|

Re: Grounded Experimental Delta Printer May 15, 2013 11:09AM |

Registered: 11 years ago Posts: 979 |

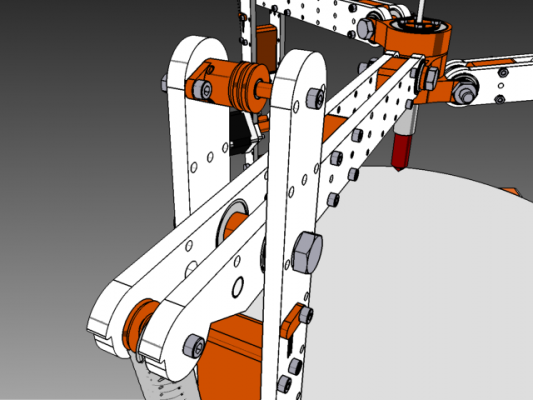

First, I have ditched the quadlink idea and have gone back to the simple two link arms. I just couldn't get my head around a simple design that didn't send my vitamin count through the roof.

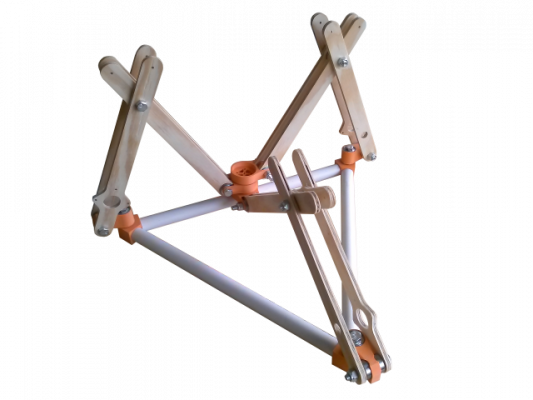

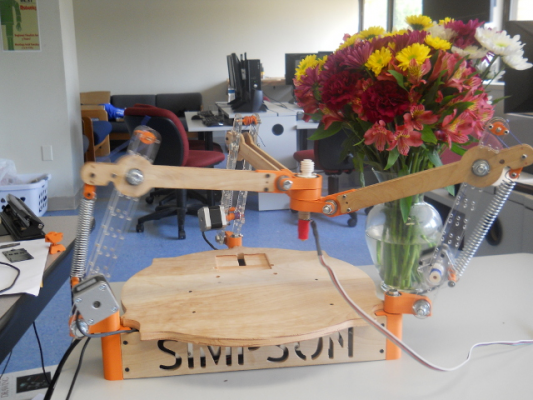

Not a rendering! (I probably shouldn't have removed the background in GIMP so it would seem real.)

I couldn't just let myself wait to get my Polypropylene laser cut. I had to CNC out some 1/4" wood to see how everything will look and get an idea for the stability of the design. The wood can't stand up to the press fit bearings but even so there is remarkable stability. I can only pitch and roll the head by 10 degrees or so. The yaw play is practically zero. (Not that the yaw will affect the quality of a print at all.)

That sounds like a lot of play but I am missing some parts and remember the wood is broken where the bearings insert. Most importantly, I didn't have the big bearings so I printed out a loose fitting approximation so I could see everything together. With the real bearings bolted on it should get much stiffer. Also, I was able to identify another area to could be improved. The biggest problem is torsional stiffness of the members so I will bolt on some spacers between the sides of the arms and this whole design should be rock solid. I was excited about this design before. Now I am ecstatic. I am just waiting on vitamins to be delivered and this thing will take shape shortly.

Great News: I contacted QU-BD about using their small extruder for this design and they offered to provide one for free. I also went to them to try to buy all my electronics and they offered to sponsor me for the whole project! How cool is that?

Edited 3 time(s). Last edit at 05/15/2013 11:28AM by nicholas.seward.

Not a rendering! (I probably shouldn't have removed the background in GIMP so it would seem real.)

I couldn't just let myself wait to get my Polypropylene laser cut. I had to CNC out some 1/4" wood to see how everything will look and get an idea for the stability of the design. The wood can't stand up to the press fit bearings but even so there is remarkable stability. I can only pitch and roll the head by 10 degrees or so. The yaw play is practically zero. (Not that the yaw will affect the quality of a print at all.)

That sounds like a lot of play but I am missing some parts and remember the wood is broken where the bearings insert. Most importantly, I didn't have the big bearings so I printed out a loose fitting approximation so I could see everything together. With the real bearings bolted on it should get much stiffer. Also, I was able to identify another area to could be improved. The biggest problem is torsional stiffness of the members so I will bolt on some spacers between the sides of the arms and this whole design should be rock solid. I was excited about this design before. Now I am ecstatic. I am just waiting on vitamins to be delivered and this thing will take shape shortly.

Great News: I contacted QU-BD about using their small extruder for this design and they offered to provide one for free. I also went to them to try to buy all my electronics and they offered to sponsor me for the whole project! How cool is that?

Edited 3 time(s). Last edit at 05/15/2013 11:28AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 16, 2013 05:35AM |

Registered: 12 years ago Posts: 23 |

|

Re: Grounded Experimental Delta Printer May 16, 2013 10:15AM |

Registered: 11 years ago Posts: 265 |

|

Re: Grounded Experimental Delta Printer May 16, 2013 11:28AM |

Registered: 11 years ago Posts: 979 |

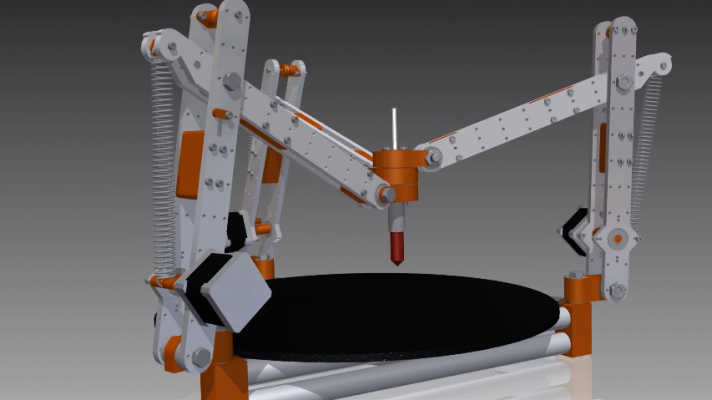

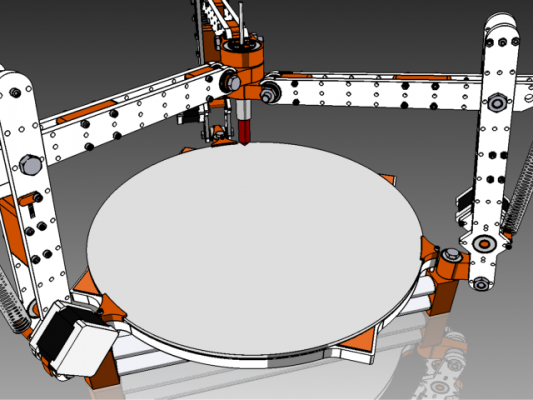

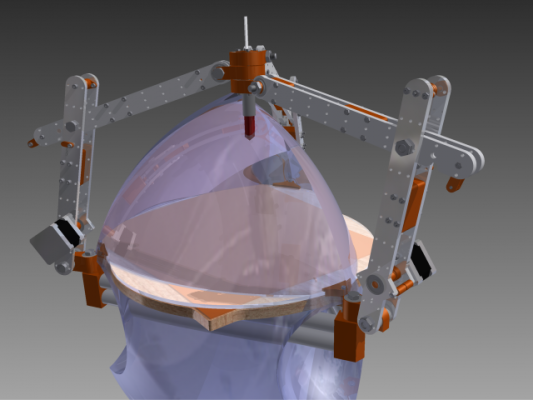

CAD is done!!! Most all the orange plastic parts are already printed. The white arms will be laser cut on Monday. All the vitamins have been ordered in duplicate (gotta replicate) and are racing towards me as I type. I am so excited. This thing might breath as early as next week. It was 20 days ago that I seriously started thinking about making a 3D printer that has no linear rails and low center of mass. 10 days ago I hit upon this basic geometry that allows a delta robot to actuate the elbow instead of the shoulder. 10 days in the future I hope to have this thing done with enough documentation to enter the Gada Prize.

Here is some Youtube candy of my machine. Note: I have all the parts that you see made except for the white arms. Vitamins should arrive end of this week or early next week. I can already tell you that wiring is going to be the biggest hurdle. Firmware could also be a challenge since I have never modified firmware before. The geometry is easier than a Rostock so I will probably just steal their codebase and change the geometry. I hope it is that easy.)

I am putting a 15" round platform on Simpson and he can reach almost every inch. Under the glass I am going to put a 12x12" silicone rubber heater bed. (I understand that it will stick off some.) I am quite sure that this is over kill but most every position on the platform is reachable so why not use it.

@qharley: This isn't real for me yet. I feel so fortunate. I am jealous of what you have already achieved. I am trying hard to emulate you.

Edited 1 time(s). Last edit at 05/16/2013 11:28AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 16, 2013 11:16PM |

Registered: 11 years ago Posts: 979 |

Here are details on everything but the filament drive which will be easy enough to finish up this weekend. The 12 pieces that make up the arm will get laser cut on monday and I should have enough vitamins by Monday or Tuesday to do a simple motion test. Very exciting times.

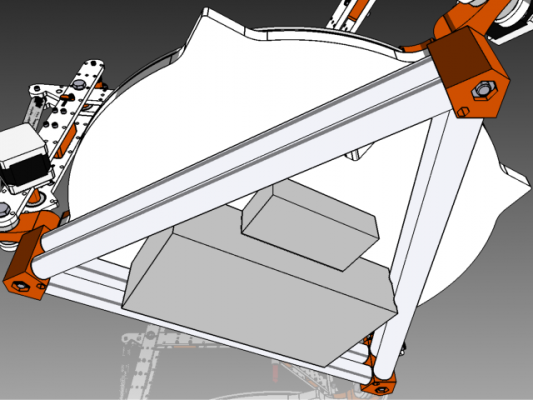

Here I placed some rough boxes to make sure I can fit the power supply and the controller. I will have to print some mounts but I will wait until I have the physical objects.

This is a bottom shoulder joint. Both sides of the arm are identical. I also included Nema14 mount points if it ends up that I have an excess of power. You can also see my bed complete with a silicone heater pad, glass, retainer clip, and spring. (The spring is just barely visible and will allow for easy leveling.)

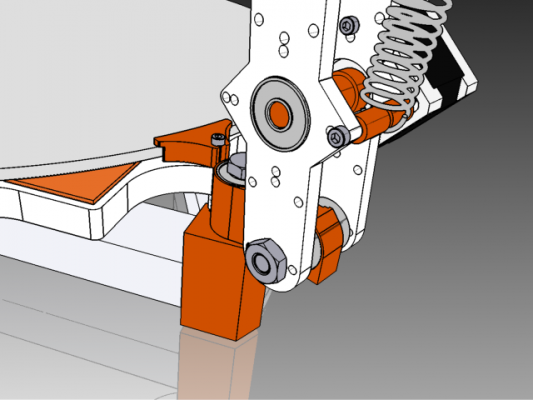

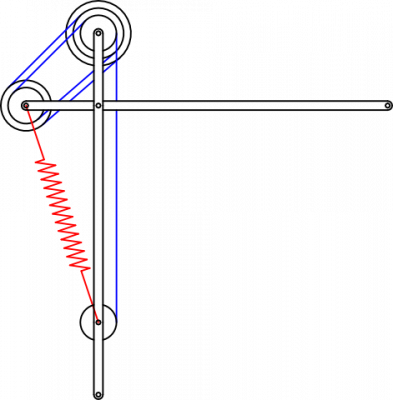

Here you can see the block and tackles setup. I also included a static mounted cylinder for the termination of the string. The termination cylinder will keep the math from getting complicated. The one thing that I don't like and am going to fix is that this joint has not retainers on the bearings. However, I am going to use a thermal interference fit so those bearings will never budge. (Polypropylene has a very large coefficient of linear expansion. I will heat the arms up and will freeze the bearings. They will then just drop in and then very quickly get stuck.) You can also notice in the middle of the arms are torsion blocks to boost the rigidity. My mock up showed that to be the number one weak point but not anymore.

You can also see the hall effect sensor and the magnet. I actually did some science/math to get the optimal placement so that the stop is close but not too close to the physical limit of motion.

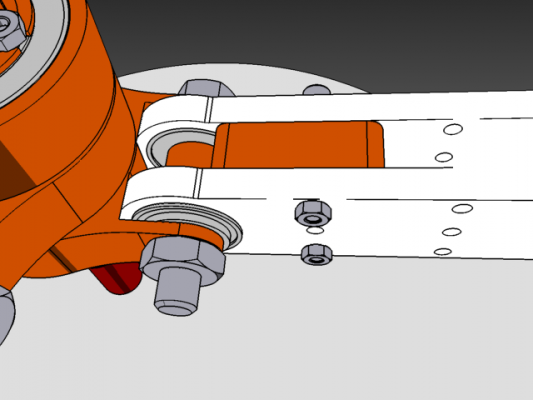

The only thing to really see here is the torsion block/ bearing retainer.

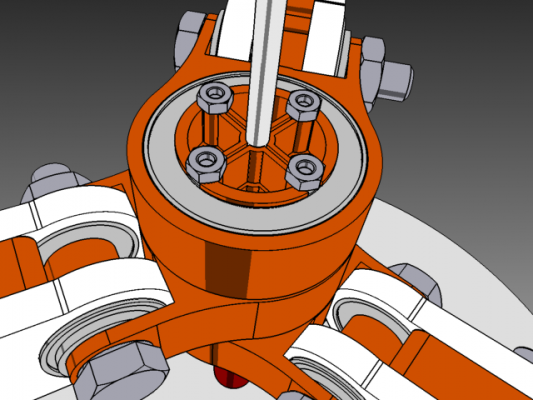

Here all the arms meet with some oversized thin section bearings. Right now I have no quick release for the bowden tube so that will have to be fixed. You can see that wires can freely be routed through the middle. I also have a magnetic angular encoder insert designed to embed right in the center of this guy so that we can get all the benefits of direct drive with a bowden tube. (I have printed the parts and ordered the encoder but I am going to leave it out until I get over all the other hurdles to getting this up and running.)

I like the look of everything but the extra holes make it look more complicated than it really is. However, the ability to have mounting holes for just about anything appeals to me especially when this isn't a proven design. The holes stay and I will get over it.

Here he is in the flesh. He watched a little TV tonight with the family. It is amazing how quickly you learn to love your children. On his bed are all the parts needed in front and all the reject parts in the back. You can also see a squirrel that was lending some emotional support.

Let me know what you think? If I have done something stupid, I would like to know. I have two days until this initial design will get baked in.

Thanks,

Nicholas Seward

Edited 1 time(s). Last edit at 05/16/2013 11:27PM by nicholas.seward.

Here I placed some rough boxes to make sure I can fit the power supply and the controller. I will have to print some mounts but I will wait until I have the physical objects.

This is a bottom shoulder joint. Both sides of the arm are identical. I also included Nema14 mount points if it ends up that I have an excess of power. You can also see my bed complete with a silicone heater pad, glass, retainer clip, and spring. (The spring is just barely visible and will allow for easy leveling.)

Here you can see the block and tackles setup. I also included a static mounted cylinder for the termination of the string. The termination cylinder will keep the math from getting complicated. The one thing that I don't like and am going to fix is that this joint has not retainers on the bearings. However, I am going to use a thermal interference fit so those bearings will never budge. (Polypropylene has a very large coefficient of linear expansion. I will heat the arms up and will freeze the bearings. They will then just drop in and then very quickly get stuck.) You can also notice in the middle of the arms are torsion blocks to boost the rigidity. My mock up showed that to be the number one weak point but not anymore.

You can also see the hall effect sensor and the magnet. I actually did some science/math to get the optimal placement so that the stop is close but not too close to the physical limit of motion.

The only thing to really see here is the torsion block/ bearing retainer.

Here all the arms meet with some oversized thin section bearings. Right now I have no quick release for the bowden tube so that will have to be fixed. You can see that wires can freely be routed through the middle. I also have a magnetic angular encoder insert designed to embed right in the center of this guy so that we can get all the benefits of direct drive with a bowden tube. (I have printed the parts and ordered the encoder but I am going to leave it out until I get over all the other hurdles to getting this up and running.)

I like the look of everything but the extra holes make it look more complicated than it really is. However, the ability to have mounting holes for just about anything appeals to me especially when this isn't a proven design. The holes stay and I will get over it.

Here he is in the flesh. He watched a little TV tonight with the family. It is amazing how quickly you learn to love your children. On his bed are all the parts needed in front and all the reject parts in the back. You can also see a squirrel that was lending some emotional support.

Let me know what you think? If I have done something stupid, I would like to know. I have two days until this initial design will get baked in.

Thanks,

Nicholas Seward

Edited 1 time(s). Last edit at 05/16/2013 11:27PM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 17, 2013 12:09AM |

Admin Registered: 15 years ago Posts: 1,470 |

Very cool! I just read through this entire thread. What you are doing is pretty impressive. Keep us updated!

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Grounded Experimental Delta Printer May 17, 2013 09:31AM |

Registered: 11 years ago Posts: 265 |

Pretty awesome

Wait what?!?

What are your programming skills like?

You will need to implement all the complex math Annirak posted, but just not get it working,

but write the code in a way that will be efficient for a low powered Arduino to crunch through fast enough.

You are writing firmware from almost scratch, and it will be MUCH more complex than the standard Delta Rostock.

You will have A LOT of dynamic forces at play in this setup with all the steppers pushing against each other and inertial weights moving around.

Writing the firmware for this thing and getting it to work is the single biggest most complex thing you will have to do. It will be by no means a trivial task.

Edited 2 time(s). Last edit at 05/17/2013 09:33AM by ShadowRam.

Quote

Firmware could also be a challenge since I have never modified firmware before.

Wait what?!?

What are your programming skills like?

You will need to implement all the complex math Annirak posted, but just not get it working,

but write the code in a way that will be efficient for a low powered Arduino to crunch through fast enough.

You are writing firmware from almost scratch, and it will be MUCH more complex than the standard Delta Rostock.

You will have A LOT of dynamic forces at play in this setup with all the steppers pushing against each other and inertial weights moving around.

Writing the firmware for this thing and getting it to work is the single biggest most complex thing you will have to do. It will be by no means a trivial task.

Edited 2 time(s). Last edit at 05/17/2013 09:33AM by ShadowRam.

|

Re: Grounded Experimental Delta Printer May 17, 2013 10:36AM |

Registered: 11 years ago Posts: 979 |

ShadowRam Wrote:

-------------------------------------------------------

> Pretty awesome

>

> Firmware could also be a challenge since I have

> never modified firmware before.

>

> Wait what?!?

>

> What are your programming skills like?

>

> You will need to implement all the complex math

> Annirak posted, but just not get it working,

> but write the code in a way that will be efficient

> for a low powered Arduino to crunch through fast

> enough.

>

> You are writing firmware from almost scratch, and

> it will be MUCH more complex than the standard

> Delta Rostock.

>

> You will have A LOT of dynamic forces at play in

> this setup with all the steppers pushing against

> each other and inertial weights moving around.

>

> Writing the firmware for this thing and getting it

> to work is the single biggest most complex thing

> you will have to do. It will be by no means a

> trivial task.

I guess I should state that I am a computer scientist with almost a physics masters (all but thesis). Let me assure you that the math on this is very similar to the Rostock. With the design as is (sans wheels. The wheels cause major math issues.) there is a direct correlation between the string length and the distance from swivel to tool. I won't have to use any trig just the good all Pythagorean Theorem. One position can be solved for with 15 additions, 9 multiplies, and 3 square roots. I just sat down and looked at Rostock's inverse kinematics and it is almost the same. The only meaningful differences are some additions go to subtractions. I think a weekend of digging through the Rostock code will get this done. (I am knocking on the base of Simpson right now. (Knocking on wood.))

Edited 2 time(s). Last edit at 05/17/2013 10:39AM by nicholas.seward.

-------------------------------------------------------

> Pretty awesome

>

> Firmware could also be a challenge since I have

> never modified firmware before.

>

> Wait what?!?

>

> What are your programming skills like?

>

> You will need to implement all the complex math

> Annirak posted, but just not get it working,

> but write the code in a way that will be efficient

> for a low powered Arduino to crunch through fast

> enough.

>

> You are writing firmware from almost scratch, and

> it will be MUCH more complex than the standard

> Delta Rostock.

>

> You will have A LOT of dynamic forces at play in

> this setup with all the steppers pushing against

> each other and inertial weights moving around.

>

> Writing the firmware for this thing and getting it

> to work is the single biggest most complex thing

> you will have to do. It will be by no means a

> trivial task.

I guess I should state that I am a computer scientist with almost a physics masters (all but thesis). Let me assure you that the math on this is very similar to the Rostock. With the design as is (sans wheels. The wheels cause major math issues.) there is a direct correlation between the string length and the distance from swivel to tool. I won't have to use any trig just the good all Pythagorean Theorem. One position can be solved for with 15 additions, 9 multiplies, and 3 square roots. I just sat down and looked at Rostock's inverse kinematics and it is almost the same. The only meaningful differences are some additions go to subtractions. I think a weekend of digging through the Rostock code will get this done. (I am knocking on the base of Simpson right now. (Knocking on wood.))

Edited 2 time(s). Last edit at 05/17/2013 10:39AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 17, 2013 10:49AM |

Admin Registered: 16 years ago Posts: 13,888 |

... good luck! - when I first time calculated the positions for my 'magnetic-spheres-joints'-tripod in 2007 this was a trigonometric 'mess', but then found the simplicity in pythagoras based on a 'ground'-line between two of the columns ... it's really not so complex when simplifying the kinematics to the joints instead of calculating the radii and tooth-counts of gears

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Grounded Experimental Delta Printer May 17, 2013 12:59PM |

Registered: 15 years ago Posts: 401 |

nicholas.seward Wrote:

-------------------------------------------------------

> It was

> 20 days ago that I seriously started thinking

> about making a 3D printer that has no linear rails

> and low center of mass. 10 days ago I hit upon

> this basic geometry that allows a delta robot to

> actuate the elbow instead of the shoulder. 10

> days in the future I hope to have this thing done

> with enough documentation to enter the Gada

> Prize.

nicholas.seward Wrote:

-------------------------------------------------------

> I won't have to use any trig just the good all Pythagorean Theorem.

Do I get an honourable mention for removing your trig?

Good luck! I hope you manage to get the BOM costs of the extruder and frame low enough to hit the Gada Prize threshold!

-------------------------------------------------------

> It was

> 20 days ago that I seriously started thinking

> about making a 3D printer that has no linear rails

> and low center of mass. 10 days ago I hit upon

> this basic geometry that allows a delta robot to

> actuate the elbow instead of the shoulder. 10

> days in the future I hope to have this thing done

> with enough documentation to enter the Gada

> Prize.

nicholas.seward Wrote:

-------------------------------------------------------

> I won't have to use any trig just the good all Pythagorean Theorem.

Do I get an honourable mention for removing your trig?

Good luck! I hope you manage to get the BOM costs of the extruder and frame low enough to hit the Gada Prize threshold!

|

Re: Grounded Experimental Delta Printer May 17, 2013 01:07PM |

Registered: 11 years ago Posts: 979 |

Annirak Wrote:

-------------------------------------------------------

> nicholas.seward Wrote:

> --------------------------------------------------

> -----

> > It was

> > 20 days ago that I seriously started thinking

> > about making a 3D printer that has no linear

> rails

> > and low center of mass. 10 days ago I hit upon

> > this basic geometry that allows a delta robot

> to

> > actuate the elbow instead of the shoulder. 10

> > days in the future I hope to have this thing

> done

> > with enough documentation to enter the Gada

> > Prize.

>

> nicholas.seward Wrote:

> --------------------------------------------------

> -----

> > I won't have to use any trig just the good all

> Pythagorean Theorem.

>

> Do I get an honourable mention for removing your

> trig?

>

>

>

> Good luck! I hope you manage to get the BOM costs

> of the extruder and frame low enough to hit the

> Gada Prize threshold!

You have been instrumental in this whole process!!! I would be messing with wheels, string tensioning, and firmware from hell if it wasn't for you.

-------------------------------------------------------

> nicholas.seward Wrote:

> --------------------------------------------------

> -----

> > It was

> > 20 days ago that I seriously started thinking

> > about making a 3D printer that has no linear

> rails

> > and low center of mass. 10 days ago I hit upon

> > this basic geometry that allows a delta robot

> to

> > actuate the elbow instead of the shoulder. 10

> > days in the future I hope to have this thing

> done

> > with enough documentation to enter the Gada

> > Prize.

>

> nicholas.seward Wrote:

> --------------------------------------------------

> -----

> > I won't have to use any trig just the good all

> Pythagorean Theorem.

>

> Do I get an honourable mention for removing your

> trig?

>

>

>

> Good luck! I hope you manage to get the BOM costs

> of the extruder and frame low enough to hit the

> Gada Prize threshold!

You have been instrumental in this whole process!!! I would be messing with wheels, string tensioning, and firmware from hell if it wasn't for you.

|

Re: Grounded Experimental Delta Printer May 17, 2013 05:37PM |

Registered: 11 years ago Posts: 979 |

Here is the bill of materials. I am not going to stick to this exactly. For instance, I will use a 12"x12" heated bed but it is more expensive than the 8"x8". This also doesn't include tax and shipping. None of these prices are special bulk discounts. I have attached a more detailed spreadsheet complete with vendors. I would appreciate if you guys would take a look and see if I can further reduce the price. Does anyone know what price point I need to hit for the Gada Prize. I can't seems to find any mention of a price point only that it should be cheap.

Edited 10 time(s). Last edit at 05/18/2013 12:12AM by nicholas.seward.

Item Unit Cost Quantity Total

Microcontroller (Azteeg) $70.00 1 $70.00

Hot End $59.00 1 $59.00

Stepper Driver $12.49 4 $49.96

2lb Plastic $38.85 1 $38.85

Stepper $9.35 4 $37.40

3x6x2 Minature Bearing $1.42 18 $25.56

Silicone Heater Bed $19.99 1 $19.99

Glass $18.00 1 $18.00

Power Supply $17.99 1 $17.99

25x37x7 Thin Section Bearing $3.93 4 $15.72

Skate Bearing $0.40 26 $10.40

Hobbed Bolt $8.00 1 $8.00

Big Spring $2.01 3 $6.03

Hall Effect Sensor $1.34 3 $4.02

M3x45 $0.22 18 $3.96

Bowden Tube $1.37 2 $2.74

Braided Filament $2.54 1 $2.54

M3x25 $0.12 21 $2.52

Bed Leveling Spring $0.82 3 $2.46

Wooden Bed $2.28 1 $2.28

M3 Stopnut $0.04 51 $2.04

.25"x.25" N48 Magnet $0.50 3 $1.50

M3x10 $0.07 21 $1.47

5/16x3 Bolt $0.24 3 $0.72

5/16 Stopnut $0.06 12 $0.72

5/16x7.5 Bolt $0.65 1 $0.65

M3x50 $0.15 4 $0.60

5/16x2 Bolt $0.12 3 $0.36

5/16x1.5 Bolt $0.11 3 $0.33

M3x4 Set Screw $0.05 3 $0.15

M3 Nut $0.02 3 $0.06

Total: $406.02

Edited 10 time(s). Last edit at 05/18/2013 12:12AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 18, 2013 04:42AM |

Registered: 15 years ago Posts: 401 |

nicholas.seward Wrote:

-------------------------------------------------------

> You have been instrumental in this whole

> process!!! I would be messing with wheels, string

> tensioning, and firmware from hell if it wasn't

> for you.

Well, I'm glad I could help in the inception of a new architecture.

I don't think I can really help in cost reduction of the hardware parts. That's not really where my expertise lies; I'm more of an electronics and compsci guy. And, while I am aiming for improving the electronics, that's probably a few months away.

-------------------------------------------------------

> You have been instrumental in this whole

> process!!! I would be messing with wheels, string

> tensioning, and firmware from hell if it wasn't

> for you.

Well, I'm glad I could help in the inception of a new architecture.

I don't think I can really help in cost reduction of the hardware parts. That's not really where my expertise lies; I'm more of an electronics and compsci guy. And, while I am aiming for improving the electronics, that's probably a few months away.

|

Re: Grounded Experimental Delta Printer May 18, 2013 05:17AM |

Registered: 11 years ago Posts: 979 |

I finally figured out the work envelope. Each arm can drive the extruder from 3.568" to 15.259". If you do an intersection of the allowable zone for each arm you get this.

The usuable envelope that sticks above the build plate is roughly a Reuleaux Tetrahedron. The tip is 8.5" above the base. The footprint on the build platform has a Reuleaux Triangle shape where the inscribed triangle would have a side length of 14.5". The volume of the envelope is 600 cubic inches with no chance of the arm hitting a part that I can see. For reference, an 8" cube has a volume of 512 cubic inches. I personally think that this work envelope is great. You can do super wide parts and super tall parts. There is 140 square inches of build area. That is at least twice as big as most other RepRap machines.

I am so glad I did this. As you can see, most of the envelope is below the printer. I can make pylons for the corners if I would like an extra tall work envelope. I won't do the pylon idea yet because the main motivation is to make this cheap and portable with a low center of gravity. It is nice to know that I will be able to compete with Rostock on the height front if I want to. I think most people need wider more often than they need taller.

Update: I am getting lots of boxes. By Tuesday, I should have everything that is needed for a motion test.

Edited 2 time(s). Last edit at 05/18/2013 05:21AM by nicholas.seward.

The usuable envelope that sticks above the build plate is roughly a Reuleaux Tetrahedron. The tip is 8.5" above the base. The footprint on the build platform has a Reuleaux Triangle shape where the inscribed triangle would have a side length of 14.5". The volume of the envelope is 600 cubic inches with no chance of the arm hitting a part that I can see. For reference, an 8" cube has a volume of 512 cubic inches. I personally think that this work envelope is great. You can do super wide parts and super tall parts. There is 140 square inches of build area. That is at least twice as big as most other RepRap machines.

I am so glad I did this. As you can see, most of the envelope is below the printer. I can make pylons for the corners if I would like an extra tall work envelope. I won't do the pylon idea yet because the main motivation is to make this cheap and portable with a low center of gravity. It is nice to know that I will be able to compete with Rostock on the height front if I want to. I think most people need wider more often than they need taller.

Update: I am getting lots of boxes. By Tuesday, I should have everything that is needed for a motion test.

Edited 2 time(s). Last edit at 05/18/2013 05:21AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 19, 2013 04:50AM |

Registered: 11 years ago Posts: 30 |

Hello!

First of all, nice work!

I think all this talk about having to have a simple math is irrelevant.

One can write a script to convert the xyz paths that the slicer prints out to whatever geometry before printing, on the computer. (this script should split straight lines to small segments, because straight lines in xyz geometry are tipically not straight lines in other geometries) Than one can just use almost the regular Marlin or whatever. (only homeing needs to be changed)

I also have a question: What I don't see on this new design, how the steppers move the arms? Is there some spectra line or some belt which is not included on the pictures?

First of all, nice work!

I think all this talk about having to have a simple math is irrelevant.

One can write a script to convert the xyz paths that the slicer prints out to whatever geometry before printing, on the computer. (this script should split straight lines to small segments, because straight lines in xyz geometry are tipically not straight lines in other geometries) Than one can just use almost the regular Marlin or whatever. (only homeing needs to be changed)

I also have a question: What I don't see on this new design, how the steppers move the arms? Is there some spectra line or some belt which is not included on the pictures?

|

Re: Grounded Experimental Delta Printer May 19, 2013 06:23AM |

Registered: 15 years ago Posts: 401 |

alagi Wrote:

-------------------------------------------------------

> Hello!

>

> First of all, nice work!

>

> I think all this talk about having to have a

> simple math is irrelevant.

> One can write a script to convert the xyz paths

> that the slicer prints out to whatever geometry

> before printing, on the computer. (this script

> should split straight lines to small segments,

> because straight lines in xyz geometry are

> tipically not straight lines in other geometries)

> Than one can just use almost the regular Marlin or

> whatever. (only homeing needs to be changed)

It depends on how much preprocessing you want to do. In addition acceleration planning needs to take into account the real geometry. Suffice it to say that it's not even relevant since the architecture with the simpler math is simpler to build and calibrate too

> I also have a question: What I don't see on this

> new design, how the steppers move the arms? Is

> there some spectra line or some belt which is not

> included on the pictures?

nicholas.seward has not drawn in the 80lbs test fishing line which will be used. It connects from the stepper to the top of the arm that connects to the base, then loops around the pulley on the arm that connects to the toolhead. You'll note that he talks about using a block and tackle, which means that the precision can be increased by looping more fishing line, or that a weaker stepper motor can compensate with more loops.

-------------------------------------------------------

> Hello!

>

> First of all, nice work!

>

> I think all this talk about having to have a

> simple math is irrelevant.

> One can write a script to convert the xyz paths

> that the slicer prints out to whatever geometry

> before printing, on the computer. (this script

> should split straight lines to small segments,

> because straight lines in xyz geometry are

> tipically not straight lines in other geometries)

> Than one can just use almost the regular Marlin or

> whatever. (only homeing needs to be changed)

It depends on how much preprocessing you want to do. In addition acceleration planning needs to take into account the real geometry. Suffice it to say that it's not even relevant since the architecture with the simpler math is simpler to build and calibrate too

> I also have a question: What I don't see on this

> new design, how the steppers move the arms? Is

> there some spectra line or some belt which is not

> included on the pictures?

nicholas.seward has not drawn in the 80lbs test fishing line which will be used. It connects from the stepper to the top of the arm that connects to the base, then loops around the pulley on the arm that connects to the toolhead. You'll note that he talks about using a block and tackle, which means that the precision can be increased by looping more fishing line, or that a weaker stepper motor can compensate with more loops.

|

Re: Grounded Experimental Delta Printer May 19, 2013 06:54AM |

Registered: 11 years ago Posts: 30 |

"Suffice it to say that it's not even relevant since the architecture with the simpler math is simpler to build and calibrate too"

That's the real reason to build it this way, I don't think one should think about the math being a limiting factor. Find the best solution mechanically, the math problems are much easier to solve.

I think as a first solution one can leave acceleration settings as they are. The acceleration of the hotend will be some function times the acceleration of the coordinates, where this function will not be something very wild, in the whole build volume it should not change more than say a factor of 2 or so (because the angle of the arms, and so the effective radius of an arm do not change that much for the whole of the build volume), so one can give a setting for the worst case scenario (biggest effective radius), and in practice the acceleration of the hotend will be even a little bit smaller than that.

"nicholas.seward has not drawn in the 80lbs test fishing line which will be used. It connects from the stepper to the top of the arm that connects to the base, then loops around the pulley on the arm that connects to the toolhead."

Do I understand correctly that it is not a closed loop of fishing line, but the stepper has a spool which it winds up and unwinds as needed? The tricky part seems to be sourcing that big springs. Where do you get some like that?

Edited 1 time(s). Last edit at 05/19/2013 06:59AM by alagi.

That's the real reason to build it this way, I don't think one should think about the math being a limiting factor. Find the best solution mechanically, the math problems are much easier to solve.

I think as a first solution one can leave acceleration settings as they are. The acceleration of the hotend will be some function times the acceleration of the coordinates, where this function will not be something very wild, in the whole build volume it should not change more than say a factor of 2 or so (because the angle of the arms, and so the effective radius of an arm do not change that much for the whole of the build volume), so one can give a setting for the worst case scenario (biggest effective radius), and in practice the acceleration of the hotend will be even a little bit smaller than that.

"nicholas.seward has not drawn in the 80lbs test fishing line which will be used. It connects from the stepper to the top of the arm that connects to the base, then loops around the pulley on the arm that connects to the toolhead."

Do I understand correctly that it is not a closed loop of fishing line, but the stepper has a spool which it winds up and unwinds as needed? The tricky part seems to be sourcing that big springs. Where do you get some like that?

Edited 1 time(s). Last edit at 05/19/2013 06:59AM by alagi.

|

Re: Grounded Experimental Delta Printer May 19, 2013 10:04AM |

Registered: 11 years ago Posts: 979 |

@alagi:

I am using this spring. I have actually already received the parts and they are stiffer than I hoped so I had to make some hangers to shorten the needed spring extension. I will have to run tests but I suspect that I can half the stiffness of the spring and transition to Nema14 motors and everything will be fine. The design as is should be able to do 5g plus without overcoming the springs. If I limit that to 2g's the smaller springs would be fine.

Sorry, I haven't been able to draw the string in yet. Here is the arrangement. Everything that Annirak said is accurate. You are right that the string winds and and unwinds.

You are also right that the need to handle the geometry in firmware is not required but it would be nice. I would like to be able to connect my printer up to anyone elses computer that is setup for a 3D printer and have them be able to use it. At this point, with the reduced geometry, there is no reason not to put it in firmware.

Edited 1 time(s). Last edit at 05/19/2013 10:04AM by nicholas.seward.

I am using this spring. I have actually already received the parts and they are stiffer than I hoped so I had to make some hangers to shorten the needed spring extension. I will have to run tests but I suspect that I can half the stiffness of the spring and transition to Nema14 motors and everything will be fine. The design as is should be able to do 5g plus without overcoming the springs. If I limit that to 2g's the smaller springs would be fine.

Sorry, I haven't been able to draw the string in yet. Here is the arrangement. Everything that Annirak said is accurate. You are right that the string winds and and unwinds.

You are also right that the need to handle the geometry in firmware is not required but it would be nice. I would like to be able to connect my printer up to anyone elses computer that is setup for a 3D printer and have them be able to use it. At this point, with the reduced geometry, there is no reason not to put it in firmware.

Edited 1 time(s). Last edit at 05/19/2013 10:04AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 24, 2013 06:06PM |

Registered: 11 years ago Posts: 979 |

Simpson lives!

This is the first (documented) dry run of Simpson. A RepRap 3D printer. There are some visible issues. The extruder will pitch and roll causing the extruder tip to be as much as 5mm from the expected position. I have ideas on how to fix that. Stay tuned. (Almost all the sound is coming from plastic pulleys grinding on plastic pulleys. I already have a redesign that should eliminate this. Additionally, the next source of sound is power supply's fan. I am going to crack it open and replace the fan with a more expensive one or a bigger one. If I can address those issues, the steppers with 1/32 micro-stepping are virtually silent.)

Interesting note: I don't think I will need any electronic end stops. As soon as the motors turn off Simpson zooms up to the top most position. I am planning on pulling each arm in 10 mm and then pulse the hold on the steppers on and off so Simpson can gracefully reach the natural home position without hurting himself.

The pitch and roll can be solved with multiple mount points. This will cause me to double up each arm. This will add complexity. I was pretty sure I was already going to have to do this but I am a big fan of not solving problems before they are problems. Can I fix it in 7 days and document in time for the Gada Prize? Probably not. I will try anyways. Heck, this was only an idea 16 days ago. In that time I have gone through 3 major redesigns, acquired all the parts, and have successfully built a functional prototype.

For those that are interested, the spring is perfect. If it was any weaker or stronger, there would be issues. When the extruder is close to the bed the springs are almost too weak and when the arms make a 90 degree angle, the spring is almost too strong. It is unlikely that I will be able to go with Nema14 motors unless I put a few more loops on the block and tackle setup.

Edited 4 time(s). Last edit at 05/24/2013 06:33PM by nicholas.seward.

This is the first (documented) dry run of Simpson. A RepRap 3D printer. There are some visible issues. The extruder will pitch and roll causing the extruder tip to be as much as 5mm from the expected position. I have ideas on how to fix that. Stay tuned. (Almost all the sound is coming from plastic pulleys grinding on plastic pulleys. I already have a redesign that should eliminate this. Additionally, the next source of sound is power supply's fan. I am going to crack it open and replace the fan with a more expensive one or a bigger one. If I can address those issues, the steppers with 1/32 micro-stepping are virtually silent.)

Interesting note: I don't think I will need any electronic end stops. As soon as the motors turn off Simpson zooms up to the top most position. I am planning on pulling each arm in 10 mm and then pulse the hold on the steppers on and off so Simpson can gracefully reach the natural home position without hurting himself.

The pitch and roll can be solved with multiple mount points. This will cause me to double up each arm. This will add complexity. I was pretty sure I was already going to have to do this but I am a big fan of not solving problems before they are problems. Can I fix it in 7 days and document in time for the Gada Prize? Probably not. I will try anyways. Heck, this was only an idea 16 days ago. In that time I have gone through 3 major redesigns, acquired all the parts, and have successfully built a functional prototype.

For those that are interested, the spring is perfect. If it was any weaker or stronger, there would be issues. When the extruder is close to the bed the springs are almost too weak and when the arms make a 90 degree angle, the spring is almost too strong. It is unlikely that I will be able to go with Nema14 motors unless I put a few more loops on the block and tackle setup.

Edited 4 time(s). Last edit at 05/24/2013 06:33PM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer May 27, 2013 09:32PM |

Registered: 11 years ago Posts: 89 |

|

Re: Grounded Experimental Delta Printer May 28, 2013 09:42AM |

Registered: 11 years ago Posts: 265 |

|

Re: Grounded Experimental Delta Printer May 28, 2013 01:56PM |

Registered: 11 years ago Posts: 979 |

Thanks guys. I am sure trying.

I have a radical redesign in the mix. I will be heading over to QU-BD today. They are going to help me laser-cut most of the design. Unfortunately, I don't get to reuse any of the printed pieces from my first attempt. I will be printing nonstop for the next 24 hours. (The design will work and will be great but it just isn't as elegant as my first attempt. I feel that it is overly complex but at this point I am going to charge ahead with a design I know will work instead of worrying about every detail. Once the internet comes back on at my house, I will post a new video without the strings and springs.)

One cool advancement that I have made is to move the block and tackle to the inside of the arm. That allows me to take more liberties when attaching parallel linkages. One bad thing I had to do was to increase the diameter of the machine by 6 inches. This thing is getting a little unruly. However, I have to start somewhere. I will get this second prototype done in the next few days and put a token entry in for the Gada Prize. (I don't expect much.) After (when) I get some good prints, I will start optimizing the design. My most important goal is to have Simpson on this page. Miles to go!

I have a radical redesign in the mix. I will be heading over to QU-BD today. They are going to help me laser-cut most of the design. Unfortunately, I don't get to reuse any of the printed pieces from my first attempt. I will be printing nonstop for the next 24 hours. (The design will work and will be great but it just isn't as elegant as my first attempt. I feel that it is overly complex but at this point I am going to charge ahead with a design I know will work instead of worrying about every detail. Once the internet comes back on at my house, I will post a new video without the strings and springs.)

One cool advancement that I have made is to move the block and tackle to the inside of the arm. That allows me to take more liberties when attaching parallel linkages. One bad thing I had to do was to increase the diameter of the machine by 6 inches. This thing is getting a little unruly. However, I have to start somewhere. I will get this second prototype done in the next few days and put a token entry in for the Gada Prize. (I don't expect much.) After (when) I get some good prints, I will start optimizing the design. My most important goal is to have Simpson on this page. Miles to go!

|

Re: Grounded Experimental Delta Printer May 28, 2013 04:22PM |

Admin Registered: 16 years ago Posts: 13,888 |

... your head with two gears hold in plastic won't be stable enough - reread my post with the 2-store-'press-bearing' - you need a much more squeezed setup or the tool wont get enough rigidity with printed parts!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Grounded Experimental Delta Printer May 29, 2013 12:56AM |

Registered: 11 years ago Posts: 979 |

VDX Wrote:

-------------------------------------------------------

> ... your head with two gears hold in plastic won't

> be stable enough - reread my post with the

> 2-store-'press-bearing' - you need a much more

> squeezed setup or the tool wont get enough

> rigidity with printed parts!

I pretty much do what you are saying only with side loaded off the shelf bearings instead of building my own. You can see the exploded assembly here of a previous design that is similar to what I am still using. Based on my experiments, play due to this bearing stack is virtually nil. I don't believe it will have an effect on prints. It is definitely a second order effect compared to the torsion of the 16" arms. My new design will hopefully eliminate the need to have torsional stability.

Thanks,

Nicholas Seward

-------------------------------------------------------

> ... your head with two gears hold in plastic won't

> be stable enough - reread my post with the

> 2-store-'press-bearing' - you need a much more

> squeezed setup or the tool wont get enough

> rigidity with printed parts!

I pretty much do what you are saying only with side loaded off the shelf bearings instead of building my own. You can see the exploded assembly here of a previous design that is similar to what I am still using. Based on my experiments, play due to this bearing stack is virtually nil. I don't believe it will have an effect on prints. It is definitely a second order effect compared to the torsion of the 16" arms. My new design will hopefully eliminate the need to have torsional stability.

Thanks,

Nicholas Seward

|

Re: Grounded Experimental Delta Printer May 29, 2013 01:26AM |

Registered: 11 years ago Posts: 979 |

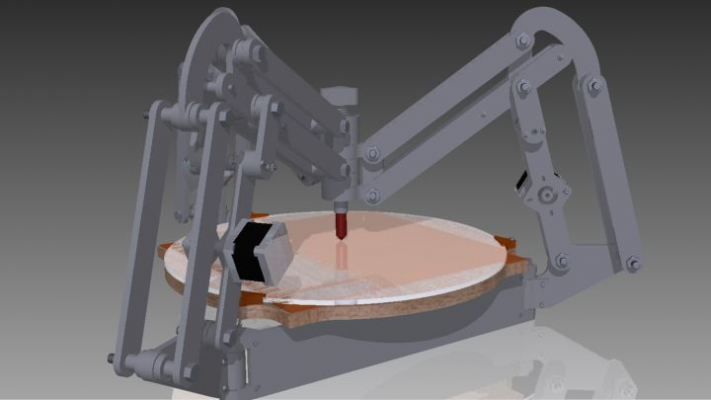

Video

Here is a rendering of my new design. I have just gotten back from QU-BD. They were generous enough to laser cut all my parts. I am now frantically printing out the remainder of the parts. (I hate plastic that isn't spooled. I am probably 8 hours behind due to rat nesting killing some of my unattended prints.) This is a very ugly design in my eyes. I think it will work but I hate the complexity. It does have the benefit of side stepping the torsional rigidity issue. I may grow to love it. Who knows?

My previous design is very elegant and I am going to revisit it to see if I can achieve the torsional rigidity that I need to make this a 3D printer. A few simple tricks (namely creating a unibeam instead of two uncoupled pieces of 1/4" flat stock) could increase the rigidity by a factor of 10. That has the potential of reducing the 5mm play down to .5mm. I definitely want to try that out before I give up on its simplicity.

Edited 5 time(s). Last edit at 05/30/2013 02:36AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer June 01, 2013 11:07AM |

Registered: 11 years ago Posts: 979 |

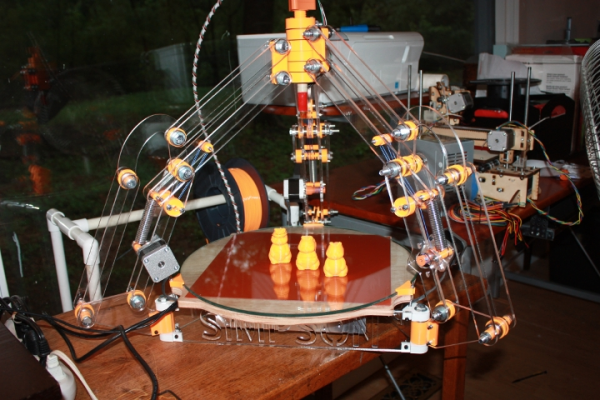

SIMPSON'S FIRST PRINT

Here is Simpson showing off his creations. I didn't print all at the same time. In fact, I won't be able to until I work on bed leveling issues.

Left: 30mm/s, .3 layer height, no standard bowden tweaks (The filament drive had a loose set screw.)

Middle: 30-90mm/s, .4 layer height, no standard bowden tweaks (This is my printrbot's configuration file.)

Right: 30mm/s, .25 layer height, bowden tweaks (I could push the speed up. With stiffer springs, I expect to be able to print at 100mm/s without diminished quality.)

You can see the near perfect print on the right. Not a striation looks out of place.

I still have a few issues to work out.

*The spring should probably be twice as stiff and the springs attaching geometry should be analyzed with math (Oh no, not math.) to make sure the spring is effective in the whole print envelope.

*Work out the math for quick calibration. I had to spend a lot of time on calibration. There is no reason I could not have a sheet of paper with a few dots on it and move the tip of the extruder to each dot and then enter in all the position data and have the computer figure out the exact geometry. Some of the distances that need to be measured are hard to measure to the accuracy needed in the traditional way.

*Come up with a good way to make it easy to string the pulleys and hard for the string to slip off. (The string never slipped off during a print but as I was calibrating I would occasionally have the printer go the wrong direction and then everything would get messed up.)

*I don't have firmware written yet. I tried to modify repetier and failed. (I spent 1 hour. Time is very tight right now.) In the interest of time, I wrote a super simple python program that transforms standard gcode to match my geometry.

Surprises:

*The x and y rigidity are amazing. There is just a little hysteresis in the z direction but nothing that really shows up in a print and it will disappear with stronger springs.

*The central hub doesn't really need to tight when you have two connections per arm.

*Homing by turning the motors off and letting the printer go to its apex under spring assist and then zeroing all the motors works amazingly. It is very repeatable.

*I can probably remove half of some of the double arms and keep the rigidity.

*Even a poorly calibrated machine can print if you can find a way to get past the first couple of layers.

*Long moves (30-40mm) don't bow much even when I don't break a move into a bunch of little segments. All the long moves are inside the part and it bows so the highest point is in the middle of a move. The way it is now, there is little need to segmentize unless I am print perimeters with straight lines. My test squirrel had no straight lines.

*Ignore the fact that I didn't fully tighten the set screw, my new filament drive worked great. I is a very compact unit. It is designed to sit on the table and to pull filament from its side and push it out the top. It isn't much bigger than the stepper itself. I will be refining it and publishing it on Thingiverse soon.

*Assuming this printer isn't perfectly made, it is over constrained. That is usually a bad thing but in this case it uses the flexibility of the system to average between the fighting constraints. This allows a system with low rigidity to have a rigid effector.

*The machines prints get better with time. It literally works out its own kinks.

Crazy Ideas:

*You could flip this upside down and get rid of the springs and add enough weight to the head so you can get repeatable positioning.

*You could get rid of most of the bearings, if not all. Close tolerances paired with bolts and stop nuts would probably be good enough. This design is very tolerant of slop.

For those of you that are following all my designs and redesigns, the other design I built with the simpler arms is going to get revisited. Now that I have a large 3D printer, I will be able to print out 10 inch arms that are optimized for torsional rigidity.

Gada Prize News: I almost pushed out a bunch documentation and parts for the current iteration of my printer. I realized that it doesn't really stand a chance as is and I don't want to proliferate a substandard design. I got the bright idea that I could ask for an extension since I have only been at this for 23 days. I just got news that I am cleared for a 15 day extension. Based on my current trajectory, I can do a lot in that time.

Edited 1 time(s). Last edit at 06/01/2013 11:11AM by nicholas.seward.

Here is Simpson showing off his creations. I didn't print all at the same time. In fact, I won't be able to until I work on bed leveling issues.

Left: 30mm/s, .3 layer height, no standard bowden tweaks (The filament drive had a loose set screw.)

Middle: 30-90mm/s, .4 layer height, no standard bowden tweaks (This is my printrbot's configuration file.)

Right: 30mm/s, .25 layer height, bowden tweaks (I could push the speed up. With stiffer springs, I expect to be able to print at 100mm/s without diminished quality.)

You can see the near perfect print on the right. Not a striation looks out of place.

I still have a few issues to work out.

*The spring should probably be twice as stiff and the springs attaching geometry should be analyzed with math (Oh no, not math.) to make sure the spring is effective in the whole print envelope.

*Work out the math for quick calibration. I had to spend a lot of time on calibration. There is no reason I could not have a sheet of paper with a few dots on it and move the tip of the extruder to each dot and then enter in all the position data and have the computer figure out the exact geometry. Some of the distances that need to be measured are hard to measure to the accuracy needed in the traditional way.

*Come up with a good way to make it easy to string the pulleys and hard for the string to slip off. (The string never slipped off during a print but as I was calibrating I would occasionally have the printer go the wrong direction and then everything would get messed up.)

*I don't have firmware written yet. I tried to modify repetier and failed. (I spent 1 hour. Time is very tight right now.) In the interest of time, I wrote a super simple python program that transforms standard gcode to match my geometry.

Surprises:

*The x and y rigidity are amazing. There is just a little hysteresis in the z direction but nothing that really shows up in a print and it will disappear with stronger springs.

*The central hub doesn't really need to tight when you have two connections per arm.

*Homing by turning the motors off and letting the printer go to its apex under spring assist and then zeroing all the motors works amazingly. It is very repeatable.

*I can probably remove half of some of the double arms and keep the rigidity.

*Even a poorly calibrated machine can print if you can find a way to get past the first couple of layers.

*Long moves (30-40mm) don't bow much even when I don't break a move into a bunch of little segments. All the long moves are inside the part and it bows so the highest point is in the middle of a move. The way it is now, there is little need to segmentize unless I am print perimeters with straight lines. My test squirrel had no straight lines.

*Ignore the fact that I didn't fully tighten the set screw, my new filament drive worked great. I is a very compact unit. It is designed to sit on the table and to pull filament from its side and push it out the top. It isn't much bigger than the stepper itself. I will be refining it and publishing it on Thingiverse soon.

*Assuming this printer isn't perfectly made, it is over constrained. That is usually a bad thing but in this case it uses the flexibility of the system to average between the fighting constraints. This allows a system with low rigidity to have a rigid effector.

*The machines prints get better with time. It literally works out its own kinks.

Crazy Ideas:

*You could flip this upside down and get rid of the springs and add enough weight to the head so you can get repeatable positioning.

*You could get rid of most of the bearings, if not all. Close tolerances paired with bolts and stop nuts would probably be good enough. This design is very tolerant of slop.

For those of you that are following all my designs and redesigns, the other design I built with the simpler arms is going to get revisited. Now that I have a large 3D printer, I will be able to print out 10 inch arms that are optimized for torsional rigidity.

Gada Prize News: I almost pushed out a bunch documentation and parts for the current iteration of my printer. I realized that it doesn't really stand a chance as is and I don't want to proliferate a substandard design. I got the bright idea that I could ask for an extension since I have only been at this for 23 days. I just got news that I am cleared for a 15 day extension. Based on my current trajectory, I can do a lot in that time.

Edited 1 time(s). Last edit at 06/01/2013 11:11AM by nicholas.seward.

|

Re: Grounded Experimental Delta Printer June 01, 2013 01:03PM |

Admin Registered: 17 years ago Posts: 7,879 |

Amazing! I never thought it would work so well. Well done for pulling it off.

Edited 1 time(s). Last edit at 06/01/2013 01:03PM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 06/01/2013 01:03PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Grounded Experimental Delta Printer June 01, 2013 01:22PM |

Registered: 11 years ago Posts: 979 |

I didn't expect it to be this good at this point. I always expected it to work but I was doubtful that it would be able to do high quality prints. I have about 5 optimization that I am going to throw on next week so I think this has the potential to be a serious printer.

This is a testament that if you throw enough engineering at a problem you can eventually solve it.

This is a testament that if you throw enough engineering at a problem you can eventually solve it.

|

Re: Grounded Experimental Delta Printer June 01, 2013 01:48PM |

Registered: 11 years ago Posts: 89 |

|

Re: Grounded Experimental Delta Printer June 01, 2013 06:00PM |

Admin Registered: 16 years ago Posts: 13,888 |

Hi Nicholas,

really well done!

It shows, the stability of the head is good enough to stay in place with low torques.

Next question - how fast can you go with some 'beefier' motors?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

really well done!

It shows, the stability of the head is good enough to stay in place with low torques.

Next question - how fast can you go with some 'beefier' motors?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.