Grounded Experimental Delta Printer

Posted by nicholas.seward

|

Re: Grounded Experimental Delta Printer August 08, 2013 06:03PM |

Registered: 10 years ago Posts: 2 |

|

Re: Grounded Experimental Delta Printer August 10, 2013 01:54AM |

Registered: 10 years ago Posts: 979 |

All is going well. I have had two hangups. I don't have a printer that can print the arms as-is in PLA and my CNC mill had some serious y-drift. I fixed the mill and am redesigning the arms so they can fit on my 148x128mm platform. Hopefully Wally or Simpson will get me the ability to print 200mm+ parts very soon. (My prototype Simpson needs a new filament drive but I can't bring myself to spend the time on it plus all the time need to do the calibration when it is about to be outdated.)

It looks like a toy doesn't it. That is definitely my intent. The central hub turned out better than I could have hoped for.

I got my custom springs in so I can try them out. They feel way stiffer than I intended. I am trying not to freak out and will get them on an arm soon to see if they work. Worse case scenario is that I have to order different springs. They are far from being a major expense. For the beta run they cost me $3/spring. For a production run, they will be 75 cents. (Stay calm Nick. It is not the end of the world to get the springs wrong.)

Wish I had more for you guys but I am definitely moving forward. Getting stuff ordered and sourced for the 20 beta Simpson has also taken a lot of my time. Luckily, that is almost completely done. Now I can settle in for the month long printing marathon. I think I will make a big sign that says "_ days since a plastic part has been mangled".

Edited 1 time(s). Last edit at 08/10/2013 01:56AM by nicholas.seward.

It looks like a toy doesn't it. That is definitely my intent. The central hub turned out better than I could have hoped for.

I got my custom springs in so I can try them out. They feel way stiffer than I intended. I am trying not to freak out and will get them on an arm soon to see if they work. Worse case scenario is that I have to order different springs. They are far from being a major expense. For the beta run they cost me $3/spring. For a production run, they will be 75 cents. (Stay calm Nick. It is not the end of the world to get the springs wrong.)

Wish I had more for you guys but I am definitely moving forward. Getting stuff ordered and sourced for the 20 beta Simpson has also taken a lot of my time. Luckily, that is almost completely done. Now I can settle in for the month long printing marathon. I think I will make a big sign that says "_ days since a plastic part has been mangled".

Edited 1 time(s). Last edit at 08/10/2013 01:56AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer August 10, 2013 10:34AM |

Registered: 11 years ago Posts: 58 |

I'm willing to bet that there are folks on the beta list, including at least me, who would be happy to print the parts for either machine ourselves in order to help you out and accelerate the process. I know that's not entirely in keeping with the beta principle since the entire supply chain should be controlled, but sooner or later (probably sooner!) there will be people wanting to print their own. I, too have an extruder issue with my big printer right now, but my little printer is making a new one for his big brother

|

Re: Grounded Experimental Delta Printer August 10, 2013 10:47AM |

Registered: 10 years ago Posts: 979 |

I do want to enable others to print their own. Here is the issue, I am not charging for my labor on these beta machines so I wouldn't be able to charge the testers a reduced price for the "print-your-own" version and I already ordered a spool of PLA for every machine. I guess I will leave it up to the individual testers. They can either get the parts printed by me or they can get a kit complete with a spool of PLA for the plastic parts they need to print. I am probably less than a month away from being able to ship "print-your-own" kits.

BTW, I will publish files as soon as I can verify that this is a valid design.

Edited 1 time(s). Last edit at 08/10/2013 10:57AM by nicholas.seward.

BTW, I will publish files as soon as I can verify that this is a valid design.

Edited 1 time(s). Last edit at 08/10/2013 10:57AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer August 10, 2013 11:00AM |

Registered: 11 years ago Posts: 58 |

The intellectual labor you've put into this is staggering, and just about unimaginable to someone like me who can't even visualize how these linkages work until they're designed (and sometimes it's difficult even then). Asking you do put more labor into babysitting a printer seems silly to me. I can't speak for anyone else but for me it's not about the cost, or getting a spool of PLA with the kit, it's simply a matter of making the process easier and perhaps getting to the point of assembling the printer sooner. This is not meant to pressure or rush you, by the way, it's not that I *need* another printer, but this is just such a cool project that I'm excited and champing at the bit

... and on that front I texted your picture of the first printed Simpson parts to my daughter, my co-conspirator in 3D printing, and her response was "Ooooo!" I am absolutely certain that after we build whichever model we're assigned in the beta, she will want to make the other one too.

... and on that front I texted your picture of the first printed Simpson parts to my daughter, my co-conspirator in 3D printing, and her response was "Ooooo!" I am absolutely certain that after we build whichever model we're assigned in the beta, she will want to make the other one too.

|

Re: Grounded Experimental Delta Printer August 11, 2013 12:33AM |

Registered: 12 years ago Posts: 85 |

I love the design direction. Exploring feedback..

It seems like the linear range in these designs is spread out enough that something like a linear potentiometer bearing could be useful for some applications, using multiple cheaper limited range pots?

If the spring was magnetized, could you measure its compression?

Or a spring pot toolhead for detecting true-Z-zero throughout the range of motion? One of your three default heads -- [www.vexforum.com]

-- [www.vexforum.com]

It seems like the linear range in these designs is spread out enough that something like a linear potentiometer bearing could be useful for some applications, using multiple cheaper limited range pots?

If the spring was magnetized, could you measure its compression?

Or a spring pot toolhead for detecting true-Z-zero throughout the range of motion? One of your three default heads

-- [www.vexforum.com]

-- [www.vexforum.com]

|

Re: Grounded Experimental Delta Printer August 12, 2013 02:43AM |

Registered: 12 years ago Posts: 85 |

|

Re: Grounded Experimental Delta Printer August 12, 2013 08:13AM |

Registered: 15 years ago Posts: 401 |

I've been exploring feedback too. I think the best option for measuring joint deflection is to build a circular capacitive vernier into the joints. The problem with this approach is two-fold. First, the scale will not be as precise as you'd like--this is an issue of error amplification: an error of 10um around the joint will be around 100um at the toolhead. Second, a circular capacitive vernier will require one (closely located) microcontroller per joint.

|

Re: Grounded Experimental Delta Printer August 13, 2013 02:36PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Grounded Experimental Delta Printer August 13, 2013 03:02PM |

Registered: 10 years ago Posts: 979 |

I already have the electronics for the beta kits but all of those will be getting paired with the mechanicals so I can do some consistent beta testing. It won't be until December when I will be doing this for real.

Beta Simpson Electronics

1 - Azteeg X1 $65

4 - SureStep Drivers $10

4 - Steppers $12

1 - 12or24 Power Suppy $36

1 - 200mm Round Heating Pad $14

1 - Hot End $16

1 - Filament Drive $12

Total: $230 (my cost)

These are prices I got from ordering for 40 machines. I imagine I can do much better when I order for 1000.

Beta Simpson Electronics

1 - Azteeg X1 $65

4 - SureStep Drivers $10

4 - Steppers $12

1 - 12or24 Power Suppy $36

1 - 200mm Round Heating Pad $14

1 - Hot End $16

1 - Filament Drive $12

Total: $230 (my cost)

These are prices I got from ordering for 40 machines. I imagine I can do much better when I order for 1000.

|

Re: Grounded Experimental Delta Printer August 13, 2013 04:58PM |

Registered: 10 years ago Posts: 23 |

Hello,

I've been followed Reprap Simpson progress for a while, the machine is amazing! I'm new to 3D Printing and don't know much about it, but I would like to get one. I've some experience in importing electronic parts from China and Hong Kong. And I think the board pricing can be reduce a lot if you can find a reliable sources. It will take some time, but I'm sure it will be worth in long run. You can do while doing beta tests, before final version.

I was lucky enough to find good product for my shop, customers are happy and only 1%-2% need to be repair in last year. The key is not going to the cheapest, but reasonable priced. Usually, I found that the sweet spot is about 50% of the market price, and go to 30% for wholesale. But that is the completed electronic products, not just parts though.

I hope these would help:

[www.alibaba.com]

[s.taobao.com]

[www.ebay.com]

Many sellers found in Alibaba / taobao are valid. To select right suppliers, inquire them about the product. There'll be some who have deep understanding about their product. Ask them about sample unit.

Good luck!

I've been followed Reprap Simpson progress for a while, the machine is amazing! I'm new to 3D Printing and don't know much about it, but I would like to get one. I've some experience in importing electronic parts from China and Hong Kong. And I think the board pricing can be reduce a lot if you can find a reliable sources. It will take some time, but I'm sure it will be worth in long run. You can do while doing beta tests, before final version.

I was lucky enough to find good product for my shop, customers are happy and only 1%-2% need to be repair in last year. The key is not going to the cheapest, but reasonable priced. Usually, I found that the sweet spot is about 50% of the market price, and go to 30% for wholesale. But that is the completed electronic products, not just parts though.

I hope these would help:

[www.alibaba.com]

[s.taobao.com]

[www.ebay.com]

Many sellers found in Alibaba / taobao are valid. To select right suppliers, inquire them about the product. There'll be some who have deep understanding about their product. Ask them about sample unit.

Good luck!

|

Re: Grounded Experimental Delta Printer August 15, 2013 07:51PM |

Registered: 10 years ago Posts: 979 |

Announcing the Gear Drive. Guizmo made a new thread to discuss a bearingless Simpson among other things. (It is a great read if you like math and mechanisms.) One product of that thread is the Gear Drive or the Proportional Gear Drive Joint. It has smashed all my expectations and was so impressive that I am rolling it into the beta build.

It is strong. It can apply more the 5lbf at the arm ends.

It is fast. It can go faster than 500mm/s

It is simple. 2 plastic parts. No bearings.

It is a two sided drive. Gravity and springs don't limit performance anymore.

I look forward to modeling what beta Simpson is going to look like now.

Todo: I am waiting on springs and guitar tuning pegs for the motor arms. I also need to add limit switches. Spring assisted auto-home is gone. I have the perfect place for the limit switch.

It is strong. It can apply more the 5lbf at the arm ends.

It is fast. It can go faster than 500mm/s

It is simple. 2 plastic parts. No bearings.

It is a two sided drive. Gravity and springs don't limit performance anymore.

I look forward to modeling what beta Simpson is going to look like now.

Todo: I am waiting on springs and guitar tuning pegs for the motor arms. I also need to add limit switches. Spring assisted auto-home is gone. I have the perfect place for the limit switch.

|

Re: Grounded Experimental Delta Printer August 15, 2013 10:18PM |

Hey Nicholas, what if you used another motor working in reverse in place of the guitar tuning peg? Wouldn't that eliminate the spring and the tensioning of the line?

I know the "cost" might increase but it seems like it would work, one could pre-tension the line with manual control of the motors.

Ralph

I know the "cost" might increase but it seems like it would work, one could pre-tension the line with manual control of the motors.

Ralph

|

Re: Grounded Experimental Delta Printer August 15, 2013 11:06PM |

Registered: 10 years ago Posts: 979 |

Using stepper's to apply a constant force would probably work but is definitely not what they are designed to do. I think you will make a few engineers cry to see one used in such a manner. The real reason I can't go with that is that it will send my electronics control package cost through the roof.

|

Re: Grounded Experimental Delta Printer August 15, 2013 11:28PM |

Registered: 10 years ago Posts: 14 |

@Annirak:

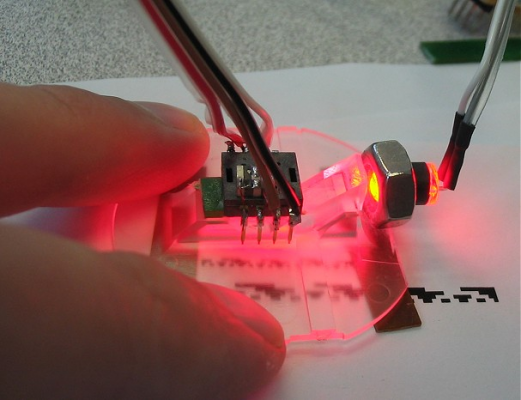

With regards to feedback: What about some sort of optical linear encoder? Optical mice are cheap and tend to offer fairly good resolution. Maybe strip one down to components, or just order new lenses/ICs? It seems that the AvagoTech/Pixart ADNS series is relatively commonly used, seem to take mostly DIP form factor, and have readily available data sheets (e.g. [www.pixart.com.tw] for the ADNS7550, a combination laser emitter/sensor IC).

In addition to performing registration/relative motion detection automatically, most of these ICs offer the ability to directly read from their small grayscale image sensors (e.g. the ADNS7550 has a 25x25 sensor with 8 bits of signal resolution). It might be possible with a clever design to come up with a strip irregular enough for the chip's motion detection algorithms to follow, but with enough encoded information that it's possible to detect absolute position by dumping the image sensor and performing some decoding process. Maybe start with a 11-bit binary reflected gray code (which enumerates all 2048 combinations of 11 bits, changing only 1 bit from step to step), but then invert every other entry?

The main downside I see right now is sourcing. Buying a cheap optical mouse and hoping to disassemble it for a useful IC+lens seems like a bit of a crapshoot. On the other hand, DigiKey distributes the ADNS7550 (and matching ADNS-6150, ADNS-

6160-001 or ADNS-6170-002 lens), but their website makes it look like they only sell in bulk. Findchips.com (http://www.findchips.com/avail?part=adns7550#A1391574944) suggests that they might be willing to sell in smaller quantity for reasonable prices, though.

So, for example, on Nick's new arm, you could have each arm's sensor drive a light belt, print up a sticker and stick it to the belt, and mount the mouse optics to read the belt. Or if there's not enough motion there, have the stepper drive a wheel to amplify the motion.

Edited 3 time(s). Last edit at 08/15/2013 11:55PM by Shawn.Walker.

With regards to feedback: What about some sort of optical linear encoder? Optical mice are cheap and tend to offer fairly good resolution. Maybe strip one down to components, or just order new lenses/ICs? It seems that the AvagoTech/Pixart ADNS series is relatively commonly used, seem to take mostly DIP form factor, and have readily available data sheets (e.g. [www.pixart.com.tw] for the ADNS7550, a combination laser emitter/sensor IC).

In addition to performing registration/relative motion detection automatically, most of these ICs offer the ability to directly read from their small grayscale image sensors (e.g. the ADNS7550 has a 25x25 sensor with 8 bits of signal resolution). It might be possible with a clever design to come up with a strip irregular enough for the chip's motion detection algorithms to follow, but with enough encoded information that it's possible to detect absolute position by dumping the image sensor and performing some decoding process. Maybe start with a 11-bit binary reflected gray code (which enumerates all 2048 combinations of 11 bits, changing only 1 bit from step to step), but then invert every other entry?

The main downside I see right now is sourcing. Buying a cheap optical mouse and hoping to disassemble it for a useful IC+lens seems like a bit of a crapshoot. On the other hand, DigiKey distributes the ADNS7550 (and matching ADNS-6150, ADNS-

6160-001 or ADNS-6170-002 lens), but their website makes it look like they only sell in bulk. Findchips.com (http://www.findchips.com/avail?part=adns7550#A1391574944) suggests that they might be willing to sell in smaller quantity for reasonable prices, though.

So, for example, on Nick's new arm, you could have each arm's sensor drive a light belt, print up a sticker and stick it to the belt, and mount the mouse optics to read the belt. Or if there's not enough motion there, have the stepper drive a wheel to amplify the motion.

Edited 3 time(s). Last edit at 08/15/2013 11:55PM by Shawn.Walker.

|

Re: Grounded Experimental Delta Printer August 15, 2013 11:55PM |

Registered: 10 years ago Posts: 979 |

Thank you Shawn Walker! Annirak and I have been going back and forth on web cams. (It is a far out plan.) I never really liked the solution I was pitching but I was sure I could make it work. One of the major problems is you have to worry about lens distortion and/or focal length. The other problem is resolution. The optical mouse solves all of this. I can use it as a contactless z probe and I can use it to run over the a printed calibration pattern or on-bed engraving.

I had no idea that some mice have the ability to tap into the camera feed. I didn't believe you until I looked at this page. Unfortunately, my mouse is too old. However, I did some quick math to see if this will work for us.

A 12pt "e" is 1.8mm tall in Inkscape. The picture shows the "e" to be 14 pixels tall. That means each pixel is about 130 microns. Using greyscale values you could calculate subpixel placement of a registration dot. You can also oversample. I would like to think we can do better than 50 microns.

@Annirak: what do you think?

I had no idea that some mice have the ability to tap into the camera feed. I didn't believe you until I looked at this page. Unfortunately, my mouse is too old. However, I did some quick math to see if this will work for us.

A 12pt "e" is 1.8mm tall in Inkscape. The picture shows the "e" to be 14 pixels tall. That means each pixel is about 130 microns. Using greyscale values you could calculate subpixel placement of a registration dot. You can also oversample. I would like to think we can do better than 50 microns.

@Annirak: what do you think?

|

Re: Grounded Experimental Delta Printer August 16, 2013 12:45AM |

Registered: 10 years ago Posts: 14 |

50 microns might be pushing your luck -- I bet you could do it with the sensor and some good algorithms, but I'm not sure how you'd cheaply manufacture an accurate registration pattern at that resolution. If my numbers are right, 50 microns is about 500dpi. Inkjet photo printer resolutions are advertised at "2400 dpi"!, but in practice tend to have resolutions closer to only 1200x600 dpi, before accounting for tolerances due to ink spread and mechanical positioning.

|

Re: Grounded Experimental Delta Printer August 16, 2013 12:55AM |

Registered: 10 years ago Posts: 979 |

Remember I don't need a 50 micron dot. I just need to find the center of something to within 50 microns. For instance, I think we could find the center of the "e" above to within +/-50 microns. The DPI is the resolution. The question is how accurate is the printer. I think we could get better than 50 microns with a 100dpi printer as long as it was accurate.

BTW, I am putting a laser engraved pattern on the beds of Simpson and Wally. The patterns won't affect printing but will be visible.

BTW, I am putting a laser engraved pattern on the beds of Simpson and Wally. The patterns won't affect printing but will be visible.

|

Re: Grounded Experimental Delta Printer August 16, 2013 01:13AM |

Registered: 10 years ago Posts: 14 |

Good point on the resolution, hadn't thought of that.

If you were to try to use a mouse sensor as a z probe, clear glass (even with a few patterns/logos etched into it) might be problematic. I'd think you'd want something with more optical features, like some sort of frosted glass, or a different surface entirely, like a ceramic. Or possibly laser engrave a fairly dense pattern across the whole surface? (Is that difficult/expensive? I have no idea.)

Or maybe I'm just overthinking this, and it's not an issue at all.

Edited 1 time(s). Last edit at 08/16/2013 01:17AM by Shawn.Walker.

If you were to try to use a mouse sensor as a z probe, clear glass (even with a few patterns/logos etched into it) might be problematic. I'd think you'd want something with more optical features, like some sort of frosted glass, or a different surface entirely, like a ceramic. Or possibly laser engrave a fairly dense pattern across the whole surface? (Is that difficult/expensive? I have no idea.)

Or maybe I'm just overthinking this, and it's not an issue at all.

Edited 1 time(s). Last edit at 08/16/2013 01:17AM by Shawn.Walker.

|

Re: Grounded Experimental Delta Printer August 16, 2013 01:14AM |

Registered: 10 years ago Posts: 979 |

|

Re: Grounded Experimental Delta Printer August 16, 2013 01:20AM |

Registered: 10 years ago Posts: 14 |

|

Re: Grounded Experimental Delta Printer August 16, 2013 03:45AM |

Registered: 15 years ago Posts: 401 |

I've looked into the mouse sensors in the past. They're interesting, but I have a number of concerns with them.

[*] They're built for non-critical motion detection. That means that they don't care about repeatability. If you drop a frame, it's no big deal.

[*] The interface (I'm talking about SPI, not USB here) they use is completely proprietary and specific not just to each company, but to each device.

[*] The optics are made of plastic and are tuned for a fixed distance from the surface.

None of these is a show-stopper, provided that you're using them as a cheap camera, not a motion estimator, but they require a lot of careful handling.

[*] They're built for non-critical motion detection. That means that they don't care about repeatability. If you drop a frame, it's no big deal.

[*] The interface (I'm talking about SPI, not USB here) they use is completely proprietary and specific not just to each company, but to each device.

[*] The optics are made of plastic and are tuned for a fixed distance from the surface.

None of these is a show-stopper, provided that you're using them as a cheap camera, not a motion estimator, but they require a lot of careful handling.

|

Re: Grounded Experimental Delta Printer August 16, 2013 11:43AM |

Registered: 10 years ago Posts: 1,381 |

Micropositioning using cheap mouse cameras with Arduino Library

2D position finding using the “Christopher Carter Algorithm”

Absolute 2D position encoding/decoding using a Gray Code pattern.

Position is resolvable generally to 1 pixel, in this case measured at about 2.4 mils (about 70um).

[tim.cexx.org]

I can envision using the tracking device to verify the printing process.

If in front of the fusion path is missing structure, it could either stop and throw an error, or it could call a subroutine, map the missing structure with the optical sensor, then fill the void in, and then continue on where it left off at.

A2

Video's

Optical mouse hack #1

[www.youtube.com]

Optical Mouse hack #2

[www.youtube.com]

Arduino Library

[tim.cexx.org]

Edited 1 time(s). Last edit at 08/16/2013 11:44AM by A2.

|

Re: Grounded Experimental Delta Printer August 17, 2013 12:32AM |

Registered: 10 years ago Posts: 10 |

Annirak: You said something about wanting a bend sensor, but they're too expensive for your purposes. I remember the team I was on (1683) in FIRST FRC kludging together a bend sensor, I think. I also clearly remember linear sensor for a telescoping arm. I can't really remember how we did the bend sensor (or if we ever actually passed going "oh, yeah, we could do it that way), but I clearly remember that we used a photosensor, LED, and a tape measure with holes punched in it for the linear sensor. PID is extremely common for motor control in FRC, so if you looked around some FRC forums you might be able to find a cheap way to do it. I'm actually thinking a light, photosensor or something, and patterned string or something might work for a bend sensor, although I don't have the idea of where you want to use it quite clear in my head, so I'm really just throwing ideas out there.

Edited 1 time(s). Last edit at 08/17/2013 12:44AM by terribleperson.

Edited 1 time(s). Last edit at 08/17/2013 12:44AM by terribleperson.

|

Re: Grounded Experimental Delta Printer August 17, 2013 08:39PM |

Registered: 10 years ago Posts: 14 |

I changed my mind about a dozen times, but here is my addition to the project:

[www.youtube.com]

No belts or cables and no odd shaped gears.

[www.youtube.com]

No belts or cables and no odd shaped gears.

|

Re: Grounded Experimental Delta Printer August 17, 2013 10:30PM |

Registered: 10 years ago Posts: 14 |

So this can be simplified even more. You can remove the need for the springs by adding a stopped to the end of the rack gears and then putting them in a sleeve past the arm.

This means the gears would need to be longer (this could be an issue as I think about 280MMs will be the limit), and a very simple bearing could be used.

This means the gears would need to be longer (this could be an issue as I think about 280MMs will be the limit), and a very simple bearing could be used.

|

Re: Grounded Experimental Delta Printer August 19, 2013 04:33PM |

Registered: 10 years ago Posts: 10 |

Is it just me or does the Simpson setup look pretty good for milling? I don't know much about milling (or even really 3D printing), but the Simpson appears to be far stiffer and more robust than most repraps. If you scale it up, I imagine the weight and the shape would negate most vibration, making it possible to mill steel (and potentially harder materials), rather than the usual 'wood and maybe aluminum' you get out of most hobbyist mills.

edit: Is the ability to print arms larger than the printer is currently using inherent to the Simpson design, or just to a particular implementation?

Edited 1 time(s). Last edit at 08/19/2013 04:34PM by terribleperson.

edit: Is the ability to print arms larger than the printer is currently using inherent to the Simpson design, or just to a particular implementation?

Edited 1 time(s). Last edit at 08/19/2013 04:34PM by terribleperson.

|

Re: Grounded Experimental Delta Printer August 20, 2013 07:04AM |

Registered: 15 years ago Posts: 401 |

I'm not sure that Simpson is stiff enough for milling.

Generally, mills use threaded rod to guarantee that they can exert a lot of pressure, and the toolhead is mounted to a huge lump of iron to reduce vibration and keep it rigid. In 5-axis milling, they move the toolhead, but again, everything is built around stiffness and maximum force. In a cartesian mill (x,y,z, no funny business), ever bearing is mounted to be orthogonal from any other bearing that's attached to the same piece. That means that if you put force on the Y direction, X will be completely unaffected.

With Simpson, we have plastic arms, which are going to have some flex in them, friction-fit drive string, and all the axes are tied together. These factors combine to offer a mill which is less than stiff.

None of this stops you from building a metal Simpson. You could replace the strings with a rack&worm drive, which would be far stiffer, but you'd end up dealing with backlash.

So, no, as designed, Simpson is good for printing and light milling, but I wouldn't try steel.

Generally, mills use threaded rod to guarantee that they can exert a lot of pressure, and the toolhead is mounted to a huge lump of iron to reduce vibration and keep it rigid. In 5-axis milling, they move the toolhead, but again, everything is built around stiffness and maximum force. In a cartesian mill (x,y,z, no funny business), ever bearing is mounted to be orthogonal from any other bearing that's attached to the same piece. That means that if you put force on the Y direction, X will be completely unaffected.

With Simpson, we have plastic arms, which are going to have some flex in them, friction-fit drive string, and all the axes are tied together. These factors combine to offer a mill which is less than stiff.

None of this stops you from building a metal Simpson. You could replace the strings with a rack&worm drive, which would be far stiffer, but you'd end up dealing with backlash.

So, no, as designed, Simpson is good for printing and light milling, but I wouldn't try steel.

|

Re: Grounded Experimental Delta Printer August 20, 2013 08:22AM |

Registered: 10 years ago Posts: 10 |

I certainly wouldn't disagree with using metal arms for a milling simpson. I don't see why I'd want to replace the strings, though. 1/8th" dia. braided Spectra speargun line is 1050lb test, and extremely low stretch (parallel core). Very low friction, too, although that might cause some problems. I'll have to think about it, but I'm pretty sure you can make string tensioning work.

edit: Ah, I see, are you suggesting that side to side motion of the line allows a certain amount of flex? That's easily solveable past where it winds up, but I'm not sure how one regularizes the winding... surely there's a way.

Edited 2 time(s). Last edit at 08/20/2013 08:30AM by terribleperson.

edit: Ah, I see, are you suggesting that side to side motion of the line allows a certain amount of flex? That's easily solveable past where it winds up, but I'm not sure how one regularizes the winding... surely there's a way.

Edited 2 time(s). Last edit at 08/20/2013 08:30AM by terribleperson.

|

Re: Grounded Experimental Delta Printer August 20, 2013 11:38AM |

Registered: 15 years ago Posts: 401 |

Sorry, only registered users may post in this forum.