RepRap 3DR Delta printer Released

Posted by richrap

|

Re: RepRap 3DR Delta printer Released April 12, 2014 06:27PM |

Registered: 11 years ago Posts: 142 |

Here is a quick update about building the 3DR Simple, but the issue I had here is general and is not related to the Delta.

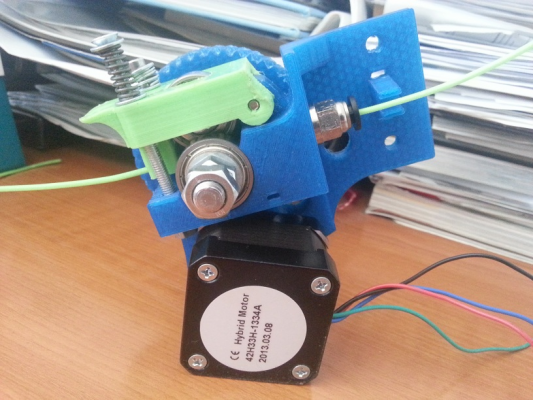

I wanted to get rid of the bulky original extruder with it big gear and because I had the MK7 gear in my desk, I thought it s time to use it and did some CAD work, that looks like this:;

Of course coupled with housing to hold the MK7 gear....but 10 days later...1 Kg filament later...I must admit...the torque pruduced was not enough. I tryed everything...I solved all hotend problems that I had and even that i could have....I was able to push filament with my breath...:-) but not the extruder....at the end gave up and reverted to greg s extruder setup.

JohnSL wanted to know about the MK7...this was my experience....MK7 as bowden extruder...never again.

video of my 3DR

I wanted to get rid of the bulky original extruder with it big gear and because I had the MK7 gear in my desk, I thought it s time to use it and did some CAD work, that looks like this:;

Of course coupled with housing to hold the MK7 gear....but 10 days later...1 Kg filament later...I must admit...the torque pruduced was not enough. I tryed everything...I solved all hotend problems that I had and even that i could have....I was able to push filament with my breath...:-) but not the extruder....at the end gave up and reverted to greg s extruder setup.

JohnSL wanted to know about the MK7...this was my experience....MK7 as bowden extruder...never again.

video of my 3DR

|

Re: RepRap 3DR Delta printer Released April 13, 2014 09:27AM |

Registered: 10 years ago Posts: 13 |

@zacbot So, here you have the video, excuse the poor quality, as I said I don't have much time for these things. there are no big differences with Richrap's 3DR. The carriages are different because I assembled the spectra line as RichRap suggested, but then the spectra lines didn't run straight. I should have tied the line on the right rather than on the left, but I also wanted to modify the carriage to leave a small gap for a LED strip to fit between the carriage and the Alu profiles, so I did both modifications. Also, I recently changed to Igus bushings... they are great!

As I said previously, the diagonal rods are all the same length to 0.02mm, except one of them that has a difference of 0.05mm to the average. I have a home metal workshop, so I am used to doing mechanical measurements and I have some measuring tools.

I believe that hercek has really spotted the problem here as some bad dimensioning going on. I understand your point, and when I assembled the printer, the parts were pretty decently built, I really had no problems to fit everything together, the aluminum extrusions went nice and smooth. But still, I am assembling all together, and I might have made a mistake, overtightened something, etc. And, actually, how much deviation do you need for something like this to happen? By the way, I printed the parts on my other printer.

So now, I built a one-time z-probe (the bulky red stuff you can see in the video) to calibrate everything as a temporary thing. I might do a good z-probe later to have it permanently installed, who knows. But it is not working very well because the spools are slipping when the endstop hits the table. @HaDe I saw you also complained about slippage in the spools, how did you solve it? Having a lathe, I'm already thinking about turning some aluminum spools, but maybe there is an easier solution.

By the way, the video is with RichCattels firmware.

Cheers,

As I said previously, the diagonal rods are all the same length to 0.02mm, except one of them that has a difference of 0.05mm to the average. I have a home metal workshop, so I am used to doing mechanical measurements and I have some measuring tools.

I believe that hercek has really spotted the problem here as some bad dimensioning going on. I understand your point, and when I assembled the printer, the parts were pretty decently built, I really had no problems to fit everything together, the aluminum extrusions went nice and smooth. But still, I am assembling all together, and I might have made a mistake, overtightened something, etc. And, actually, how much deviation do you need for something like this to happen? By the way, I printed the parts on my other printer.

So now, I built a one-time z-probe (the bulky red stuff you can see in the video) to calibrate everything as a temporary thing. I might do a good z-probe later to have it permanently installed, who knows. But it is not working very well because the spools are slipping when the endstop hits the table. @HaDe I saw you also complained about slippage in the spools, how did you solve it? Having a lathe, I'm already thinking about turning some aluminum spools, but maybe there is an easier solution.

By the way, the video is with RichCattels firmware.

Cheers,

|

Re: RepRap 3DR Delta printer Released April 13, 2014 10:20AM |

Registered: 10 years ago Posts: 732 |

If only one rod is slightly longer/shorter then it will lead mostly to head rotations. These will not have significant impact on bed levelling but will have impact on XY error. Since your pair of diagonal rods is not too near to each other then one diagonal rod error should not amplify much.Quote

payala

the diagonal rods are all the same length to 0.02mm, except one of them that has a difference of 0.05mm to the average

If your measurements are correct then diagonal rods are almost for sure not why your first layer is so bad. It looks like first layer z-error is significantly more than 0.1mm. Tower position or tower carriage position errors will lead to a slightly smaller errors in X/Y/Z coordinate. Because one source error (on tower location or carriage location) will distribute into 3 coordinate (X/Y/Z) errors. So provided there is only one error in the system calibration then this will have bigger or equal absolute value than its biggest impact on bed z-height error.

Also I noticed that you run Richie's firmware with rather low bed diameter. Especially for the measurement points opposite of a tower, you should measure them really far away ... significantly behind the line connecting the bases of the other two virtual towers. The idea is that at the connection point of the other two virtual towers the z-height error (from wrong radial tower position) just changes it's sign. So it is not a good idea to measure it just there.

|

Re: RepRap 3DR Delta printer Released April 13, 2014 11:50AM |

Registered: 10 years ago Posts: 1 |

Hello Im building my first 3D printer and i chose 3DR..(yikes) so far so good though its being going ok. got most of my parts from ebay. Here are some pics from my page

[instagram.com]

[instagram.com]

I am having trouble understanding the extruder part though. Does anyone have clear front and back pics so i can put it together rightly? It wasnt too clear to me on Rich's lesson 2&3 pages.

[instagram.com]

[instagram.com]

I am having trouble understanding the extruder part though. Does anyone have clear front and back pics so i can put it together rightly? It wasnt too clear to me on Rich's lesson 2&3 pages.

|

Re: RepRap 3DR Delta printer Released April 13, 2014 04:51PM |

Registered: 11 years ago Posts: 142 |

Thanks for the video, it saves our time to guess what could be wrong

Richrap provided two kind of carriage, one for LMU and one for bushing. I printed the one for bushing but soon I saw there is a little problem with it. It doesn t fit good and because Richrap didn t build a 3DR with bushing at that time, I thought this part is untested and is a beta. So I took the seconde one for LMU. As far as I can see, you also took this seconde carriage. So I don t see any big potential for failure here, just a small correction in your firmware:

Instead of guessing, you could replace some parts one by one until you discover which one was faulty. I mean:

1. Measure the diameter of the plastic spool you have printed and check if they are identical. Then update your firmware with this information. The firmware is calculating the steps value based on this diameter. If it is wrong, the steps are wrong. If they are not all the same, guess what could happen.

2. Eleminate these printed joints. Make it simple, take a 4 mm threaded rod (1$/m), cut and screw them into Traxxas Rod Ends 5347 (12 / $6.95). You don t need anything else. Use a jig to be sure they are all the same length. The carriage and the effector you are using have 2 mm holes, either you enlarge the hole (as I did) or change it in CAD and print new one. I know, carbon rods are lighter and allows higher speeds, but I think at this stage you are looking for a working printer.

3. If the above didn t help, replace the spectra line with GT2 Belts and pulley. The alu spool for spectra is an option but for me not the best.

Good luck!

video of my 3DR

Richrap provided two kind of carriage, one for LMU and one for bushing. I printed the one for bushing but soon I saw there is a little problem with it. It doesn t fit good and because Richrap didn t build a 3DR with bushing at that time, I thought this part is untested and is a beta. So I took the seconde one for LMU. As far as I can see, you also took this seconde carriage. So I don t see any big potential for failure here, just a small correction in your firmware:

// Horizontal offset of the universal joints on the carriages. (This is measured from the edge of the M6mm Rod to the cent of universal joint, 14mm on Mini Delta (3DR) #define DELTA_CARRIAGE_OFFSET 14.0 // mm // Was 25.0 // mm This you may need to change if you are using a different linear bearing / rod size / bushing / or a modified carriage design. If not, 14.0mm should be correct for 3DR using normal carriages and LU6UU bearings.code source

Instead of guessing, you could replace some parts one by one until you discover which one was faulty. I mean:

1. Measure the diameter of the plastic spool you have printed and check if they are identical. Then update your firmware with this information. The firmware is calculating the steps value based on this diameter. If it is wrong, the steps are wrong. If they are not all the same, guess what could happen.

2. Eleminate these printed joints. Make it simple, take a 4 mm threaded rod (1$/m), cut and screw them into Traxxas Rod Ends 5347 (12 / $6.95). You don t need anything else. Use a jig to be sure they are all the same length. The carriage and the effector you are using have 2 mm holes, either you enlarge the hole (as I did) or change it in CAD and print new one. I know, carbon rods are lighter and allows higher speeds, but I think at this stage you are looking for a working printer.

3. If the above didn t help, replace the spectra line with GT2 Belts and pulley. The alu spool for spectra is an option but for me not the best.

Good luck!

video of my 3DR

|

Re: RepRap 3DR Delta printer Released April 14, 2014 10:59AM |

Registered: 10 years ago Posts: 63 |

>> @HaDe I saw you also complained about slippage in the spools, how did you solve it? <<

Guess I wrote about that in the list already but the problem was that the three original length clamping screws turned out to be too short. Alas PLA is not a good material for load-bearing applications because of its creep properties, so the spool would expand from the clamping screws tension and finally slip on the motor axle even with screws fully tightened. The solution was simple: use longer screws :-) No problems ever since.

Guess I wrote about that in the list already but the problem was that the three original length clamping screws turned out to be too short. Alas PLA is not a good material for load-bearing applications because of its creep properties, so the spool would expand from the clamping screws tension and finally slip on the motor axle even with screws fully tightened. The solution was simple: use longer screws :-) No problems ever since.

|

Re: RepRap 3DR Delta printer Released May 23, 2014 06:18AM |

Registered: 13 years ago Posts: 79 |

|

Re: RepRap 3DR Delta printer Released June 02, 2014 10:47PM |

Registered: 11 years ago Posts: 364 |

i finally managed to complete my 3dr delta after almost 4 months,,, I replaced my spools with aluminum ones .. the rest of the specs are stock ... There 2 issues i am still not able to solve...

1. The calibration cube is 0.2 mm bigger in y and 0.5 mm in z direction ... how do you correct this??

2. when the cooling fan (80 mm fan mounted on the side) comes on the j-head looses temperature by almost 30 degrees... i tried insulating it with ceramic tape on the sides but it still looses temperature... anybody facing this issue?

1. The calibration cube is 0.2 mm bigger in y and 0.5 mm in z direction ... how do you correct this??

2. when the cooling fan (80 mm fan mounted on the side) comes on the j-head looses temperature by almost 30 degrees... i tried insulating it with ceramic tape on the sides but it still looses temperature... anybody facing this issue?

|

Re: RepRap 3DR Delta printer Released June 03, 2014 07:03PM |

Registered: 10 years ago Posts: 13 |

@ekaggrat

about 1. Have you calibrated the steps/mm of each carriage? I usually calibrate it by measuring how much the carriage is lowered with a digital caliper with the effector as close as possible to each tower. Close to a tower, z movement error is due to that tower's carriage movement error, errors on other carriage movements create x and y errors, but not z errors.

about 1. Have you calibrated the steps/mm of each carriage? I usually calibrate it by measuring how much the carriage is lowered with a digital caliper with the effector as close as possible to each tower. Close to a tower, z movement error is due to that tower's carriage movement error, errors on other carriage movements create x and y errors, but not z errors.

|

Re: RepRap 3DR Delta printer Released June 03, 2014 11:49PM |

Registered: 11 years ago Posts: 364 |

@payala

I calibrated the steps by centering the carriage and then moving along z axis by 100 mm... and the steps are very close to 100 mm.... is there a formula to calulate the steps per mm from the spool diameter? i am using aluminum spools and they measure 18.3 mm diameter exactly. and the spectra cord is 0.7mm in diameter....

I calibrated the steps by centering the carriage and then moving along z axis by 100 mm... and the steps are very close to 100 mm.... is there a formula to calulate the steps per mm from the spool diameter? i am using aluminum spools and they measure 18.3 mm diameter exactly. and the spectra cord is 0.7mm in diameter....

|

Re: RepRap 3DR Delta printer Released June 04, 2014 03:31PM |

Registered: 10 years ago Posts: 13 |

@ekaggrat

Yes, but the problem is that when you do it like that (with the effector centered) errors in one carriage can compensate errors from other carriages, becoming into x and/or y errors and not being very visible in a z measurement. That is why it is a better method to to that with the effector close to each tower, so you isolate each carriage's movement. About the formula, of course you can calculate it, but I think there will always be some error due to different diameters, line tension, etc. Maybe it is not significant, I haven't gone into the detail of calculating the influence, but I can give you the values I have after calibrating each tower so you get an idea of the differences that are possible:

#define DEFAULT_AXIS_STEPS_PER_UNIT {53.015, 53.270, 52.512, 511}

@hercek

Thanks again for your insight with my problem, I have finally adjusted the printer and it is working fine. Initially I tried with your Maxima notebook and while I did get some results initially, after building a z-probe and trying again, I got to a point where I couldn't get the notebook to solve properly and was giving me some errors. I tried RichCattel's Marlin autotuning, but it didn't converge either. But it was a good working base to modify and do some further tests.

My next step, and one I'm pretty happy with was that I implemented a genetic algorithm python script to tune the printer. It worked very well and adjusted the geometry in the way you predicted. Actually it was a nice solution for me because not having a lot of time I implemented the script and left it running continuously while I continued with my busy life. But it did take a long time to find a good solution, genetic algorithms are solid, but slow.

However, there still was a 0.2mm error on the opposite of each tower that I couldn't get rid of... and it was all due to the fact that in that position, the geometry of the rods is less robust than inside of the triangle formed by the towers. So, some flexing was happening because I had an endstop based z-probe. So, I think a good tip with delta printers, or at least with the 3DR is to use a z-probe with hall effect sensor. I know someone will ask which endstop did I use, so it is an Omron D2F-F.

By the way, in the end my z-tower is 2.02mm away from the center.

Yes, but the problem is that when you do it like that (with the effector centered) errors in one carriage can compensate errors from other carriages, becoming into x and/or y errors and not being very visible in a z measurement. That is why it is a better method to to that with the effector close to each tower, so you isolate each carriage's movement. About the formula, of course you can calculate it, but I think there will always be some error due to different diameters, line tension, etc. Maybe it is not significant, I haven't gone into the detail of calculating the influence, but I can give you the values I have after calibrating each tower so you get an idea of the differences that are possible:

#define DEFAULT_AXIS_STEPS_PER_UNIT {53.015, 53.270, 52.512, 511}

@hercek

Thanks again for your insight with my problem, I have finally adjusted the printer and it is working fine. Initially I tried with your Maxima notebook and while I did get some results initially, after building a z-probe and trying again, I got to a point where I couldn't get the notebook to solve properly and was giving me some errors. I tried RichCattel's Marlin autotuning, but it didn't converge either. But it was a good working base to modify and do some further tests.

My next step, and one I'm pretty happy with was that I implemented a genetic algorithm python script to tune the printer. It worked very well and adjusted the geometry in the way you predicted. Actually it was a nice solution for me because not having a lot of time I implemented the script and left it running continuously while I continued with my busy life. But it did take a long time to find a good solution, genetic algorithms are solid, but slow.

However, there still was a 0.2mm error on the opposite of each tower that I couldn't get rid of... and it was all due to the fact that in that position, the geometry of the rods is less robust than inside of the triangle formed by the towers. So, some flexing was happening because I had an endstop based z-probe. So, I think a good tip with delta printers, or at least with the 3DR is to use a z-probe with hall effect sensor. I know someone will ask which endstop did I use, so it is an Omron D2F-F.

By the way, in the end my z-tower is 2.02mm away from the center.

|

Re: RepRap 3DR Delta printer Released June 06, 2014 03:15AM |

Registered: 11 years ago Posts: 24 |

|

Re: RepRap 3DR Delta printer Released August 07, 2014 07:36PM |

Registered: 9 years ago Posts: 14 |

Hey guys I just finished building my 3DR and i have a question for you guys: I'm using repetier host, and after i home the machine my z value reads correct(219 mm) But my x and y values are at like 85 mm and -85 mm. I think this is my problem because whenever i try to print the machine extends in a direction too far and doesn't stop until I power it down/ cancel the print. Ant thoughts? I'm sure its just something I am missing. Thanks

|

Re: RepRap 3DR Delta printer Released August 08, 2014 01:22PM |

Registered: 12 years ago Posts: 972 |

|

Re: RepRap 3DR Delta printer Released August 08, 2014 02:11PM |

Registered: 9 years ago Posts: 14 |

Quote

misan

First thing is to tell your slicing software to position the parts at 0,0 (not at 100,100 like many cartesian printers with 200x200mm beds).

But when you home your printer x and y should be at 0,0.... what firmware are you using? have you tried starting with Richard's?

How do i tell my slicer to do that? I am using slic3r

|

Re: RepRap 3DR Delta printer Released August 08, 2014 04:23PM |

Registered: 12 years ago Posts: 972 |

Have a look at printer settings [manual.slic3r.org]

Edited 1 time(s). Last edit at 08/08/2014 04:27PM by misan.

Edited 1 time(s). Last edit at 08/08/2014 04:27PM by misan.

|

Re: RepRap 3DR Delta printer Released August 08, 2014 07:30PM |

Registered: 9 years ago Posts: 14 |

|

3DR Delta printer and Melzi V2.0 August 16, 2014 06:59AM |

Registered: 10 years ago Posts: 5 |

Hi everyone

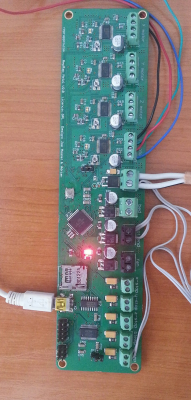

Just finish mechanical part of build and go to use firmware on Melzi V2.0 and have a strange issue....

My extruder, extrude a 1/5 (or reverse the same) of length given through Printrun. Also - speed is so slow.....even i say 350 mm/min.

Here are some pictures to.....

Any help will be appreciated

Just finish mechanical part of build and go to use firmware on Melzi V2.0 and have a strange issue....

My extruder, extrude a 1/5 (or reverse the same) of length given through Printrun. Also - speed is so slow.....even i say 350 mm/min.

Here are some pictures to.....

Any help will be appreciated

|

Re: 3DR Delta printer and Melzi V2.0 August 18, 2014 10:25AM |

Registered: 9 years ago Posts: 42 |

|

Re: 3DR Delta printer and Melzi V2.0 August 18, 2014 10:54AM |

Registered: 10 years ago Posts: 13 |

|

Re: 3DR Delta printer and Melzi V2.0 August 19, 2014 02:49PM |

Registered: 10 years ago Posts: 5 |

|

Re: RepRap 3DR Delta printer Released August 20, 2014 11:50AM |

Registered: 10 years ago Posts: 5 |

Update about my last situation.....

The problem with extruder is resolved.

Main mechanical problems are resolved to, but.....

When i begin to print, on brim and on first level everything going fine and on second level.....in time to time the filament stop to go through extruder! Some strange voice there is available to....like a stop to go out from nozzle and motor fight to push the filament out!

Any advices or shared experiences?

Thank you in advance!

The problem with extruder is resolved.

Main mechanical problems are resolved to, but.....

When i begin to print, on brim and on first level everything going fine and on second level.....in time to time the filament stop to go through extruder! Some strange voice there is available to....like a stop to go out from nozzle and motor fight to push the filament out!

Any advices or shared experiences?

Thank you in advance!

|

Re: RepRap 3DR Delta printer Released August 24, 2014 05:46PM |

Registered: 10 years ago Posts: 28 |

Hi, My name is Andrea and I have built a 3DR over the last months. I am about finished, now I have FSR auto bed levelling, fully graphic smart display. I printed the parts myself with my Mendel90, a kit bought from Nophead and built last year. I want to share my experience with the community, hoping it will be of help for users that are starting to build one and hopefully to get some advice from more experienced users on some issues I have.

To start off I had a problem with the pushrods. I build them 150mm but this was enough only to print 130mm, over that the traxxas joint would be at its most angled position and would not go further. my solution was to rebuild them with a longer rod. I fist started with 220mm, but it was too long, I then rebuild another set 200mm. these work fine, the only drawback is the max Z is not reduced to 140mm.

I added the FSR bed levelling, using ZMIN endstop connection. to increase the response I built 3 bed supports with integrated pods to increase the sensitivity of the sensors. (http://www.thingiverse.com/thing:439852). to get them to work I modified the FSR version of marlin from Johann (http://github.com/jcrocholl/Marlin/tree/fsr).

I had troubles with the printer stuttering during moves, creating blobs in the print. After googling it seems like the RUMBA board is a little underpowered to drive a fully graphic LCD while doing the math to keep the delta running, I "kinda" solver the issue lowering the DELTA_SEGMENTS_PER_SECOND to 50, but this figure seems a little low.

I initially started the project wanting to use 3mm filament as I have a good stock, but this failed due to the difficulties to force tightly wound filament into the bowden tube. so I switched to 1.75, bought some filament and a J-HEAD for 1.75mm filament. I ended up with another problem, even worse than before... for some reason that I have yet to figure out, the filament is very hard to push out of the nozzle, even at 230°C, so I can only print at incredibly low speeds (<10mm/s), otherwise the extruder slips. I use the geared extruder that was included with the 3DR files, and I do not understand why this happens. I am thinking either a defective J-HEAD or a bad filament. I bought both on RepRapWorld, and the filament I got was 1 spool red and 1 spool gold. even printing very slow is a problem, the pressure on the filament becomes so big that ooze is unacceptable. I tried putting back on the 3mm J-HEAD I bought from NOPHEAD, with some faberdashery filament and it works better, even if the ooze is still present (retraction 3mm)... and this one has a .4mm nozzle, while the RRW one has a .5 nozzle. maybe the nozzle is smaller than what was declared? how do I measure a 0.5 or smaller hole?

So, while I look for some solution for the above problem, I am also looking for a neat fan solution, to cool down PLA while printing and keep the J-HEAD from clogging during long prints. (I am really thinking of getting a E3D V6...)

so this is my story so far, any suggestion or comment is greatly appreciated.

To start off I had a problem with the pushrods. I build them 150mm but this was enough only to print 130mm, over that the traxxas joint would be at its most angled position and would not go further. my solution was to rebuild them with a longer rod. I fist started with 220mm, but it was too long, I then rebuild another set 200mm. these work fine, the only drawback is the max Z is not reduced to 140mm.

I added the FSR bed levelling, using ZMIN endstop connection. to increase the response I built 3 bed supports with integrated pods to increase the sensitivity of the sensors. (http://www.thingiverse.com/thing:439852). to get them to work I modified the FSR version of marlin from Johann (http://github.com/jcrocholl/Marlin/tree/fsr).

I had troubles with the printer stuttering during moves, creating blobs in the print. After googling it seems like the RUMBA board is a little underpowered to drive a fully graphic LCD while doing the math to keep the delta running, I "kinda" solver the issue lowering the DELTA_SEGMENTS_PER_SECOND to 50, but this figure seems a little low.

I initially started the project wanting to use 3mm filament as I have a good stock, but this failed due to the difficulties to force tightly wound filament into the bowden tube. so I switched to 1.75, bought some filament and a J-HEAD for 1.75mm filament. I ended up with another problem, even worse than before... for some reason that I have yet to figure out, the filament is very hard to push out of the nozzle, even at 230°C, so I can only print at incredibly low speeds (<10mm/s), otherwise the extruder slips. I use the geared extruder that was included with the 3DR files, and I do not understand why this happens. I am thinking either a defective J-HEAD or a bad filament. I bought both on RepRapWorld, and the filament I got was 1 spool red and 1 spool gold. even printing very slow is a problem, the pressure on the filament becomes so big that ooze is unacceptable. I tried putting back on the 3mm J-HEAD I bought from NOPHEAD, with some faberdashery filament and it works better, even if the ooze is still present (retraction 3mm)... and this one has a .4mm nozzle, while the RRW one has a .5 nozzle. maybe the nozzle is smaller than what was declared? how do I measure a 0.5 or smaller hole?

So, while I look for some solution for the above problem, I am also looking for a neat fan solution, to cool down PLA while printing and keep the J-HEAD from clogging during long prints. (I am really thinking of getting a E3D V6...)

so this is my story so far, any suggestion or comment is greatly appreciated.

|

Re: RepRap 3DR Delta printer Released August 24, 2014 06:07PM |

Registered: 10 years ago Posts: 13 |

Wow Andrea, congratulations and welcome!

It's good that you say about the stuttering, I also had noticed that, but I hadn't tracked it down. I'll try what you suggest, and maybe we should start talking about a more powerful platform...

About the J-Head, I had the same problems, a lot of force required to push the 1.75mm filament. I also had some leakage problems on the J-Head which I managed to solve, but it never worked as it should. I contacted Brian, and he tried to help me to solve the leakage, but never offered to change the extruder for the stuck extruder. So I gave up and I made an E3D and it has been working MUCH nicer! The one single thing that I have seen to improve results is the extruder orifice length, it should be around 0.5mm (the depth, not the diameter) if you have the slightest (0.5mm) more, it takes a lot more force to extrude. I think the E3D V6 will probably work very well too.

By the way, for me, the best way to measure the extruder orifice diameter, is to insert a small drill bit of the same size. But it is not very common to have a set of sub 1mm drills.

Cheers!

It's good that you say about the stuttering, I also had noticed that, but I hadn't tracked it down. I'll try what you suggest, and maybe we should start talking about a more powerful platform...

About the J-Head, I had the same problems, a lot of force required to push the 1.75mm filament. I also had some leakage problems on the J-Head which I managed to solve, but it never worked as it should. I contacted Brian, and he tried to help me to solve the leakage, but never offered to change the extruder for the stuck extruder. So I gave up and I made an E3D and it has been working MUCH nicer! The one single thing that I have seen to improve results is the extruder orifice length, it should be around 0.5mm (the depth, not the diameter) if you have the slightest (0.5mm) more, it takes a lot more force to extrude. I think the E3D V6 will probably work very well too.

By the way, for me, the best way to measure the extruder orifice diameter, is to insert a small drill bit of the same size. But it is not very common to have a set of sub 1mm drills.

Cheers!

|

Re: RepRap 3DR Delta printer Released August 24, 2014 11:38PM |

Registered: 11 years ago Posts: 364 |

@andrea

even for me after struggling with a j-head requiring too much force i change the extruder to a mk8 drive wheel which solved the problem to a great extent but too be on a safer side i am going to change my j-head to a E3d v6 as soon as i recieve it.. I have a self built shorter e3d (35mm length ) working on my mendelmax and that made a huge difference to the print quality from a clone j-head ..

if by any chance you are using one of the clone chinese j-heads just throw them out of the window. They are not worth the waste of time and filament.

even for me after struggling with a j-head requiring too much force i change the extruder to a mk8 drive wheel which solved the problem to a great extent but too be on a safer side i am going to change my j-head to a E3d v6 as soon as i recieve it.. I have a self built shorter e3d (35mm length ) working on my mendelmax and that made a huge difference to the print quality from a clone j-head ..

if by any chance you are using one of the clone chinese j-heads just throw them out of the window. They are not worth the waste of time and filament.

|

Re: RepRap 3DR Delta printer Released August 25, 2014 05:12PM |

Registered: 10 years ago Posts: 28 |

today I contacted the tech support at RRW and they have suggested to try a manual extrusion with just the heating block. I started cleaning the hot end by heating it up to 230° and then pushing out all the filament using compressed air: at 6 bars the pressure could barely push out the residue, something like 1mm of extrusion every 5 seconds. yesterday I did the same thing with a J-HEAD from NOPHEAD's kit and it just blew all the residue plastics out in a matter of 10 seconds. indeed the printer works much better with NOPHEAD's j-head, so I think there is indeed something different between the 2. the explanation of the longer nozzle makes sense, as from what I read on this forum, the longer calibrated diameter makes it for less die swell, at the expenses of a higher extrusion force.

indeed I remeasured the extruded thread and found to be 0.5-0.51mm... today at work I also measured the nozzle, and found it to be 0.498, so die swell is really limited.

to reduce the nozzle length I could use a 2mm drill bit to shorten the 0.5mm hole to about 0.5mm, but I believe the risk of passing on the other side is high.

on the other hand I have a cart at E3D webstor filled with 1 kit, 2 extra nozzles and a spare heat barrier, just waiting to click enter.... its more that £100 and I'm a little reluctant to spend all that money for an hot end, but I'm really tempted...

by the way, If anyone is interested, here a video of the auto bed levelling with FSR...

[www.youtube.com]

indeed I remeasured the extruded thread and found to be 0.5-0.51mm... today at work I also measured the nozzle, and found it to be 0.498, so die swell is really limited.

to reduce the nozzle length I could use a 2mm drill bit to shorten the 0.5mm hole to about 0.5mm, but I believe the risk of passing on the other side is high.

on the other hand I have a cart at E3D webstor filled with 1 kit, 2 extra nozzles and a spare heat barrier, just waiting to click enter.... its more that £100 and I'm a little reluctant to spend all that money for an hot end, but I'm really tempted...

by the way, If anyone is interested, here a video of the auto bed levelling with FSR...

[www.youtube.com]

|

Re: RepRap 3DR Delta printer Released August 26, 2014 05:20AM |

Registered: 10 years ago Posts: 28 |

@payala

I checked today the spare nozzle I bought along with the hotend, which should be identical to the one installed...

the length of the 0.5 orifice is 1.96mm, so it's out of the specs found on (http://reprap.org/wiki/J_Head_Nozzle). in that page it says:

tonight I am going to drill the 2mm hole a little further to allow the orifice length to be reduced to 0.5mm and create a flat of about 1.2 mm. I'll report back if that worked.

A.

I checked today the spare nozzle I bought along with the hotend, which should be identical to the one installed...

the length of the 0.5 orifice is 1.96mm, so it's out of the specs found on (http://reprap.org/wiki/J_Head_Nozzle). in that page it says:

moreover, it's missing the 1.28 mm flat part around the orifice, so it practically ends with a sharp point with a flat of only 0.7-0.8mm diameter.Quote

reprap.org, chapter 8.2.2

Nozzle orifice length

Mk IV hot-ends (up to the middle of May 2012), and earlier models, had a nozzle orifice length of approximately 1.25mm.

Mk IV hot-ends (after the middle of May 2012) and Mk V hot-ends have a nozzle orifice length of approximately 0.50mm.

Note: Due to the nature of 5c collets, the nozzle orifice length can vary as much as 0.25mm.

tonight I am going to drill the 2mm hole a little further to allow the orifice length to be reduced to 0.5mm and create a flat of about 1.2 mm. I'll report back if that worked.

A.

|

Re: RepRap 3DR Delta printer Released August 30, 2014 07:54PM |

Registered: 9 years ago Posts: 14 |

Hey guys I am still having trouble getting my extruder motor to turn. I connected the motor to one of the other axis and it turned fine, so then i switched stepper drivers and again it worked fine. So i am thinking maybe i didn't define the extruder pins on the board correctly? I am using rumba. Any ideas?

|

Re: RepRap 3DR Delta printer Released September 25, 2014 06:39PM |

Registered: 10 years ago Posts: 30 |

Hi,

Old thread is old. Let's see if someone with a 3DR still sticks around.

I have a question about the rod lengths and the traxxas (or similar) joints. Are you able to move the head right to the outer edge of the bed? With the swivel joints I have bought, I can only move it to approx. 20mm away from the outer edge thus loosing build volume. That's due to the movement angle of the joints. So to put it short - with wich kind of joints (and rod lengths) are you able to move to the head to the outer edge of the bed?

Thanks.

Stefan

Old thread is old. Let's see if someone with a 3DR still sticks around.

I have a question about the rod lengths and the traxxas (or similar) joints. Are you able to move the head right to the outer edge of the bed? With the swivel joints I have bought, I can only move it to approx. 20mm away from the outer edge thus loosing build volume. That's due to the movement angle of the joints. So to put it short - with wich kind of joints (and rod lengths) are you able to move to the head to the outer edge of the bed?

Thanks.

Stefan

|

Re: RepRap 3DR Delta printer Released September 26, 2014 04:58PM |

Registered: 10 years ago Posts: 28 |

Sorry, only registered users may post in this forum.