RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released November 10, 2013 03:40PM |

Registered: 10 years ago Posts: 21 |

I have not seen any repetier settings so I am not sure how to set up anything if anyone has a thread regarding that or something they can share it will be greatly appreciated. I am still on the new side of working with github and getting all the packages I need, so I may have a slight issue there. Here is what I did

I followed the link from Rich to his marlin firmware setup git page and I downloaded it

I opened it in Arduino and I compiled and uploaded it as is no other steps ......did I miss something???

Now what I see on my LCD is the Rich Rap 3Dr printer

Functionally the home button works as I expect it should I do that and all the motors move to the hall stops and tehy activate and the motors stop it is all smooth

and I can turn on the hot end and turn it off and watch it rise and hold as normal

That is where normal stops

if I try to manually move any movement motors (XYZ) at all from the LCD first of all I only see a reaction if turn the knob in one direction even the smallest change .1mm on any axis immediately begins motion on all three motors two very quickly and one very slowly and because of the arms the slow moving axis motor causes the extruder plate to slam repeatedly into that axis' extruded beams as it tries to keep moving in the same way. this continues until I hit emergency stop. Turning the knob in the other direction reads on the display but nothing moves.

If I do not Home it first and manually moves the arms to different heights and then try and move them via the controller they do move in distances associated with what I am doing but only in the same single direction .1mm gives the smallest movement 1mm the next and 10mm the most I can not verify if it is exact or not yet.

Now the weirder part if I go into repetier and try the movements everything seems to work just fine movement wise and the hotend heating and maintaining

Not sure maybe I am missing something in the git hub process and if so please let me know and if someone has a repetier setup that would be helpful as well

I followed the link from Rich to his marlin firmware setup git page and I downloaded it

I opened it in Arduino and I compiled and uploaded it as is no other steps ......did I miss something???

Now what I see on my LCD is the Rich Rap 3Dr printer

Functionally the home button works as I expect it should I do that and all the motors move to the hall stops and tehy activate and the motors stop it is all smooth

and I can turn on the hot end and turn it off and watch it rise and hold as normal

That is where normal stops

if I try to manually move any movement motors (XYZ) at all from the LCD first of all I only see a reaction if turn the knob in one direction even the smallest change .1mm on any axis immediately begins motion on all three motors two very quickly and one very slowly and because of the arms the slow moving axis motor causes the extruder plate to slam repeatedly into that axis' extruded beams as it tries to keep moving in the same way. this continues until I hit emergency stop. Turning the knob in the other direction reads on the display but nothing moves.

If I do not Home it first and manually moves the arms to different heights and then try and move them via the controller they do move in distances associated with what I am doing but only in the same single direction .1mm gives the smallest movement 1mm the next and 10mm the most I can not verify if it is exact or not yet.

Now the weirder part if I go into repetier and try the movements everything seems to work just fine movement wise and the hotend heating and maintaining

Not sure maybe I am missing something in the git hub process and if so please let me know and if someone has a repetier setup that would be helpful as well

|

Re: RepRap 3DR Delta printer Released November 11, 2013 02:02PM |

Registered: 10 years ago Posts: 5 |

Hi fellows,

The work of Rich is amazing!

I begin my printer to (of course )

)

But....here is little bit complicated to receive any parts from some of main suppliers of parts... (no names!)

So, i think that one little advice will be so helpful for me

What if, i don't use explained Hall effect end-stops with Megatronics 2.0, but i use that once: [www.pic-gmbh.com] ...

The other option that i have is to use standard mechanical end-stops.

Any advice and notes will be welcomed!

Hope that this will be helpful not just for me but for any one that use any different parts!

The work of Rich is amazing!

I begin my printer to (of course

)

)But....here is little bit complicated to receive any parts from some of main suppliers of parts... (no names!)

So, i think that one little advice will be so helpful for me

What if, i don't use explained Hall effect end-stops with Megatronics 2.0, but i use that once: [www.pic-gmbh.com] ...

The other option that i have is to use standard mechanical end-stops.

Any advice and notes will be welcomed!

Hope that this will be helpful not just for me but for any one that use any different parts!

|

Re: RepRap 3DR Delta printer Released November 11, 2013 04:23PM |

Registered: 10 years ago Posts: 515 |

Tesseract

I had the same issue. I just downloaded the Marlin latest version from Erik Zalm's Github and now all is good. It also has the M666 command in it to allow endstop offsets. You can use these to set the endstop values in firmware/eeprom to save messing around with the fiddly trimpots on the hall boards.

Make sure you get the Delta configuration.h files from the example configs folder.

PS Hade. Many thanks for your offer to check my firmware. It's not necessary now though.

Andy

I had the same issue. I just downloaded the Marlin latest version from Erik Zalm's Github and now all is good. It also has the M666 command in it to allow endstop offsets. You can use these to set the endstop values in firmware/eeprom to save messing around with the fiddly trimpots on the hall boards.

Make sure you get the Delta configuration.h files from the example configs folder.

PS Hade. Many thanks for your offer to check my firmware. It's not necessary now though.

Andy

|

Re: RepRap 3DR Delta printer Released November 12, 2013 03:22PM |

Registered: 11 years ago Posts: 142 |

Here is a quick update of the progress I made the last hours:

In my setup, there are 3 things which are different from Rich setup.

1. Electronic: I use Ramps 1.4

2. Morors: nema17 stepper motor 17HS4417 40mm 1.7A 40N.cm (which I thought..are not so much different from Rich motors).

3. Firmware: I am using the latest build of Marlin (Delta branche) that I modified with the settings that Rich used in his released configuration.h

Now the results:

1. The motors were loud....I mean this noise one can hear on the videos I have posted above. I have first thought I had too much current, so I have set the current at Vref 0.4 V but didn t help. After many hours I started to play with the firmware until I found it out. It was due to the acceleration settings which are too high for my setup at least. . After changing them, the noise stopped.

2. The motion didn t stop after hiting the endstop. It wasn t a wrong wiring, but a wrong connection. I have (wrongly) connected the wire to the min plug on the board and not to the max endstops plug.

What next:

I have connected the hotend and wanted to start a "dry print" to test. But after homing, when it starts printing...One axis moves down until the botom, one is in the middle and the last one stays somewhere at the top.

I don t know if the slic3r must "know" that he is slicing for a delta printer or not. I don t know how the host software should be configured to use Delta. Repetier Host is already prepared to drive delta printer, but somethings must be provided by the user...

This is my enigme to solve....

Edited 1 time(s). Last edit at 11/12/2013 03:23PM by zacbot.

video of my 3DR

In my setup, there are 3 things which are different from Rich setup.

1. Electronic: I use Ramps 1.4

2. Morors: nema17 stepper motor 17HS4417 40mm 1.7A 40N.cm (which I thought..are not so much different from Rich motors).

3. Firmware: I am using the latest build of Marlin (Delta branche) that I modified with the settings that Rich used in his released configuration.h

Now the results:

1. The motors were loud....I mean this noise one can hear on the videos I have posted above. I have first thought I had too much current, so I have set the current at Vref 0.4 V but didn t help. After many hours I started to play with the firmware until I found it out. It was due to the acceleration settings which are too high for my setup at least. . After changing them, the noise stopped.

2. The motion didn t stop after hiting the endstop. It wasn t a wrong wiring, but a wrong connection. I have (wrongly) connected the wire to the min plug on the board and not to the max endstops plug.

What next:

I have connected the hotend and wanted to start a "dry print" to test. But after homing, when it starts printing...One axis moves down until the botom, one is in the middle and the last one stays somewhere at the top.

I don t know if the slic3r must "know" that he is slicing for a delta printer or not. I don t know how the host software should be configured to use Delta. Repetier Host is already prepared to drive delta printer, but somethings must be provided by the user...

This is my enigme to solve....

Edited 1 time(s). Last edit at 11/12/2013 03:23PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 12, 2013 03:48PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 12, 2013 06:26PM |

Registered: 11 years ago Posts: 142 |

Hi Andy,

thanks a lor for the help. Right now I am too tired, I tried many things...without sucess...I know it will be a pioneer work as always

I made 2 videos for this stage:, the first shows the homing, the second shows the start of the print.

All axis are going in the right direction, but not the right position, this is the actual problem. Or they went really to the position they were told to go to, and I am not aware of it. I have no concept of delta yet....I will check this next day. Todday was enough....

It is good, I didn t mount the arms and the Hotend...otherwise...

Video: Homing [youtu.be]

Video: Printing [youtu.be]

Edited 1 time(s). Last edit at 11/12/2013 06:28PM by zacbot.

video of my 3DR

thanks a lor for the help. Right now I am too tired, I tried many things...without sucess...I know it will be a pioneer work as always

I made 2 videos for this stage:, the first shows the homing, the second shows the start of the print.

All axis are going in the right direction, but not the right position, this is the actual problem. Or they went really to the position they were told to go to, and I am not aware of it. I have no concept of delta yet....I will check this next day. Todday was enough....

It is good, I didn t mount the arms and the Hotend...otherwise...

Video: Homing [youtu.be]

Video: Printing [youtu.be]

Edited 1 time(s). Last edit at 11/12/2013 06:28PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 12, 2013 10:24PM |

Registered: 11 years ago Posts: 1 |

@CidVilas - ha! we're in the process of doing the very same thing! We have a small group of 4 folks who are going to be building 3DRs, and began making this list:

[docs.google.com]

This list is a work in progress - we still need to narrow some things down and find some cheaper buys. I wish we had found this first before we did it, but that's ok. Mostly the same as yours, we have some comments on some other locations to buy things cheaper.

Greg

[docs.google.com]

This list is a work in progress - we still need to narrow some things down and find some cheaper buys. I wish we had found this first before we did it, but that's ok. Mostly the same as yours, we have some comments on some other locations to buy things cheaper.

Greg

|

Re: RepRap 3DR Delta printer Released November 13, 2013 04:51PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 13, 2013 05:00PM |

Registered: 10 years ago Posts: 63 |

>> It randomly shows , + ' *. (- etc, single character at a time instead of the correct X or Y position i.e a number <<

Same here, but only while printing. The display apears to show the correct position when standing still (after performing some moves using the LCD UI). Haven't bothered to debug this yet...

Glad you got your 3DR working!

Mine is printing happily without major problems for quite some time now - the efforts building this thing have been well rewarded. Thanks again for this clever design, Richard!

Same here, but only while printing. The display apears to show the correct position when standing still (after performing some moves using the LCD UI). Haven't bothered to debug this yet...

Glad you got your 3DR working!

Mine is printing happily without major problems for quite some time now - the efforts building this thing have been well rewarded. Thanks again for this clever design, Richard!

|

Re: RepRap 3DR Delta printer Released November 13, 2013 05:49PM |

Registered: 10 years ago Posts: 21 |

HI Andy and HaDe,

I am still in the build I have so many different versions of firmware going around I am not sure what is what any more. Would it be possible to get either you to actually zip up your firmware folder and attach it or send it to me.

I recently tried Eriks firmware and per Andy's suggestion and replaced teh config and config_adv.h files with the ones in the delta folder and compiled and uploaded and tried it.

Afeter uploading the reprapLCD would not function and the three axis motors just started buzzing I powered down and relaoded the files from rich and the LCD came back but so did the motor issue where it home correctly but then movements don;t work right

I may have been close but maybe I did not do something right I was thinking I missed something in the git hub stuff

I even tried doing a comparison of the two main file from Eriks to Rich and found some changes and tried to breing them across in to a third revision and that worked better but not perfectly

On thing in rich firmware he has teh rumba board active which is what I have but in Eriks had #33and in the description it show the different parts it controlled like movment fan extruder 1 etc whereas the RUMBA did not have that listed and I am not sure if there were other changes I had to have in place when I change the motherboard type to rumba for example a motherboard.h that may may enable the controls for the each motherboard type or something.

Still have no movement or power on my extruder with the hot end hot nothing I switched controllers and motors and nothing works on E0.

E1 when I tried it made the motor buzz loudly so I turned everything off quickly retested the motor and it still worked on one of the movement axis so that is good.

but that is as close as I got to making an extruder work I have a cartesian printer and this will be my first delta so I am anxious to put my cartesain printing skills to work in teh delta environment and see how things change.

Thanks and I hope you can get me your firmware files so I know I have an operational set.

I am still in the build I have so many different versions of firmware going around I am not sure what is what any more. Would it be possible to get either you to actually zip up your firmware folder and attach it or send it to me.

I recently tried Eriks firmware and per Andy's suggestion and replaced teh config and config_adv.h files with the ones in the delta folder and compiled and uploaded and tried it.

Afeter uploading the reprapLCD would not function and the three axis motors just started buzzing I powered down and relaoded the files from rich and the LCD came back but so did the motor issue where it home correctly but then movements don;t work right

I may have been close but maybe I did not do something right I was thinking I missed something in the git hub stuff

I even tried doing a comparison of the two main file from Eriks to Rich and found some changes and tried to breing them across in to a third revision and that worked better but not perfectly

On thing in rich firmware he has teh rumba board active which is what I have but in Eriks had #33and in the description it show the different parts it controlled like movment fan extruder 1 etc whereas the RUMBA did not have that listed and I am not sure if there were other changes I had to have in place when I change the motherboard type to rumba for example a motherboard.h that may may enable the controls for the each motherboard type or something.

Still have no movement or power on my extruder with the hot end hot nothing I switched controllers and motors and nothing works on E0.

E1 when I tried it made the motor buzz loudly so I turned everything off quickly retested the motor and it still worked on one of the movement axis so that is good.

but that is as close as I got to making an extruder work I have a cartesian printer and this will be my first delta so I am anxious to put my cartesain printing skills to work in teh delta environment and see how things change.

Thanks and I hope you can get me your firmware files so I know I have an operational set.

|

Re: RepRap 3DR Delta printer Released November 14, 2013 03:27AM |

Registered: 10 years ago Posts: 515 |

Hi Tesseract

I've attached a copy of my Marlin firmware. Hope it helps sort your issue out. You will need to change some parameters in Config.h such as MANUAL_Z_HOME_POS, DEFAULT_AXIS_STEPS_PER_UNIT, DELTA_SMOOTH_ROD_OFFSET and your PID values (this page tells you how to do that [reprap.org])

I've used the new M666 command to set my endstop values as it's much easier than messsing about with the hall effect board trimpots.

Regards

Andy

I've attached a copy of my Marlin firmware. Hope it helps sort your issue out. You will need to change some parameters in Config.h such as MANUAL_Z_HOME_POS, DEFAULT_AXIS_STEPS_PER_UNIT, DELTA_SMOOTH_ROD_OFFSET and your PID values (this page tells you how to do that [reprap.org])

I've used the new M666 command to set my endstop values as it's much easier than messsing about with the hall effect board trimpots.

Regards

Andy

|

Re: RepRap 3DR Delta printer Released November 14, 2013 07:36AM |

Registered: 10 years ago Posts: 8 |

Thanks everyone for the advice given out so far.

Like many people here, I was having trouble with my motors continuing after reaching the endstops. I did M119 commands and it said triggered or open as expected. What I didn't do was test the enstops individually. When I did, I found that I had my x & y mixed up on the driver board. Swopping them around has fixed the problem. Hopefully this will help someone who has the same issue.

On another note, is anyone else using megatronics V2.0 with a LCD and Keypad. I was unable to get the Rumba board as they wouldn't ship to South Africa so I went for megatronics. So far, all I have managed to do is get the LCD to light up in blue but it would be nice to get some text displayed on it. If anyone has a working configuration please can they let me know.

Thanks

Roger

Like many people here, I was having trouble with my motors continuing after reaching the endstops. I did M119 commands and it said triggered or open as expected. What I didn't do was test the enstops individually. When I did, I found that I had my x & y mixed up on the driver board. Swopping them around has fixed the problem. Hopefully this will help someone who has the same issue.

On another note, is anyone else using megatronics V2.0 with a LCD and Keypad. I was unable to get the Rumba board as they wouldn't ship to South Africa so I went for megatronics. So far, all I have managed to do is get the LCD to light up in blue but it would be nice to get some text displayed on it. If anyone has a working configuration please can they let me know.

Thanks

Roger

|

Re: RepRap 3DR Delta printer Released November 14, 2013 11:44AM |

Registered: 10 years ago Posts: 21 |

Thank you Andy very much My 3dr is much further along now. autohome works fine from the LCD as do the movements of X Y and Z up and down and the same from Repetier. The one thing I did notice and not sure what this means but when I power on the unit and connect in Repetier I showthe normal extruder 1 what it currently is and what it is set to and normally I would see the bed settings right after this but in this case I see the extruder 1 then I see another extruder with a crzy number like 1612453734 and it shows the exact same readings as extruder 1 then I see the bed settings. If i press the reset button on the LCD everything resets and when it comes back I have 2 mysterious extruders and I get one a new one each time I reset.

I noticed because I was trying to run the PID autotune sequence from the reprap page and it seems to error out say the extruder got to hot it was in the 200-210 range when this error occurred. I have done no research on this whatsoever yet as this just happened about 10 mins ago but I though I would drop you a note and see if it rang any bells with you in the first place.

Thank you so much for the files not sure what I was doing wrong but it was obviously something

Jeff

I noticed because I was trying to run the PID autotune sequence from the reprap page and it seems to error out say the extruder got to hot it was in the 200-210 range when this error occurred. I have done no research on this whatsoever yet as this just happened about 10 mins ago but I though I would drop you a note and see if it rang any bells with you in the first place.

Thank you so much for the files not sure what I was doing wrong but it was obviously something

Jeff

|

Re: RepRap 3DR Delta printer Released November 14, 2013 02:27PM |

Registered: 11 years ago Posts: 142 |

Here is a quick update of the progress I made the last hours:

1. Repetier Host configuration: Printer Typ: Rostock / Home X=0 / Home Y=0 / Home Z=max / Radius=80 / High: 187.5

2. Motors noise 1 (clicking): I tuned the motors again, 0.4 V was still not ok for my motors, best for my motors is at 0.34 V

3. Motors noise 2 (police sirene): This was due to the Filament Drive Spool hiting the extrusion and blocking motor movement which resulted in motor stall. Even after using M3 nuts, it was still hitting the extrusion and I didn t see it.

4. Firmware: Why the printer moved 50 mm and not 10 mm when requested is due to this setting (I still need to calculate the correct sitting for the Filament Drive Spool I have printed):

Rich original firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 120} // Regardless of calculations 120 is a good figure here for main at x4 and injector at x16

But with the above setting, the printer did about 50 mm instead of 10 mm

My actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {5, 5, 5, 120} // Regardless of calculations 120 is a good figure here for main at x4 and injector at x16

And now I could make the first dry print....By the way, I know now that the translating of the gcode to delta geometry is done on the fly by the firmware.

Andy s actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {110.69, 110.69,110.69, 1200.261} // default steps per unit for Kossel (GT2, 20 tooth)

Repetier firmware

#define PULLEY_DIAMETER 10 <-- this is a default setting in repetier firmware

#define PULLEY_CIRCUMFERENCE (PULLEY_DIAMETER * 3.1415927)

// Calculations

#define AXIS_STEPS_PER_MM ((float)(MICRO_STEPS * STEPS_PER_ROTATION) / PULLEY_CIRCUMFERENCE)

So, if I calculate like repetier firmware for our spool which (should) have a:

Spool Length: 17 mm

Spool Diameter: 18 mm

Overall Length: 25.5 mm

Fits 5 mm drive shaft

AXIS_STEPS_PER_MM=(16 * 200) / (18*3.1415927) = 56.58

So Rich and Repetier calculation are the same...But how to explain Andy s and my setting ?

video of my 3DR

1. Repetier Host configuration: Printer Typ: Rostock / Home X=0 / Home Y=0 / Home Z=max / Radius=80 / High: 187.5

2. Motors noise 1 (clicking): I tuned the motors again, 0.4 V was still not ok for my motors, best for my motors is at 0.34 V

3. Motors noise 2 (police sirene): This was due to the Filament Drive Spool hiting the extrusion and blocking motor movement which resulted in motor stall. Even after using M3 nuts, it was still hitting the extrusion and I didn t see it.

4. Firmware: Why the printer moved 50 mm and not 10 mm when requested is due to this setting (I still need to calculate the correct sitting for the Filament Drive Spool I have printed):

Rich original firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 120} // Regardless of calculations 120 is a good figure here for main at x4 and injector at x16

But with the above setting, the printer did about 50 mm instead of 10 mm

My actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {5, 5, 5, 120} // Regardless of calculations 120 is a good figure here for main at x4 and injector at x16

And now I could make the first dry print....By the way, I know now that the translating of the gcode to delta geometry is done on the fly by the firmware.

Andy s actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {110.69, 110.69,110.69, 1200.261} // default steps per unit for Kossel (GT2, 20 tooth)

Repetier firmware

#define PULLEY_DIAMETER 10 <-- this is a default setting in repetier firmware

#define PULLEY_CIRCUMFERENCE (PULLEY_DIAMETER * 3.1415927)

// Calculations

#define AXIS_STEPS_PER_MM ((float)(MICRO_STEPS * STEPS_PER_ROTATION) / PULLEY_CIRCUMFERENCE)

So, if I calculate like repetier firmware for our spool which (should) have a:

Spool Length: 17 mm

Spool Diameter: 18 mm

Overall Length: 25.5 mm

Fits 5 mm drive shaft

AXIS_STEPS_PER_MM=(16 * 200) / (18*3.1415927) = 56.58

So Rich and Repetier calculation are the same...But how to explain Andy s and my setting ?

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 14, 2013 02:56PM |

Registered: 10 years ago Posts: 5 |

|

Re: RepRap 3DR Delta printer Released November 14, 2013 03:27PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 14, 2013 03:46PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 14, 2013 03:47PM |

Registered: 11 years ago Posts: 142 |

I have tried to calclate myself, and explain the difference:

Andy s actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {110.69, 110.69,110.69, 1200.261} // default steps per unit for Kossel (GT2, 20 tooth)

--> (16 * X Steps per rotation) / (18*3.14) = (16 * X) /56,54 = 110.69 --> X = 110.69*56,54/16 = 391

hmm this is near 400 Steps per rotation which mean Andy has a 0.9 degree motor and and not 1.8 like mine and would explain the setting

My actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {5, 5, 5, 120}

--> (X * 200) / (18*3.14) = (X * 200) /56,54 = 5 --> X = 5*56,54/200 = 1.41

Ok this mean thay I am not microstepping, and would explain the value, but why ?

video of my 3DR

Andy s actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {110.69, 110.69,110.69, 1200.261} // default steps per unit for Kossel (GT2, 20 tooth)

--> (16 * X Steps per rotation) / (18*3.14) = (16 * X) /56,54 = 110.69 --> X = 110.69*56,54/16 = 391

hmm this is near 400 Steps per rotation which mean Andy has a 0.9 degree motor and and not 1.8 like mine and would explain the setting

My actual firmware setting

#define DEFAULT_AXIS_STEPS_PER_UNIT {5, 5, 5, 120}

--> (X * 200) / (18*3.14) = (X * 200) /56,54 = 5 --> X = 5*56,54/200 = 1.41

Ok this mean thay I am not microstepping, and would explain the value, but why ?

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 14, 2013 03:52PM |

Registered: 11 years ago Posts: 142 |

Hi Andy,

thanks for the info...I was calculating as you posted. So you have 32 microsteping, this is also another combination. I think Rich config is at 16.

Now all is clear, I must find out why is mine not microstepping.

video of my 3DR

thanks for the info...I was calculating as you posted. So you have 32 microsteping, this is also another combination. I think Rich config is at 16.

Now all is clear, I must find out why is mine not microstepping.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 14, 2013 05:49PM |

Registered: 11 years ago Posts: 142 |

Ok, I found the mother of all problems I had until now.

I bought a complete Ramps 1.4 board Kit from a new manufacturer. They didn t jumpered the board for 16 stepping. They also didn t deliver the needed jumpers, 15 pieces are needed to activate the highest micro stepping mode, which is 16 on this board. They also didn t inform the customer (me) that the board is not jumpered for microsteping and that I have to buy the needed jumpers. The board is sold explicitly for 3D Printers but not configured for the best what this board can give.

So I took a spare Ramps 1.4 kit from Reprapdiscount and looked at it, and was very upset to see the default 1/16 micro stepping hardware configuration (all jumpers installed under drivers), which is conform to [reprap.org]

So after connecting all jumpers on the new board, took measure of the diameter of my printed spool, which is 17,7 mm, replaced in the forumula the diameter and came out with:

#define DEFAULT_AXIS_STEPS_PER_UNIT {57.54, 57.54, 57.54, 120} // Formula 3200÷(17.7*3.1415927) default steps per unit for zacbot 3DR

uploaded the new firmware...All problems has disapered and it s working with All firmware variation I have saved in this process!

Now I have learned that microstepping must be configured on the board and on the firmware. And they must be the same. And that the RUMBA board has 32 microstepping but Rich is running 16 on his published 3DR firmware, I think to avoid compatibility issues with other boards that do not support this high microstepping mode. For example Ramps is limited to 1/16. So be aware of this when using Andy s firmware branch and your board does not support 1/32 microstepping.

video of my 3DR

I bought a complete Ramps 1.4 board Kit from a new manufacturer. They didn t jumpered the board for 16 stepping. They also didn t deliver the needed jumpers, 15 pieces are needed to activate the highest micro stepping mode, which is 16 on this board. They also didn t inform the customer (me) that the board is not jumpered for microsteping and that I have to buy the needed jumpers. The board is sold explicitly for 3D Printers but not configured for the best what this board can give.

So I took a spare Ramps 1.4 kit from Reprapdiscount and looked at it, and was very upset to see the default 1/16 micro stepping hardware configuration (all jumpers installed under drivers), which is conform to [reprap.org]

So after connecting all jumpers on the new board, took measure of the diameter of my printed spool, which is 17,7 mm, replaced in the forumula the diameter and came out with:

#define DEFAULT_AXIS_STEPS_PER_UNIT {57.54, 57.54, 57.54, 120} // Formula 3200÷(17.7*3.1415927) default steps per unit for zacbot 3DR

uploaded the new firmware...All problems has disapered and it s working with All firmware variation I have saved in this process!

Now I have learned that microstepping must be configured on the board and on the firmware. And they must be the same. And that the RUMBA board has 32 microstepping but Rich is running 16 on his published 3DR firmware, I think to avoid compatibility issues with other boards that do not support this high microstepping mode. For example Ramps is limited to 1/16. So be aware of this when using Andy s firmware branch and your board does not support 1/32 microstepping.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 14, 2013 06:39PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 14, 2013 06:56PM |

Registered: 11 years ago Posts: 142 |

Ah Ok. but they delivered them together, why are the jumper missing ?

Edited 1 time(s). Last edit at 11/14/2013 06:58PM by zacbot.

video of my 3DR

Edited 1 time(s). Last edit at 11/14/2013 06:58PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 15, 2013 10:22AM |

Registered: 11 years ago Posts: 142 |

Hi Andy,

In Marlin advanced config file you are using, there is

// MS1 MS2 Stepper Driver Microstepping mode table

#define MICROSTEP1 LOW,LOW

#define MICROSTEP2 HIGH,LOW

#define MICROSTEP4 LOW,HIGH

#define MICROSTEP8 HIGH,HIGH

#define MICROSTEP16 HIGH,HIGH

// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.

#define MICROSTEP_MODES {16,16,16,16,16} // [1,2,4,8,16]

What does the above mean for the firmware?

video of my 3DR

In Marlin advanced config file you are using, there is

// MS1 MS2 Stepper Driver Microstepping mode table

#define MICROSTEP1 LOW,LOW

#define MICROSTEP2 HIGH,LOW

#define MICROSTEP4 LOW,HIGH

#define MICROSTEP8 HIGH,HIGH

#define MICROSTEP16 HIGH,HIGH

// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.

#define MICROSTEP_MODES {16,16,16,16,16} // [1,2,4,8,16]

What does the above mean for the firmware?

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 15, 2013 01:01PM |

Registered: 10 years ago Posts: 515 |

|

Re: RepRap 3DR Delta printer Released November 15, 2013 07:57PM |

Registered: 10 years ago Posts: 56 |

Hi Andy,

Could you please explain how you set the hall effect endstops offset with that M666 command? Should it be placed in Marlin firmware configuration.h?... I have just finished my 3DR but, of course, I have the bed unleveled...

After that I guess I'll have to tweak the DELTA_RADIUS in case the bed is not flat but I'm stucked with that "towers fine leveling", doesn't it?

Thanks

Could you please explain how you set the hall effect endstops offset with that M666 command? Should it be placed in Marlin firmware configuration.h?... I have just finished my 3DR but, of course, I have the bed unleveled...

After that I guess I'll have to tweak the DELTA_RADIUS in case the bed is not flat but I'm stucked with that "towers fine leveling", doesn't it?

Thanks

|

Re: RepRap 3DR Delta printer Released November 15, 2013 08:21PM |

Registered: 10 years ago Posts: 21 |

Hey Andy any idea why I keep getting new extruders popping up each time I rest thing i get the regular one and then first pass I get another one as well this is labeled 35434563234 186.7/200.0 and its current temp value is changing just like Extruder is if I reset those two show back up and I get a third and so on and so on

|

Re: RepRap 3DR Delta printer Released November 15, 2013 08:58PM |

Registered: 11 years ago Posts: 142 |

Thanks Andy. Now many things are clear....

My board Ramps 1.4 does also not support microstepping control over firmware. If it did, I wouldn t have all this problems with a jumperless "new" board on ebay.

Now I will attach the extruder and move further to the next stage.

Thanks again.

Edited 1 time(s). Last edit at 11/15/2013 08:59PM by zacbot.

video of my 3DR

My board Ramps 1.4 does also not support microstepping control over firmware. If it did, I wouldn t have all this problems with a jumperless "new" board on ebay.

Now I will attach the extruder and move further to the next stage.

Thanks again.

Edited 1 time(s). Last edit at 11/15/2013 08:59PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released November 16, 2013 12:41PM |

Registered: 10 years ago Posts: 515 |

Hi Guys

I have no clue about the 'ghost extruded' issue. Maybe someone more knowledgeable than I could chip in and help. The M666 question is much easier to answer. Just type M666 X-5.0 Y-5.0 Z-5.0 (the numbers are irrelevant at this point you would use the values you require) this, assuming you have the Marlin version that supports it, will place your carriages 5mm below the position set by the end stops after homing. M500 saves the values to EEPROM, make sure you use it before you switch the printer off. It's really easy to set your carriages with this command. The process I used was :/

Set steps per mm to give accurate Z travel

Set front left X carriage Z height by placing the hot end right next to the tower extrusion I.e delta rods parallel to the extrusion in all planes. Keep homing and moving back to this position (I wrote a script in Repetier Host) and adjusting the X value with M666 until it's correct.

Do same for rear, Z, tower

Do same for front right, Y, tower

At this point hot end should be about 0.1 mm above the bed at the foot of each tower.

Move the hot end to 0,0 check the height unless you are very lucky it will be too high or too low. If it's too high decrease the delta smooth rod offset by 0.5 mm and check again. Raise the value if the hot end is too low. The 0,0 position won't alter but the three tower base heights will. Keep adjusting until the height at the base of each tower and the height at 0,0 are all equal.

Now set your Z height in firmware to bring the hot end 0.1 above the bed.

Print out a calibration piece with a 100mm dimension. Measure the print and then adjust the delta rod length with this formula :-

(Length of calibration piece/100) x current delta rod length. This will give you the correct value for delta rod length. Print the calibration piece again, measure and repeat the process if necessary.

At this point your printer is running and you can go play with the other five million settings in firmware and Repetier or Pronterface :-)

Andy

I have no clue about the 'ghost extruded' issue. Maybe someone more knowledgeable than I could chip in and help. The M666 question is much easier to answer. Just type M666 X-5.0 Y-5.0 Z-5.0 (the numbers are irrelevant at this point you would use the values you require) this, assuming you have the Marlin version that supports it, will place your carriages 5mm below the position set by the end stops after homing. M500 saves the values to EEPROM, make sure you use it before you switch the printer off. It's really easy to set your carriages with this command. The process I used was :/

Set steps per mm to give accurate Z travel

Set front left X carriage Z height by placing the hot end right next to the tower extrusion I.e delta rods parallel to the extrusion in all planes. Keep homing and moving back to this position (I wrote a script in Repetier Host) and adjusting the X value with M666 until it's correct.

Do same for rear, Z, tower

Do same for front right, Y, tower

At this point hot end should be about 0.1 mm above the bed at the foot of each tower.

Move the hot end to 0,0 check the height unless you are very lucky it will be too high or too low. If it's too high decrease the delta smooth rod offset by 0.5 mm and check again. Raise the value if the hot end is too low. The 0,0 position won't alter but the three tower base heights will. Keep adjusting until the height at the base of each tower and the height at 0,0 are all equal.

Now set your Z height in firmware to bring the hot end 0.1 above the bed.

Print out a calibration piece with a 100mm dimension. Measure the print and then adjust the delta rod length with this formula :-

(Length of calibration piece/100) x current delta rod length. This will give you the correct value for delta rod length. Print the calibration piece again, measure and repeat the process if necessary.

At this point your printer is running and you can go play with the other five million settings in firmware and Repetier or Pronterface :-)

Andy

|

Re: RepRap 3DR Delta printer Released November 16, 2013 03:02PM |

Registered: 10 years ago Posts: 21 |

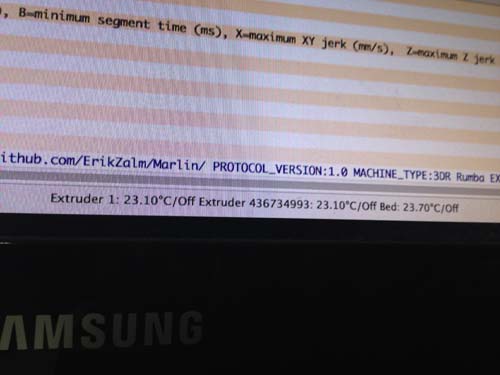

Hey guys

This is just to show you want I see each time I hit the reset button on my LCD

Never knew it was so easy to add extruders

Never knew it was so easy to add extruders

I just thought of something is there something in the firmware code that is expecting a certain type of extruder I am using the E3D and I have seen lines referring to the PRUSA J type could this be an issue of some type functionally they should be the same and there is no intelligence to them but it was something that popped in my head.

Edited 1 time(s). Last edit at 11/16/2013 03:35PM by tesseract.

This is just to show you want I see each time I hit the reset button on my LCD

Never knew it was so easy to add extruders

Never knew it was so easy to add extruders

I just thought of something is there something in the firmware code that is expecting a certain type of extruder I am using the E3D and I have seen lines referring to the PRUSA J type could this be an issue of some type functionally they should be the same and there is no intelligence to them but it was something that popped in my head.

Edited 1 time(s). Last edit at 11/16/2013 03:35PM by tesseract.

|

Re: RepRap 3DR Delta printer Released November 16, 2013 06:36PM |

Registered: 10 years ago Posts: 56 |

Hi Andy,

Thank you very much for your brief instructions, they are helping, anyway I'm not understanding correctly some points, if you don't mind, please, could you make it more clear the following steps?:

As a side note, I have seen my hall effect sensors have a little trim pot... hehehe, anyway I prefer the new M666 process (if I'm finally able to figure out the whole process)

Thank you very much for your brief instructions, they are helping, anyway I'm not understanding correctly some points, if you don't mind, please, could you make it more clear the following steps?:

- "Set front left X carriage Z height by placing the hot end right next to the tower extrusion I.e delta rods parallel to the extrusion in all planes. Keep homing and moving back to this position (I wrote a script in Repetier Host) and adjusting the X value with M666 until it's correct", I can't figure out the process step by step... could you also share the gcode you are using so that we can use it to better understand the process?

- I understand the corrections to DELTA_SMOOTH_ROD_OFFSET but I don't know what do you mean with "check again", do you mean to repeat the tower calibrations or just to place the hotend in X0 Y0 Z0? Also, this could be done in Repetier Host or should I modify it in firmware?

As a side note, I have seen my hall effect sensors have a little trim pot... hehehe, anyway I prefer the new M666 process (if I'm finally able to figure out the whole process)

Sorry, only registered users may post in this forum.