RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released January 11, 2014 04:44AM |

Registered: 10 years ago Posts: 56 |

I have used vanilla ErikZalm Marlin firmware to assure to have the most updated firmware, modifying the parameters that RichRap had on his and using mines when required.

My microstepping setting ("#define MICROSTEP_MODES" at "configuration_adv.h") is set to 16 as I thought it was a parameter inherited from the stepper (Nema 17, these ones) and drivers (A4988, these ones). Should I try 32 microsteps?

HaDe, you said "RUMBA set to 32 microsteps for X/Y/Z"... where in firmware is written that?

My microstepping setting ("#define MICROSTEP_MODES" at "configuration_adv.h") is set to 16 as I thought it was a parameter inherited from the stepper (Nema 17, these ones) and drivers (A4988, these ones). Should I try 32 microsteps?

HaDe, you said "RUMBA set to 32 microsteps for X/Y/Z"... where in firmware is written that?

|

Re: RepRap 3DR Delta printer Released January 11, 2014 05:32AM |

Registered: 10 years ago Posts: 63 |

>> Should I try 32 microsteps? <<

As I just said, I didn't notice much difference. I see you're using A4988 drivers which support only 16 microsteps, so if you want to try 32 you'd have to replace those by DRV8825 types.

>> where in firmware is written that? <<

Look at the line above the MICROSTEP_MODES setting which mentions "// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.". Which board do you have? The ones I know require setting microsteps via switches directly on the board (check your hardware documentation), so MICROSTEP_MODES will have no effect.

As I just said, I didn't notice much difference. I see you're using A4988 drivers which support only 16 microsteps, so if you want to try 32 you'd have to replace those by DRV8825 types.

>> where in firmware is written that? <<

Look at the line above the MICROSTEP_MODES setting which mentions "// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.". Which board do you have? The ones I know require setting microsteps via switches directly on the board (check your hardware documentation), so MICROSTEP_MODES will have no effect.

|

Re: RepRap 3DR Delta printer Released January 11, 2014 11:36AM |

Registered: 10 years ago Posts: 56 |

I have RUMBA board, I'll check if I should set it manually in the board, I thought it was a firmware config...

I forgot to mention that I also have the Chinese bearing... I feel they are not good quality that's why I want to try with a set of ABS printed ones, in case the vibration and noise are reduced I can think about buying quality bearings.

I forgot to mention that I also have the Chinese bearing... I feel they are not good quality that's why I want to try with a set of ABS printed ones, in case the vibration and noise are reduced I can think about buying quality bearings.

|

Re: RepRap 3DR Delta printer Released January 21, 2014 05:27PM |

Registered: 10 years ago Posts: 56 |

Vibration update:

I checked the stepper driver jumpers of my RUMBA and they are set to (1, 1, 1) so I guess it is the correct position for my Pololus A4988 and 16 microstepping.

I have tried ABS printed linear bearing and they aren't the ones that causes the vibration.

I have played with various Slic3r configs and I think the problem is related with movement speeds:

One last thing, checking the steppers and its parts, I have seen that the steps per millimeter are set by RichRap on 55.5 but doing a calculation with the spools (in fact, with the .stl provided by him) it goes to 56.588:

I checked the stepper driver jumpers of my RUMBA and they are set to (1, 1, 1) so I guess it is the correct position for my Pololus A4988 and 16 microstepping.

I have tried ABS printed linear bearing and they aren't the ones that causes the vibration.

I have played with various Slic3r configs and I think the problem is related with movement speeds:

- at about 20mm/s I get vibration but above 30mm/s everything goes fine

- when moving along a line, it vibrates in the center... I thing it's due accelerations but I don't know to to manage this feature. I see how it start the line at a higher speed but it reduces in the second third of the whole line, finally the speed goes higher at the last third of the line.

One last thing, checking the steppers and its parts, I have seen that the steps per millimeter are set by RichRap on 55.5 but doing a calculation with the spools (in fact, with the .stl provided by him) it goes to 56.588:

Quote

steps_per_mm = ((360/motor_step_angle) * driver_microstep) / thread_pitch = ((360/1.8) * 16 ) / 56.549 = 56.588

|

Re: RepRap 3DR Delta printer Released January 21, 2014 06:57PM |

Registered: 10 years ago Posts: 63 |

>> would be great to have any of your Slic3r config in order to compare with mines and see how it goes <<

Attached please find my current Slic3r settings (for 0.1mm layers)... and this is the relevant section of my Marlin config:

Attached please find my current Slic3r settings (for 0.1mm layers)... and this is the relevant section of my Marlin config:

#define DEFAULT_AXIS_STEPS_PER_UNIT {110.6, 110.6, 110.6, 230}

#define DEFAULT_MAX_FEEDRATE {380, 380, 380, 50} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000, 9000, 9000, 9000} // X, Y, Z, E maximum start speed for accelerated moves

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

#define DEFAULT_XYJERK 35.0 // (mm/sec)

#define DEFAULT_ZJERK 35.0 // (mm/sec) Must be same as XY for delta

#define DEFAULT_EJERK 20.0 // (mm/sec)

|

Re: RepRap 3DR Delta printer Released January 21, 2014 09:40PM |

Registered: 11 years ago Posts: 142 |

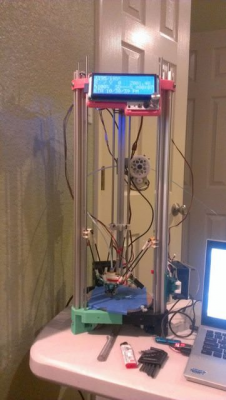

Yesterday I have printed the first object with the 3DR. I started with 50 mm/s and used Repetier Host to increase the speed while printing. I wanted to see where the printer would fail...but it didn t...not after an increase to 300 % of the speed....Yes the speed had its impact on the quality but it was amazing to see how fast this machine could go...if the extruder was also so fast...and the best was, that thet test finished with success.

Without any "big" calibration efforts...Here is a first shot of the first object, it is the torture test you can download from the internet....

The first print...not perfect...but nothing to compare with the printers I have build until now. Talking about vibration, I don t know from where one could get them, there is nothing in this machine that could produce vibrations....A video would be helpful to visualize the problem.

video of my 3DR

Without any "big" calibration efforts...Here is a first shot of the first object, it is the torture test you can download from the internet....

The first print...not perfect...but nothing to compare with the printers I have build until now. Talking about vibration, I don t know from where one could get them, there is nothing in this machine that could produce vibrations....A video would be helpful to visualize the problem.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released January 22, 2014 12:11AM |

Registered: 10 years ago Posts: 8 |

Hopefully someone can help me out. Not sure what I'm doing wrong.

I'm using Slic3r to complie G-Code and I've tried both Richard's and Andy's version of the firmware.

Using Prointerface I can move x,y and z in the correct directions using the arrow interface on the left. The problem comes when I try to print. See the following video

[www.youtube.com]

In this I am trying to print the RepRap coin linked in second 4 of the guide. As you can see it wants to move my x all the way down. I'm not sure why this is but I have to stop the machine.

In Slic3r I have tried configuring it as was done in section 4 as well as defaults all around.

Anyone have any suggestions?

I'm using Slic3r to complie G-Code and I've tried both Richard's and Andy's version of the firmware.

Using Prointerface I can move x,y and z in the correct directions using the arrow interface on the left. The problem comes when I try to print. See the following video

[www.youtube.com]

In this I am trying to print the RepRap coin linked in second 4 of the guide. As you can see it wants to move my x all the way down. I'm not sure why this is but I have to stop the machine.

In Slic3r I have tried configuring it as was done in section 4 as well as defaults all around.

Anyone have any suggestions?

|

Re: RepRap 3DR Delta printer Released January 22, 2014 12:26AM |

Registered: 11 years ago Posts: 142 |

We would but there is a problem with your video....it is private, so no one can see it, please check your publishing settings.

>> I'm using Slic3r to complie G-Code and I've tried both Richard's and Andy's version of the firmware.

As you write, there is a firmware for Richard, for Andy, for me and for each one. There is no firmware for everyone. You have to tune your machine yourself.

Without looking to the video, this can t have something to do with the Slicer, no matters which slicer you are using.

Hope it helps.

video of my 3DR

>> I'm using Slic3r to complie G-Code and I've tried both Richard's and Andy's version of the firmware.

As you write, there is a firmware for Richard, for Andy, for me and for each one. There is no firmware for everyone. You have to tune your machine yourself.

Without looking to the video, this can t have something to do with the Slicer, no matters which slicer you are using.

Hope it helps.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released January 22, 2014 12:43AM |

Registered: 10 years ago Posts: 8 |

|

Re: RepRap 3DR Delta printer Released January 22, 2014 02:45AM |

Registered: 10 years ago Posts: 56 |

It happened something similar to me on my first prints, it's probably because you set the print center to the half of global printer XY area and in delta machines it should be set at 0 (X = 0, Y = 0). In your video X tower carriage tries to move the extruder outside the print area but, of course, it never reaches the point its wants because of "dimensional limits" of arms... I don't know if you understand me. Anyway, I see you have solved the problem =)Quote

caffeinatedsoap

Not to worry about the video. I grabbed HaDe's Slic3r config file and compiled using that. It works fine. Seems that I need to go over this and learn what I did wrong. Thanks for the quick reply though.

HaDe: thanks a lot, your config is quite different from RichRap one and from Marlin firmware defaults so I think it could work, I'll let you know. Thanks a lot!

|

Re: RepRap 3DR Delta printer Released January 22, 2014 02:52AM |

Registered: 11 years ago Posts: 142 |

Ah ok, you are welcome too.

Edited 2 time(s). Last edit at 01/22/2014 03:11AM by zacbot.

video of my 3DR

Edited 2 time(s). Last edit at 01/22/2014 03:11AM by zacbot.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released January 22, 2014 07:12AM |

Registered: 10 years ago Posts: 63 |

Always nice to see progress with those interesting machines...

Pablo, I ran exactly into the same problem (incorrect settings for the printable area) when I struggled with my own 3DR buildup. In fact, like zacbot said, there's no real turnkey solution for delta printers yet which still require a great deal of experimenting, analyzing and learning. But I think that contributes to the fascination and the satisfaction when we finally get it working the way we want it to.

As for vibrations... I think that the discontinuous operation principle of stepper motors and also the firmware's delta segmenting seem to be the main sources, and I'm afraid we can't do much to eliminate those. Now what we *can* influence is how those sources will propagate & resonate in the mechanics of the printer: eliminating slop and play, increasing stiffness, reducing moving weight etc. - Pablo, here are a few points to look into:

- hot end cooling fan seems quite large and thus heavy, might go for a much smaller fan (like this one: [www.sepa-europe.com])

- guess this has been mentioned before, but the Spectra drive line should be tensioned to produce a high pitched sound when plucked

- an enlarged 3DR using only 3,5mm delta rods (my standard sized 3DR uses 5 mm thin wall carbon tubes)

- using the standard carriage which I feel is just ok for a standard sized 3DR at normal printing speeds, but too sloppy and soft for *precise* printing at higher speed (BTW this is the main thing I'd still like to improve on mine: probably longer bearings, or going up to 8mm guide rods)

Pablo, I ran exactly into the same problem (incorrect settings for the printable area) when I struggled with my own 3DR buildup. In fact, like zacbot said, there's no real turnkey solution for delta printers yet which still require a great deal of experimenting, analyzing and learning. But I think that contributes to the fascination and the satisfaction when we finally get it working the way we want it to.

As for vibrations... I think that the discontinuous operation principle of stepper motors and also the firmware's delta segmenting seem to be the main sources, and I'm afraid we can't do much to eliminate those. Now what we *can* influence is how those sources will propagate & resonate in the mechanics of the printer: eliminating slop and play, increasing stiffness, reducing moving weight etc. - Pablo, here are a few points to look into:

- hot end cooling fan seems quite large and thus heavy, might go for a much smaller fan (like this one: [www.sepa-europe.com])

- guess this has been mentioned before, but the Spectra drive line should be tensioned to produce a high pitched sound when plucked

- an enlarged 3DR using only 3,5mm delta rods (my standard sized 3DR uses 5 mm thin wall carbon tubes)

- using the standard carriage which I feel is just ok for a standard sized 3DR at normal printing speeds, but too sloppy and soft for *precise* printing at higher speed (BTW this is the main thing I'd still like to improve on mine: probably longer bearings, or going up to 8mm guide rods)

|

Re: RepRap 3DR Delta printer Released January 22, 2014 03:14PM |

Registered: 10 years ago Posts: 56 |

Sure, all these experimentations increase your knowledge and makes you be prepared for potencial future events, hehehe.

As for vibrations... all are gone with your Slic3r settings!! thank you very much again, it has been a big help. I have tweaked a little bit them to meet my printer, hotend, etc and now I'm printing the first part that I can consider 99% perfect. So, finally I can assure the "3DR with extensions" works fine with no mechanical problems =)

Anyway, the points you have listed seems very interesting and I'll investigate them ir order to improve printing precision.

Other thing I have discovered while testing is that the printable area is squared, I mean, my theoretical printable area is a circle of 26cm of diameter but it takes the circumscribed square, that is a 18.38cm. I have no idea by now if it's a Slic3r limit or if it's "engraved" in the firmware. Trying a Slic3r setting with a printable area which contains a circumscribed square of 26cm goes to 36.77cm but it doesn't works so in my opinion is inside firmware... but, it's strange that Repetier Host lets me move in any position inside this 26cm circle. Any idea?

As for vibrations... all are gone with your Slic3r settings!! thank you very much again, it has been a big help. I have tweaked a little bit them to meet my printer, hotend, etc and now I'm printing the first part that I can consider 99% perfect. So, finally I can assure the "3DR with extensions" works fine with no mechanical problems =)

Anyway, the points you have listed seems very interesting and I'll investigate them ir order to improve printing precision.

Other thing I have discovered while testing is that the printable area is squared, I mean, my theoretical printable area is a circle of 26cm of diameter but it takes the circumscribed square, that is a 18.38cm. I have no idea by now if it's a Slic3r limit or if it's "engraved" in the firmware. Trying a Slic3r setting with a printable area which contains a circumscribed square of 26cm goes to 36.77cm but it doesn't works so in my opinion is inside firmware... but, it's strange that Repetier Host lets me move in any position inside this 26cm circle. Any idea?

|

Re: RepRap 3DR Delta printer Released January 22, 2014 05:38PM |

Registered: 10 years ago Posts: 9 |

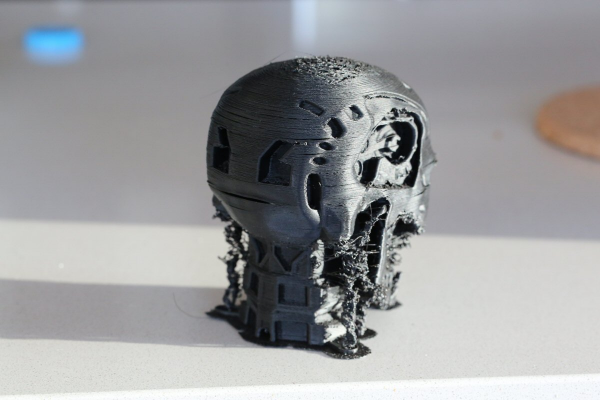

Had fun printing the T800 model in black ABS at 0.2mm, however the bowden tube lag is rearing its ugly head. I can't get the cables to print properly because the filament is not starting and stopping in sync with the hotend movements. It ends up being a partial cylinder for the first few layers and then eventually gets knocked off and becomes a blob. Anybody have experience dealing with this type of issue? Retraction settings don't seem to help much on this... shorten the tube perhaps?

|

Re: RepRap 3DR Delta printer Released January 26, 2014 09:03PM |

Registered: 10 years ago Posts: 6 |

If you are seeing the effects of something that looks like vibrations here are some tips I have found with my delta printer (It's a Rostock Max, I've got all the electronics for a 3DR I'm just saving up for the rest of the hardware) that haven't been mentioned.

My Rostock Max is fairly weighty with the melamine and all the electronics inside, I still improved my prints by clamping it down (there are some cork plates between it and the table) to the table it is on. VERY helpful at higher speeds.

Check the carriage arms. Rubber bands tensioning the arms can help remove some slop. Also consider looking into magnetic arms as have been done on some delta printers. They do a fantastic job at high print speeds. I don't know what material you have for the arms themselves, but there is flex the longer the arms are. I did a set of magnetic arms and instead of just using carbon rods I used arrow shafts while picking a set with the stiffest / lowest deflection the store had. I'd have preferred crossbow bolts, but they didn't carry those.

Hopefully those suggestions may still apply when refining your 3DR for high speeds. I hope to join you guys in the 3DR club soon!

My Rostock Max is fairly weighty with the melamine and all the electronics inside, I still improved my prints by clamping it down (there are some cork plates between it and the table) to the table it is on. VERY helpful at higher speeds.

Check the carriage arms. Rubber bands tensioning the arms can help remove some slop. Also consider looking into magnetic arms as have been done on some delta printers. They do a fantastic job at high print speeds. I don't know what material you have for the arms themselves, but there is flex the longer the arms are. I did a set of magnetic arms and instead of just using carbon rods I used arrow shafts while picking a set with the stiffest / lowest deflection the store had. I'd have preferred crossbow bolts, but they didn't carry those.

Hopefully those suggestions may still apply when refining your 3DR for high speeds. I hope to join you guys in the 3DR club soon!

|

Re: RepRap 3DR Delta printer Released January 26, 2014 11:05PM |

Registered: 10 years ago Posts: 8 |

Everything seems to be working as it should now. The only issues I'm having now are mechanical.

1. Having extruder slippage.

-I've ordered a few different hobbed bolts. I'll report back with what I find.

2. The smooth rods I ordered aren't exactly the same diameter the whole length. This is causing some slop when printing.

-Anyone know a good place to order 6mm rod? Or should I go with V-Slot and the sliders?

3. I am very unfamiliar with PLA.

-This one will take time I assume.

1. Having extruder slippage.

-I've ordered a few different hobbed bolts. I'll report back with what I find.

2. The smooth rods I ordered aren't exactly the same diameter the whole length. This is causing some slop when printing.

-Anyone know a good place to order 6mm rod? Or should I go with V-Slot and the sliders?

3. I am very unfamiliar with PLA.

-This one will take time I assume.

|

Re: RepRap 3DR Delta printer Released January 27, 2014 02:34AM |

Registered: 10 years ago Posts: 56 |

Hi masterbinky, thanks for your comments about vibration, I'll add them to HaDe's list and take care of paying attention to them. Anyway, the most notable vibration issue was the loud noise from the steppers and now they are gone when I changed print speed to a higher value (lower than 20mm/s it start vibrating) and acceleration that I had it all at 0.

caffeinatedsoap, I also bought "non calibrated" rods and got the same sloop when inserting the 6mm bearings. I took a time here in Spain to find a decent place to buy the rods, they are not difficult to find and provably you are able to find them at a local store but always ask for "calibrated 6mm stainless steel rods", from that they may ask you about mate or bright, alloys, etc but all of them will fit perfect.

caffeinatedsoap, I also bought "non calibrated" rods and got the same sloop when inserting the 6mm bearings. I took a time here in Spain to find a decent place to buy the rods, they are not difficult to find and provably you are able to find them at a local store but always ask for "calibrated 6mm stainless steel rods", from that they may ask you about mate or bright, alloys, etc but all of them will fit perfect.

|

Re: RepRap 3DR Delta printer Released February 19, 2014 06:52PM |

Registered: 10 years ago Posts: 63 |

|

Re: RepRap 3DR Delta printer Released February 20, 2014 01:05AM |

Registered: 11 years ago Posts: 142 |

Looks good Hade. I have this system on my old Uventorbot printer...It adds weight to the total machine weight...

But why did you use that in this setup? Just to test or is there other reasons ?

video of my 3DR

But why did you use that in this setup? Just to test or is there other reasons ?

video of my 3DR

|

Re: RepRap 3DR Delta printer Released February 20, 2014 04:35AM |

Registered: 10 years ago Posts: 63 |

Hi... here are the weight figures:

Non-Moving, original: steel rods 6/420 mm (2 x 94 g) = 188 g

Non-Moving, modified: 300 mm rail (90 g), fasteners (36 g) = 126 g

Moving, original: printed carriage, 2 bushings and magnet = 19.5 g

Moving: modified: linear carriage, printed adapter plate and magnet = 21,5 g

So this nets a substantial decrease in non-moving and, luckily, only a slight increase in moving weight.

You may have noticed that I left the original steel rods in place for added rigidity (even glued them into the printed parts at the bottom) because rigidity of the tower assembly is not quite satisfactory anyway, at least with my 3DR. To check, position the nozzle somewhere close to the bed, grip the 3DR at the top, rock it in all directions and watch the nozzle move about quite a bit horizontally! This doesn't seem much of a problem with low to moderate printing speeds but WILL decrease print quality when trying to print faster (and with high acceleration, as required to mask the extrusion elasticity introduced by the bowden extruder).

>> But why did you use that in this setup? Just to test or is there other reasons ? <<

All things considered, I don't think this is a must-have modification, because I got only a slight improvement in print quality from it. But, as you said, it was for testing, to get rid of the remaining slack of the linear bushings, and to gain some experience with this type of linear guide (DIN standard 9 mm size MR 9NM by taiwanese manufacturer CPC, 60 Euros each here in Germany) for my next printer projects.

How's your 3DR doing? Have you found points and/or solutions for improvements? I still would like to increase frame stiffness, but have no idea how to get real improvements without a major redesign. The main flex appears to be in the top & bottom printed parts.

Non-Moving, original: steel rods 6/420 mm (2 x 94 g) = 188 g

Non-Moving, modified: 300 mm rail (90 g), fasteners (36 g) = 126 g

Moving, original: printed carriage, 2 bushings and magnet = 19.5 g

Moving: modified: linear carriage, printed adapter plate and magnet = 21,5 g

So this nets a substantial decrease in non-moving and, luckily, only a slight increase in moving weight.

You may have noticed that I left the original steel rods in place for added rigidity (even glued them into the printed parts at the bottom) because rigidity of the tower assembly is not quite satisfactory anyway, at least with my 3DR. To check, position the nozzle somewhere close to the bed, grip the 3DR at the top, rock it in all directions and watch the nozzle move about quite a bit horizontally! This doesn't seem much of a problem with low to moderate printing speeds but WILL decrease print quality when trying to print faster (and with high acceleration, as required to mask the extrusion elasticity introduced by the bowden extruder).

>> But why did you use that in this setup? Just to test or is there other reasons ? <<

All things considered, I don't think this is a must-have modification, because I got only a slight improvement in print quality from it. But, as you said, it was for testing, to get rid of the remaining slack of the linear bushings, and to gain some experience with this type of linear guide (DIN standard 9 mm size MR 9NM by taiwanese manufacturer CPC, 60 Euros each here in Germany) for my next printer projects.

How's your 3DR doing? Have you found points and/or solutions for improvements? I still would like to increase frame stiffness, but have no idea how to get real improvements without a major redesign. The main flex appears to be in the top & bottom printed parts.

|

Re: RepRap 3DR Delta printer Released February 20, 2014 10:24PM |

Registered: 11 years ago Posts: 364 |

|

Re: RepRap 3DR Delta printer Released February 21, 2014 07:27AM |

Registered: 10 years ago Posts: 63 |

>> wont the PLA in the motor base soften with the motor heat in a long duration print ? <<

If the motor current is adjusted properly (only little is required, about 1/3 of the maximum setting), the motors only get slightly warm at maximum... they're way overdimensioned for the low moving mass of the 3DR.

At first I was more concerned about softening the PLA base because of the heated bed, but my usual 50°C setting seems too low to cause any problems, and also there's a 6 mm cork insulation between the heater and the PLA base.

If the motor current is adjusted properly (only little is required, about 1/3 of the maximum setting), the motors only get slightly warm at maximum... they're way overdimensioned for the low moving mass of the 3DR.

At first I was more concerned about softening the PLA base because of the heated bed, but my usual 50°C setting seems too low to cause any problems, and also there's a 6 mm cork insulation between the heater and the PLA base.

|

Re: RepRap 3DR Delta printer Released February 24, 2014 09:08PM |

Registered: 11 years ago Posts: 364 |

|

Re: RepRap 3DR Delta printer Released February 25, 2014 02:41AM |

Registered: 10 years ago Posts: 56 |

|

Re: RepRap 3DR Delta printer Released February 25, 2014 04:34AM |

Registered: 11 years ago Posts: 364 |

|

Re: RepRap 3DR Delta printer Released February 25, 2014 04:43AM |

Registered: 10 years ago Posts: 56 |

|

Re: RepRap 3DR Delta printer Released February 25, 2014 04:52AM |

Registered: 11 years ago Posts: 364 |

|

Re: RepRap 3DR Delta printer Released February 25, 2014 07:51PM |

Registered: 10 years ago Posts: 515 |

I very often import .stl files into Sketchup. Initially they are a mass of lines and triangles but the Cleanup plugin that you can download from the Extension Warehouse fixes all that and they end up looking like any other Sketckup model and are much easier to work with. I would be lost without it!

|

Re: RepRap 3DR Delta printer Released February 27, 2014 08:29AM |

Registered: 10 years ago Posts: 88 |

|

Re: RepRap 3DR Delta printer Released February 28, 2014 09:02AM |

Registered: 11 years ago Posts: 364 |

Sorry, only registered users may post in this forum.