RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released December 05, 2013 06:27PM |

Registered: 10 years ago Posts: 21 |

HI Andy your firmware has gotten me the closest I believe the movements all work from the LCD but the I can't get past the last command when I connect via the computer my status bar show

1 command waiting WAITING FOR TEMPERATURE

if I could get past this point then I may be able to throw in the M302 command as you stated but I can't add the command via the LCD this would at least get me to the next step

I believe other firmwares get me passed this point the one I tried before yours but that gave me teh mysterious extruders a it kept adding one, each with along number, each time I reset

My next plan is to do a compare of some different firmware version and see what is different maybe I can find the common thread

Edited 1 time(s). Last edit at 12/05/2013 06:28PM by tesseract.

1 command waiting WAITING FOR TEMPERATURE

if I could get past this point then I may be able to throw in the M302 command as you stated but I can't add the command via the LCD this would at least get me to the next step

I believe other firmwares get me passed this point the one I tried before yours but that gave me teh mysterious extruders a it kept adding one, each with along number, each time I reset

My next plan is to do a compare of some different firmware version and see what is different maybe I can find the common thread

Edited 1 time(s). Last edit at 12/05/2013 06:28PM by tesseract.

|

Re: RepRap 3DR Delta printer Released December 06, 2013 03:38AM |

Registered: 10 years ago Posts: 6 |

tesseract ,

I just got my arms moving properly.

Not been bothering about the extruder yet, becauce my hotend is not in yet.

But in your firmware is a prevent dangerous extrusion temperture ( 160 deg ) maybe you are below this point

My 3DR project : [printedtools.nl]

I just got my arms moving properly.

Not been bothering about the extruder yet, becauce my hotend is not in yet.

But in your firmware is a prevent dangerous extrusion temperture ( 160 deg ) maybe you are below this point

My 3DR project : [printedtools.nl]

|

Re: RepRap 3DR Delta printer Released December 06, 2013 03:47AM |

Registered: 10 years ago Posts: 21 |

|

Re: RepRap 3DR Delta printer Released December 06, 2013 04:46AM |

Registered: 13 years ago Posts: 818 |

Quote

HeAdWaVe

Thanks Richard. im diving in tonight!!

And thanks for sharing my Ramps design!

Edit, Richard, the link in your article to the Ramps adapterplate is not working! ( [www.thingiverse.com] )

Thanks for spotting that - I have fixed it.

Hope it's all going well.

[richrap.blogspot.com]

|

Re: RepRap 3DR Delta printer Released December 06, 2013 03:32PM |

Registered: 10 years ago Posts: 5 |

Quote

Tomek

Did the guy who made the 3DR "extensions" for a bigger build platform release his files? I was having trouble finding them.

I'm the guy who made 3DR "extensions" but got my MacBook Pro stollen before I did a backup or published them

I haven't yet had the time to re-do it ...

Edited 1 time(s). Last edit at 12/06/2013 03:35PM by cybug.

|

Re: RepRap 3DR Delta printer Released December 08, 2013 01:20PM |

Registered: 10 years ago Posts: 12 |

Hi all,

I am in the process of gathering all of the parts to make a 3DR and I read Rich's blog about using Traxxas parts for the carriage arms.

My local model shop (Penn Models, West Midlands) has a great selection to choose from and the guys in there just let me have a look at everything and measure up for what might be suitable.

I think that the following parts and numbers might be useful for others, so I thought I would post.

Traxxas parts:

#5348 - Rod ends, Revo (Large for rear toe link only) (4 in the pack) -- £1.55 --- 3 packs purchased.

#5529 - Shim set, 3x7x1 (2), 3x6x0.5mm (4), 3x7x2mm (2) / Hollow balls, captured (4) -- £3.29 --- 3 packs purchased.

#5338 - Toe link, 6.0mm Steel, (Front or rear) (2) -- £7.75 --- 3 packs purchased.

This gives a grand total of £37.77 for the complete set. I think you'll all agree that it's not cheap!

However, if you try, I'm sure that you will find these items on ebay or wherever possibly a little cheaper.

What makes it a nice option is that there is no glueing to do and they are adjustable by a nut half way along the shaft - with the rod ends attached, the overall length can still be changed as they have left and right handed threads - turn clockwise, they get shorter and anti-clockwise to make them longer.

You can get around 155mm between rod end centres, so should be fine for the 3DR.

Hope this helps,

Ian

I am in the process of gathering all of the parts to make a 3DR and I read Rich's blog about using Traxxas parts for the carriage arms.

My local model shop (Penn Models, West Midlands) has a great selection to choose from and the guys in there just let me have a look at everything and measure up for what might be suitable.

I think that the following parts and numbers might be useful for others, so I thought I would post.

Traxxas parts:

#5348 - Rod ends, Revo (Large for rear toe link only) (4 in the pack) -- £1.55 --- 3 packs purchased.

#5529 - Shim set, 3x7x1 (2), 3x6x0.5mm (4), 3x7x2mm (2) / Hollow balls, captured (4) -- £3.29 --- 3 packs purchased.

#5338 - Toe link, 6.0mm Steel, (Front or rear) (2) -- £7.75 --- 3 packs purchased.

This gives a grand total of £37.77 for the complete set. I think you'll all agree that it's not cheap!

However, if you try, I'm sure that you will find these items on ebay or wherever possibly a little cheaper.

What makes it a nice option is that there is no glueing to do and they are adjustable by a nut half way along the shaft - with the rod ends attached, the overall length can still be changed as they have left and right handed threads - turn clockwise, they get shorter and anti-clockwise to make them longer.

You can get around 155mm between rod end centres, so should be fine for the 3DR.

Hope this helps,

Ian

|

Re: RepRap 3DR Delta printer Released December 09, 2013 01:52AM |

Registered: 12 years ago Posts: 138 |

This is my first delta. I've got motors working. Can someone walk me through the correct settings for Repetier Host. (I'm on Ramps 1.4 if that makes a difference).Z- axis moves slowly.

In Repetier, I changed the printer to ROSTOCK DELTA.

I'm trying to test endstops etc.

In Manual, X+ does go upwards.

Y+ goes down???

Z+ Goes up.

In Printer settings, I have HOME for each set to MAX (is this correct)?

OOnly the Y motor when I execute Y home goes up. The X ad Z go down.

1) How can I get my motors go up for HOME?

2) Why does Y+ go down? ( I have all the motor wires in correct orientation)

Thanks for your advice.

Almost there.

More observations:

The Z motor moves much slower than the other two in manual stepping.

The Y motor sounds very smooth, quiet and fast. The X motor is a bit more grumbly. Haven't had a chance to tune the a4988s.

The Y motor which goes opposite the manual direction, will go home and the end stop works.

In Repetier, I changed the printer to ROSTOCK DELTA.

I'm trying to test endstops etc.

In Manual, X+ does go upwards.

Y+ goes down???

Z+ Goes up.

In Printer settings, I have HOME for each set to MAX (is this correct)?

OOnly the Y motor when I execute Y home goes up. The X ad Z go down.

1) How can I get my motors go up for HOME?

2) Why does Y+ go down? ( I have all the motor wires in correct orientation)

Thanks for your advice.

Almost there.

More observations:

The Z motor moves much slower than the other two in manual stepping.

The Y motor sounds very smooth, quiet and fast. The X motor is a bit more grumbly. Haven't had a chance to tune the a4988s.

The Y motor which goes opposite the manual direction, will go home and the end stop works.

|

Re: RepRap 3DR Delta printer Released December 09, 2013 03:51AM |

Registered: 10 years ago Posts: 3 |

Hi all, I've just come across the 3DR on Richard's blogspot and I'm keen to build one. I don't have a 3D printer of my own though and with the sheer volume of parts I might not be able to print them on the student-run printers at uni (half the time they are down for repairs anyway). I'm all the way over in Ausralia, but can any of you folks point me towards where I might be able to print these parts? If worst comes to worst I could use a commercial service (shapeways?) but that could be quite expensive.

|

Re: RepRap 3DR Delta printer Released December 09, 2013 06:19AM |

Registered: 10 years ago Posts: 1,381 |

reprapPIF

The purpose of this sub-reddit is to help people find other people with a RepRap to get the parts,

and in turn they "Print-It-Forward" and print off a set of parts and send them off to someone else.

Here we also want to be as altruistic as possible, so if you happen to have a spare 3D printer lying around...you know what to do!

[www.reddit.com]

reprapclassifieds

Private sales, no vendors. Anyone doing this will get banned.

Delete post when item has sold

Put your state/region in the title.

Base it off your willingness to ship.

If you live in New York City, put NYC Metro Area.

If shipping is practical and you are willing to ship nation wide, put USA.

Put worldwide if there are no restrictions on where you'll ship.

[www.reddit.com]

3Dprintmything

Charge MAX €10 per print (excluding shipping)! This is a community, not a freelance business.

Have a printer and want to help people out? Prepend your post title with [HAVE:COUNTRY],

replace COUNTRY with your location and put your pricetag (if any), location/any shipping details and details about printer in the post.

Also proof of quality is highly recommended (pictures of example prints).

Want/need something printed? Prepend your post title with [WANT:COUNTRY], and have a model ready.

More rules to come, does something look sketchy or just plain wrong? PM Mods or create a post and we'll discuss it!

[www.reddit.com]

Edited 1 time(s). Last edit at 12/09/2013 06:19AM by A2.

|

Re: RepRap 3DR Delta printer Released December 10, 2013 02:46AM |

Registered: 10 years ago Posts: 21 |

Anyone understand why I get this when I connect to the 3dr

when using repetier

1 command waiting WAITING FOR TEMPERATURE

I am connected

I am communicating

commands prior to are successfully completed

LCD functions and I can see and set and adjust temp via the LCD but not in repetier

So how come the ramps card see the signal and give it to the LCD but repetier can't seem to get it

Edited 1 time(s). Last edit at 12/10/2013 02:46AM by tesseract.

when using repetier

1 command waiting WAITING FOR TEMPERATURE

I am connected

I am communicating

commands prior to are successfully completed

LCD functions and I can see and set and adjust temp via the LCD but not in repetier

So how come the ramps card see the signal and give it to the LCD but repetier can't seem to get it

Edited 1 time(s). Last edit at 12/10/2013 02:46AM by tesseract.

|

Re: RepRap 3DR Delta printer Released December 11, 2013 07:05AM |

Registered: 12 years ago Posts: 803 |

|

Re: RepRap 3DR Delta printer Released December 13, 2013 10:12AM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released December 21, 2013 02:13AM |

Registered: 12 years ago Posts: 138 |

Having some trouble. This is my first ever build. I'm trying to set up the Marlins firmware to control the Gregg's Wade's extruder Rich has in the original design. The one with the Harringbone gears. I even am using the same exact Wantai 42BYGHW811 nema 17 motors. I do have a a4988 driver though. I tuned all my drivers to 0.45v

2 problems.

I was trying to calibrate the filament travel, My calculations gave me:

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 613}

In testing 613 gave me 100mm.

Then I have the speed in Repetier Host low I think - Speed (mm/min) 100. And I'm getting some hammering sounds from the motor? Here is a video. There are more at the end.

[www.youtube.com]

What is the proper Marlin setting for this extruder?

The Wantai motor is listed 2.5A. Can I increase the 0.45v on that driver? Will that give it more power?

I really want to get printing. I have been working on this 3 months now and am very close I think.

---------------------------------------------------

Also,

for

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 613}

How do I calibrate the XYZ numbers? So far I'm just guessing, but I want my prints to be as close to accurate as possible.

Thanks

Alex

2 problems.

I was trying to calibrate the filament travel, My calculations gave me:

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 613}

In testing 613 gave me 100mm.

Then I have the speed in Repetier Host low I think - Speed (mm/min) 100. And I'm getting some hammering sounds from the motor? Here is a video. There are more at the end.

[www.youtube.com]

What is the proper Marlin setting for this extruder?

The Wantai motor is listed 2.5A. Can I increase the 0.45v on that driver? Will that give it more power?

I really want to get printing. I have been working on this 3 months now and am very close I think.

---------------------------------------------------

Also,

for

#define DEFAULT_AXIS_STEPS_PER_UNIT {55.5, 55.5, 55.5, 613}

How do I calibrate the XYZ numbers? So far I'm just guessing, but I want my prints to be as close to accurate as possible.

Thanks

Alex

|

Re: RepRap 3DR Delta printer Released December 21, 2013 11:52AM |

Registered: 12 years ago Posts: 972 |

Hi Alex,

It is unclear to me whether your gears have a point where more force is needed and motor skips or if the driver is overheating and thermal shutdown is kicking in. You can rule out the latter by checking the chip temperature on your pololu.

While a 2.5A motor can happily handle that current, our common electronics (A4988-based pololus) cannot deliver much more than 1A without additional cooling. While it may seem the more current the better, this is only true while you keep your driver away from thermal shutdown.

I haven't reached calibration yet, but I'd guess that you can use Z moves (that should move the three motors at once) and verifying if the travel in height matches your command. RIght?

Edited 1 time(s). Last edit at 12/21/2013 02:21PM by misan.

It is unclear to me whether your gears have a point where more force is needed and motor skips or if the driver is overheating and thermal shutdown is kicking in. You can rule out the latter by checking the chip temperature on your pololu.

While a 2.5A motor can happily handle that current, our common electronics (A4988-based pololus) cannot deliver much more than 1A without additional cooling. While it may seem the more current the better, this is only true while you keep your driver away from thermal shutdown.

I haven't reached calibration yet, but I'd guess that you can use Z moves (that should move the three motors at once) and verifying if the travel in height matches your command. RIght?

Edited 1 time(s). Last edit at 12/21/2013 02:21PM by misan.

|

Re: RepRap 3DR Delta printer Released December 21, 2013 03:49PM |

Registered: 12 years ago Posts: 138 |

|

Re: RepRap 3DR Delta printer Released December 21, 2013 06:12PM |

Registered: 10 years ago Posts: 515 |

Hi Disneytoy

Steps per mm for x,y and z just sets your z travel. Get that dialled in correctly first. Then create 4 scripts to move your hot end to the base of tower 1,2,3 and 0,0 (centre of print bed). Towers are designated x, front left, y front right, z rear. 1, 2 and 3 respectively. Now send the script for base of tower 1 and adjust your z height with either the hall board pot, microswitch (whichever you are using) or in firmware with M666. Once you have T1 dialled in do the same for T2 and 3. Send the hot end to 0,0 it should be the same z height as the base of the 3 towers. If not adjust one of the delta radius components, usually smooth rod offset, until all 4 positions are at the same height. Once all that is done print a calibration object and measure it. The x and y size is altered by changing the delta diagonal rod value. Read through Rich's latest blog it's all explained there much better than I can do it. Good luck

Andy

Steps per mm for x,y and z just sets your z travel. Get that dialled in correctly first. Then create 4 scripts to move your hot end to the base of tower 1,2,3 and 0,0 (centre of print bed). Towers are designated x, front left, y front right, z rear. 1, 2 and 3 respectively. Now send the script for base of tower 1 and adjust your z height with either the hall board pot, microswitch (whichever you are using) or in firmware with M666. Once you have T1 dialled in do the same for T2 and 3. Send the hot end to 0,0 it should be the same z height as the base of the 3 towers. If not adjust one of the delta radius components, usually smooth rod offset, until all 4 positions are at the same height. Once all that is done print a calibration object and measure it. The x and y size is altered by changing the delta diagonal rod value. Read through Rich's latest blog it's all explained there much better than I can do it. Good luck

Andy

|

Re: RepRap 3DR Delta printer Released January 10, 2014 12:54AM |

Registered: 10 years ago Posts: 9 |

Hello All,

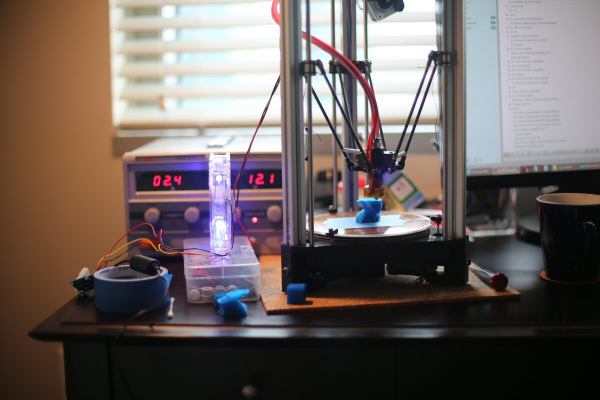

I've been gathering the parts for my 3DR build for the past few weeks. This is my first foray into 3D Printing so I needed a set of printed parts to get me started. A big thanks to Mitch over at BusyBotz 3D Printing for printing me a set for a small fee - apparently there were some headaches with printing the large flat parts in ABS but Mitch pulled through and delivered a beautiful set of parts. Just take a look at this extruder gear that Mitch churned out and you'll see the quality of his work.

The printed parts required minimal post processing, just some light deburring to get rid of the platform lip and to make the faces fit flush. For the rods, I went with Traxxas TRA1942 Ball Ends and CF Tube, 150mm center to center. I cut some threaded rod to use as a stud and cemented it in place with aerospace grade Hysol Epoxy.

I also encountered a problem with clearance of the rod ends and the mounts, which required me to add a 3mm cone washer (google "ofna 3mm cone washer") which is perfect for the application. You can see the washer as the blue anodized cone at the end of the ball.

Other vitamins include a J-Head Mk-V with 0.3mm Nozzle, a Trinity Labs 170mm Borosilicate Glass Plate + 160mm Kapton Heater, Lin Engineering 4218L Steppers, RepRapDiscount RUMBA + Hall Sensors + XXL Controller as suggested by RichRap.

A word on the heated bed - I've insulated the bottom with two sheets of cardboard. They heat up very quick at 12V, on the order of a minute or two to 60 degrees for PLA. It does dramatically increase the current requirements of your power supply, however. The heated bed by itself draws 10A when on. Luckily I am using a big benchtop power supply (Mastech HY5020E).

One part that held me up for a while and that apparently wasn't on the BOM I looked at is the 4mm T-slot Nut that anchors the upper pulley. I ended up ordering some oval 4mm T-Slot Nuts from Adafruit as well as some plastic extrusion endcaps.

Calibrating my first Delta Bot was a daunting task, but since this 3DR is mostly bone stock I was able to run with most of Rich's original firmware settings (Marlin) which let me zero in relatively quickly to the right values for my build.

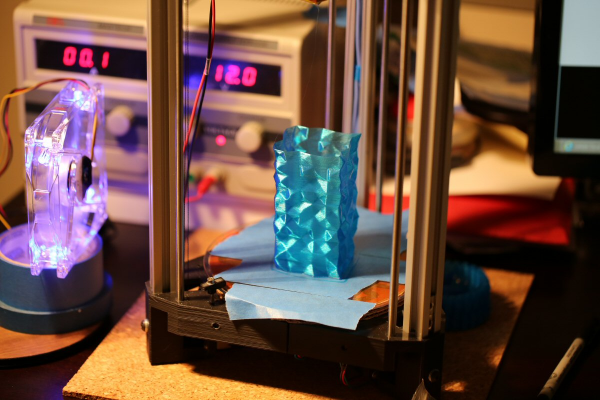

My impressions so far: Once dialed in, get ready for some great prints! Repeatability is excellent and I'm printing down to 0.2mm PLA with no issues. As you can see from the faceted vase close-up, the layers are pristine. The vase was done at 30mm/s which I understand to be conservative. Interested to see how much I can push it.

I do have one remaining issue that is vexing me however, which is a slight skew I get in my prints that are supposed to have vertical walls, on the order of 1-2 degrees. I understand that this type of error is most likely due to the frame members not being equidistant, but as far as I can tell they are. Will have to look more carefully into this before I attempt self replication or building some other dimensionally important parts. I've also been looking at the Kossel Pro, maybe one of those is in my future

Edited 1 time(s). Last edit at 01/10/2014 12:56AM by BaconLover.

I've been gathering the parts for my 3DR build for the past few weeks. This is my first foray into 3D Printing so I needed a set of printed parts to get me started. A big thanks to Mitch over at BusyBotz 3D Printing for printing me a set for a small fee - apparently there were some headaches with printing the large flat parts in ABS but Mitch pulled through and delivered a beautiful set of parts. Just take a look at this extruder gear that Mitch churned out and you'll see the quality of his work.

The printed parts required minimal post processing, just some light deburring to get rid of the platform lip and to make the faces fit flush. For the rods, I went with Traxxas TRA1942 Ball Ends and CF Tube, 150mm center to center. I cut some threaded rod to use as a stud and cemented it in place with aerospace grade Hysol Epoxy.

I also encountered a problem with clearance of the rod ends and the mounts, which required me to add a 3mm cone washer (google "ofna 3mm cone washer") which is perfect for the application. You can see the washer as the blue anodized cone at the end of the ball.

Other vitamins include a J-Head Mk-V with 0.3mm Nozzle, a Trinity Labs 170mm Borosilicate Glass Plate + 160mm Kapton Heater, Lin Engineering 4218L Steppers, RepRapDiscount RUMBA + Hall Sensors + XXL Controller as suggested by RichRap.

A word on the heated bed - I've insulated the bottom with two sheets of cardboard. They heat up very quick at 12V, on the order of a minute or two to 60 degrees for PLA. It does dramatically increase the current requirements of your power supply, however. The heated bed by itself draws 10A when on. Luckily I am using a big benchtop power supply (Mastech HY5020E).

One part that held me up for a while and that apparently wasn't on the BOM I looked at is the 4mm T-slot Nut that anchors the upper pulley. I ended up ordering some oval 4mm T-Slot Nuts from Adafruit as well as some plastic extrusion endcaps.

Calibrating my first Delta Bot was a daunting task, but since this 3DR is mostly bone stock I was able to run with most of Rich's original firmware settings (Marlin) which let me zero in relatively quickly to the right values for my build.

My impressions so far: Once dialed in, get ready for some great prints! Repeatability is excellent and I'm printing down to 0.2mm PLA with no issues. As you can see from the faceted vase close-up, the layers are pristine. The vase was done at 30mm/s which I understand to be conservative. Interested to see how much I can push it.

I do have one remaining issue that is vexing me however, which is a slight skew I get in my prints that are supposed to have vertical walls, on the order of 1-2 degrees. I understand that this type of error is most likely due to the frame members not being equidistant, but as far as I can tell they are. Will have to look more carefully into this before I attempt self replication or building some other dimensionally important parts. I've also been looking at the Kossel Pro, maybe one of those is in my future

Edited 1 time(s). Last edit at 01/10/2014 12:56AM by BaconLover.

|

Re: RepRap 3DR Delta printer Released January 10, 2014 05:58AM |

Registered: 10 years ago Posts: 63 |

Looks fine, congratulations!

As for the bed heater: I use a quite lowly 17W circular heater foil which is barely enough to reach 60C - usually I print PLA at 50C. Insulation is 5mm cork.

As for the bed: I tried several materials, including the Trinity Labs Borosilicate, which I found to be uneven so much that it had to be retired (see my earler posts in this thread). I currently use a 3mm aluminum bed.

My 3DR is printing along happily without major issues for several months now. The only thing which still bugs me is that I can't seem to get the bed levelled better than, say, a 0.1 to 0.2 mm Z error mainly towards the edges of the build area. The pattern of this Z error hints that is is caused not by miscalibration but by (slight) dimensional and angular tolerances of the whole machine. This error might be fixed using a Z correction map in firmware similar to what Johann implemented in his Marlin branch.

Hannes.

#################

My 3DR album: [flic.kr]

As for the bed heater: I use a quite lowly 17W circular heater foil which is barely enough to reach 60C - usually I print PLA at 50C. Insulation is 5mm cork.

As for the bed: I tried several materials, including the Trinity Labs Borosilicate, which I found to be uneven so much that it had to be retired (see my earler posts in this thread). I currently use a 3mm aluminum bed.

My 3DR is printing along happily without major issues for several months now. The only thing which still bugs me is that I can't seem to get the bed levelled better than, say, a 0.1 to 0.2 mm Z error mainly towards the edges of the build area. The pattern of this Z error hints that is is caused not by miscalibration but by (slight) dimensional and angular tolerances of the whole machine. This error might be fixed using a Z correction map in firmware similar to what Johann implemented in his Marlin branch.

Hannes.

#################

My 3DR album: [flic.kr]

|

Re: RepRap 3DR Delta printer Released January 10, 2014 08:23AM |

Registered: 10 years ago Posts: 56 |

Hello,

I have just finished my 3DR with extensions and Full Graphic Smart LCD (From ReprapDiscount) resulting in a printable area of 26cm diameter and 22cm height (it has a cubic printable volume of 18x18x22cm).

I'll post later some pics and the extra files I designed, but first I have a little issue that would like to solve: The arm carriages vibrate so much, I have some clues about what is causing it but I'm not sure:

Any idea?

Thanks

I have just finished my 3DR with extensions and Full Graphic Smart LCD (From ReprapDiscount) resulting in a printable area of 26cm diameter and 22cm height (it has a cubic printable volume of 18x18x22cm).

I'll post later some pics and the extra files I designed, but first I have a little issue that would like to solve: The arm carriages vibrate so much, I have some clues about what is causing it but I'm not sure:

- low/high voltage arriving to steppers (I have Pololu A4988 Steppers set at 0,5 volts as RichRap suggests)

- bad quality of linear bearings (if I move them manually I can feel small tics)

- overtighting Spectra lines

- something related with motors (I feel like they are too noisy...). They are Nema 17 steppers

Any idea?

Thanks

|

Re: RepRap 3DR Delta printer Released January 10, 2014 09:59AM |

Registered: 10 years ago Posts: 63 |

Vibrations... some thoughts and experiences:

- I usually adjust stepper current not by measuring but by adjusting by ear to obtain reasonable smooth operation (I ended up close to the middle position of the pots)

- It pays to experiment with varying travel speeds (in the slicer settings) in order to stay clear of mechanical resonances - 200 mm/s works fine here

- Delta segmentation in the firmware: going too high (such as the default of 200 segments/s) may result in noisy operation too - I use 100 segments/s in Marlin

- Mechanical slop or inadequate rigidity will lead to vibration... have not seen your design modifications yet, but I suspect that after enlarging the build area by a great extent it would be absolutely mandatory to modify the carriage design for added stiffness too, because the original design is just adequate for the original geometry and I can't imagine it will tolerate higher mechanical loads.

- I usually adjust stepper current not by measuring but by adjusting by ear to obtain reasonable smooth operation (I ended up close to the middle position of the pots)

- It pays to experiment with varying travel speeds (in the slicer settings) in order to stay clear of mechanical resonances - 200 mm/s works fine here

- Delta segmentation in the firmware: going too high (such as the default of 200 segments/s) may result in noisy operation too - I use 100 segments/s in Marlin

- Mechanical slop or inadequate rigidity will lead to vibration... have not seen your design modifications yet, but I suspect that after enlarging the build area by a great extent it would be absolutely mandatory to modify the carriage design for added stiffness too, because the original design is just adequate for the original geometry and I can't imagine it will tolerate higher mechanical loads.

|

Re: RepRap 3DR Delta printer Released January 10, 2014 01:14PM |

Registered: 10 years ago Posts: 9 |

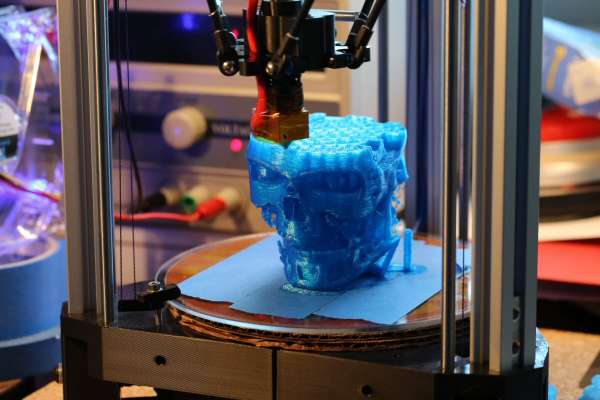

Couldn't help sharing my overnight progress. Had a helluva time getting the lower jaw to stick to the platform without getting knocked off about 1cm in, but enabled the raft feature in Cura which seems to have done the trick. It looks like either the X or Y towers got stuck and lost a few steps right at the teeth split line, but it seems to have recovered nicely. It kinda gives it some character and grit. This one is done at 0.2mm with 10% fill. I think it'd be fine with much lower fill now that I see it

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: RepRap 3DR Delta printer Released January 10, 2014 05:56PM |

Registered: 10 years ago Posts: 56 |

Thanks for your comments HaDe,

I'm playing a little with driver voltage in order to find the smoothest configuration.

What I have seen it that when it moves slow it vibrates much more, this effect is also more notable in the lowest layers... I have also set the travel speed to 200mm/s, I think it's fine.

My delta segmentation is also set at 100, I don't know if I should go under that point to reduce vibration...

And finally, I'm confident of the design, it's only 50mm higher than RichRap's original and the assembly is perfect. As I said the only thing that vibrates is the arm carriage, due to the bearings or the steppers (I should also try ABS 3D printed bearings in order to eliminate the possibility of the vibrations in the linear bearings).

I'll post my investigations and if anyone has more clues just let me know

I'm playing a little with driver voltage in order to find the smoothest configuration.

What I have seen it that when it moves slow it vibrates much more, this effect is also more notable in the lowest layers... I have also set the travel speed to 200mm/s, I think it's fine.

My delta segmentation is also set at 100, I don't know if I should go under that point to reduce vibration...

And finally, I'm confident of the design, it's only 50mm higher than RichRap's original and the assembly is perfect. As I said the only thing that vibrates is the arm carriage, due to the bearings or the steppers (I should also try ABS 3D printed bearings in order to eliminate the possibility of the vibrations in the linear bearings).

I'll post my investigations and if anyone has more clues just let me know

|

Re: RepRap 3DR Delta printer Released January 10, 2014 06:17PM |

Registered: 10 years ago Posts: 63 |

I assume we both use the same cheap chinese linar bearing bearings? :-) I found those to run a little rough at times, but not so much that it would cause binding and/or vibrations. In fact I bought more than required and selected those with NO slop. Those with slop caused noises and sometimes vibration - not constantly nor with constant frequency, but varying a great deal during printing moves.

Will the vibration change or disappear when you disconnect the arms? Also, is the vibration more or less constant regardless of current axis speed or do you feel it happens only at certain speeds which match resonance frequencies? In fact I can *feel* (but barely *hear*) the carriages moving discontinously with a constant overlaid low frequency during printing moves - not sure but this might be due to delta move segmentation.

Will the vibration change or disappear when you disconnect the arms? Also, is the vibration more or less constant regardless of current axis speed or do you feel it happens only at certain speeds which match resonance frequencies? In fact I can *feel* (but barely *hear*) the carriages moving discontinously with a constant overlaid low frequency during printing moves - not sure but this might be due to delta move segmentation.

|

Re: RepRap 3DR Delta printer Released January 10, 2014 06:33PM |

Registered: 11 years ago Posts: 142 |

|

Re: RepRap 3DR Delta printer Released January 10, 2014 06:38PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released January 10, 2014 06:39PM |

Registered: 11 years ago Posts: 142 |

was meinste damit ? du weist was er hat ?

Die ganze sache hier, ist so aufgebaut, das man das verwendet was ihr euch ausgedacht habt.

Das Problem, wenn Ihr die experten euren Senf abgibt, nicht bedenkt, daß die anderen andere Hardware am werk haben.

Ich scheisse auf dem englisch, weil ich mit den deutschen rede.

Edited 1 time(s). Last edit at 01/10/2014 06:45PM by zacbot.

video of my 3DR

Die ganze sache hier, ist so aufgebaut, das man das verwendet was ihr euch ausgedacht habt.

Das Problem, wenn Ihr die experten euren Senf abgibt, nicht bedenkt, daß die anderen andere Hardware am werk haben.

Ich scheisse auf dem englisch, weil ich mit den deutschen rede.

Edited 1 time(s). Last edit at 01/10/2014 06:45PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released January 10, 2014 06:54PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released January 10, 2014 07:07PM |

Registered: 11 years ago Posts: 142 |

Say:

Richrap wanted to introduce 32 stepping. We don t know yet why he did..

We have nothing against 32 stepping.

We just want to be informed, that this THING is for that THING.

It means, anyone who build the machine, should know, that its basic firmware is 32 steps and not the normal 16 steps.

Edited 1 time(s). Last edit at 01/10/2014 07:13PM by zacbot.

video of my 3DR

Richrap wanted to introduce 32 stepping. We don t know yet why he did..

We have nothing against 32 stepping.

We just want to be informed, that this THING is for that THING.

It means, anyone who build the machine, should know, that its basic firmware is 32 steps and not the normal 16 steps.

Edited 1 time(s). Last edit at 01/10/2014 07:13PM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released January 10, 2014 07:15PM |

Registered: 10 years ago Posts: 63 |

Well one man's THING sure might differ from another man's THING :-) - but seriously I lost track of what everybody else did so I just took a little time and tested it for myself, both 16 and 32 microsteps - didn't see nor hear much difference so I simply stuck with 32 for higher (theroretical) resolution.

|

Re: RepRap 3DR Delta printer Released January 10, 2014 07:34PM |

Registered: 11 years ago Posts: 142 |

OK, we have now the knowledge of HaDe which confirms, that stepping at 16 and 32 microsteps does not "show" difference.

So the manufacturer could remove the jumpers from the boards and firmware writer can forget the complicated calculations for different stepping modes.

PS: Du has NUR XX Beiträge aber ein "geballtes Wissen", das zeigt schon wer "steckt dahinter" und was du willst.

Edited 4 time(s). Last edit at 01/10/2014 07:51PM by zacbot.

video of my 3DR

So the manufacturer could remove the jumpers from the boards and firmware writer can forget the complicated calculations for different stepping modes.

PS: Du has NUR XX Beiträge aber ein "geballtes Wissen", das zeigt schon wer "steckt dahinter" und was du willst.

Edited 4 time(s). Last edit at 01/10/2014 07:51PM by zacbot.

video of my 3DR

Sorry, only registered users may post in this forum.