The "Flying Extruder" Mod

Posted by ähM_Key

|

Re: The "Flying Extruder" Mod February 03, 2016 10:21PM |

Registered: 8 years ago Posts: 75 |

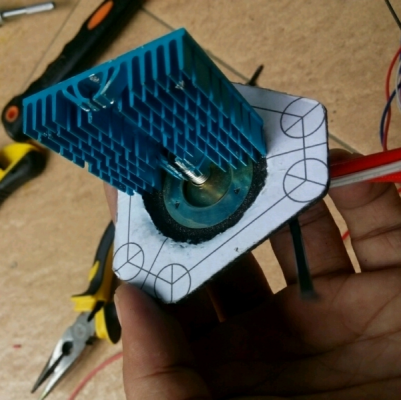

Oh, that contraption? I bought my kit from local guy. So I need to bend some fins on a computer heatsink, and force the cold end through the fins so the cold end taps the thread on the aluminium.Quote

sungod3k

Never mind the extrudercan I get a pic of the other side of the hot end? how are the cooling ribs integrated in the hot zone?

If you need pictures, see the thread here.

|

Re: The "Flying Extruder" Mod February 03, 2016 11:02PM |

Registered: 8 years ago Posts: 916 |

|

Re: The "Flying Extruder" Mod February 04, 2016 12:17AM |

Registered: 8 years ago Posts: 75 |

|

Re: The "Flying Extruder" Mod February 04, 2016 12:52AM |

Registered: 11 years ago Posts: 805 |

|

Re: The "Flying Extruder" Mod February 20, 2016 11:15PM |

Registered: 9 years ago Posts: 58 |

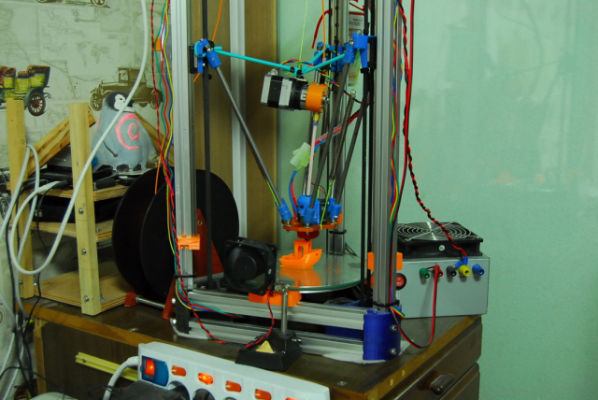

My version of the Flying Extruder .

|

Re: The "Flying Extruder" Mod February 21, 2016 07:56PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: The "Flying Extruder" Mod February 22, 2016 07:54AM |

Registered: 9 years ago Posts: 58 |

|

Re: The "Flying Extruder" Mod March 10, 2016 06:28AM |

Registered: 9 years ago Posts: 189 |

|

Re: The "Flying Extruder" Mod March 10, 2016 06:40AM |

Registered: 9 years ago Posts: 189 |

|

Re: The "Flying Extruder" Mod March 12, 2016 02:06PM |

Registered: 9 years ago Posts: 51 |

Quote

nebbian

Thank you all for posting your ideas and experiences with this system.

I finally put mine together tonight, here's a picture of it:

[attachment 69215 IMG_5147.jpeg]

Haven't had much time with it yet, but I have high hopes. I've hit the limits of a long bowden tube, this one is 5 times shorter than the old system so that's got to be 5 times better, right?

Looking forward to seeing how it performs.

Thanks for posting your files on thingiverse

Here's mine in action...

[youtu.be]

|

Re: The "Flying Extruder" Mod March 13, 2016 10:12AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: The "Flying Extruder" Mod March 13, 2016 10:49PM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

I wonder how long it will be until the flying extruder is the default system for deltas. The only thing that comes close is flex3drive, and I chose not to fit one as the flying extruder works so well.

Agreed! I was close to ordering a flex3drive, and would have done so if the flying extruder hadn't worked out. The flying extruder is free, compared to the price of a flex3drive, which helped make my mind up

It would be nice if someone came up with a flexible mounting system that didn't look as backyard bodge as my rubber bands... maybe those silicon oil filled tubes with a hook on each end, that you use to stop tennis racquets from making a 'boing' noise?

|

Re: The "Flying Extruder" Mod March 15, 2016 09:08AM |

Registered: 9 years ago Posts: 51 |

I was thinking of using shocks from an RC car. Without the spring but the oil filled damper would work well I think. Now i have it built i can work out the best stroke length.

One thing I'm not keen on is if the motors turn off while the head is off to one edge the weight/mass causes the head to drop to the middle (where all three carrages/motors have enough resistance to hold the weight, or it hits the bed). This happens to me while to me while the head is heating up and is parked close to the edge of the build plate (so drips dont fall within the build area). After a few seconds of holding strong the motors relax and..... crash/lost position. There is probably something in the code i can change. For now i'm just parking in the center of the bed, it solves the problem but causes its own problem with drips on the build plate.

One thing I'm not keen on is if the motors turn off while the head is off to one edge the weight/mass causes the head to drop to the middle (where all three carrages/motors have enough resistance to hold the weight, or it hits the bed). This happens to me while to me while the head is heating up and is parked close to the edge of the build plate (so drips dont fall within the build area). After a few seconds of holding strong the motors relax and..... crash/lost position. There is probably something in the code i can change. For now i'm just parking in the center of the bed, it solves the problem but causes its own problem with drips on the build plate.

|

Re: The "Flying Extruder" Mod March 17, 2016 11:55AM |

Registered: 9 years ago Posts: 58 |

I updated my flying extruder with a counterweight suspension system. There's virtually no shaking and thrashing about of the extruder. Extra load on the effector and motors virtually zero.

Edited 1 time(s). Last edit at 03/17/2016 02:41PM by boksbox.

Edited 1 time(s). Last edit at 03/17/2016 02:41PM by boksbox.

|

Re: The "Flying Extruder" Mod March 17, 2016 12:07PM |

Registered: 11 years ago Posts: 805 |

private videoQuote

boksbox

I updated my flying extruder with a counterweight suspension system. There's virtually no shaking and thrashing about of the extruder. Load on steppers virtually zero.

|

Re: The "Flying Extruder" Mod March 17, 2016 02:43PM |

Registered: 9 years ago Posts: 58 |

Quote

sungod3k

private videoQuote

boksbox

I updated my flying extruder with a counterweight suspension system. There's virtually no shaking and thrashing about of the extruder. Load on steppers virtually zero.

Oops! Fixed

|

Re: The "Flying Extruder" Mod March 17, 2016 02:50PM |

Registered: 11 years ago Posts: 27 |

Quote

boksbox

I updated my flying extruder with a counterweight suspension system

Great!

Could be a good alternative to my counterweight system with 3 weights.

MK

Edited 1 time(s). Last edit at 03/17/2016 02:50PM by ähM_Key.

|

Re: The "Flying Extruder" Mod March 18, 2016 10:52AM |

Registered: 9 years ago Posts: 58 |

|

Re: The "Flying Extruder" Mod March 20, 2016 10:35AM |

Registered: 9 years ago Posts: 189 |

Kudos to the OP and other members!

Here is mine.

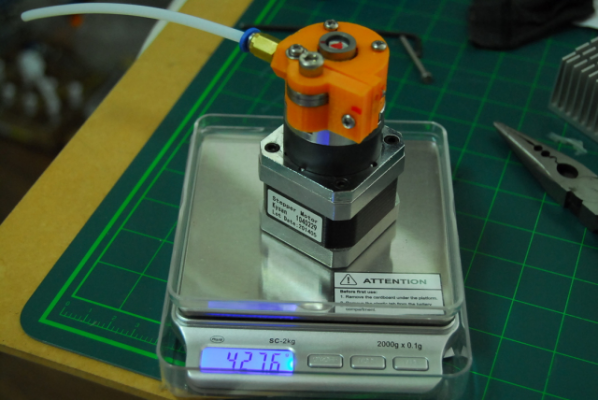

Two pulleys support the 480 g of counter weight.

The extruder weighs 427.6 g.

Nema 17 geared motor was heavier than I thought. I made the PTFE tube's length to 15 cm.

Printing a 3D bench ship model.

Layer height: 0.25 mm

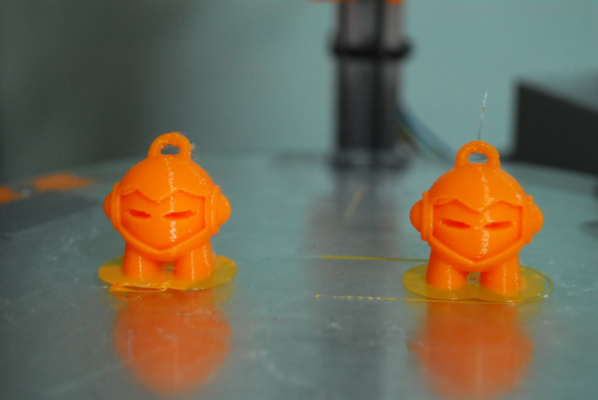

Second test printing, two Marvins.

Layer height: 0.25 mm

Here is mine.

Two pulleys support the 480 g of counter weight.

The extruder weighs 427.6 g.

Nema 17 geared motor was heavier than I thought. I made the PTFE tube's length to 15 cm.

Printing a 3D bench ship model.

Layer height: 0.25 mm

Second test printing, two Marvins.

Layer height: 0.25 mm

|

Re: The "Flying Extruder" Mod March 21, 2016 10:36AM |

Registered: 9 years ago Posts: 51 |

|

Re: The "Flying Extruder" Mod March 23, 2016 10:40PM |

Registered: 9 years ago Posts: 189 |

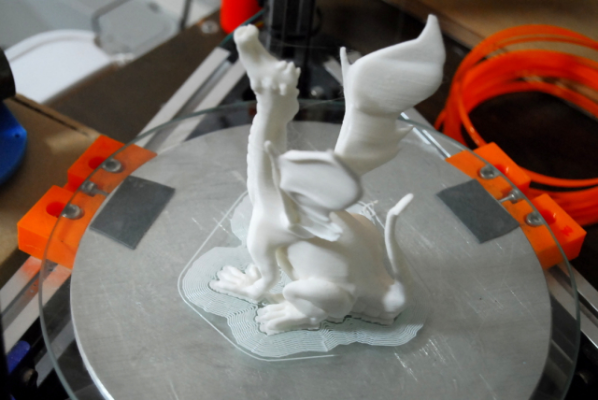

While in printing the extrude moves alot, which is fun to watch.

But strangely printing results so far are quite amazing beyond my wildest imagination.

I reduce the Bowden tube's length and see how it would affect printing quality.

Loaded /home/penguin/Wsp/3D_Printer/gcode_files/loubie_adalinda_dragon_eSun_PLA.gcode, 545837 lines

14597.81mm of filament used in this print

The print goes:

- from -42.68 mm to 42.67 mm in X and is 85.35 mm wide

- from -41.23 mm to 44.74 mm in Y and is 85.97 mm deep

- from 0.00 mm to 103.80 mm in Z and is 103.80 mm high

Estimated duration: 516 layers, 5:53:06

Print started at: 21:14:20

SENDING:M107

Print ended at: 01:10:32 and took 3:56:12

Edited 1 time(s). Last edit at 03/23/2016 10:42PM by janpenguin.

But strangely printing results so far are quite amazing beyond my wildest imagination.

I reduce the Bowden tube's length and see how it would affect printing quality.

Loaded /home/penguin/Wsp/3D_Printer/gcode_files/loubie_adalinda_dragon_eSun_PLA.gcode, 545837 lines

14597.81mm of filament used in this print

The print goes:

- from -42.68 mm to 42.67 mm in X and is 85.35 mm wide

- from -41.23 mm to 44.74 mm in Y and is 85.97 mm deep

- from 0.00 mm to 103.80 mm in Z and is 103.80 mm high

Estimated duration: 516 layers, 5:53:06

Print started at: 21:14:20

SENDING:M107

Print ended at: 01:10:32 and took 3:56:12

Edited 1 time(s). Last edit at 03/23/2016 10:42PM by janpenguin.

|

Re: The "Flying Extruder" Mod March 24, 2016 08:59AM |

Registered: 8 years ago Posts: 916 |

|

Re: The "Flying Extruder" Mod April 07, 2016 09:39AM |

Registered: 8 years ago Posts: 3,525 |

I think this mod is so successful that it ought to be considered stabdard for delta printers. You could achieve the same with flex3drive but that's £100 of kit not some new carriages and some elastic.

I'm thinking about trying to make one for a corexy which would be an extruder suspended from perhaps a single elastic.

I'm thinking about trying to make one for a corexy which would be an extruder suspended from perhaps a single elastic.

|

Re: The "Flying Extruder" Mod April 07, 2016 11:44AM |

Registered: 8 years ago Posts: 916 |

You're not wrong DjDemonD, I've been going down a similar thought pattern myself.

I'm also considering a coreXY, if only to finally be able to get repeatable prints (within 0.02mm) when printed in different areas of the bed. A flying extruder on a CoreXY would give the best of all worlds.

Strange that you can't buy a commercial CoreXY yet.

I'm also considering a coreXY, if only to finally be able to get repeatable prints (within 0.02mm) when printed in different areas of the bed. A flying extruder on a CoreXY would give the best of all worlds.

Strange that you can't buy a commercial CoreXY yet.

|

Re: The "Flying Extruder" Mod April 07, 2016 12:20PM |

Registered: 10 years ago Posts: 140 |

Quote

nebbian

You're not wrong DjDemonD, I've been going down a similar thought pattern myself.

I'm also considering a coreXY, if only to finally be able to get repeatable prints (within 0.02mm) when printed in different areas of the bed. A flying extruder on a CoreXY would give the best of all worlds.

Strange that you can't buy a commercial CoreXY yet.

You can purchase the fusion f306.

|

Re: The "Flying Extruder" Mod April 07, 2016 12:39PM |

Registered: 8 years ago Posts: 3,525 |

Commercial no, but smartrapcore alu is good. I've got one and its very precise with a few necessary mods. I'm going to extend it to 300x200mm and enclose it. A flying extruder would be a huge boost, but flex3drive works very well, its just more complex and expensive than flying extruder.

|

Re: The "Flying Extruder" Mod April 11, 2016 09:48PM |

Registered: 9 years ago Posts: 58 |

|

Re: The "Flying Extruder" Mod April 12, 2016 03:49AM |

Registered: 8 years ago Posts: 3,525 |

The only thing I can think of and I haven't tried it at all, would be the extruder suspended on a single elastic from a support above the print head.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod April 12, 2016 10:05AM |

Registered: 8 years ago Posts: 916 |

How about something like the gantry you see above car washes, maybe with an elbow joint in the middle?

That would support the extruder motor, and with a small bowden cable you'd get decoupling of the extruder motor to the hot end.

That would support the extruder motor, and with a small bowden cable you'd get decoupling of the extruder motor to the hot end.

|

Re: The "Flying Extruder" Mod April 12, 2016 10:50AM |

Registered: 8 years ago Posts: 3,525 |

That's a good idea, its trying to work out exactly what range of movement you would need in order to reach the extremes of the bed without pulling the bowden tube out, and be able to operate over bed centre without too much interference to the print head of the bowden tube at its shortest approach. I am sure with super elastic materials we can bridge the gap, some sort of free moving arm would help immensely. It would have to be very low friction, and dampened or limited somehow to prevent it getting stuck in any particular position. I think this could work, it looks a bit unlikely but that's what I thought (and many still think) about the delta flying extruder before actually building one and finding out.

On the other side of the coin if we could build/buy a light-enough direct extruder we would have the problem solved since increasing print head mass is less critical on corexy than on delta. So the gain from flying/suspended extruder is potentially less over a lightweight direct extruder. Flex3drive is good but a $100+ addition.

If I get time I might try to suspend a bowden extruder over the corexy somehow. I wonder if it would work just suspended on one elastic element? As long as its elastic enough or long enough (or both).

How about just taking the 4 verticals of the corexy upwards by say 200mm and suspending the extruder from 4 elastics just the same as with the delta version? The elastics are by definition longer, so will stretch more, this then makes enclosing the printer really easy as you can put a lid on across the four verticals.

There's no simple way I can see of getting the bowden tube as short as it is on a delta, so the "improvement margin" is again slightly less for the corexy than the delta.

Edited 1 time(s). Last edit at 04/12/2016 10:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

On the other side of the coin if we could build/buy a light-enough direct extruder we would have the problem solved since increasing print head mass is less critical on corexy than on delta. So the gain from flying/suspended extruder is potentially less over a lightweight direct extruder. Flex3drive is good but a $100+ addition.

If I get time I might try to suspend a bowden extruder over the corexy somehow. I wonder if it would work just suspended on one elastic element? As long as its elastic enough or long enough (or both).

How about just taking the 4 verticals of the corexy upwards by say 200mm and suspending the extruder from 4 elastics just the same as with the delta version? The elastics are by definition longer, so will stretch more, this then makes enclosing the printer really easy as you can put a lid on across the four verticals.

There's no simple way I can see of getting the bowden tube as short as it is on a delta, so the "improvement margin" is again slightly less for the corexy than the delta.

Edited 1 time(s). Last edit at 04/12/2016 10:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.