply, so the RAMPS can stil have its needed 12V...

ATTENTION! If your Heatbed has 120W at 12V, it means at 15V it has 187.5W! - The Current increases the same ammount, the voltage is increased, because the resisstance is stable!

2.) get a MOSFET like IRF540Z - has a very low RDSon and is perfect to be driven by 5V electronics like RAMPS.

3.) Solder one Wire to the Gate (left pin) of the Heatbed FET on the RAMPS, and solder it to the new IRF540Z

4.) Connect the "-" of the both powersupplies

5.) connect the "+" of the new powersuplly to the Heatbed

6.) Connect the '-' of the Heatbed to the new IRF540Z (middle Pin)

7.) Connect the right Pin of the new IRF540Z to the '-' of the Powersupply

Wires for steps 5,6,7 should have higher diameter/cross section (As you are from Europe I'd recommend 2,5mm²-Wire)

Eventually attach small cooling fins to IRF540Z - I have None and it still stays cool...

Edited 1 time(s). Last edit at 02/19/2016 07:12AM by Sir_Death.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 07:35AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Sir_Death

You can go the expensive way, of SSRs, 32bit electronic, ....

I was suggesting using modern electronics (which may as well be 32-bit), NO SSR, and only one power supply. By the time you have spent money on a second PSU and SSR, you might as well have bought a decent controller board.

btw the IRF540Z is most definitely a bad choice for what you are proposing - it id designed for 10V gate drive, not 5V, as the datasheet [www.irf.com] makes clear.

The OP does have another alternative. Keep the main 12V power supply, use a separate 24V LED PSU (probably turned up to 28V) to feed the 11A input to the RAMPS, use the 24V connections on the bed heater, and drive it directly from the RAMPS. This assumes that the heated bed FET he replaced on the RAMPS is rated 30V or more. Also the 11A fuse on the RAMPS would have to be replaced by an automobile-type fuse to handle the higher voltage.

Edited 2 time(s). Last edit at 02/19/2016 07:39AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Anonymous User

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 08:04AM |

Quote

dc42

Quote

Sir_Death

You can go the expensive way, of SSRs, 32bit electronic, ....

I was suggesting using modern electronics (which may as well be 32-bit), NO SSR, and only one power supply. By the time you have spent money on a second PSU and SSR, you might as well have bought a decent controller board.

btw the IRF540Z is most definitely a bad choice for what you are proposing - it id designed for 10V gate drive, not 5V, as the datasheet [www.irf.com] makes clear.

The OP does have another alternative. Keep the main 12V power supply, use a separate 24V LED PSU (probably turned up to 28V) to feed the 11A input to the RAMPS, use the 24V connections on the bed heater, and drive it directly from the RAMPS. This assumes that the heated bed FET he replaced on the RAMPS is rated 30V or more. Also the 11A fuse on the RAMPS would have to be replaced by an automobile-type fuse to handle the higher voltage.

I do not see anything in the IRF540Z Datasheet for the need of 10V VGS...

Page 2: Static Drain-to-Source On-Resistance is max 26.5mOhm at 10V UGS - does not say what it is at 5V....

Page 2: Gate Threshold Voltage: Min 2V, Max 4V

Page 3: Fig 3. Typical Transfer Characteristics says even TJ at Roomtemperature, VGS at 5V -->ID of over 20A possible

Page 5: Fig 10. Normalized On-Resistance Vs. Temperature only gives the RDSon at 10V UGS... but it does not say 10V is needed...

I've built many electronic devices using IRF540Z always directly connected to 5V Controllers... they are still working - some of them since many years for 24h/365 days in PWM usage... --> always switching...

So "...most definitely a bad choce...." --> get some, test them and don't spread rumors if you never used them.

EDIT: Maybe you should ad to your Signature why you would like everybody to purchase a 32bit Controller... and afterwards the paneldue....

Edited 1 time(s). Last edit at 02/19/2016 08:51AM by Sir_Death.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 10:47AM |

Registered: 8 years ago Posts: 14 |

Quote

dc42

The OP does have another alternative. Keep the main 12V power supply, use a separate 24V LED PSU (probably turned up to 28V) to feed the 11A input to the RAMPS, use the 24V connections on the bed heater, and drive it directly from the RAMPS. This assumes that the heated bed FET he replaced on the RAMPS is rated 30V or more. Also the 11A fuse on the RAMPS would have to be replaced by an automobile-type fuse to handle the higher voltage.

By "11A fuse" you mean I need to replace F2, like the one that RAMPS 1.4.2 has, correct?

There is no much space there, but I can try

But if I remember correctly the new MOSFET is irl2203n [www.irf.com]

If you mean Gate-to-Source, the value it is 16V.

BTW as far as I understood from other users experience, running the bed at 24V using 24V pads does not accelerate the heating process, while it is worth to run it at 14/15V using 12V pads.

There is also one guy that wired it at 12V and feeding with 24V

What if I use a 14V power supply to feed the 11A input to the RAMPS? do you think I need to replace the F2 fuse?

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 01:45PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Sir_Death

Quote

dc42

Quote

Sir_Death

You can go the expensive way, of SSRs, 32bit electronic, ....

I was suggesting using modern electronics (which may as well be 32-bit), NO SSR, and only one power supply. By the time you have spent money on a second PSU and SSR, you might as well have bought a decent controller board.

btw the IRF540Z is most definitely a bad choice for what you are proposing - it id designed for 10V gate drive, not 5V, as the datasheet [www.irf.com] makes clear.

The OP does have another alternative. Keep the main 12V power supply, use a separate 24V LED PSU (probably turned up to 28V) to feed the 11A input to the RAMPS, use the 24V connections on the bed heater, and drive it directly from the RAMPS. This assumes that the heated bed FET he replaced on the RAMPS is rated 30V or more. Also the 11A fuse on the RAMPS would have to be replaced by an automobile-type fuse to handle the higher voltage.

I do not see anything in the IRF540Z Datasheet for the need of 10V VGS...

Page 2: Static Drain-to-Source On-Resistance is max 26.5mOhm at 10V UGS - does not say what it is at 5V....

Page 2: Gate Threshold Voltage: Min 2V, Max 4V

Page 3: Fig 3. Typical Transfer Characteristics says even TJ at Roomtemperature, VGS at 5V -->ID of over 20A possible

Page 5: Fig 10. Normalized On-Resistance Vs. Temperature only gives the RDSon at 10V UGS... but it does not say 10V is needed...

I've built many electronic devices using IRF540Z always directly connected to 5V Controllers... they are still working - some of them since many years for 24h/365 days in PWM usage... --> always switching...

So "...most definitely a bad choce...." --> get some, test them and don't spread rumors if you never used them.

You are clearly an electronics amateur because you don't appreciate the difference between typical characteristics (which will be met or exceeded only if you are lucky) and guaranteed characteristics. You pointed out yourself that the gate threshold voltage can be as high as 4V for that device. That means it may only just start to conduct at 4V. Another 1V (assuming the 5V rail really is at precisely 5V and not lower e.g. 4.75V) isn't going to turn it on enough to conduct enough current for the heated bed. The STP55NF06L mosfet specified on RAMPS 1.4 isn't a very good choice by modern standards, but it is far better for the purpose than your IRF540Z, i.e. Rds(on) guaranteed no more than 0.02 ohms @ Vgs = 5V, Ids = 27.5A, vs. Rds(on) guaranteed no more than 0.0265 ohms @ Id = 22A and Vgs double what is actually provided.

Quote

Sir_Death

EDIT: Maybe you should ad to your Signature why you would like everybody to purchase a 32bit Controller... and afterwards the paneldue....

The reason I suggest modern electronics instead of the ancient Arduino/RAMPS combination is that Arduino/RAMPS has too many traps for novices, e.g. getting the motor currents wrong or killing the drivers whole trying to set them, killing the 5V regulator if you miswire the endstop switches, overheating the 5V regulator if you connect a graphics LCD, or (as here) needing to turn up the power supply voltage to work around an under-powered bed heater, but that is also liable to overheat the voltage regulator. I recently helped someone fix a printer that was assembled by a supposed professional 3D printer builder, and even on that one the motor currents were way off what they should be, causing some drivers to overheat and some motors to produce too little torque. If the pros can't get it right, what hope is there for novices?

Edited 1 time(s). Last edit at 02/19/2016 01:56PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 01:56PM |

Registered: 10 years ago Posts: 14,672 |

Quote

darkoddio

By "11A fuse" you mean I need to replace F2, like the one that RAMPS 1.4.2 has, correct?

Yes. The specified 11A polyfuse has a voltage rating of 16V AFAIR, meaning that if you use a 28V supply and then short out the bed then the polyfuse will get hot enough to burn out or maybe start a fire.

Quote

darkoddio

But if I remember correctly the new MOSFET is irl2203n [www.irf.com]

If you mean Gate-to-Source, the value it is 16V.

I mean Vdss, which is 30V for that mosfet, so OK.

Quote

darkoddio

BTW as far as I understood from other users experience, running the bed at 24V using 24V pads does not accelerate the heating process, while it is worth to run it at 14/15V using 12V pads.

Using 24V and the 24V pads instead of 12V using the 12V pads will give you a small improvement because the loss in the PSU and heated bed connecting wires, the mosfet and the fuse will be lower. The real benefit is that when you turn up the voltage from 24V to 28V, the current only goes up from nominally 5A to 5.8A, which is well within the capacirty of the mosfet and the connectors on the RAMPS. Whereas if you use a 12V supply and turn it up to 14V, then the current goes up from nominally 10A to 11.6A, which is higher than the RAMPS was designed for and the 11A fuse rating.

Sounds like a good way to start a fire or burn out the heater to me. That will run the bed heater at four times the power it was designed for.

Quote

darkoddio

What if I use a 14V power supply to feed the 11A input to the RAMPS? do you think I need to replace the F2 fuse?

Yes, because the bed heater will probably take more than 11A @ 14V.

Edited 2 time(s). Last edit at 02/19/2016 01:58PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 06:08PM |

Registered: 8 years ago Posts: 14 |

I was wrong, sorryQuote

dc42

I mean Vdss, which is 30V for that mosfet, so OK.Quote

darkoddio

But if I remember correctly the new MOSFET is irl2203n [www.irf.com]

If you mean Gate-to-Source, the value it is 16V.

it is irlb8743 but Vdss should be 30V as well

mmm, I'm not an electrician expert, so maybe I'm wrong, but if the bed absorbs 120W and I use 14V 120W power supply, isn't the bed going to take 8.6A?Quote

dc42

Yes, because the bed heater will probably take more than 11A @ 14V.Quote

darkoddio

What if I use a 14V power supply to feed the 11A input to the RAMPS? do you think I need to replace the F2 fuse?

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 06:14PM |

Registered: 10 years ago Posts: 14,672 |

Quote

darkoddio

mmm, I'm not an electrician expert, so maybe I'm wrong, but if the bed absorbs 120W and I use 14V 120W power supply, isn't the bed going to take 8.6A?

The bed absorbs 120W at 12V. The point of increasing the voltage is to make it absorb more power, and thereby produce more heat. If we ignore the small increase in resistance as the bed gets hotter, at 14V it will draw 163W.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 19, 2016 06:55PM |

Registered: 10 years ago Posts: 293 |

Power = Voltage * Current

Power = Current(squared) * Resistance

Current = Voltage / Resistance

As DC42 said power is not a constant, it depends on the Voltage and Resistance values. Since they control the Current and Current is the main driving factor in power as you can see I the two equations above the power changes as you change the voltage.

Power = Current(squared) * Resistance

Current = Voltage / Resistance

As DC42 said power is not a constant, it depends on the Voltage and Resistance values. Since they control the Current and Current is the main driving factor in power as you can see I the two equations above the power changes as you change the voltage.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 20, 2016 04:12AM |

Registered: 8 years ago Posts: 14 |

Yes, thanksQuote

WZ9V

Power = Voltage * Current

Power = Current(squared) * Resistance

Current = Voltage / Resistance

As DC42 said power is not a constant, it depends on the Voltage and Resistance values. Since they control the Current and Current is the main driving factor in power as you can see I the two equations above the power changes as you change the voltage.

I found them yesterday just after writing my post

This means that, if I want to use a dedicated power supply for the bed, I need to go for at least 14V/160W or 15V/190W

I also found a way to raise the voltage of my power supply up to 13.8 [www.ultimaterc.com]

Not sure if it is enough and btw I think I cannot connect it directly to 5A input on ramps

Edited 1 time(s). Last edit at 02/20/2016 04:29AM by darkoddio.

|

Re: 265mm 12V/24V round heatbed feedbacks needed February 20, 2016 05:09AM |

Registered: 10 years ago Posts: 14,672 |

Quote

darkoddio

I also found a way to raise the voltage of my power supply up to 13.8 [www.ultimaterc.com]

Not sure if it is enough and btw I think I cannot connect it directly to 5A input on ramps

13.8V will give you 32% more heating power than 12v. But you risk drawing more than 10A from the RAMPS - unless your bed heater was drawing less than 10A to start with, which may be the case. As you have already changed the mosfet for a better one, you may choose to risk this. If you then find that the 11A polyfuse is getting very hot, you can replace it by a 15A auto fuse - which will also give you a little more heating power by reducing the voltage drop in the fuse.

An Arduino/RAMPS with no other loads on the 5V rail can handle 13.8V on the 5A input; but if you have an LCD panel connected then you risk overheating the voltage regulator (or it may be overheating already). You could work around this by adding an external regulator to provide 5V and removing D1, or by putting about 3 more silicon diodes in series with D1. Feeding the Arduino/RAMPS 5V from the server PSU may be another option, but only if increasing the 12V output voltage doesn't also increase the 5V output.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.