RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released October 07, 2013 10:38AM |

Registered: 10 years ago Posts: 6 |

Could you possibly get some pictures on how you attached the LCD to the mount? I Can't seem to figure that out. Then could you get me a picture of how the hotend and it's adapter connect to the "gantry"? Then, would you mind telling me the exact parts you used for the idler bearings up top that the string goes on? I can't get my cover to fit over my screw/bearings. Lastly, just a few pictures of how you did your wiring? Also how did you test out the magnets for the hall effect endstops? Thanks so much for those pictures they are a great help!

- HV

- HV

|

Re: RepRap 3DR Delta printer Released October 07, 2013 11:19AM |

Registered: 11 years ago Posts: 142 |

FraNtik Wrote:

-------------------------------------------------------

> Here is something I'd learn the hard way. Not all

> Traxxas joints are the same.

>

> I ordered 12 joints froma local hobby shop.

> Traxxas ref. #2742

> I went ahead and make the holes in the joints and

> platform wider so I could use M3 screws and fit

> the carbon rods. Then I realized they only have 45

> degreees of freedom. That is too few, at best it

> can move 8cm side to side, instead of the 17cm

> expected.

>

> Now I'd ordered the ones Richrap linked

> [url=http://kcmodelaccessories.com/store/products/

> single-end-knuckle-extender-swivel-joint/]KCmodels

> [/url]

>

> Live and learn.

I have also ordered the ones Richrap linked and the the 3 mm carbon rod. But I can t print the joints as precise as they should with my printer, and I am not able to find a similar joint on the net......

So I thought instead of using the 3 mm carbon rod, I could order this 2 mm steel threaded rod

[url]http://www.conrad.de/ce/de/product/237230/Stahl-Gewindestange-500-mm-M2[/url]

and screw it directly in the 2 mm hole of the Traxxas without using the adapter.

But I don t have yet experience with this and I don t know if a 2 mm steel rod (110 mm long) is ok? I mean, is there any reason to use a 3 mm and not a 2 mm rod?

Thanks for any advice.

Edit: updated the link to the rod

Edited 2 time(s). Last edit at 10/07/2013 11:35AM by zacbot.

-------------------------------------------------------

> Here is something I'd learn the hard way. Not all

> Traxxas joints are the same.

>

> I ordered 12 joints froma local hobby shop.

> Traxxas ref. #2742

> I went ahead and make the holes in the joints and

> platform wider so I could use M3 screws and fit

> the carbon rods. Then I realized they only have 45

> degreees of freedom. That is too few, at best it

> can move 8cm side to side, instead of the 17cm

> expected.

>

> Now I'd ordered the ones Richrap linked

> [url=http://kcmodelaccessories.com/store/products/

> single-end-knuckle-extender-swivel-joint/]KCmodels

> [/url]

>

> Live and learn.

I have also ordered the ones Richrap linked and the the 3 mm carbon rod. But I can t print the joints as precise as they should with my printer, and I am not able to find a similar joint on the net......

So I thought instead of using the 3 mm carbon rod, I could order this 2 mm steel threaded rod

[url]http://www.conrad.de/ce/de/product/237230/Stahl-Gewindestange-500-mm-M2[/url]

and screw it directly in the 2 mm hole of the Traxxas without using the adapter.

But I don t have yet experience with this and I don t know if a 2 mm steel rod (110 mm long) is ok? I mean, is there any reason to use a 3 mm and not a 2 mm rod?

Thanks for any advice.

Edit: updated the link to the rod

Edited 2 time(s). Last edit at 10/07/2013 11:35AM by zacbot.

|

Re: RepRap 3DR Delta printer Released October 07, 2013 02:45PM |

Registered: 10 years ago Posts: 10 |

FraNtik Wrote:

-------------------------------------------------------

> Nyarlathotep Wrote:

> --------------------------------------------------

> -----

> > If you're having interference problems you may

> try

> > twisting the stepper motor wire pairs (one

> twisted

> > pair 1A+1B, and a separate twisted pair 2A+2

> --

> > it's recommended anyways for stepper motors so

> > won't hurt anything.

>

> Yeah, I'll try some twisting, but I won't pass the

> cables again (pain in the ass). The USB works fine

> until the motor in that column moves

> Maybe some ferrite cores would help to kill the

> interference?

> The plan is to use it mostly with the SD card, so

> is not vital to make it work.

The ferrite cores did the trick. No more interference.

-------------------------------------------------------

> Nyarlathotep Wrote:

> --------------------------------------------------

> -----

> > If you're having interference problems you may

> try

> > twisting the stepper motor wire pairs (one

> twisted

> > pair 1A+1B, and a separate twisted pair 2A+2

> --

> > it's recommended anyways for stepper motors so

> > won't hurt anything.

>

> Yeah, I'll try some twisting, but I won't pass the

> cables again (pain in the ass). The USB works fine

> until the motor in that column moves

> Maybe some ferrite cores would help to kill the

> interference?

> The plan is to use it mostly with the SD card, so

> is not vital to make it work.

The ferrite cores did the trick. No more interference.

|

Re: RepRap 3DR Delta printer Released October 07, 2013 03:03PM |

Registered: 10 years ago Posts: 10 |

hvalner Wrote:

-------------------------------------------------------

> Could you possibly get some pictures on how you

> attached the LCD to the mount? I Can't seem to

> figure that out. Then could you get me a picture

> of how the hotend and it's adapter connect to the

> "gantry"? Then, would you mind telling me the

> exact parts you used for the idler bearings up top

> that the string goes on? I can't get my cover to

> fit over my screw/bearings. Lastly, just a few

> pictures of how you did your wiring? Also how did

> you test out the magnets for the hall effect

> endstops? Thanks so much for those pictures they

> are a great help!

> - HV

I added a few more pics to my gallery I hope it helps.

-The hotend+mount is held by 2 M3 screws to the gantry (I used very long ones so I can tie the cables around if needed)

-The LCD + mount are put together as a unit, then it's hold by 2 M4 screws to the printer (the M4 nuts are trapped between the case and the mount). The bottom part of the case and the mount are put together first, by 2 selftapping screws (I had to drill a bit the mount's holes), then the LCD is screwed in and then the top cover (don't forget to insert the button like I did )

)

- The idler bearing were made as RichRap describes in his blog. 1 M4 domed screw of 20mm, 2 M4 washers, 2 624ZZ bearings, 1 M4 nut, 1 M5 washer and the T-slot hammer nut (I think that's the name). The cover fits tightly , I have more problems with the extra wires I passed thru the columns.

- The endstops can be easily tested by powering up the board, as soon you approach the magnet on the right side it will light up a green led on the endstop. You can see them in action in the last frames of this RichRap's youtube video

My setup and wiring is still messy, don't judge me

-------------------------------------------------------

> Could you possibly get some pictures on how you

> attached the LCD to the mount? I Can't seem to

> figure that out. Then could you get me a picture

> of how the hotend and it's adapter connect to the

> "gantry"? Then, would you mind telling me the

> exact parts you used for the idler bearings up top

> that the string goes on? I can't get my cover to

> fit over my screw/bearings. Lastly, just a few

> pictures of how you did your wiring? Also how did

> you test out the magnets for the hall effect

> endstops? Thanks so much for those pictures they

> are a great help!

> - HV

I added a few more pics to my gallery I hope it helps.

-The hotend+mount is held by 2 M3 screws to the gantry (I used very long ones so I can tie the cables around if needed)

-The LCD + mount are put together as a unit, then it's hold by 2 M4 screws to the printer (the M4 nuts are trapped between the case and the mount). The bottom part of the case and the mount are put together first, by 2 selftapping screws (I had to drill a bit the mount's holes), then the LCD is screwed in and then the top cover (don't forget to insert the button like I did

)

)- The idler bearing were made as RichRap describes in his blog. 1 M4 domed screw of 20mm, 2 M4 washers, 2 624ZZ bearings, 1 M4 nut, 1 M5 washer and the T-slot hammer nut (I think that's the name). The cover fits tightly , I have more problems with the extra wires I passed thru the columns.

- The endstops can be easily tested by powering up the board, as soon you approach the magnet on the right side it will light up a green led on the endstop. You can see them in action in the last frames of this RichRap's youtube video

My setup and wiring is still messy, don't judge me

|

Re: RepRap 3DR Delta printer Released October 08, 2013 02:36AM |

Registered: 14 years ago Posts: 80 |

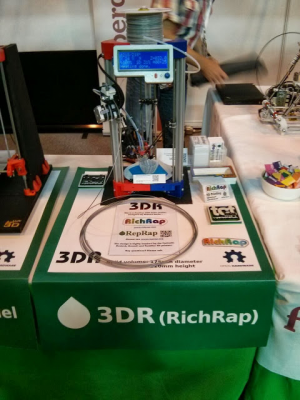

Building the 3DR printer as well.

[www.flickr.com]

Progress pictures, but i tend to jump around alot. Maybe someone will learn from my mistakes.

Primary mistake so far: I bought spectra line which is plastic single thread, instead of the recommended braided line. This stuff i have is very springy which can cause some slop in motion. Waiting delivery of new 100lb threaded line. Also, cheap linear bearings. They are just so cheap, its hard to resist. Get good linear bearings. It makes a huge difference in delta printers.

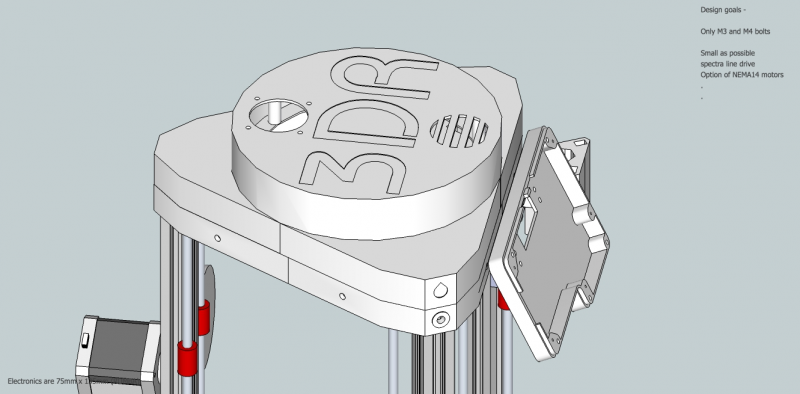

Also, i had an alternative idea for the top of the printer. Not all people, at least myself, plan to mount the spool on top. Mostly because the spools i usually buy dont fit into that hole. So i want to mount my electronics in this area, as well as a raspberry pi. The picture shows my modification. I also branded it with the 3DR name. Hope RichRap doesnt mind.

Hope RichRap doesnt mind.

[www.flickr.com]

Progress pictures, but i tend to jump around alot. Maybe someone will learn from my mistakes.

Primary mistake so far: I bought spectra line which is plastic single thread, instead of the recommended braided line. This stuff i have is very springy which can cause some slop in motion. Waiting delivery of new 100lb threaded line. Also, cheap linear bearings. They are just so cheap, its hard to resist. Get good linear bearings. It makes a huge difference in delta printers.

Also, i had an alternative idea for the top of the printer. Not all people, at least myself, plan to mount the spool on top. Mostly because the spools i usually buy dont fit into that hole. So i want to mount my electronics in this area, as well as a raspberry pi. The picture shows my modification. I also branded it with the 3DR name.

Hope RichRap doesnt mind.

Hope RichRap doesnt mind.|

Re: RepRap 3DR Delta printer Released October 08, 2013 07:17AM |

Registered: 10 years ago Posts: 63 |

>> Also, cheap linear bearings. They are just so cheap, its hard to resist. Get good linear bearings. It makes a huge difference in delta printers. <<

Well I admit going for those dirt cheap chinese linear bearings too... but I went ahead and bought 20 of those and selected the best ones (read: with minimal slack) which are actually quite good.

Well I admit going for those dirt cheap chinese linear bearings too... but I went ahead and bought 20 of those and selected the best ones (read: with minimal slack) which are actually quite good.

|

Re: RepRap 3DR Delta printer Released October 08, 2013 08:05AM |

Registered: 11 years ago Posts: 142 |

I had enough from these cheap chinese linear bearings... I have opted for self-lubricating sinter bronze bearings, that are pressed from tin-bronze powder with a porosity of 25% to 30% and impregnated with oil, making lubrication redundant, made in germany and not really expensive...we will see how they will perform.

video of my 3DR

video of my 3DR

|

Re: RepRap 3DR Delta printer Released October 08, 2013 09:15AM |

Registered: 13 years ago Posts: 818 |

Hello Everyone,

Thanks all so much for building up 3DR's and posting here, I have been keeping up with all your developments, so great work all and I hope you like the printer. I'm really impressed with all your builds, changes and upgrades!

For anyone still needing a little help Part 3 (Electronics) is now posted and I will have Part 4 (Firmware) up soon.

Any questions, do let me know.

Cheers,

Rich.

[richrap.blogspot.com]

Thanks all so much for building up 3DR's and posting here, I have been keeping up with all your developments, so great work all and I hope you like the printer. I'm really impressed with all your builds, changes and upgrades!

For anyone still needing a little help Part 3 (Electronics) is now posted and I will have Part 4 (Firmware) up soon.

Any questions, do let me know.

Cheers,

Rich.

[richrap.blogspot.com]

|

Re: RepRap 3DR Delta printer Released October 08, 2013 08:10PM |

Registered: 11 years ago Posts: 15 |

Thanks Rich for all your hard work, I'm sure everyone here is really appreciative of all the hard work you have put into this project.

I'm planning to build this printer as soon as I have finished working out the final details for the modifications I have planned to your design. At the moment I am planning to enlarge the printer quite a lot and also add a heated chamber to the design so we'll see how it goes.

I'm planning to build this printer as soon as I have finished working out the final details for the modifications I have planned to your design. At the moment I am planning to enlarge the printer quite a lot and also add a heated chamber to the design so we'll see how it goes.

|

Re: RepRap 3DR Delta printer Released October 11, 2013 10:36PM |

Registered: 11 years ago Posts: 10 |

Hi,

Firstly, thank you for the great design. I've printed almost all my parts and started assembly.

I had a hard time printing the TOP LCD cover. The first time it went crazy at layer 100, just at the point where it prints the overlapping part of the top and bottom cover. I then tried a few more times not having much success. Just now I managed to get another good print but then again it went crazy at layer 100. My suspicion is there is a problem in the Gcode at layer 100.

I'm using Slice3R 0.9.10b.

Thank you

Firstly, thank you for the great design. I've printed almost all my parts and started assembly.

I had a hard time printing the TOP LCD cover. The first time it went crazy at layer 100, just at the point where it prints the overlapping part of the top and bottom cover. I then tried a few more times not having much success. Just now I managed to get another good print but then again it went crazy at layer 100. My suspicion is there is a problem in the Gcode at layer 100.

I'm using Slice3R 0.9.10b.

Thank you

|

Re: RepRap 3DR Delta printer Released October 13, 2013 09:12AM |

Registered: 12 years ago Posts: 8 |

Great Design. Totally love it. Building a miture out of this and the 3DR simple, because I am useing 8mm rods. Extruder is already finished. Printing out parts and waiting for some to arrive.

@bluescape:

What do you mean by "it went crazy"? I did not print out this part yet, but I had a simpilar problem with another part where everything went fine, but at exactly the same line, everthing was shifted for some Millimeters, so the whole print was scrap. Is this your problem?

I solved this by setting the vibration limit to 20Hz. (Slicer-->Printer seetings--> Advanced (menu point at the bottom))

The reason were stepping errors while filling out small parts and going back and forth very quickly, so quickly that the printer could not follow and missed some steps and everything was shifted. 20Hz was the value which is optimal for my Mendelmax. I use this now on every print and did not have the problem again.

@Richrap:

Soved the problem with warping of large prints. Put a 1:10 mixture of white glue for wood and water onto the glass surface of the heated bed and it sticks perfectly. Found this somewhere in the forums.

Regards,

Philip

Edited 1 time(s). Last edit at 10/13/2013 09:27AM by Duesentrieb.

@bluescape:

What do you mean by "it went crazy"? I did not print out this part yet, but I had a simpilar problem with another part where everything went fine, but at exactly the same line, everthing was shifted for some Millimeters, so the whole print was scrap. Is this your problem?

I solved this by setting the vibration limit to 20Hz. (Slicer-->Printer seetings--> Advanced (menu point at the bottom))

The reason were stepping errors while filling out small parts and going back and forth very quickly, so quickly that the printer could not follow and missed some steps and everything was shifted. 20Hz was the value which is optimal for my Mendelmax. I use this now on every print and did not have the problem again.

@Richrap:

Soved the problem with warping of large prints. Put a 1:10 mixture of white glue for wood and water onto the glass surface of the heated bed and it sticks perfectly. Found this somewhere in the forums.

Regards,

Philip

Edited 1 time(s). Last edit at 10/13/2013 09:27AM by Duesentrieb.

|

Re: RepRap 3DR Delta printer Released October 13, 2013 11:24PM |

Registered: 10 years ago Posts: 2 |

HaDe Wrote:

-------------------------------------------------------

> As for the heated bed: just an experiment...

> actually two self adhesive heating foils, pretty

> mild with 15W each, a larger one with 160 mm and a

> smaller one with 80mm diameter layered on top of

> each other. I can plug in either one, the larger

> will heat up to 60°C and the larger one beyond

> 90°C. The insulation is cork. We'll see how it

> works, have just finished the modification but no

> prints yet.

HaDe,

Where can I buy those self adhesive heating foils? I would love to have a heated bed on my 3DR.

-------------------------------------------------------

> As for the heated bed: just an experiment...

> actually two self adhesive heating foils, pretty

> mild with 15W each, a larger one with 160 mm and a

> smaller one with 80mm diameter layered on top of

> each other. I can plug in either one, the larger

> will heat up to 60°C and the larger one beyond

> 90°C. The insulation is cork. We'll see how it

> works, have just finished the modification but no

> prints yet.

HaDe,

Where can I buy those self adhesive heating foils? I would love to have a heated bed on my 3DR.

|

Re: RepRap 3DR Delta printer Released October 14, 2013 10:29AM |

Registered: 10 years ago Posts: 63 |

>> Where can I buy those self adhesive heating foils? <<

[www.reichelt.de]

[www.reichelt.de]

With my setup, the larger one will heat up the bed to 50°C quite nicely (and top out at approx. 60°C, though it will take some time), which works fine for PLA.

The smaller one will do more than 90°C which allows printing (small) ABS parts. Alas the 5mm cork insulation seems to be inadequate to protect the PLA printed base from the heat over longer printing times... so I would not really recommend using the smaller heater foil.

Keep in mind that the above heaters are quite weak with max. 15W each... Trinitylabs offers a much more powerful 120W heater (but I would not dare using this one for the 3DR without better insulation):

[trinitylabs.com]

[www.reichelt.de]

[www.reichelt.de]

With my setup, the larger one will heat up the bed to 50°C quite nicely (and top out at approx. 60°C, though it will take some time), which works fine for PLA.

The smaller one will do more than 90°C which allows printing (small) ABS parts. Alas the 5mm cork insulation seems to be inadequate to protect the PLA printed base from the heat over longer printing times... so I would not really recommend using the smaller heater foil.

Keep in mind that the above heaters are quite weak with max. 15W each... Trinitylabs offers a much more powerful 120W heater (but I would not dare using this one for the 3DR without better insulation):

[trinitylabs.com]

|

Re: RepRap 3DR Delta printer Released October 15, 2013 12:16PM |

Registered: 11 years ago Posts: 10 |

@Duesentrieb

Exactly that, I will get a few millimeters offset when I get to layer 100. But, I've tried printing the cover with and without other objects and got the same result. So if yours was due to too fast movement having to print other objects then I'm not sure if the vibration limit will solve my problem.

Quote

What do you mean by "it went crazy"? I did not print out this part yet, but I had a simpilar problem with another part where everything went fine, but at exactly the same line, everthing was shifted for some Millimeters, so the whole print was scrap. Is this your problem? I solved this by setting the vibration limit to 20Hz. (Slicer-->Printer seetings--> Advanced (menu point at the bottom)) The reason were stepping errors while filling out small parts and going back and forth very quickly, so quickly that the printer could not follow and missed some steps and everything was shifted. 20Hz was the value which is optimal for my Mendelmax. I use this now on every print and did not have the problem again.

Exactly that, I will get a few millimeters offset when I get to layer 100. But, I've tried printing the cover with and without other objects and got the same result. So if yours was due to too fast movement having to print other objects then I'm not sure if the vibration limit will solve my problem.

|

Re: RepRap 3DR Delta printer Released October 15, 2013 01:52PM |

Registered: 10 years ago Posts: 2 |

@HaDe:

Thanks for the links.

Have you tried Fiber glass paper as insulation. I've been using that on my Plastibot Mendel with good results. I bought the fiber glass from McMaster P/N 9323K21.

I'll give the 120W a try. I'm printing my 3DR on ABS so hopefully that plus the fiber glass insulation will be enough.

Thanks for the links.

Have you tried Fiber glass paper as insulation. I've been using that on my Plastibot Mendel with good results. I bought the fiber glass from McMaster P/N 9323K21.

I'll give the 120W a try. I'm printing my 3DR on ABS so hopefully that plus the fiber glass insulation will be enough.

|

Re: RepRap 3DR Delta printer Released October 15, 2013 03:14PM |

Registered: 13 years ago Posts: 118 |

So as as non-Sketchup user ( I gave it a try of 2+ hours today) what does it take to get the top and bottom parts for 8MM rods and the carriage for LM8UU? I prefer these parts to the Simple 3DR by JohnL (I don't think several smaller pieced screwed together is as stiff as a single part). Normally I would import into OpenScad and add a plug while removing a bigger hole for the top and bottom pieces, but Openscad won't render the imported STL's. I did download a Sketchup plugin called Solid Inspector and there were a dozen or so non-connected lines in (3DR_Bottom_Motor_Mount_V2_001.skp), but removing them didn't make any difference.

Any Sketchup gurus that are willing to help out?

Any Sketchup gurus that are willing to help out?

|

Re: RepRap 3DR Delta printer Released October 15, 2013 06:28PM |

Registered: 10 years ago Posts: 6 |

|

Re: RepRap 3DR Delta printer Released October 15, 2013 07:11PM |

Registered: 10 years ago Posts: 63 |

You mean the small fan on the underside of the carriage? This one is meant to cool the nozzle holder (not the print), though you might get along without one if you print only PLA and take care not to let it sit there heated up for prolonged times.

I use a 20x20 fan stuck to the carriage (effector) with double sided tape.

I use a 20x20 fan stuck to the carriage (effector) with double sided tape.

|

Re: RepRap 3DR Delta printer Released October 17, 2013 08:22AM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap 3DR Delta printer Released October 17, 2013 08:42AM |

Registered: 13 years ago Posts: 818 |

@bluscape

I only have a preference when printing different materials, they all work well.

I print PLA and Nylon with the 3DR so Use the J-head MK5 - I still find it's the best for Nylon printing and is fast for PLA, lightweight and easy to make Bowden

The Prusa V2 nozzle is very good for PET and ABS, for PLA it oozes just a bit more than the E3D.

The E3D nozzle is bigger and heavier so I have not used it on 3DR, but it's fantastic for PLA and all sorts of other materials too. It does not need such a big heatsink, the size was decided because of the Fan dimensions, it could be a lot smaller.

I like them all, but for different reasons.

[richrap.blogspot.com]

I only have a preference when printing different materials, they all work well.

I print PLA and Nylon with the 3DR so Use the J-head MK5 - I still find it's the best for Nylon printing and is fast for PLA, lightweight and easy to make Bowden

The Prusa V2 nozzle is very good for PET and ABS, for PLA it oozes just a bit more than the E3D.

The E3D nozzle is bigger and heavier so I have not used it on 3DR, but it's fantastic for PLA and all sorts of other materials too. It does not need such a big heatsink, the size was decided because of the Fan dimensions, it could be a lot smaller.

I like them all, but for different reasons.

[richrap.blogspot.com]

|

Re: RepRap 3DR Delta printer Released October 17, 2013 01:08PM |

Registered: 13 years ago Posts: 118 |

Update: looks like JohnSL converted the original part files as well as breaking them into Simple 100mm sized sub-parts to use 8mm rods.

[forums.reprap.org]

Edited 1 time(s). Last edit at 10/17/2013 01:08PM by jaydmdigital.

[forums.reprap.org]

Edited 1 time(s). Last edit at 10/17/2013 01:08PM by jaydmdigital.

|

Re: RepRap 3DR Delta printer Released October 17, 2013 01:33PM |

Registered: 14 years ago Posts: 80 |

Ive installed an E3D hotend on my 3DR and finally printed my first part. First time using the E3D and its great! It is larger so you probably lose some Z height but its a great hotend design.

[www.flickr.com]

[www.flickr.com]

|

Re: RepRap 3DR Delta printer Released October 19, 2013 07:56AM |

Registered: 10 years ago Posts: 1 |

hercek Wrote:

> These links were used: MP JET Ball Link (Ø7 mm,

> M3, M3 short); code: MPJ2451B

>

> The rods with the ball links work very well so

> far.

Do you know what angle of movement these joints give before binding please? I bought some TRAXXAS 5347 joints but not too happy with the movement range, about 45 degrees total.

> These links were used: MP JET Ball Link (Ø7 mm,

> M3, M3 short); code: MPJ2451B

>

> The rods with the ball links work very well so

> far.

Do you know what angle of movement these joints give before binding please? I bought some TRAXXAS 5347 joints but not too happy with the movement range, about 45 degrees total.

|

Re: RepRap 3DR Delta printer Released October 19, 2013 04:33PM |

Registered: 10 years ago Posts: 110 |

|

Re: RepRap 3DR Delta printer Released October 19, 2013 07:40PM |

Registered: 14 years ago Posts: 80 |

My b3DR gets about 110mm diameter maximum. To be safe im sticking to 104mm diameter.

JohnSL Wrote:

-------------------------------------------------------

> For those of you who have working 3DR printers,

> what's your usable printing radius? I have my 3DR

> "Simple" almost running, and it looks like I'll be

> able to get about 140mm to 150mm diameter as the

> maximum printer area. I was curious to see how

> this compared with purebread 3DR printers.

JohnSL Wrote:

-------------------------------------------------------

> For those of you who have working 3DR printers,

> what's your usable printing radius? I have my 3DR

> "Simple" almost running, and it looks like I'll be

> able to get about 140mm to 150mm diameter as the

> maximum printer area. I was curious to see how

> this compared with purebread 3DR printers.

|

Re: RepRap 3DR Delta printer Released October 19, 2013 11:14PM |

Registered: 10 years ago Posts: 1 |

Richrap -

Is this the Delta printer that you are controlling with a Reprapdiscount RUMBA board? I am trying to get my Delta printer running with the same board and have run into serious roadblocks trying to get the thing to work correctly. I have done everything I can think of within the firmware (I have tried Marlin as well as the Repetier version) to get things to work. I seem to have better luck with the Repetier firmware, but since it doesn't support the Full Graphics LCD controller, I would prefer to use the Marlin firmware. Marlin, however, does wierd things with my X-carriage. If you have any suggestions or can tell me the types of problems you have run into with your RUMBA and Delta printer, I would sure appreciate hearing about them.

TIA

Is this the Delta printer that you are controlling with a Reprapdiscount RUMBA board? I am trying to get my Delta printer running with the same board and have run into serious roadblocks trying to get the thing to work correctly. I have done everything I can think of within the firmware (I have tried Marlin as well as the Repetier version) to get things to work. I seem to have better luck with the Repetier firmware, but since it doesn't support the Full Graphics LCD controller, I would prefer to use the Marlin firmware. Marlin, however, does wierd things with my X-carriage. If you have any suggestions or can tell me the types of problems you have run into with your RUMBA and Delta printer, I would sure appreciate hearing about them.

TIA

|

Re: RepRap 3DR Delta printer Released October 20, 2013 02:26AM |

Registered: 10 years ago Posts: 110 |

Thanks, CidVilas.

I have another question. I have my 3DR "Simple" assembled and everything is working, but I'm not printing just yet because I don't have the Z adjusted correctly. How did you adjust your Z? It seems like you have to download the firmware to adjust the Z. Is that correct? Or is there an easier way to adjust Z?

One of the reasons I ask is because downloading new firmware to a Printrboard Rev. D is a real pain. You have reset the board while shorting two pins to switch to programming mode, build the hex file, use FLIP to download the hex file, and the reset the board again. I've tried to use various g-code commands to change the z offset, but they don't seem to make a difference.

Thanks.

I have another question. I have my 3DR "Simple" assembled and everything is working, but I'm not printing just yet because I don't have the Z adjusted correctly. How did you adjust your Z? It seems like you have to download the firmware to adjust the Z. Is that correct? Or is there an easier way to adjust Z?

One of the reasons I ask is because downloading new firmware to a Printrboard Rev. D is a real pain. You have reset the board while shorting two pins to switch to programming mode, build the hex file, use FLIP to download the hex file, and the reset the board again. I've tried to use various g-code commands to change the z offset, but they don't seem to make a difference.

Thanks.

|

Re: RepRap 3DR Delta printer Released October 20, 2013 06:02PM |

Registered: 10 years ago Posts: 46 |

not sure what you're using for endstops, but the standard 3DRs' hall sensors are adjusted via a pot on the board I think ? (I've not used them) , a few of us are using fixed hall sensors so you have to adjust via firmware (would be the same for mech and opto endstops, unless they're mounted on the smooth rods)

to adjust in marlin you can use the M666 command , changes are then stored in eprom so no need to re-upload firmware each time.

By the sounds of it john ,it's going to be a right pain calibrating your 3dr with your controller setup, you have to adjust/re-adjust other parameters during calibration, these have to be uploaded each time.

to adjust in marlin you can use the M666 command , changes are then stored in eprom so no need to re-upload firmware each time.

By the sounds of it john ,it's going to be a right pain calibrating your 3dr with your controller setup, you have to adjust/re-adjust other parameters during calibration, these have to be uploaded each time.

|

Re: RepRap 3DR Delta printer Released October 20, 2013 08:37PM |

Registered: 10 years ago Posts: 110 |

I'm using microswitch end stops, and I didn't make them adjustable in my current design because I figured adjusting them individually would just change the center location. And adjusting them all to change the Z height didn't seem like the right way to do it.

I looked for the M666 command and couldn't find it on the wiki, and I also didn't find it in the source code in RichRap's version of Marlin. Is that a new command that has been added recently to Marlin?

At this point I think I'm going to go with either an adjustable bed for fine tuning (sure beats downloading the firmware), or go with auto leveling. It looks like the version of Marlin that RichRap forked doesn't have this support, so I may switch versions. There's some pretty interesting work going on in the Google group with auto bed leveling. On the other hand, it probably doesn't hurt to allow both, so I may start with a bed leveling system.

I looked for the M666 command and couldn't find it on the wiki, and I also didn't find it in the source code in RichRap's version of Marlin. Is that a new command that has been added recently to Marlin?

At this point I think I'm going to go with either an adjustable bed for fine tuning (sure beats downloading the firmware), or go with auto leveling. It looks like the version of Marlin that RichRap forked doesn't have this support, so I may switch versions. There's some pretty interesting work going on in the Google group with auto bed leveling. On the other hand, it probably doesn't hurt to allow both, so I may start with a bed leveling system.

|

Re: RepRap 3DR Delta printer Released October 20, 2013 10:33PM |

Registered: 14 years ago Posts: 80 |

I loaded Repetier firmware on my 3DR because i could not get Marlin to work for some reason. Im running Arduino2560 with RAMPs 1.4 and the XXL LCD from Reprap Discount. The LCD works great with Repetier, and at least in the case of Repetier, the Z height and Leveling can be handled through the LCD interface. I simply go to that menu, and Homa All axis then move Z down until i touch the bed and Set Origin in the UI. Its pretty straight forward. I didnt know what i was doing and figured it out pretty quick. Really loving the LCD. I was against SD card printing for a long time as not having an interface or one with limited functionality was not ideal for me, but Repetier is pretty slick.

JohnSL Wrote:

-------------------------------------------------------

> Thanks, CidVilas.

>

> I have another question. I have my 3DR "Simple"

> assembled and everything is working, but I'm not

> printing just yet because I don't have the Z

> adjusted correctly. How did you adjust your Z? It

> seems like you have to download the firmware to

> adjust the Z. Is that correct? Or is there an

> easier way to adjust Z?

>

> One of the reasons I ask is because downloading

> new firmware to a Printrboard Rev. D is a real

> pain. You have reset the board while shorting two

> pins to switch to programming mode, build the hex

> file, use FLIP to download the hex file, and the

> reset the board again. I've tried to use various

> g-code commands to change the z offset, but they

> don't seem to make a difference.

>

> Thanks.

JohnSL Wrote:

-------------------------------------------------------

> Thanks, CidVilas.

>

> I have another question. I have my 3DR "Simple"

> assembled and everything is working, but I'm not

> printing just yet because I don't have the Z

> adjusted correctly. How did you adjust your Z? It

> seems like you have to download the firmware to

> adjust the Z. Is that correct? Or is there an

> easier way to adjust Z?

>

> One of the reasons I ask is because downloading

> new firmware to a Printrboard Rev. D is a real

> pain. You have reset the board while shorting two

> pins to switch to programming mode, build the hex

> file, use FLIP to download the hex file, and the

> reset the board again. I've tried to use various

> g-code commands to change the z offset, but they

> don't seem to make a difference.

>

> Thanks.

Sorry, only registered users may post in this forum.