RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released October 21, 2013 03:24AM |

Registered: 10 years ago Posts: 732 |

JohnSL Wrote:

-------------------------------------------------------

> I looked for the M666 command and couldn't find it

> on the wiki, and I also didn't find it in the

> source code in RichRap's version of Marlin. Is

> that a new command that has been added recently to

> Marlin?

[github.com]

[github.com]

-------------------------------------------------------

> I looked for the M666 command and couldn't find it

> on the wiki, and I also didn't find it in the

> source code in RichRap's version of Marlin. Is

> that a new command that has been added recently to

> Marlin?

[github.com]

[github.com]

|

Re: RepRap 3DR Delta printer Released October 23, 2013 02:54PM |

Registered: 11 years ago Posts: 10 |

Hi Guys,

I've been using this reflective sensor (HOA1180-2) in other projects for distance measurement. It has excellent measuring properties in a 10mm range.

I would like to use it for auto leveling/calibration in my 3DR. What do you guys think?

Cheers

I've been using this reflective sensor (HOA1180-2) in other projects for distance measurement. It has excellent measuring properties in a 10mm range.

I would like to use it for auto leveling/calibration in my 3DR. What do you guys think?

Cheers

|

Re: RepRap 3DR Delta printer Released October 23, 2013 05:42PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released October 31, 2013 11:56AM |

Registered: 10 years ago Posts: 5 |

Hi Rich,

Congratulation for the 3DR !

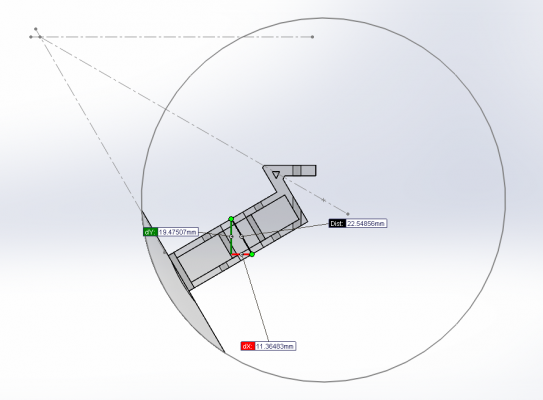

I've designed a pair of parts to extend the bed diameter to 200 mm. Ì want to use a circular silicon heated bed and its diameter is 200 mm.

I didn't want to re-design bottom and top parts because :

1 - yours seems to be good

2 - you can use extenders on a "stock" 3DR (but need to rebuild it).

Here are pics of parts for the 3DR-X (X for extended) :

Edited 3 time(s). Last edit at 10/31/2013 12:00PM by cybug.

Congratulation for the 3DR !

I've designed a pair of parts to extend the bed diameter to 200 mm. Ì want to use a circular silicon heated bed and its diameter is 200 mm.

I didn't want to re-design bottom and top parts because :

1 - yours seems to be good

2 - you can use extenders on a "stock" 3DR (but need to rebuild it).

Here are pics of parts for the 3DR-X (X for extended) :

Edited 3 time(s). Last edit at 10/31/2013 12:00PM by cybug.

|

Re: RepRap 3DR Delta printer Released November 04, 2013 02:31PM |

Registered: 11 years ago Posts: 142 |

I don t know if I should leave these two new options (in bold) found in the actual Marlin version:

Edit: updated...

Edited 2 time(s). Last edit at 11/05/2013 04:31PM by zacbot.

video of my 3DR

//=========================================================================== //============================== Delta Settings ============================= //=========================================================================== // Enable DELTA kinematics and most of the default configuration for Deltas #define DELTA ..... // Effective horizontal distance bridged by diagonal push rods. //#define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET) #define DELTA_DIAGONAL_ROD_2 sq(DELTA_DIAGONAL_ROD)

Edit: updated...

Edited 2 time(s). Last edit at 11/05/2013 04:31PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 05, 2013 03:56PM |

Registered: 10 years ago Posts: 39 |

Quote

cybug

Hi Rich,

Congratulation for the 3DR !

I've designed a pair of parts to extend the bed diameter to 200 mm. Ì want to use a circular silicon heated bed and its diameter is 200 mm.

-----------

Here are pics of parts for the 3DR-X (X for extended) :

That is awesome!

I have just started to build my 3DR and I would prefer to have a larger circle and sacrifice build height and just logged on to ask if anybody already is designing extenders before I started. What thickness of the spacer do you need to get 200mm, and rod eye-to-eye length? I don't have a printer so I was thinking of just putting a spacer of whatever material there to get it running.

They are very good looking by the way

Thanks!

|

Re: RepRap 3DR Delta printer Released November 06, 2013 01:02PM |

Registered: 10 years ago Posts: 5 |

Quote

Mallgan.O

That is awesome!

I have just started to build my 3DR and I would prefer to have a larger circle and sacrifice build height and just logged on to ask if anybody already is designing extenders before I started. What thickness of the spacer do you need to get 200mm, and rod eye-to-eye length? I don't have a printer so I was thinking of just putting a spacer of whatever material there to get it running.

They are very good looking by the way

Thanks!

Thickness is about 22.55mm. I haven't yet done the math for extended eye-to-eye rod length. May be proportionnal with 200/170 factor ...

Edit : Picture is top extender, not bottom.

Edited 1 time(s). Last edit at 11/06/2013 01:33PM by cybug.

|

Re: RepRap 3DR Delta printer Released November 06, 2013 01:11PM |

Registered: 10 years ago Posts: 5 |

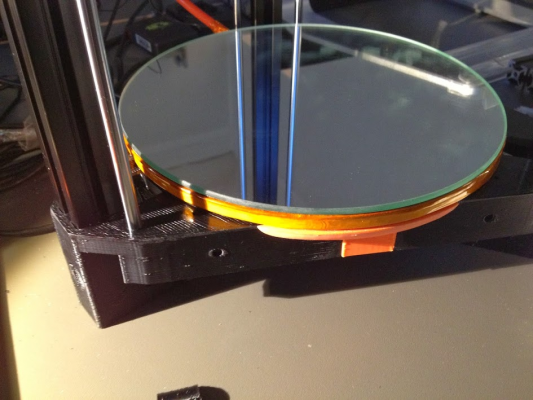

Received new parts and did some progress on my 3DR-X :

I've installed the silicone heating bed with thermal insulation :

More pictures including how-to install the heatng bed (not yet tested, only concept) : 3DR-X

I've installed the silicone heating bed with thermal insulation :

More pictures including how-to install the heatng bed (not yet tested, only concept) : 3DR-X

|

Re: RepRap 3DR Delta printer Released November 06, 2013 03:19PM |

Registered: 10 years ago Posts: 39 |

|

Re: RepRap 3DR Delta printer Released November 08, 2013 11:02AM |

Registered: 10 years ago Posts: 515 |

Hi Guys

I have spent the last few weeks building a 3DR as per Rich's design using hall effect endstops and a Rumba board. I am now at initial testing stages and have a problem with Z homing using G28. The three carriages go up and I can see all of the green leds on the hall boards lighting up but the motors continue to try turning and they clatter around for about 5 seconds before stopping. My LCD display reads z=0 at that point. Any ideas? I'm using the firmware for marlin from Rich's github.

Regards

Andy

I have spent the last few weeks building a 3DR as per Rich's design using hall effect endstops and a Rumba board. I am now at initial testing stages and have a problem with Z homing using G28. The three carriages go up and I can see all of the green leds on the hall boards lighting up but the motors continue to try turning and they clatter around for about 5 seconds before stopping. My LCD display reads z=0 at that point. Any ideas? I'm using the firmware for marlin from Rich's github.

Regards

Andy

|

Re: RepRap 3DR Delta printer Released November 08, 2013 12:27PM |

Registered: 11 years ago Posts: 142 |

I am at the same stage with the same problem...using RAMPS 1.4 and up to date Marlin firmware....

I had something similar with my first printer and It had to do with the Endstop configuration....

video of my 3DR

I had something similar with my first printer and It had to do with the Endstop configuration....

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 08, 2013 12:34PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released November 08, 2013 01:40PM |

Registered: 11 years ago Posts: 142 |

|

Re: RepRap 3DR Delta printer Released November 08, 2013 05:02PM |

Registered: 11 years ago Posts: 142 |

It is always the same status, it does not change...what does this mean ? The logic of the end stop in the firmware ?

23:01:24.593 : Reporting endstop status

23:01:24.593 : x_max: TRIGGERED

23:01:24.593 : y_max: TRIGGERED

23:01:24.593 : z_max: TRIGGERED

video of my 3DR

23:01:24.593 : Reporting endstop status

23:01:24.593 : x_max: TRIGGERED

23:01:24.593 : y_max: TRIGGERED

23:01:24.593 : z_max: TRIGGERED

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 08, 2013 05:43PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released November 08, 2013 09:01PM |

Registered: 11 years ago Posts: 142 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 03:29AM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 04:42AM |

Registered: 10 years ago Posts: 153 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 05:43AM |

Registered: 10 years ago Posts: 10 |

So I got mine up and running finally.

Some problems I bumped into (some had been mentioned in this thread before):

- The teflon tube I bought at a local hardware store was not the right one. Being my first 3D printer I didn't know how the tube should be. This one looked right, but it was not rigid enough and maybe a bit too flexible and with more friction. All this caused the filament to jam through the tube and make noises. Then I decided to get one from an online shop, and boy oh boy what a difference.

- The E steps in RichRap's firmware were set to 120. This turned out to be far too low. After many calibrations I got a result of 584 steps. I don't know if anyone else got close that number. Maybe that value was for a direct drive extruder.

- The extruder's connector has to be flipped on the board (180 degrees turn).

- The fishing line spools are a bit too long (less than 1mm maybe). They will bump into the columns. Either trim them a bit, or push the motors away with washers.

- The LCD case can't be printed by the 3DR. Maybe someone can make a printable version? please?

- I tried to place a USB female connector in the base by passing 4 extra wires thru a column, this didn't work at the end, too much interference from the motor wires. It works for a bit but then the connection with the PC fails. Maybe the motor wires need to be twisted and USB wires shielded.

- On that note, the USB pins in the Rumba have one marked. That one IS NOT VCC, it's GND!

- If you use Repetier-Host make sure that you disable or edit the 'Park position' in 'Printer settings/printer'. By default it will move the head to a coordinate beyond 3DR's limits. One of the carriage will crash to the bottom after the print.

- The filament I'm using comes in spools that won't fit at 3DR's top. I made a inverted cone of 25mm to rise the original spool holder (I used a longer M8 screw of course) and works lovely. You can see it in one of the last photos at my gallery.

Great machine anyway, loving it. Thanks RichRap!

PS: Pro tip: Use a PC duster upsidedown on the printed pieces. It'll freeze them and they pop right out. Learned here: http://youtu.be/GJtRKDhfnqo?t=2m21s

Edited 1 time(s). Last edit at 11/09/2013 05:47AM by FraNtik.

Some problems I bumped into (some had been mentioned in this thread before):

- The teflon tube I bought at a local hardware store was not the right one. Being my first 3D printer I didn't know how the tube should be. This one looked right, but it was not rigid enough and maybe a bit too flexible and with more friction. All this caused the filament to jam through the tube and make noises. Then I decided to get one from an online shop, and boy oh boy what a difference.

- The E steps in RichRap's firmware were set to 120. This turned out to be far too low. After many calibrations I got a result of 584 steps. I don't know if anyone else got close that number. Maybe that value was for a direct drive extruder.

- The extruder's connector has to be flipped on the board (180 degrees turn).

- The fishing line spools are a bit too long (less than 1mm maybe). They will bump into the columns. Either trim them a bit, or push the motors away with washers.

- The LCD case can't be printed by the 3DR. Maybe someone can make a printable version? please?

- I tried to place a USB female connector in the base by passing 4 extra wires thru a column, this didn't work at the end, too much interference from the motor wires. It works for a bit but then the connection with the PC fails. Maybe the motor wires need to be twisted and USB wires shielded.

- On that note, the USB pins in the Rumba have one marked. That one IS NOT VCC, it's GND!

- If you use Repetier-Host make sure that you disable or edit the 'Park position' in 'Printer settings/printer'. By default it will move the head to a coordinate beyond 3DR's limits. One of the carriage will crash to the bottom after the print.

- The filament I'm using comes in spools that won't fit at 3DR's top. I made a inverted cone of 25mm to rise the original spool holder (I used a longer M8 screw of course) and works lovely. You can see it in one of the last photos at my gallery.

Great machine anyway, loving it. Thanks RichRap!

PS: Pro tip: Use a PC duster upsidedown on the printed pieces. It'll freeze them and they pop right out. Learned here: http://youtu.be/GJtRKDhfnqo?t=2m21s

Edited 1 time(s). Last edit at 11/09/2013 05:47AM by FraNtik.

|

Re: RepRap 3DR Delta printer Released -Minor Issues November 09, 2013 12:59PM |

Registered: 10 years ago Posts: 21 |

Hello Rich Thank you for releasing such a nice printer I am partially through my build and enjoying it a lot so far.I am running into some issues and maybe you or someone else could provide some guidance.

I currently have a few issues I have been battling and at best I am at a stalemate

I have the frame built and the rumba board installed and this is what I see

I have a very difficult time connecting and talking to the rumba board via the USB

-running on a new Mac Mini

-tried with both a powered USB line and non powered(the powered worked better)

-I see the connection issues in both Arduino and Repetier-Slic3r

-at this point it is a straight connection issue I seem to communicate OK was teh connection can be established

During one of the times I was able to connect with Arduino I managed to get the firmware uploaded and my LCD seems to show the right information. Here is where the next issue begins

-via the controller without homing I can make movements on the three directional motors X Y Z but only in one direction nothing happens if I try to move in the opposite direction

-if I do a Home first on the controller printer responds by moving all the axis correctly to the home position but any subsequent instruction I give for movement on XYZ motors will cause two axis' to move as they are supposed to but quickly and the third to move extremely slowly resulting in the arms brings that axis crashing into the support on that side

a video can be seem here

[www.dropbox.com]

This interesting part is that this only seems to occur through the LCD controller

Lastly I have the Rumba board with four polulu drivers (the white boards) pretty much just like in the images in your assembly posts. They are one X, Y, Z, and E0 all have been tuned to show 4.5V as per the instructions and have the heat sink on them I have the hotend mounted and wired to the rumba board along with the endstops as well. Now when trying to drive from the LCD I have the issues described above that is not the case when driving from repetier. Once I am able to establish a connection in Repetier I can see all the hot end temps and the motors home properly and movement can be achieved both up and down on the 3 directional motors. I can turn on and off the hot end temp and the temperature will hold at the temp it is set to and the hotend actually gets hot. I have set it to anywhere between 180-210 and the directional motors all move as stated BUT the extruder motor does absolutely nothing. I have it connected to E0 with a polulu but nothing happens. In testing I have swapped the polulu board and the motor with the items on the z axis individually (motors and polulus) and as a set and when on the z axis it seems to operate fine and the original items swapped to the E0 circuit do not respond.

I have tried reversing the how it is wired to the board by reversing the plug as well.

When I move the motor and polulu to the E1 circuit path I can feel the motor begin to vibrate as if it is ready to move but does not respond to extruder control direction in repetier.

I am not sure if I need to modify firmware to use E1 in place of E0 as the main controller for the extruder but I was planning to try your 3 extruder combination which means I need to have three controllers E0, E1 and E2 all working,

Any ideas on what I can try next from you Rich or anyone would be greatly appreciated.

Thanks

Hope to be printing soon

Edited 1 time(s). Last edit at 11/09/2013 01:02PM by tesseract.

I currently have a few issues I have been battling and at best I am at a stalemate

I have the frame built and the rumba board installed and this is what I see

I have a very difficult time connecting and talking to the rumba board via the USB

-running on a new Mac Mini

-tried with both a powered USB line and non powered(the powered worked better)

-I see the connection issues in both Arduino and Repetier-Slic3r

-at this point it is a straight connection issue I seem to communicate OK was teh connection can be established

During one of the times I was able to connect with Arduino I managed to get the firmware uploaded and my LCD seems to show the right information. Here is where the next issue begins

-via the controller without homing I can make movements on the three directional motors X Y Z but only in one direction nothing happens if I try to move in the opposite direction

-if I do a Home first on the controller printer responds by moving all the axis correctly to the home position but any subsequent instruction I give for movement on XYZ motors will cause two axis' to move as they are supposed to but quickly and the third to move extremely slowly resulting in the arms brings that axis crashing into the support on that side

a video can be seem here

[www.dropbox.com]

This interesting part is that this only seems to occur through the LCD controller

Lastly I have the Rumba board with four polulu drivers (the white boards) pretty much just like in the images in your assembly posts. They are one X, Y, Z, and E0 all have been tuned to show 4.5V as per the instructions and have the heat sink on them I have the hotend mounted and wired to the rumba board along with the endstops as well. Now when trying to drive from the LCD I have the issues described above that is not the case when driving from repetier. Once I am able to establish a connection in Repetier I can see all the hot end temps and the motors home properly and movement can be achieved both up and down on the 3 directional motors. I can turn on and off the hot end temp and the temperature will hold at the temp it is set to and the hotend actually gets hot. I have set it to anywhere between 180-210 and the directional motors all move as stated BUT the extruder motor does absolutely nothing. I have it connected to E0 with a polulu but nothing happens. In testing I have swapped the polulu board and the motor with the items on the z axis individually (motors and polulus) and as a set and when on the z axis it seems to operate fine and the original items swapped to the E0 circuit do not respond.

I have tried reversing the how it is wired to the board by reversing the plug as well.

When I move the motor and polulu to the E1 circuit path I can feel the motor begin to vibrate as if it is ready to move but does not respond to extruder control direction in repetier.

I am not sure if I need to modify firmware to use E1 in place of E0 as the main controller for the extruder but I was planning to try your 3 extruder combination which means I need to have three controllers E0, E1 and E2 all working,

Any ideas on what I can try next from you Rich or anyone would be greatly appreciated.

Thanks

Hope to be printing soon

Edited 1 time(s). Last edit at 11/09/2013 01:02PM by tesseract.

|

Re: RepRap 3DR Delta printer Released -Minor Issues November 09, 2013 01:29PM |

Registered: 10 years ago Posts: 63 |

Three problems if I understand correctly:

1) unreliable USB connection: for the RUMBA board, I noticed that short cables (< 1 m) mostly work ok but longer ones (I need 3 m for my current setup) can be troublesome - had to try a few until I found one that works reliably.

2) funny movement only with UI: not clear from the video what you're actually doing but it appears that you're trying to command a Y move from home position, is that correct? This is not a good idea because at least one axis has to move UP for this. Try a Z down move first.

3) extruder not working: as a first step, I suggest swapping stepper drivers :-) ... if that doesn't help: is the extruder motor powered on (so it cannot be moved by hand)? Also, the firmweare will prevent the extruder from moving if the hotend temperatur is below a defined threshold.

Also: exactly what firmware are you using, and what did you modify in configuration.h?

1) unreliable USB connection: for the RUMBA board, I noticed that short cables (< 1 m) mostly work ok but longer ones (I need 3 m for my current setup) can be troublesome - had to try a few until I found one that works reliably.

2) funny movement only with UI: not clear from the video what you're actually doing but it appears that you're trying to command a Y move from home position, is that correct? This is not a good idea because at least one axis has to move UP for this. Try a Z down move first.

3) extruder not working: as a first step, I suggest swapping stepper drivers :-) ... if that doesn't help: is the extruder motor powered on (so it cannot be moved by hand)? Also, the firmweare will prevent the extruder from moving if the hotend temperatur is below a defined threshold.

Also: exactly what firmware are you using, and what did you modify in configuration.h?

|

Re: RepRap 3DR Delta printer Released November 09, 2013 06:32PM |

Registered: 10 years ago Posts: 515 |

Hi Guys

With a lot of help from this thread and many thanks to Richrap for a great design I now have a 'sort of' working printer. At least I've managed to squirt some hot plastic in a semi controlled way onto the bed! I now have a lot of playing around to do to get everything dialled in. I've come across an issue with the lcd controller though. If I use the panel to command movement on any axis only the motor on each tower moves I.e if I tell Z to move instead of all three motors moving the hot end down just the motor on the rear tower moves. It's as if the lcd knows nothing about the delta setup and thinks it's controlling a conventional printer. I'm using Richraps Marlin firmware. Any ideas?

Andy

With a lot of help from this thread and many thanks to Richrap for a great design I now have a 'sort of' working printer. At least I've managed to squirt some hot plastic in a semi controlled way onto the bed! I now have a lot of playing around to do to get everything dialled in. I've come across an issue with the lcd controller though. If I use the panel to command movement on any axis only the motor on each tower moves I.e if I tell Z to move instead of all three motors moving the hot end down just the motor on the rear tower moves. It's as if the lcd knows nothing about the delta setup and thinks it's controlling a conventional printer. I'm using Richraps Marlin firmware. Any ideas?

Andy

|

Re: RepRap 3DR Delta printer Released November 09, 2013 06:41PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 06:46PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 06:49PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released November 09, 2013 06:52PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released -Minor Issues November 09, 2013 07:10PM |

Registered: 10 years ago Posts: 21 |

Yes Ha De

Those are the three issues.

I have tried alternate cables along of a length of about 6 feet but will keep checking into it

What you see in the video is me trying to issue commands from the LCD controller the two things that I see it can do correctly is identify the firmware used and display and the homeing process. After that nothing else seems to work. In the video you see me trying to move an axis that is the only direction it does anything if I try and move it in the opposite direction nothing at all happens if I move it in the direction you see me this is what happens the two axis motors start turning and moving the respective arms but they do not stop they simply start moving both at the same rate and in the same direction. The third motor also moves in the same direction but at probably 5%the speed of the others and also will not stop. The result is that the arms on the slower axis end up slammiing into the rails and continuing to try and move not apretty sound or sight. I say they start and don't stop, but they possibly could stop but because of the impact on the rails I have to push the emergency stop. Also the movement is not ties to the amount of movement I direct in the LCD I may try and move .1mm on any of the axis' and that simply starts them all going to the same result everytime. That really is the only functionality I can get out of the LCD.

The firmware I am using is Richraps Marlin firmware. I have not made any changes to to the configuration .h as I did not think I needed to at this point maybe I was wrong if I need to change something please let me know what it is or if a different firmware should be used please let me know and I can try that one.

The third is the extruder motor I have swapped the stepper drivers(polulu) and the extruder is definitely on and hot repetier shows it at whatever I set it to usually 190 and it is very hot to the the touch I have another 3d printer so I made sure that was the case I knew it has a cold temp range you have to aware of. The motor is totally inactive and not even powered at this point I can easily turn the shaft when the printer is on however that is not the case when I move it all to E1 instead of E0( the motor and the polulu stepper driver) then as I said I can feel that it is on because there is a kind of vibration but I can't remember if it can be moved manually at this point.

Maybe the older firmware will work. Is there a way I could get the link to the older firmware you are using and whatever changes you made on yours so I can load that and compare functionality???

Those are the three issues.

I have tried alternate cables along of a length of about 6 feet but will keep checking into it

What you see in the video is me trying to issue commands from the LCD controller the two things that I see it can do correctly is identify the firmware used and display and the homeing process. After that nothing else seems to work. In the video you see me trying to move an axis that is the only direction it does anything if I try and move it in the opposite direction nothing at all happens if I move it in the direction you see me this is what happens the two axis motors start turning and moving the respective arms but they do not stop they simply start moving both at the same rate and in the same direction. The third motor also moves in the same direction but at probably 5%the speed of the others and also will not stop. The result is that the arms on the slower axis end up slammiing into the rails and continuing to try and move not apretty sound or sight. I say they start and don't stop, but they possibly could stop but because of the impact on the rails I have to push the emergency stop. Also the movement is not ties to the amount of movement I direct in the LCD I may try and move .1mm on any of the axis' and that simply starts them all going to the same result everytime. That really is the only functionality I can get out of the LCD.

The firmware I am using is Richraps Marlin firmware. I have not made any changes to to the configuration .h as I did not think I needed to at this point maybe I was wrong if I need to change something please let me know what it is or if a different firmware should be used please let me know and I can try that one.

The third is the extruder motor I have swapped the stepper drivers(polulu) and the extruder is definitely on and hot repetier shows it at whatever I set it to usually 190 and it is very hot to the the touch I have another 3d printer so I made sure that was the case I knew it has a cold temp range you have to aware of. The motor is totally inactive and not even powered at this point I can easily turn the shaft when the printer is on however that is not the case when I move it all to E1 instead of E0( the motor and the polulu stepper driver) then as I said I can feel that it is on because there is a kind of vibration but I can't remember if it can be moved manually at this point.

Maybe the older firmware will work. Is there a way I could get the link to the older firmware you are using and whatever changes you made on yours so I can load that and compare functionality???

|

Re: RepRap 3DR Delta printer Released -Minor Issues November 10, 2013 05:01AM |

Registered: 10 years ago Posts: 63 |

AndyCart & tesseract, re. your problem of corrupt moves when commanded from the LCD UI: I examined Rich's code and found the delta implementation to be incomplete - seems to work for moves commanded by G-Code (from USB and SD-Card) but module ultralcd.cpp (where moves commanded from LCD UI are computed) looks like an older version which doesn't know about Delta Printers, so this perfectly explains your problems.

Now about how you could proceed... alas I don't have the time to either fix Rich's branch nor upload & support my particular code branch (which is based on https://github.com/ErikZalm/Marlin/tree/Marlin_v1 but has many experimental changes of my own already). You could either:

- fix it yourself - I guess this would involve *at least* adding a #define DELTA to configuration.h and replacing ultralcd.cpp/.h with more recent ones from Erik's repository - maybe that's the quickest way to get it working). If you get too many compilation errors, you could also try the files from Johann's deltabot branch (https://github.com/jcrocholl/Marlin/tree/deltabot/Marlin) which might be closer to Rich's versions.

- ask or wait for Rich to update his repository

- use Erik's repository (https://github.com/ErikZalm/Marlin/tree/Marlin_v1) and adapt it for the 3DR (this repository incorporates quite a few improvements, also you could use Rich's Configuration.h & Configuration_adv.h as a guideline).

Now about how you could proceed... alas I don't have the time to either fix Rich's branch nor upload & support my particular code branch (which is based on https://github.com/ErikZalm/Marlin/tree/Marlin_v1 but has many experimental changes of my own already). You could either:

- fix it yourself - I guess this would involve *at least* adding a #define DELTA to configuration.h and replacing ultralcd.cpp/.h with more recent ones from Erik's repository - maybe that's the quickest way to get it working). If you get too many compilation errors, you could also try the files from Johann's deltabot branch (https://github.com/jcrocholl/Marlin/tree/deltabot/Marlin) which might be closer to Rich's versions.

- ask or wait for Rich to update his repository

- use Erik's repository (https://github.com/ErikZalm/Marlin/tree/Marlin_v1) and adapt it for the 3DR (this repository incorporates quite a few improvements, also you could use Rich's Configuration.h & Configuration_adv.h as a guideline).

|

Re: RepRap 3DR Delta printer Released November 10, 2013 11:39AM |

Registered: 10 years ago Posts: 21 |

|

Re: RepRap 3DR Delta printer Released November 10, 2013 03:01PM |

Registered: 11 years ago Posts: 142 |

Looks like, we will have to spend some hours with the firmware...

I hoped and thought I just need to change the board type from Rumba to Ramps in the config.h...and since the rest of hardware is identical...I will be ready in few clicks....

Right now, I am at the stage, where homing works, the motor stops when it hits the endstop. But then, when trying to move the axis down away from the homing point, the motor just "broom vibrate".

The second bizzare thing, is the manner how it homes (not like showed on Richrap demo video). The carriage does not go directly up until it hits the endstop. It stops in the middle for a while. Then goes further up and stops before the endstop, then goes further and hits the endstop and then it stops.

I have also tried Repeitier firmware with Delta settings...this is another story...with much more fun.

And I still don t know why is "Delta" in Rich config.h file deactivated. In my case it is activated, could be this the problem? Or is it Repetier Host, I have setup to home to Zmax, or should this be zero ?

Edit: Here is a video of the homing of one axis.

[youtu.be] ---> just homing

[youtu.be] --> homing + 50 mm move (but it does just brooooms) hmmm

Edited 5 time(s). Last edit at 11/10/2013 04:13PM by zacbot.

video of my 3DR

I hoped and thought I just need to change the board type from Rumba to Ramps in the config.h...and since the rest of hardware is identical...I will be ready in few clicks....

Right now, I am at the stage, where homing works, the motor stops when it hits the endstop. But then, when trying to move the axis down away from the homing point, the motor just "broom vibrate".

The second bizzare thing, is the manner how it homes (not like showed on Richrap demo video). The carriage does not go directly up until it hits the endstop. It stops in the middle for a while. Then goes further up and stops before the endstop, then goes further and hits the endstop and then it stops.

I have also tried Repeitier firmware with Delta settings...this is another story...with much more fun.

And I still don t know why is "Delta" in Rich config.h file deactivated. In my case it is activated, could be this the problem? Or is it Repetier Host, I have setup to home to Zmax, or should this be zero ?

Edit: Here is a video of the homing of one axis.

[youtu.be] ---> just homing

[youtu.be] --> homing + 50 mm move (but it does just brooooms) hmmm

Edited 5 time(s). Last edit at 11/10/2013 04:13PM by zacbot.

video of my 3DR

Sorry, only registered users may post in this forum.