The "Flying Extruder" Mod

Posted by ähM_Key

|

Re: The "Flying Extruder" Mod April 30, 2016 04:34PM |

Registered: 7 years ago Posts: 2 |

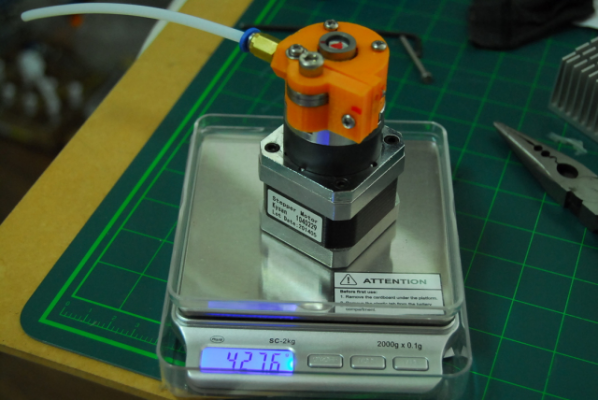

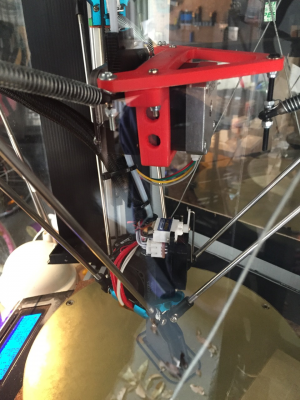

The extruder weighs 427.6 g.

Nema 17 geared motor was heavier than I thought. I made the PTFE tube's length to 15 cm.

Hi Janpenguin, very impressive printing quality. Do you think that the geared stepper is a must and it worth the extra weight and money ? I am also thinking of the flying extruder step up but I can't decide if it worth upgrading the 40mm nema 17 motor of the existing extruder. Thanks for your answer

Nema 17 geared motor was heavier than I thought. I made the PTFE tube's length to 15 cm.

Hi Janpenguin, very impressive printing quality. Do you think that the geared stepper is a must and it worth the extra weight and money ? I am also thinking of the flying extruder step up but I can't decide if it worth upgrading the 40mm nema 17 motor of the existing extruder. Thanks for your answer

|

Re: The "Flying Extruder" Mod May 04, 2016 10:51AM |

Registered: 8 years ago Posts: 3,525 |

So I got an e3d titan and following Thomas Sanladerer's suggestion used a 20mm nema 17 motor. Result, 250g flying extruder.

On thingiverse now:

[www.thingiverse.com]

Hard to say if it works better than my old 395g nema 17+minimal extruder as I wasn't really unhappy with that before but it is light. I think this will also have to be tried as a direct extruder on the corexy. I still haven't really come up with a scheme to "fly" an extruder over the top of that machine yet.

Edited 3 time(s). Last edit at 05/05/2016 05:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

On thingiverse now:

[www.thingiverse.com]

Hard to say if it works better than my old 395g nema 17+minimal extruder as I wasn't really unhappy with that before but it is light. I think this will also have to be tried as a direct extruder on the corexy. I still haven't really come up with a scheme to "fly" an extruder over the top of that machine yet.

Edited 3 time(s). Last edit at 05/05/2016 05:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod January 26, 2017 08:20AM |

Registered: 10 years ago Posts: 732 |

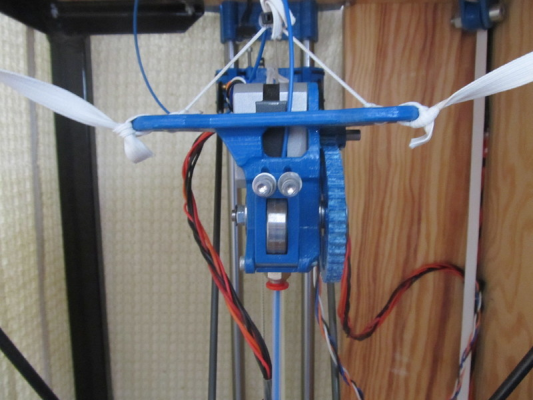

Another experiment with flying extruder:

It did not improve retraction performance as much as I hoped. I still have problems sometimes. Maybe the 15 cm bowden is still too long.

But I'm not going to return back to the full length bowden and firm extruder.

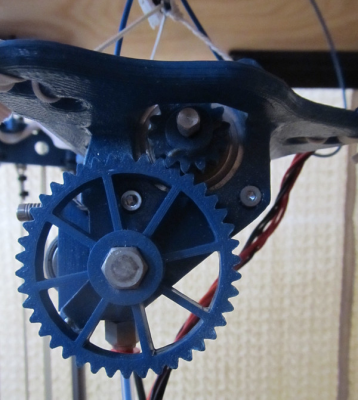

The stepper weights 200 g and the rest of the extruder should be bellow 100 g (I did not weight it). The gear ration is 1:3 and it is too much. 1:2 may have been better ... or I should have used weaker 140 g stepper. I'll try it when I get one.

The top triangle holding it should have been smaller. The idler should have used 1 screw only. But these are minor things which are not worth redesign.

Edited 1 time(s). Last edit at 01/26/2017 08:21AM by hercek.

It did not improve retraction performance as much as I hoped. I still have problems sometimes. Maybe the 15 cm bowden is still too long.

But I'm not going to return back to the full length bowden and firm extruder.

The stepper weights 200 g and the rest of the extruder should be bellow 100 g (I did not weight it). The gear ration is 1:3 and it is too much. 1:2 may have been better ... or I should have used weaker 140 g stepper. I'll try it when I get one.

The top triangle holding it should have been smaller. The idler should have used 1 screw only. But these are minor things which are not worth redesign.

Edited 1 time(s). Last edit at 01/26/2017 08:21AM by hercek.

|

Re: The "Flying Extruder" Mod January 26, 2017 08:40AM |

Registered: 8 years ago Posts: 3,525 |

Shame you didn't see the improvement I've not heard of anyone not seeing a big improvement with this setup. How many teeth are your printed gears? The titan runs 3:1 and I can't fault it.

Another thing Nebbian proposed using shock absorbers/dampers to suspend the flying extruder, which seems like a great idea. He also has a design for one you make or try RC car shocks.

Edited 3 time(s). Last edit at 01/26/2017 08:42AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Another thing Nebbian proposed using shock absorbers/dampers to suspend the flying extruder, which seems like a great idea. He also has a design for one you make or try RC car shocks.

Edited 3 time(s). Last edit at 01/26/2017 08:42AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod January 26, 2017 08:57AM |

Registered: 10 years ago Posts: 732 |

Teeth count is 14:42

It is better. I'm not going to return back. But I hoped for more. It still happens sometimes that complicated models have some of the thinner towers seriously under-extruded(*). I want to replace the bottom quick coupling with fixed connection (to remove the little play in it) and may be a shorter bowden.

I may differ from other people since I run the printer quite quickly (120 mm/s printing moves, 8000 mm/s² acceleration). Also I do not have the modern full metal hotends which are typically used now.

(*) I think it is not a slicer problem but I'll need to verify this.

It is better. I'm not going to return back. But I hoped for more. It still happens sometimes that complicated models have some of the thinner towers seriously under-extruded(*). I want to replace the bottom quick coupling with fixed connection (to remove the little play in it) and may be a shorter bowden.

I may differ from other people since I run the printer quite quickly (120 mm/s printing moves, 8000 mm/s² acceleration). Also I do not have the modern full metal hotends which are typically used now.

(*) I think it is not a slicer problem but I'll need to verify this.

|

Re: The "Flying Extruder" Mod January 26, 2017 09:27AM |

Registered: 8 years ago Posts: 3,525 |

I'm using e3d titan and that same 200g stepper (20mm one but at 24v) with a 17cm bowden tube into an e3d v6 genuine hot end and I don't think it would print better if I stuck the extruder on the effector. Reprap firmware helps out here though with working extruder pressure advance which does a nice job of reducing the effect of the Bowden tube on filament control, also reduces the slight under-extrusion after retraction and allows for a slight reduction in retraction length also.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod January 26, 2017 09:27AM |

Registered: 8 years ago Posts: 3,525 |

I'm using e3d titan and that same 200g stepper (20mm one but at 24v) with a 17cm bowden tube into an e3d v6 genuine hot end and I don't think it would print better if I stuck the extruder on the effector. Reprap firmware helps out here though with working extruder pressure advance which does a nice job of reducing the effect of the Bowden tube on filament control, also reduces the slight under-extrusion after retraction and allows for a slight reduction in retraction length also.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod January 26, 2017 12:54PM |

Registered: 10 years ago Posts: 732 |

I do not have Duet board to try Reprap firmware. Well, I can try coasting in slicer. I did not try it yet and maybe it would help. Though I have my doubts. I could also add pressure advance into the slicer but I'm not desperate enough for that yet

I realized that my problem with some parts is definitely related to speed since I printed one such part by mistake at only 60 mm/s and the problem was not there ... or at least it was not visible. And it may be related to moisture in the filament too

I realized that my problem with some parts is definitely related to speed since I printed one such part by mistake at only 60 mm/s and the problem was not there ... or at least it was not visible. And it may be related to moisture in the filament too

|

Re: The "Flying Extruder" Mod February 14, 2017 10:16AM |

Registered: 7 years ago Posts: 23 |

Quote

DjDemonD

I'm using e3d titan and that same 200g stepper (20mm one but at 24v) with a 17cm bowden tube into an e3d v6 genuine hot end and I don't think it would print better if I stuck the extruder on the effector. Reprap firmware helps out here though with working extruder pressure advance which does a nice job of reducing the effect of the Bowden tube on filament control, also reduces the slight under-extrusion after retraction and allows for a slight reduction in retraction length also.

What is the exact part no. of the stepper that you are using?

Thanks

|

Re: The "Flying Extruder" Mod February 14, 2017 12:30PM |

Registered: 8 years ago Posts: 3,525 |

[www.omc-stepperonline.com]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 14, 2017 09:43PM |

Registered: 8 years ago Posts: 916 |

Hey DJ,

How are you finding the Titan with that stepper? I ordered a Titan last week, and am about to put it onto my mini, but went with a larger 28N-cm motor to get more push.

I am running into issues at the moment with my direct drive extruder where I'm hitting the limits of push, especially with PLA at 0.3mm layer heights. If I turn the current up a bit, the stepper gets so hot that the heat softens the PLA as it goes through the extruder drive gear. Turn it slightly down and the stepper clicks. I've ended up at about 35mm/s speed which is close to the limit at 0.3mm layer height, and the extruder motor gets hot enough that it's painful to hold your finger on there for a few seconds.

Basically, what speed can you get out of the Titan, with PLA, at 0.3mm layer height? I realise that the Titan doesn't transfer heat from the stepper to the drive gear, so that's a plus.

How are you finding the Titan with that stepper? I ordered a Titan last week, and am about to put it onto my mini, but went with a larger 28N-cm motor to get more push.

I am running into issues at the moment with my direct drive extruder where I'm hitting the limits of push, especially with PLA at 0.3mm layer heights. If I turn the current up a bit, the stepper gets so hot that the heat softens the PLA as it goes through the extruder drive gear. Turn it slightly down and the stepper clicks. I've ended up at about 35mm/s speed which is close to the limit at 0.3mm layer height, and the extruder motor gets hot enough that it's painful to hold your finger on there for a few seconds.

Basically, what speed can you get out of the Titan, with PLA, at 0.3mm layer height? I realise that the Titan doesn't transfer heat from the stepper to the drive gear, so that's a plus.

|

Re: The "Flying Extruder" Mod February 15, 2017 02:31AM |

Registered: 8 years ago Posts: 3,525 |

I really don't print pla much but I'll run off a few cubes see how quick it will go. You using 1.75mm?

The 3:1 gearing on the titan is spot on loads more torque so you can go light on the motor but you get very snappy retracts. I had a play with retracting at 50mm/s at 9000 acceleration. Went back to 3000 as I worried I'd strip the gears.

I've got a printed extruder on that micro delta with a 5:1 nema 14 it's just about quick enough to retract quickly enough but I don't print fast with it as the mini hot end can't melt filament that quick.

Edited 1 time(s). Last edit at 02/15/2017 02:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The 3:1 gearing on the titan is spot on loads more torque so you can go light on the motor but you get very snappy retracts. I had a play with retracting at 50mm/s at 9000 acceleration. Went back to 3000 as I worried I'd strip the gears.

I've got a printed extruder on that micro delta with a 5:1 nema 14 it's just about quick enough to retract quickly enough but I don't print fast with it as the mini hot end can't melt filament that quick.

Edited 1 time(s). Last edit at 02/15/2017 02:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 15, 2017 03:04AM |

Registered: 8 years ago Posts: 916 |

Thanks for that, yes, 1.75mm.

I don't print much PLA either, but I've noticed it on some larger 3DHubs orders where I wanted to print reasonably quickly. ABS is no issue, but then again I don't normally go to 0.3mm on that either.

If I could get 70 mm/s print speed at 0.3mm layer height in PLA, then I'd be a happy camper. I've run the numbers, and they suggest that I should be OK to get there, but the proof of the pudding is in the eating I guess. I'd guess that the little pancake stepper you've got would be borderline.

Unpacked the Titan today, and I have to say that the filament guide in the Titan is really nice. Way better than my half baked attempt at a good filament guide.

I don't print much PLA either, but I've noticed it on some larger 3DHubs orders where I wanted to print reasonably quickly. ABS is no issue, but then again I don't normally go to 0.3mm on that either.

If I could get 70 mm/s print speed at 0.3mm layer height in PLA, then I'd be a happy camper. I've run the numbers, and they suggest that I should be OK to get there, but the proof of the pudding is in the eating I guess. I'd guess that the little pancake stepper you've got would be borderline.

Unpacked the Titan today, and I have to say that the filament guide in the Titan is really nice. Way better than my half baked attempt at a good filament guide.

|

Re: The "Flying Extruder" Mod February 15, 2017 03:07AM |

Registered: 8 years ago Posts: 3,525 |

I've been really pleased with it so far. Its actually very well designed and has some very nice touches like the filament guide. I haven't really got anything bad to say about it. Ordered one of the cloned version, the Trianglelabs extruder be interested to see how close they got.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 15, 2017 06:22AM |

Registered: 8 years ago Posts: 3,525 |

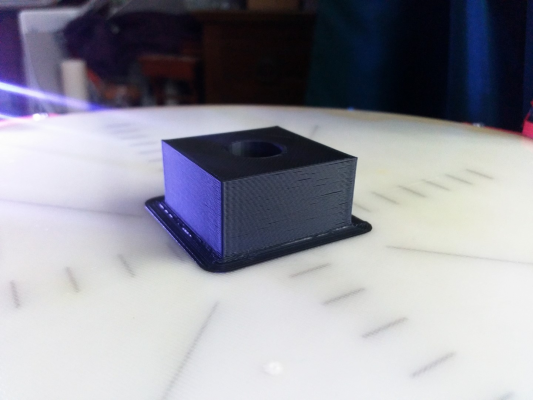

So this 40x40x20 cube with 16mm hole in the middle. 0.3 layers, 15% infill, took 26 minutes, used 4688mm of Excelvan black PLA filament.

Slic3r speed settings perimeters 60mm/s, infill 60, travel 120.

Printed at 150% speed factor. (so aggregate around 90mm/s?)

I worked out the volumetric rate (4688*1.75)/(26*60)=5.25mm3/s

So yeah I'd say titan+v6 combo can do this with PLA, my 20mm pancake gets warm so I stuck a MK8 heatsink on the back of the motor and its not too bad, I'm running it at 800mA.

It would go faster I'm sure, if I get chance I'll take up to the point where it starts to struggle.

Edited 1 time(s). Last edit at 02/15/2017 07:06AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Slic3r speed settings perimeters 60mm/s, infill 60, travel 120.

Printed at 150% speed factor. (so aggregate around 90mm/s?)

I worked out the volumetric rate (4688*1.75)/(26*60)=5.25mm3/s

So yeah I'd say titan+v6 combo can do this with PLA, my 20mm pancake gets warm so I stuck a MK8 heatsink on the back of the motor and its not too bad, I'm running it at 800mA.

It would go faster I'm sure, if I get chance I'll take up to the point where it starts to struggle.

Edited 1 time(s). Last edit at 02/15/2017 07:06AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 15, 2017 07:26AM |

Registered: 8 years ago Posts: 916 |

|

Re: The "Flying Extruder" Mod February 15, 2017 07:27AM |

Registered: 8 years ago Posts: 3,525 |

Welcome.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 15, 2017 08:12AM |

Registered: 8 years ago Posts: 916 |

|

Re: The "Flying Extruder" Mod February 15, 2017 10:43AM |

Registered: 8 years ago Posts: 3,525 |

Yes you are right there.I wonder how high it will go I've heard people saying you won't push more than 10 mm3/s through an e3d v6?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 15, 2017 03:47PM |

Registered: 8 years ago Posts: 117 |

Quote

DjDemonD

I've been really pleased with it so far. Its actually very well designed and has some very nice touches like the filament guide. I haven't really got anything bad to say about it. Ordered one of the cloned version, the Trianglelabs extruder be interested to see how close they got.

Please let us know what you think on that clone...

|

Re: The "Flying Extruder" Mod February 15, 2017 03:52PM |

Registered: 8 years ago Posts: 3,525 |

I will do, I ordered two of them and a y-splitter for an alternative version of dual extruder printing. Will review of all of it once its up and running.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod February 19, 2017 09:34PM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

I'm using e3d titan

I installed mine over the weekend, and am quite impressed with it. The instructions are great, design is superb, the steps/mm they give you are spot on. Easy to retrofit to a flying extruder setup, you just need to: a) buy the bowden adapter, and b) push the little black retainer into the adapter BEFORE adding your bowden cable.

Very happy.

|

Re: The "Flying Extruder" Mod March 01, 2017 01:18AM |

Registered: 8 years ago Posts: 916 |

I've been scratching my head over this one for a while.

The problem is that the bowden tube isn't straight, due to the extruder section being offset from the motor. This results in sloppy retracts.

So after a few iterations, I was no better off, until I added another spring to support the motor:

Ta-Daa! Straight bowden tube! It is free to move all around the bed, and at the extremities it has a bend (as you'd expect) but it's only a single curve, not a double.

Haven't tried a test print yet, but by pulling on the filament I can see that it should be a lot more direct.

Edited 1 time(s). Last edit at 03/01/2017 01:20AM by nebbian.

The problem is that the bowden tube isn't straight, due to the extruder section being offset from the motor. This results in sloppy retracts.

So after a few iterations, I was no better off, until I added another spring to support the motor:

Ta-Daa! Straight bowden tube! It is free to move all around the bed, and at the extremities it has a bend (as you'd expect) but it's only a single curve, not a double.

Haven't tried a test print yet, but by pulling on the filament I can see that it should be a lot more direct.

Edited 1 time(s). Last edit at 03/01/2017 01:20AM by nebbian.

|

Re: The "Flying Extruder" Mod March 01, 2017 07:12AM |

Registered: 8 years ago Posts: 3,525 |

Yeah I find with flying titan it's off centre on the flying bracket and one of my elastics has to be stronger than the other two. Haven't got chance to build your shocks yet, tried some rc car shocks, too stiff.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod March 22, 2017 06:51PM |

Registered: 8 years ago Posts: 3,525 |

So I recently decided to experiment with a y-splitter system to get dual extrusion going. Haven't managed to do any of that yet as I ran into a snag.

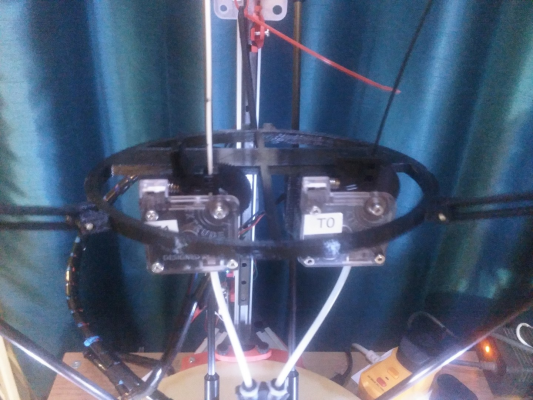

I modified my flying extruder bracket to have two titans with 20mm pancake nema 17's:

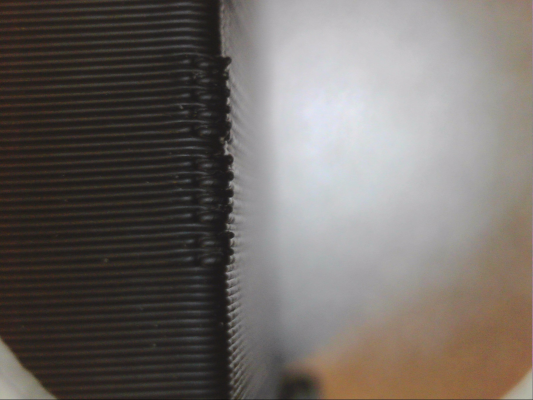

Printed a cube just to see how it was working with much heavier flying extruder setup and got this horrible thing:

This I determined was due to over-extrusion, there is not enough space every 4th layer and the filament gets pushed out sideways.

So I fixed that but was still getting this:

Which seemed to be related to jerk or acceleration at the corners. I tried a good few cubes varying these settings, as well as motor currents, and printing speed and whilst some combinations seemed to improve it none really cured it.

I've also tried slackening the elastic holding the flying bracket.

Is it just the mass of this assembly is too great not to create artefacts in the prints?

That's generic black ABS, printed 0.3mm layers with 0.4mm nozzle, e3d v6 hotend, using the genuine titan (right), at 240 deg C.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I modified my flying extruder bracket to have two titans with 20mm pancake nema 17's:

Printed a cube just to see how it was working with much heavier flying extruder setup and got this horrible thing:

This I determined was due to over-extrusion, there is not enough space every 4th layer and the filament gets pushed out sideways.

So I fixed that but was still getting this:

Which seemed to be related to jerk or acceleration at the corners. I tried a good few cubes varying these settings, as well as motor currents, and printing speed and whilst some combinations seemed to improve it none really cured it.

I've also tried slackening the elastic holding the flying bracket.

Is it just the mass of this assembly is too great not to create artefacts in the prints?

That's generic black ABS, printed 0.3mm layers with 0.4mm nozzle, e3d v6 hotend, using the genuine titan (right), at 240 deg C.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod March 23, 2017 03:22AM |

Registered: 8 years ago Posts: 5,232 |

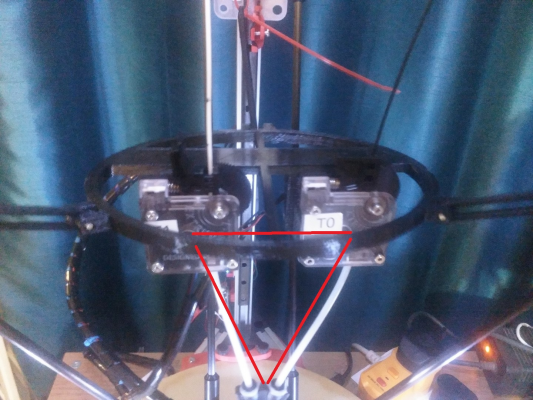

The bowden tubes and the extruders build a triangle ( see red lines ) and therefor are pretty stiff in side_to_side direction.

It might get better, when you place the Titans face to face, so the Tubes run more parallel.

If that's not possible, check my "swinging" extruder. Let the steppers rotate around their shaft center ( COG ) will eliminate the fixed triangle issue.

It might get better, when you place the Titans face to face, so the Tubes run more parallel.

If that's not possible, check my "swinging" extruder. Let the steppers rotate around their shaft center ( COG ) will eliminate the fixed triangle issue.

|

Re: The "Flying Extruder" Mod March 23, 2017 03:31AM |

Registered: 11 years ago Posts: 805 |

I dont think these artifacts come from the flying extruder, that looks like a slicing thing. Otherwise if would happen on every layer. If you really want to make sure you got rid of all flying artifacts decouple the extruder from the carriages.

Also im curious about you dual setup, do you plan on using PLA?

Also im curious about you dual setup, do you plan on using PLA?

|

Re: The "Flying Extruder" Mod March 23, 2017 04:55AM |

Registered: 8 years ago Posts: 3,525 |

O_lampe - I'll try a different configuration, that would be an easy fix.

Sungod3K - That is certainly possible, I think I had better try that test also. The only reason I ask is that prior to changing to the dual flying extruder my layer registration and walls were excellent.

I don't print much PLA no. PLA is probably one of the most challenging materials in terms of filament shaping on tool changes with this type of system. ABS should be more forgiving and break more cleanly when retracted, making for fewer jams when reinserted. That being said I'm only trying it as an experience really, I don't feel a great need for dual extrusion.

Edited 1 time(s). Last edit at 03/23/2017 04:59AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sungod3K - That is certainly possible, I think I had better try that test also. The only reason I ask is that prior to changing to the dual flying extruder my layer registration and walls were excellent.

I don't print much PLA no. PLA is probably one of the most challenging materials in terms of filament shaping on tool changes with this type of system. ABS should be more forgiving and break more cleanly when retracted, making for fewer jams when reinserted. That being said I'm only trying it as an experience really, I don't feel a great need for dual extrusion.

Edited 1 time(s). Last edit at 03/23/2017 04:59AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: The "Flying Extruder" Mod March 23, 2017 05:05AM |

Registered: 11 years ago Posts: 805 |

|

Re: The "Flying Extruder" Mod May 10, 2017 03:15PM |

Registered: 8 years ago Posts: 3,525 |

Kraegar from duet forum pointed out that certainly on larger deltas, kossel XL size, that he moved away from flying extruder as it was causing tilt at the extremities of his bed. So I thought I'd do a quick test. RRF autocal deviation with flying extruder attached 0.026, with it disconnected 0.016. MY flying extruder is a fairly substantial unit now with 2xtitans, 2x pancake steppers and the y-splitter device. It definitely doesn't track the effector as well as it did on my kossel mini, and the tube has to be longer (or the elastics under a lot of tension).

So there is definitely a significant effect being seen here. Time to use the cable driven extruders I guess.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So there is definitely a significant effect being seen here. Time to use the cable driven extruders I guess.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.