My large Delta 5 years on.....

Posted by aussiephil

|

My large Delta 5 years on..... July 12, 2021 09:26AM |

Registered: 8 years ago Posts: 177 |

History - recap

Back in 2016 I embarked on building a large delta [reprap.org] and had reason recently to reflect back on that thread to ubderstand when i built this thing and some of the reasons

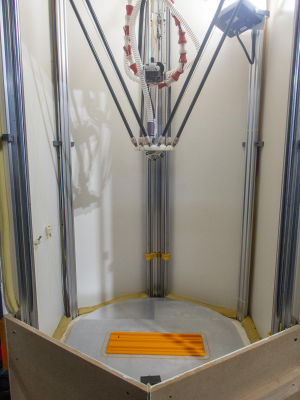

The goal was to have something with a large build volume in this case it is around 590 round and 500 tall.

Something that was faster than my FlashForge Pro

Faster and bigger, sounds familiar.

Insipration was taken from the large delta by 3DR at the time.

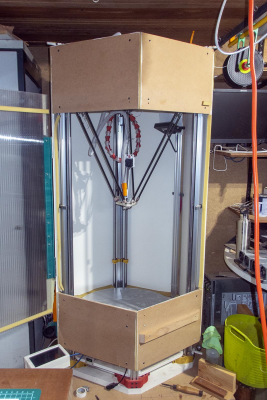

It morphed into a hexagonal shape with 5.1 towers, the .1 is the front tower that is essentially just stubs for enclosure mounting.

Despite warnings from DC42 I still used a lot of printed parts.

The name was taken from the hexagonal shape and the mega sizing.

A flying Titan extruder and a Dyze Design hotend were picked.

I started with one of the original Duet 0.8.5 beta boards and eventually it got a Duet Wifi installed.

It got used for about 12 months on and off, it always seemed like to much trouble to fire this thing up and eventually just got surrounded by shed related things and stopped being used completely.

4 years later the Flashforge Pro was feeling restrictive again despite still working hard and the plans started in the head to build a CoreXY with at least 500mm on one axis.

To do this I needed to free up some bench space and this kicked off a "i need a new bench for a new printer cycle" This has resulted in a near full garage fit out with 4 full workbench's built including one 4Metre long monster, the bench for the printer is still not built... but i know were it's going

As part of this I had to move the MHD from one side to the other. This gave me access again and i could look at getting it running again.

Nearly a year later and 5 years on from the initial build:

Initial inspection of the unit showed a pretty big show stopper to get it running ... the printed bearing blocks for each tower had significant cracking just from age.

I have always printed in ABS and these had been printed in a transparent ABS that I have come to hate as it printed and felt more like a PLA, hard and brittle to work with rather than typical easy to work ABS.

The rear sections looked solid with no cracks so just printed the front sections and changed over.

All good, so onto the Duet Wifi and just what had changed in 5 years.... answer a lot!!

I was in 1.15 and v3.3 had just been released, time to bite the bullet and upgrade. Got past the Wifi connection setting when going to 2.x first then 3.0 before finally hitting 3.3... seemed like forever to do... Many thanks still to DC42 and the team for the excellent documentation and support forum.

Moment of truth time, would anything work we turned on everything, light, no camera, action. everything moved the unit homed, bed heated up, hot-end heated up so set about running through commissioning this unit again.

Checked the extruder was working with some PLA.... had to be at least 4 years old and just pulled out of a draw

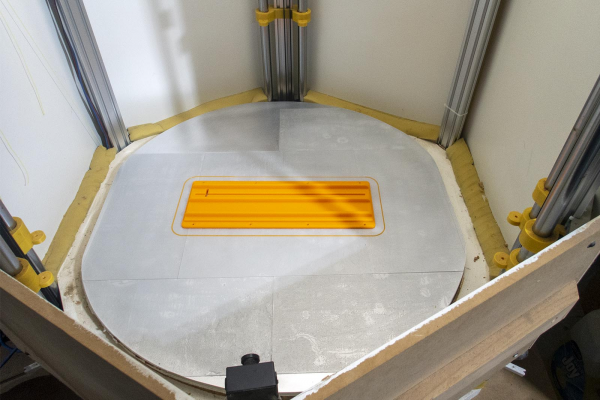

Stripped the Kapton tape from the bed and gave the 8mm cast plate a clean and then a 220 grit sand with the sander to create a matt finish so the IR probe would work correctly.

I shifted over to using PEI on the flashforge bed so parked the progress and ordered 4 sheets of 300 square so i could tile the surface with PEI.

the Dyze is running a 0.6 nozzle so pulled that out and gave it a multiday soak in acetone whilst waiting for the PEI, finally got it nice and clean after a week

I know the bed is essentially flat so for the time being I have just got Z0 correct in the middle and got consistent IR probing in the middle.

My tip for the PEI is to sand the printing surface to a matt look, initial adhesion is good whilst parts still let go as long as you get the intial Z height correct.

In got a 400mm square magnetic spring steel plate with textured powder coated PEI coming in... after pricing a 600 and 500 round versions I'm prepared to suffer the loss of build area (i think)

I have been printing again with this one for a couple of weekends now with about 5kg of old PLA disappearing at a rate last weekend that said... order more, dangerously the place i buy a lot of filament from also stocks BondTech in AU and I had been eyeing off the new LGX extruder for use in a new printer so ordered one for testing along with a 5kg of PLA.

Whilst swapping over the extruder I had time to notice that the old back half of the bearing blocks also had some pretty major cracks now!! oh well that's the crappy transparent ABS biting me again.

I am so glad still to have those in Fusion 360 .... the worry is i can't find the extruder carriage in the drawings and it's printed from the same rubbish.

Grabbed a couple rolls of PETG to try out as I have been reading a lot about this wonderful filament in a couple facebook groups so ordered some to try.

mmm love the PETG.... hate having to print it slow.

Doing some very rough free air extrusion volumetric tests shows the Dyze hotend seems to max out around 16mm cubed of flow .... I have a HF dragon on a slow boat so that may/should speed things up.

Note that the extruder is cooled by remote fan, initially i used PVC tubing but it is heavy and stiff and restrictive, have found that the CPAP tubing is excellent for this.

As a side note the idea for a CoreXY has now changed to building a standard Cartesian IDEX or more correctly IDEY printer with a 400x600 print bed, external dimensions will be whatever is needed. primary usage will be ditto printing smaller parts especially for xmas light display stuff. So orientate the print heads on the normal Y axis (400mm).

So five years on thoughts:

I would have used accurately cut and dimensioned MDF to do the initial squaring up of the towers as I now have the woodworking gear to do all the cuts accurately. It was hard to get square. Then reused that as non structural external enclosure parts.

Do NOT try and level to the real world, I did and it was obscenely complex and painful

I would not use transparent ABS for anything structural.

I would still print a lot of parts but nearly all the parts should be positional and non load stressed. ie no corners for a Cartesian frame

I would definitely buy extruder and hot ends at the upper end again, the titan and Dyze are actually still available and still relatively good.

Duet... yep definitely apart from some pcb updates the Wifi is still current and highly recommended.

Edited 1 time(s). Last edit at 07/12/2021 09:27AM by aussiephil.

Back in 2016 I embarked on building a large delta [reprap.org] and had reason recently to reflect back on that thread to ubderstand when i built this thing and some of the reasons

The goal was to have something with a large build volume in this case it is around 590 round and 500 tall.

Something that was faster than my FlashForge Pro

Faster and bigger, sounds familiar.

Insipration was taken from the large delta by 3DR at the time.

It morphed into a hexagonal shape with 5.1 towers, the .1 is the front tower that is essentially just stubs for enclosure mounting.

Despite warnings from DC42 I still used a lot of printed parts.

The name was taken from the hexagonal shape and the mega sizing.

A flying Titan extruder and a Dyze Design hotend were picked.

I started with one of the original Duet 0.8.5 beta boards and eventually it got a Duet Wifi installed.

It got used for about 12 months on and off, it always seemed like to much trouble to fire this thing up and eventually just got surrounded by shed related things and stopped being used completely.

4 years later the Flashforge Pro was feeling restrictive again despite still working hard and the plans started in the head to build a CoreXY with at least 500mm on one axis.

To do this I needed to free up some bench space and this kicked off a "i need a new bench for a new printer cycle" This has resulted in a near full garage fit out with 4 full workbench's built including one 4Metre long monster, the bench for the printer is still not built... but i know were it's going

As part of this I had to move the MHD from one side to the other. This gave me access again and i could look at getting it running again.

Nearly a year later and 5 years on from the initial build:

Initial inspection of the unit showed a pretty big show stopper to get it running ... the printed bearing blocks for each tower had significant cracking just from age.

I have always printed in ABS and these had been printed in a transparent ABS that I have come to hate as it printed and felt more like a PLA, hard and brittle to work with rather than typical easy to work ABS.

The rear sections looked solid with no cracks so just printed the front sections and changed over.

All good, so onto the Duet Wifi and just what had changed in 5 years.... answer a lot!!

I was in 1.15 and v3.3 had just been released, time to bite the bullet and upgrade. Got past the Wifi connection setting when going to 2.x first then 3.0 before finally hitting 3.3... seemed like forever to do... Many thanks still to DC42 and the team for the excellent documentation and support forum.

Moment of truth time, would anything work we turned on everything, light, no camera, action. everything moved the unit homed, bed heated up, hot-end heated up so set about running through commissioning this unit again.

Checked the extruder was working with some PLA.... had to be at least 4 years old and just pulled out of a draw

Stripped the Kapton tape from the bed and gave the 8mm cast plate a clean and then a 220 grit sand with the sander to create a matt finish so the IR probe would work correctly.

I shifted over to using PEI on the flashforge bed so parked the progress and ordered 4 sheets of 300 square so i could tile the surface with PEI.

the Dyze is running a 0.6 nozzle so pulled that out and gave it a multiday soak in acetone whilst waiting for the PEI, finally got it nice and clean after a week

I know the bed is essentially flat so for the time being I have just got Z0 correct in the middle and got consistent IR probing in the middle.

My tip for the PEI is to sand the printing surface to a matt look, initial adhesion is good whilst parts still let go as long as you get the intial Z height correct.

In got a 400mm square magnetic spring steel plate with textured powder coated PEI coming in... after pricing a 600 and 500 round versions I'm prepared to suffer the loss of build area (i think)

I have been printing again with this one for a couple of weekends now with about 5kg of old PLA disappearing at a rate last weekend that said... order more, dangerously the place i buy a lot of filament from also stocks BondTech in AU and I had been eyeing off the new LGX extruder for use in a new printer so ordered one for testing along with a 5kg of PLA.

Whilst swapping over the extruder I had time to notice that the old back half of the bearing blocks also had some pretty major cracks now!! oh well that's the crappy transparent ABS biting me again.

I am so glad still to have those in Fusion 360 .... the worry is i can't find the extruder carriage in the drawings and it's printed from the same rubbish.

Grabbed a couple rolls of PETG to try out as I have been reading a lot about this wonderful filament in a couple facebook groups so ordered some to try.

mmm love the PETG.... hate having to print it slow.

Doing some very rough free air extrusion volumetric tests shows the Dyze hotend seems to max out around 16mm cubed of flow .... I have a HF dragon on a slow boat so that may/should speed things up.

Note that the extruder is cooled by remote fan, initially i used PVC tubing but it is heavy and stiff and restrictive, have found that the CPAP tubing is excellent for this.

As a side note the idea for a CoreXY has now changed to building a standard Cartesian IDEX or more correctly IDEY printer with a 400x600 print bed, external dimensions will be whatever is needed. primary usage will be ditto printing smaller parts especially for xmas light display stuff. So orientate the print heads on the normal Y axis (400mm).

So five years on thoughts:

I would have used accurately cut and dimensioned MDF to do the initial squaring up of the towers as I now have the woodworking gear to do all the cuts accurately. It was hard to get square. Then reused that as non structural external enclosure parts.

Do NOT try and level to the real world, I did and it was obscenely complex and painful

I would not use transparent ABS for anything structural.

I would still print a lot of parts but nearly all the parts should be positional and non load stressed. ie no corners for a Cartesian frame

I would definitely buy extruder and hot ends at the upper end again, the titan and Dyze are actually still available and still relatively good.

Duet... yep definitely apart from some pcb updates the Wifi is still current and highly recommended.

Edited 1 time(s). Last edit at 07/12/2021 09:27AM by aussiephil.

|

Re: My large Delta 5 years on..... July 13, 2021 09:32AM |

Registered: 8 years ago Posts: 177 |

I know sort of bad form replying to my own thread

Some more photos.

A full height view, really should put a coat of paint on those front panels

Here is a better view of the arms and effector, the cpap tube in this photo is the normal size tube delivers the air from the 75mm radial fan to cool the cold side of the extruder, the air is exhausted back upwards from the right hand side. There is no part cooling at all though the effector has air delivery holes printed in it, just never found a need even with PLA.

Oh and that's a new Bondtech LGX extruder

Here is a close up of a carriage assemble. you can see the cracks in the transparent ABS. The arms are Carbon Fibre and the cups are printed ABS on each end, they show no signs of wear.

It's going to be fun replacing the back half of those carriages

Some more photos.

A full height view, really should put a coat of paint on those front panels

Here is a better view of the arms and effector, the cpap tube in this photo is the normal size tube delivers the air from the 75mm radial fan to cool the cold side of the extruder, the air is exhausted back upwards from the right hand side. There is no part cooling at all though the effector has air delivery holes printed in it, just never found a need even with PLA.

Oh and that's a new Bondtech LGX extruder

Here is a close up of a carriage assemble. you can see the cracks in the transparent ABS. The arms are Carbon Fibre and the cups are printed ABS on each end, they show no signs of wear.

It's going to be fun replacing the back half of those carriages

|

Re: My large Delta 5 years on..... July 13, 2021 09:51AM |

Admin Registered: 16 years ago Posts: 13,886 |

... my first delta (then named "tripod", consisting of only 12 parts and "auto-joyning magnetic hinges") was from 2007 - so pretty "oldscool" too

Have another, more common (I think a "kossel max") somewhere in the basement ... but actually more focussed on DIY-ing high power lasers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Have another, more common (I think a "kossel max") somewhere in the basement ... but actually more focussed on DIY-ing high power lasers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.