RepRap 3DR Delta printer Released

Posted by richrap

|

RepRap 3DR Delta printer Released July 29, 2013 09:52AM |

Registered: 13 years ago Posts: 818 |

Hi Everyone,

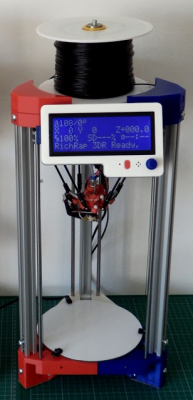

My 3DR Delta printer is now released, the design model files and source, images etc. can be found here on GitHub

An initial post about 3DR is available on my Blog here

More posts will follow to show construction, setup and use etc.

Please let me know if you decide to build one,

And let me know if you have any questions.

Many thanks,

Rich.

[richrap.blogspot.com]

My 3DR Delta printer is now released, the design model files and source, images etc. can be found here on GitHub

An initial post about 3DR is available on my Blog here

More posts will follow to show construction, setup and use etc.

Please let me know if you decide to build one,

And let me know if you have any questions.

Many thanks,

Rich.

[richrap.blogspot.com]

|

Re: RepRap 3DR Delta printer Released July 29, 2013 10:20PM |

Registered: 10 years ago Posts: 979 |

|

Re: RepRap 3DR Delta printer Released July 30, 2013 01:02AM |

Registered: 11 years ago Posts: 248 |

|

Re: RepRap 3DR Delta printer Released July 31, 2013 01:15AM |

Registered: 11 years ago Posts: 29 |

|

Re: RepRap 3DR Delta printer Released July 31, 2013 04:16AM |

Registered: 13 years ago Posts: 818 |

Yes, it should be possible to adapt for almost any type of rigid vertical frame. It's only been released a few days and already people are doing just that.

Nicolas Arias is building a version with square 20mm x 20mm Aluminium tubes instead of the T-slot - Take a look on his G+ Page here -

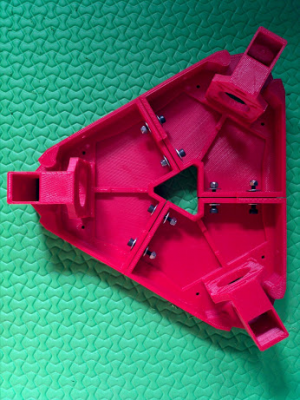

As for how much plastic, About 350g I expect, depending on fill level.

[richrap.blogspot.com]

Nicolas Arias is building a version with square 20mm x 20mm Aluminium tubes instead of the T-slot - Take a look on his G+ Page here -

As for how much plastic, About 350g I expect, depending on fill level.

[richrap.blogspot.com]

|

Re: RepRap 3DR Delta printer Released July 31, 2013 04:55AM |

Registered: 10 years ago Posts: 219 |

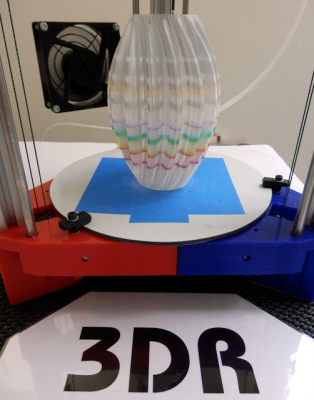

Hello Rich, I watched the video and followed your blog on this project and I like the design very much, so I going to build one.

I is a real evolutionary design , becuase it uses far less parts, screws, no timing belts and many mechanical functions have been integrated into complex parts.

I have those aluminum profiley "laying around" in my workshop from a 10 year old machine project that I gave up , so that will give them a second life.

1. I wonder wheter you could not also print them out - at least in 2 or 3 sections which will then be put togehter just with some 6-8mm tube inside to align them. Maybed even the "belts" could run inside them.

2.One thought is on the base, and if that is heavy enought to avoid tipping if the bot runs at a higher acc. or someone hits the table.

3.In order to further reduce, parts cost and get a higher rate of self replicating: Why not have the base with snap-in constructions rather than using screws?

I think your design has the potential for the first really fully printable frame construction

.

And yes, I want to build myself one :-) I am a bit older than most here and I am just trying to get my way around to find out where I can get the parts printed out and how. I worked in the electronic industry (SMD assmbly machines) for 20 years and a hexapos was always a very expensive dream for an egineer. I am amazed how far this project has come now and I like your design because of the simplycity, yet the effectiveness.

But I must tell you: Those red & blue colors hurt my eyes ;-)

I is a real evolutionary design , becuase it uses far less parts, screws, no timing belts and many mechanical functions have been integrated into complex parts.

I have those aluminum profiley "laying around" in my workshop from a 10 year old machine project that I gave up , so that will give them a second life.

1. I wonder wheter you could not also print them out - at least in 2 or 3 sections which will then be put togehter just with some 6-8mm tube inside to align them. Maybed even the "belts" could run inside them.

2.One thought is on the base, and if that is heavy enought to avoid tipping if the bot runs at a higher acc. or someone hits the table.

3.In order to further reduce, parts cost and get a higher rate of self replicating: Why not have the base with snap-in constructions rather than using screws?

I think your design has the potential for the first really fully printable frame construction

.

And yes, I want to build myself one :-) I am a bit older than most here and I am just trying to get my way around to find out where I can get the parts printed out and how. I worked in the electronic industry (SMD assmbly machines) for 20 years and a hexapos was always a very expensive dream for an egineer. I am amazed how far this project has come now and I like your design because of the simplycity, yet the effectiveness.

But I must tell you: Those red & blue colors hurt my eyes ;-)

|

Re: RepRap 3DR Delta printer Released August 01, 2013 02:44AM |

Registered: 10 years ago Posts: 17 |

|

Re: RepRap 3DR Delta printer Released August 04, 2013 04:57PM |

Admin Registered: 11 years ago Posts: 50 |

@evamvid I imagine the best place to find them is any RC heli shop, as linkages just like that are used on pretty much all heli's. I found some on ebay but way overpriced, so bought some trex heli ones which were much cheaper. Hopefully they might work, but won't know until they turn up.

|

Re: RepRap 3DR Delta printer Released August 04, 2013 09:55PM |

Registered: 14 years ago Posts: 47 |

I'm printing these parts on an Ultimaker in PLA. I'll weigh them as I print and update this post. So far I've printed :

1.2mm perimeter/top/bottom, .235 layer height, 30% infill (sliced with the wrong settings but came out fine)

3DR_Top_cover_cap_V2_001_RTP x3 = 65g

3DR_Bottom_Motor_Mount_V2_001_RTP x3 = 250g

3DR_Bottom_Boss_V2_001_RTP x1 = 22g

3DR_Top_Boss_V2_001_RTP = 6g

These parts would use about 20-30% less plastic if I used my normal settings which are: .9mm perimeter, .54mm top/bottom, .135 layer height, 35% infill (my usual settings for nearly everything)

These will all be sliced and printed at those settings, they are still pending though, I will update as they are printed :

3DR_Spool_V2_001_RTP x3 = 10g

3DR_Jhead_groove_mount_V2_001_PUSHFIT_RTP x1 = 7g

3DR_micro_platform_V2_001_RTP x1 = 6g

3DR_Print_Bed_catch_V2_001_RTP x3 = 7g

3DR_Carriage_V2_001_for_LM6UU_RTP x3 =

3DR_Extruder_body_V2_Test_001_RTP x1 =

RichRap_Greg_style_Guidler_Modified_with_grab_lever_For_1_RTP x1 =

herringbone-gear-large x1 =

herringbone-gear-small x1 =

I ran into some slicing issues with the 3DR_Top_Electronics_Mount_V2_001_RTP part as it looks like there are some holes in the STL around z=1.5mm, I sent richrap a PM about it.

Edited 2 time(s). Last edit at 08/05/2013 02:43PM by Nyarlathotep.

1.2mm perimeter/top/bottom, .235 layer height, 30% infill (sliced with the wrong settings but came out fine)

3DR_Top_cover_cap_V2_001_RTP x3 = 65g

3DR_Bottom_Motor_Mount_V2_001_RTP x3 = 250g

3DR_Bottom_Boss_V2_001_RTP x1 = 22g

3DR_Top_Boss_V2_001_RTP = 6g

These parts would use about 20-30% less plastic if I used my normal settings which are: .9mm perimeter, .54mm top/bottom, .135 layer height, 35% infill (my usual settings for nearly everything)

These will all be sliced and printed at those settings, they are still pending though, I will update as they are printed :

3DR_Spool_V2_001_RTP x3 = 10g

3DR_Jhead_groove_mount_V2_001_PUSHFIT_RTP x1 = 7g

3DR_micro_platform_V2_001_RTP x1 = 6g

3DR_Print_Bed_catch_V2_001_RTP x3 = 7g

3DR_Carriage_V2_001_for_LM6UU_RTP x3 =

3DR_Extruder_body_V2_Test_001_RTP x1 =

RichRap_Greg_style_Guidler_Modified_with_grab_lever_For_1_RTP x1 =

herringbone-gear-large x1 =

herringbone-gear-small x1 =

I ran into some slicing issues with the 3DR_Top_Electronics_Mount_V2_001_RTP part as it looks like there are some holes in the STL around z=1.5mm, I sent richrap a PM about it.

Edited 2 time(s). Last edit at 08/05/2013 02:43PM by Nyarlathotep.

|

Re: RepRap 3DR Delta printer Released August 08, 2013 02:33AM |

Registered: 14 years ago Posts: 47 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 04:14AM |

Registered: 10 years ago Posts: 1 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 04:58AM |

Admin Registered: 11 years ago Posts: 50 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 06:12AM |

Registered: 11 years ago Posts: 248 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 12:53PM |

Registered: 14 years ago Posts: 47 |

dapa79 Wrote:

-------------------------------------------------------

> Have you printed the three top electronics mount

> parts? It would be great if you could post the

> weight :-)

I printed 2 out of 3 top electronics mount, but I didn't weigh them yet and I'm travelling now and won't get the 3rd one printed until the middle of next week. I have all the other parts printed as well, except the rod joint adapters as as I will likely need to redesign these parts to fit & I'm still waiting on my ball ends to arrive so I can do that.

I have to collect a few vitamins yet but expect to start assembling next weekend. The major parts I am missing are an LCD, hotend, bowden tube, and hobbed bolt for the extruder.

-------------------------------------------------------

> Have you printed the three top electronics mount

> parts? It would be great if you could post the

> weight :-)

I printed 2 out of 3 top electronics mount, but I didn't weigh them yet and I'm travelling now and won't get the 3rd one printed until the middle of next week. I have all the other parts printed as well, except the rod joint adapters as as I will likely need to redesign these parts to fit & I'm still waiting on my ball ends to arrive so I can do that.

I have to collect a few vitamins yet but expect to start assembling next weekend. The major parts I am missing are an LCD, hotend, bowden tube, and hobbed bolt for the extruder.

|

Re: RepRap 3DR Delta printer Released August 09, 2013 02:36PM |

Registered: 11 years ago Posts: 29 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 04:03PM |

Admin Registered: 11 years ago Posts: 50 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 04:06PM |

Registered: 10 years ago Posts: 17 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 04:48PM |

Registered: 10 years ago Posts: 46 |

|

Re: RepRap 3DR Delta printer Released August 09, 2013 06:06PM |

Registered: 10 years ago Posts: 979 |

Do you know the hair spray trick for PLA? Aqua Net Hairspray

I can't hardly get my prints up it holds so well.

I can't hardly get my prints up it holds so well.

|

Re: RepRap 3DR Delta printer Released August 09, 2013 09:06PM |

Registered: 12 years ago Posts: 195 |

|

Re: RepRap 3DR Delta printer Released August 10, 2013 06:14AM |

Registered: 10 years ago Posts: 46 |

Hi thanks for the replies, I can get PLA to stick ok initially, it's stopping the

stuff lifting mid print (even with brims) that’s the main problem.

Haven't tried hairspray with PLA yet, I was using Wilko's "Extra firm hold", didn't

work with ABS on its own, but I did find that I could get an extra days printing out

of tired kapton using hairspray on it. Will do a test with PLA today. Thanks for the

link, I will keep a look out for that brand and try it.

PVA (applied on 80 Degree C bed) , was experimenting with that yesterday (didn't

work on ABS at all when I tried before). I did manage to get a PLA print to stick

well yesterday (stacked cube test with no brim), problem is I can only get 1 print

out of it, after that everything lifts off after 4-5 layers. Tried fresh PVA solution

on top of old, no go. looks like I will have to clean the glass between each print,

which is ok on bigger prints, pain when doing small calibration/test pieces though.

Will do some more experimenting today.

PVA glue I've been using is Everbuild "Universal PVA Bond"

[www.bicester-upvcdirect.com]

From what I've seen, a lot of people reporting success using PVA are using Elmer's

"Glue all" with heated bed, I haven't bought any to test because my main focus for

PLA will be cold bed printing ready for the 3DR.

Print stick, (Wilko's "Quick Stick Glue" not UHU there wasn't any in the shops)

again I tried that with ABS, it didn’t work (I did put it on top of PVA, which stuck

an ABS print, but there was fizzing going on where plastic meets print stick/PVA ,

so I didn’t pursue it lol) Will try it with PLA today (on clean glass)

Lemon Juice ("Tesco" bottle of, applied at 80C bed).

So far this as worked the most consistently (printed top and bottom 3DR centre

boss pieces ok on it, took a 7.5mm brim to do it though, Top cover cap started to

lift 30% way in with 7.5mm brim, will try 10mm when I try next (brims are getting

excessive now). Lemon Juice also seems to keep working, just reapply a few drops

between prints ay 80C and "stipple" it in. Stays sticky when cold though, makes bit

of a mess ( I imagine sugared water is similar, haven’t tried it yet).

Haven't really tried PLA on heated Kapton yet (I did but kapton was getting a bit

tired form ABS printing, that could be why it didn't work), 3M blue scotch should be

here in a few days, that will be my main focus for PLA , printing on a cold bed,

since that's what the 3DR uses.

I'll do some more experimenting today, see how that goes before attempting any of

those big top/bottom pieces again.

Cheers.

Edit : Forgot to add, that I've tried using a cooling fan (different speeds & distances etc) for PLA, just seems to make the lifting problem worse.

Edited 1 time(s). Last edit at 08/10/2013 06:22AM by Masnachu.

stuff lifting mid print (even with brims) that’s the main problem.

Haven't tried hairspray with PLA yet, I was using Wilko's "Extra firm hold", didn't

work with ABS on its own, but I did find that I could get an extra days printing out

of tired kapton using hairspray on it. Will do a test with PLA today. Thanks for the

link, I will keep a look out for that brand and try it.

PVA (applied on 80 Degree C bed) , was experimenting with that yesterday (didn't

work on ABS at all when I tried before). I did manage to get a PLA print to stick

well yesterday (stacked cube test with no brim), problem is I can only get 1 print

out of it, after that everything lifts off after 4-5 layers. Tried fresh PVA solution

on top of old, no go. looks like I will have to clean the glass between each print,

which is ok on bigger prints, pain when doing small calibration/test pieces though.

Will do some more experimenting today.

PVA glue I've been using is Everbuild "Universal PVA Bond"

[www.bicester-upvcdirect.com]

From what I've seen, a lot of people reporting success using PVA are using Elmer's

"Glue all" with heated bed, I haven't bought any to test because my main focus for

PLA will be cold bed printing ready for the 3DR.

Print stick, (Wilko's "Quick Stick Glue" not UHU there wasn't any in the shops)

again I tried that with ABS, it didn’t work (I did put it on top of PVA, which stuck

an ABS print, but there was fizzing going on where plastic meets print stick/PVA ,

so I didn’t pursue it lol) Will try it with PLA today (on clean glass)

Lemon Juice ("Tesco" bottle of, applied at 80C bed).

So far this as worked the most consistently (printed top and bottom 3DR centre

boss pieces ok on it, took a 7.5mm brim to do it though, Top cover cap started to

lift 30% way in with 7.5mm brim, will try 10mm when I try next (brims are getting

excessive now). Lemon Juice also seems to keep working, just reapply a few drops

between prints ay 80C and "stipple" it in. Stays sticky when cold though, makes bit

of a mess ( I imagine sugared water is similar, haven’t tried it yet).

Haven't really tried PLA on heated Kapton yet (I did but kapton was getting a bit

tired form ABS printing, that could be why it didn't work), 3M blue scotch should be

here in a few days, that will be my main focus for PLA , printing on a cold bed,

since that's what the 3DR uses.

I'll do some more experimenting today, see how that goes before attempting any of

those big top/bottom pieces again.

Cheers.

Edit : Forgot to add, that I've tried using a cooling fan (different speeds & distances etc) for PLA, just seems to make the lifting problem worse.

Edited 1 time(s). Last edit at 08/10/2013 06:22AM by Masnachu.

|

Re: RepRap 3DR Delta printer Released August 10, 2013 09:15AM |

Registered: 12 years ago Posts: 195 |

|

Re: RepRap 3DR Delta printer Released August 10, 2013 10:37AM |

Registered: 10 years ago Posts: 979 |

I print on 60 degree glass and 60 degree kapton with PLA and hair spray. Verify that you have VA/Crotonates/Vinyl Neodecanoate Copolymer in your hairspray. It seems like every country has only 1 major brand that is brave enough to provide a product that can make hair stronger than steel. Without that ingredient is is said not to work.

Also, I don't have to reapply hair spray every print. It can last a very long time. I haven't actually hit its limit yet. I end up touching the bed about every third print so that forces me to use some glass cleaner and then I reapply the hair spray. (Application tip: don't spray directly on the bed. Spray it on a paper towel and then wipe the area. It will keep your machine from getting crusty.)

Also, I don't have to reapply hair spray every print. It can last a very long time. I haven't actually hit its limit yet. I end up touching the bed about every third print so that forces me to use some glass cleaner and then I reapply the hair spray. (Application tip: don't spray directly on the bed. Spray it on a paper towel and then wipe the area. It will keep your machine from getting crusty.)

|

Re: RepRap 3DR Delta printer Released August 13, 2013 05:37PM |

Registered: 14 years ago Posts: 47 |

|

Re: RepRap 3DR Delta printer Released August 18, 2013 08:31AM |

Registered: 10 years ago Posts: 46 |

Thanks for the replies.

pokey9000, yep at the time I was setting bed temp to 80C (approx 70C Glass surface temp) for the first layer, then knocking it down to 60'ish (~50C surface). It was the temp I first had success in getting the rubbish PLA to initially stick, so I stayed with it. I also experimented with about every temp possible with it, eventually I was using 1st layer bed/hotend temps that were more appropriate for ABS (Don't know what they used to pack the PLA out, there was some PLA in there, could smell it). Warping and not sticking were worse when using normal PLA temps (180-200C, 50-60C)

Nicholas thanks for ingredient tip, most of the UK extra strong hairspray contains,

Octylacrylamide/Acrylates/Butylaminoethyl Methacrylate Copolymer,

not sure if it will do the job (mine doesn't have it) , I'll experiment (I found a US gov health dept website that lists hairsprays that contain the chemical you named, 1 or 2 of the brands are sold here, I'll check if they still contain the ingredient or not)

Update.

That filament I was using would just not stick well enough to anything at any temp, PVA,Kapton,Lemon Juice,Clean Glass,Blue Tape (cold) etc etc without lifting/warping.

Yesterday morning I was having another go with PVA (same result would stick, then start to lift/warp 4-6 layers in) when my KDI filament turned up, so I swapped filament, everything else kept the same (I set hotend temp back to 180 for the new filament), the KDI stuck and stayed stuck, no lift no warp, perfect (well almost its a bugger to get off PVA lol). So the original PLA as gone back, its utter junk.

Right then, back to finishing the 3DR parts, cheers for the help guys.

Edited 4 time(s). Last edit at 08/18/2013 08:46AM by Masnachu.

pokey9000, yep at the time I was setting bed temp to 80C (approx 70C Glass surface temp) for the first layer, then knocking it down to 60'ish (~50C surface). It was the temp I first had success in getting the rubbish PLA to initially stick, so I stayed with it. I also experimented with about every temp possible with it, eventually I was using 1st layer bed/hotend temps that were more appropriate for ABS (Don't know what they used to pack the PLA out, there was some PLA in there, could smell it). Warping and not sticking were worse when using normal PLA temps (180-200C, 50-60C)

Nicholas thanks for ingredient tip, most of the UK extra strong hairspray contains,

Octylacrylamide/Acrylates/Butylaminoethyl Methacrylate Copolymer,

not sure if it will do the job (mine doesn't have it) , I'll experiment (I found a US gov health dept website that lists hairsprays that contain the chemical you named, 1 or 2 of the brands are sold here, I'll check if they still contain the ingredient or not)

Update.

That filament I was using would just not stick well enough to anything at any temp, PVA,Kapton,Lemon Juice,Clean Glass,Blue Tape (cold) etc etc without lifting/warping.

Yesterday morning I was having another go with PVA (same result would stick, then start to lift/warp 4-6 layers in) when my KDI filament turned up, so I swapped filament, everything else kept the same (I set hotend temp back to 180 for the new filament), the KDI stuck and stayed stuck, no lift no warp, perfect (well almost its a bugger to get off PVA lol). So the original PLA as gone back, its utter junk.

Right then, back to finishing the 3DR parts, cheers for the help guys.

Edited 4 time(s). Last edit at 08/18/2013 08:46AM by Masnachu.

|

Re: RepRap 3DR Delta printer Released August 19, 2013 08:13AM |

Registered: 10 years ago Posts: 18 |

|

Re: RepRap 3DR Delta printer Released August 28, 2013 04:28AM |

Registered: 13 years ago Posts: 818 |

|

Re: RepRap 3DR Delta printer Released August 28, 2013 05:17AM |

Registered: 14 years ago Posts: 3,742 |

Another great job Rich!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: RepRap 3DR Delta printer Released September 15, 2013 04:22AM |

Registered: 11 years ago Posts: 142 |

Some pictures of my 3DR build (still fighting...)

[www.eventorbot.com]

Edited 1 time(s). Last edit at 09/15/2013 04:40AM by zacbot.

video of my 3DR

[www.eventorbot.com]

Edited 1 time(s). Last edit at 09/15/2013 04:40AM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released September 15, 2013 03:23PM |

Registered: 10 years ago Posts: 10 |

Awesome design, thanks Richrap. I have most of the BOM ordered now.

One thing that worries me: When I ordered the printable parts, I left off the list the LCD covers. I was planning on printing them myself once the 3DR is up and running. But now I realize those parts won't fit in 3DR's bed (I swear I saw the bed as 180mm, but now it says 170mm)

Is that so? Shouldn't the printer be able to replicate itself per Reprap philosophy?

Edited 1 time(s). Last edit at 09/15/2013 03:27PM by FraNtik.

One thing that worries me: When I ordered the printable parts, I left off the list the LCD covers. I was planning on printing them myself once the 3DR is up and running. But now I realize those parts won't fit in 3DR's bed (I swear I saw the bed as 180mm, but now it says 170mm)

Is that so? Shouldn't the printer be able to replicate itself per Reprap philosophy?

Edited 1 time(s). Last edit at 09/15/2013 03:27PM by FraNtik.

Sorry, only registered users may post in this forum.