3DR "Simple" Delta Printer

Posted by JohnSL

|

3DR "Simple" Delta Printer September 12, 2013 11:42AM |

Registered: 10 years ago Posts: 110 |

I have a Printrbot Simple I haven't used since I got my MendelMax 2.0 up and running. So I've been thinking about what to do with it. Then RichRap introduced his 3DR printer. I thought this would be a lot of fun to build, and figured I'd use the vitamins from my Simple for the new delta.

RichRap's delta uses 6mm rods, and the Simple uses 8mm rods, which means I have eight LM8UU bearings. I thought about just buying new LM6UU bearings and being done with it. But I like to design things, so I thought I'd modify his designs to work with 8mm rods.

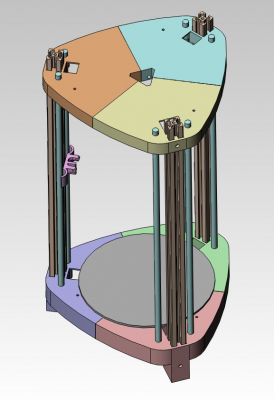

Well, I much prefer to work in SolidWorks than in Sketchup, so I figured I would build new parts from scratch for the top and bottom, and the carriage. The idea is to use all of his other parts without modification. Well, I couldn't leave well enough alone. I figured that since I was designing new parts, I could also change from straight lines to curves. Here is what I have so far:

Edited 2 time(s). Last edit at 09/12/2013 03:54PM by JohnSL.

RichRap's delta uses 6mm rods, and the Simple uses 8mm rods, which means I have eight LM8UU bearings. I thought about just buying new LM6UU bearings and being done with it. But I like to design things, so I thought I'd modify his designs to work with 8mm rods.

Well, I much prefer to work in SolidWorks than in Sketchup, so I figured I would build new parts from scratch for the top and bottom, and the carriage. The idea is to use all of his other parts without modification. Well, I couldn't leave well enough alone. I figured that since I was designing new parts, I could also change from straight lines to curves. Here is what I have so far:

Edited 2 time(s). Last edit at 09/12/2013 03:54PM by JohnSL.

|

Re: 3DR "Simple" Delta Printer September 12, 2013 09:04PM |

Admin Registered: 15 years ago Posts: 1,470 |

Looking good

Are you planning on using spectra or belts?

Are you planning on using spectra or belts?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: 3DR "Simple" Delta Printer September 13, 2013 01:07AM |

Registered: 10 years ago Posts: 110 |

I'm planning on using RichRap's drive system, which uses spectra line.

As it happens, the donor Printrbot Simple also uses spectra line, but I won't be reusing it's line because it's too short. I'm also thinking about using the Printrbot Simple's extruder, modified as a Bowden, to keep more of the Simple in this design. It just seems more fun that way.

As it happens, the donor Printrbot Simple also uses spectra line, but I won't be reusing it's line because it's too short. I'm also thinking about using the Printrbot Simple's extruder, modified as a Bowden, to keep more of the Simple in this design. It just seems more fun that way.

|

Re: 3DR "Simple" Delta Printer September 13, 2013 12:27PM |

Registered: 14 years ago Posts: 47 |

|

Re: 3DR "Simple" Delta Printer September 13, 2013 02:39PM |

Registered: 10 years ago Posts: 110 |

|

Re: 3DR "Simple" Delta Printer September 15, 2013 01:05PM |

Registered: 10 years ago Posts: 110 |

I'm working on the mounting brackets for the end stops, and I have a question for people. RichRap used hall-effect sensors, but reading some of the posts on this site, it sounds like micro switches would be plenty accurate enough. And the Kossel uses micro switches. Does anyone see any reason why I should switch to micro switches? They're certainly a lot easier to source, and they're less expensive.

|

Re: 3DR "Simple" Delta Printer September 17, 2013 02:05AM |

Registered: 10 years ago Posts: 219 |

as you call it a simple design, the you should also try to keep the BOM simple...

I have full faith in micoswitches, easy to source, low cost and proven reliability. Your design will find more friends if you dont use exotic parts. Then again, why not design an option so the builder could use microswitch, hall or opto as he wishes ? Maybe that is the best way and makes it even more universal. Just to integrate 3 endstop options.

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

I have full faith in micoswitches, easy to source, low cost and proven reliability. Your design will find more friends if you dont use exotic parts. Then again, why not design an option so the builder could use microswitch, hall or opto as he wishes ? Maybe that is the best way and makes it even more universal. Just to integrate 3 endstop options.

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

|

Re: 3DR "Simple" Delta Printer September 18, 2013 10:15PM |

Registered: 10 years ago Posts: 110 |

Thanks. I call it the "Simple" because I'm going to use a lot of the hardware from my Printrbot Simple to build this printer. But as you say, I can publish multiple versions of the parts, which I will do.

As an update, I have extrusions, rods, and bearings on the way. With any luck they'll arrive Friday or Saturday so I can start doing test builds this weekend.

As an update, I have extrusions, rods, and bearings on the way. With any luck they'll arrive Friday or Saturday so I can start doing test builds this weekend.

|

Re: 3DR "Simple" Delta Printer September 18, 2013 11:46PM |

Registered: 10 years ago Posts: 110 |

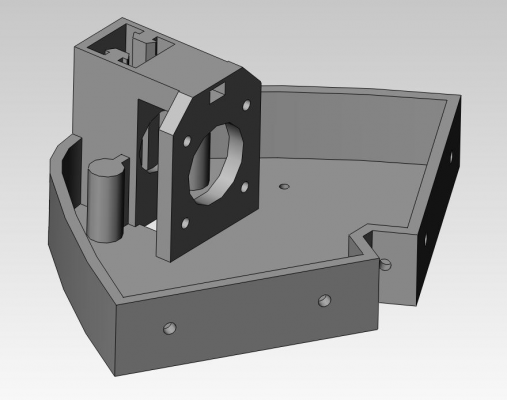

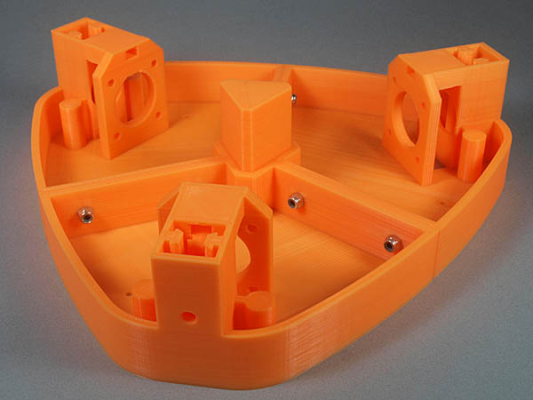

While I wait for my parts to arrive, here is how far I've gotten with the design for the top and bottom parts. I'm showing images from underneath these parts.

The bottom is probably close to being done:

RichRap had the walls near the center lower than the outside walls. I'm not sure why. It might have been to make it easier to get the stepper motors in and out. I'll try this out on a printed test part (which I'm currently printing) to see if I can tell why he did that.

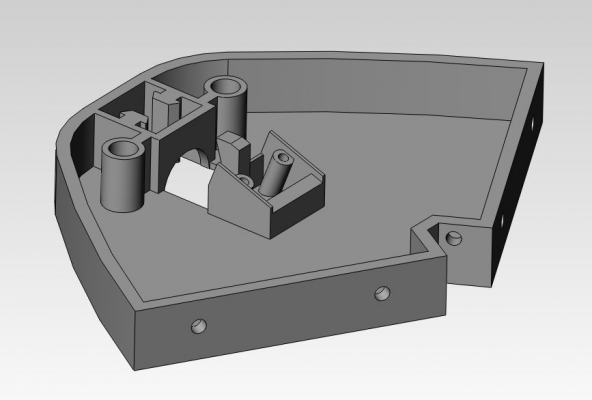

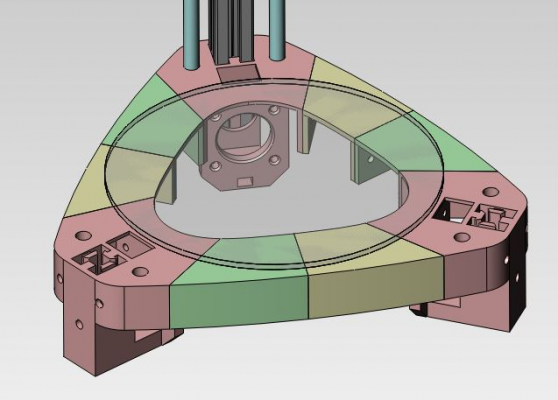

Here is what the underside of the top looks like:

As you can see, I don't have attachments yet for the printer boards. I was originally thinking I'd make them just for the Printrboard (from my Printrbot Simple). However I should be able to keep the ones he has in addition. That would allow several different choices of electronics. I also want to create a version of these parts designed for micro switches instead of the hall-effect sensors.

Edited 1 time(s). Last edit at 09/18/2013 11:51PM by JohnSL.

-- John

My Things: [www.thingiverse.com]

The bottom is probably close to being done:

RichRap had the walls near the center lower than the outside walls. I'm not sure why. It might have been to make it easier to get the stepper motors in and out. I'll try this out on a printed test part (which I'm currently printing) to see if I can tell why he did that.

Here is what the underside of the top looks like:

As you can see, I don't have attachments yet for the printer boards. I was originally thinking I'd make them just for the Printrboard (from my Printrbot Simple). However I should be able to keep the ones he has in addition. That would allow several different choices of electronics. I also want to create a version of these parts designed for micro switches instead of the hall-effect sensors.

Edited 1 time(s). Last edit at 09/18/2013 11:51PM by JohnSL.

-- John

My Things: [www.thingiverse.com]

|

Re: 3DR "Simple" Delta Printer September 21, 2013 12:40AM |

Registered: 10 years ago Posts: 110 |

My MendelMax 2.0 is having a child!

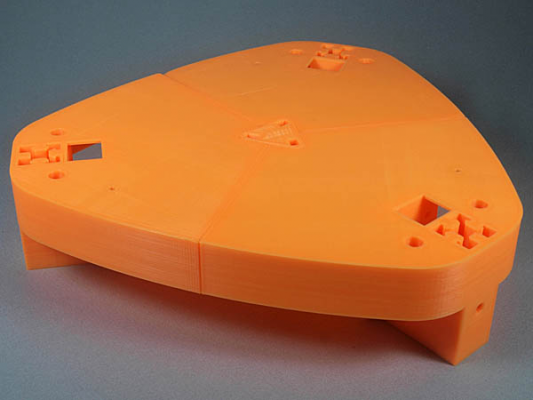

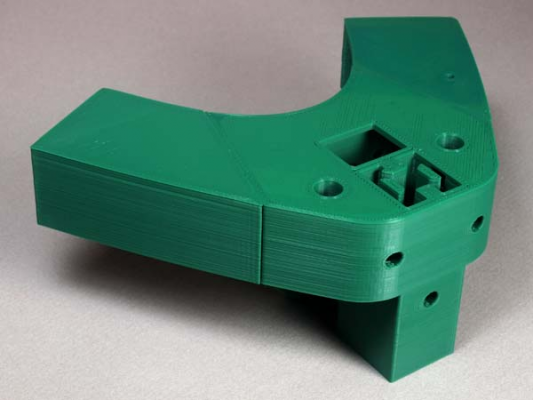

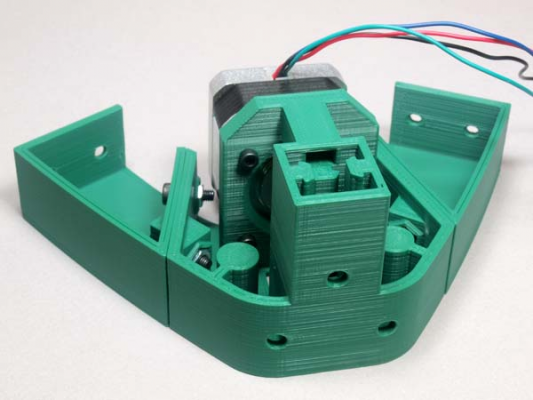

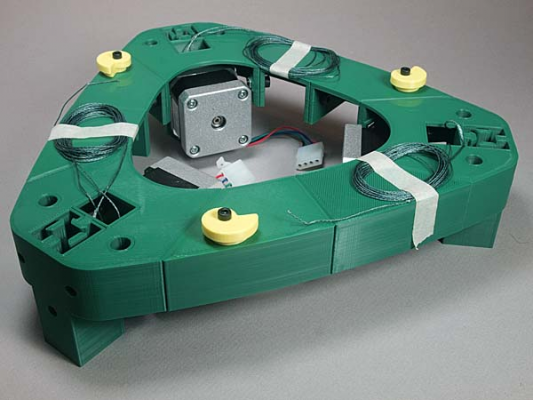

I've printed out a set of test parts for the bottom of the printer and assembled them to see how it's going to work out:

Everything fits well. The Misumi 20x20 extrusions fit perfectly, and the 8mm smooth rods fit perfectly. The next step is for me to pull the stepper motors out of the Printerbot Simple and install them.

I'm also thinking about making a couple of changes to the design. I can't figure out the advantage of having the triangular "foot" in the center. I don't think it's required for strength as these parts are already over-engineered, even though I cut back a little on the wall thickness from RichRap's design. So in my next iteration, I'm going to have the three parts meet in the middle, and remove the need for the triangular part.

I'm also want to adjust the curves a little--it's not quite as pleasing as I was hoping for.

Edited 4 time(s). Last edit at 09/21/2013 12:52AM by JohnSL.

I've printed out a set of test parts for the bottom of the printer and assembled them to see how it's going to work out:

Everything fits well. The Misumi 20x20 extrusions fit perfectly, and the 8mm smooth rods fit perfectly. The next step is for me to pull the stepper motors out of the Printerbot Simple and install them.

I'm also thinking about making a couple of changes to the design. I can't figure out the advantage of having the triangular "foot" in the center. I don't think it's required for strength as these parts are already over-engineered, even though I cut back a little on the wall thickness from RichRap's design. So in my next iteration, I'm going to have the three parts meet in the middle, and remove the need for the triangular part.

I'm also want to adjust the curves a little--it's not quite as pleasing as I was hoping for.

Edited 4 time(s). Last edit at 09/21/2013 12:52AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer September 25, 2013 10:04PM |

Registered: 10 years ago Posts: 31 |

i got suckered into buying a printrbot simple. i was wondering if i could use the simple to print all the parts for your "simple delta" model? or is the simple's bed too small?

On another note i can't seem to get the simple to print properly, is there some trick to the calibration i'm missing?

On another note i can't seem to get the simple to print properly, is there some trick to the calibration i'm missing?

|

Re: 3DR "Simple" Delta Printer September 26, 2013 09:04PM |

Registered: 10 years ago Posts: 110 |

ProfessorBean, the stock simple's print area of 4" x 4" is too small to print the parts for this delta, unfortunately. I've been doing some thinking about this, and I might do something like the "buy it forward" program that exists for the Kossel Mini where I send out some sets of parts to people who in turn agree to make two sets of parts and send them out after they get their printer running. In fact, I discovered that the parts I'd printed were too large to be printed on the 3DR, so I've redesigned them so they can be self replicating.

As to getting the Simple printing well, your best source of information is the Printrbot forum. Here is a thread that might help you get started:

[www.printrbottalk.com]

As to getting the Simple printing well, your best source of information is the Printrbot forum. Here is a thread that might help you get started:

[www.printrbottalk.com]

|

Re: 3DR "Simple" Delta Printer September 27, 2013 12:36AM |

Registered: 10 years ago Posts: 110 |

Since I'm not getting much dialog here, and I created a longer blog post documenting my progress. Here is my first blog post:

[trains.socha.com]

This pretty much covers what I've discussed above, but wordier.

I've received almost all the parts I need. Yet to arrive are the carbon fiber tubes. When I ordered them, I hadn't noticed that the expected delivery date is near the end of October. Woops. Since I needed some other hardeware from McMaster Carr, I added some 0.156" diameter carbon fiber tube (which comes out to about 3.9mm), which should work just fine with the Traxx joins I ordered (they have 4mm holes).

[trains.socha.com]

This pretty much covers what I've discussed above, but wordier.

I've received almost all the parts I need. Yet to arrive are the carbon fiber tubes. When I ordered them, I hadn't noticed that the expected delivery date is near the end of October. Woops. Since I needed some other hardeware from McMaster Carr, I added some 0.156" diameter carbon fiber tube (which comes out to about 3.9mm), which should work just fine with the Traxx joins I ordered (they have 4mm holes).

|

Re: 3DR "Simple" Delta Printer September 27, 2013 06:27PM |

Registered: 10 years ago Posts: 46 |

|

Re: 3DR "Simple" Delta Printer September 28, 2013 12:02AM |

Registered: 10 years ago Posts: 110 |

Masnachu, thanks for letting me know.

Now that I've been sourcing parts, I'm getting a better appreciation of why it's taking a while to see more of the 3DR printers in the wild. I just about have all the parts I need to build this. I'm about to print a final test part for the bottom pieces, and if it goes well, I'll print a set of bottom parts and assemble the bottom.

Now that I've been sourcing parts, I'm getting a better appreciation of why it's taking a while to see more of the 3DR printers in the wild. I just about have all the parts I need to build this. I'm about to print a final test part for the bottom pieces, and if it goes well, I'll print a set of bottom parts and assemble the bottom.

|

Re: 3DR "Simple" Delta Printer September 28, 2013 05:12AM |

Registered: 10 years ago Posts: 31 |

Thanks John, I'll be keeping an eye on all your pages, if you figure out how to cut up the pieces so they will fit on the simple's print bed do let us know. I have one of the "newer" simples with the direct drive extruder.... I think I might try a Bowden extruder for the simple to see if I can't get it to print true circles instead of the slight oval I'm getting now. makes it tough to "replicate" a 3d printer when none of the holes are round...lol

on a side note I was attempting to modify a delta parts file, it prints the delta's "arms" in two pieces and you just bolt it back together, it fits on the simples print bed... so far I haven't been able to get one to print. however if there were some way to print just the stepper motor holders, those should fit on the 4x4 bed, print a matching set of "feet" for the bottom then print bolt together supports that fit in notches on the feet and holders, really the 8mm rod would do a good job of supporting it so all you'd need is some kind of "Exo skeleton" to keep everything centered, use the print bed it's self as the bottom, I have built several heated beds for my simple so cutting a chunk of aluminum and drilling a couple holes to bolt stuff too wouldn't bother me none. Then begin the "self replication" with that one. The key here is that I'd be recycling my simple and that makes my wallet hurt less.

on a side note I was attempting to modify a delta parts file, it prints the delta's "arms" in two pieces and you just bolt it back together, it fits on the simples print bed... so far I haven't been able to get one to print. however if there were some way to print just the stepper motor holders, those should fit on the 4x4 bed, print a matching set of "feet" for the bottom then print bolt together supports that fit in notches on the feet and holders, really the 8mm rod would do a good job of supporting it so all you'd need is some kind of "Exo skeleton" to keep everything centered, use the print bed it's self as the bottom, I have built several heated beds for my simple so cutting a chunk of aluminum and drilling a couple holes to bolt stuff too wouldn't bother me none. Then begin the "self replication" with that one. The key here is that I'd be recycling my simple and that makes my wallet hurt less.

|

Re: 3DR "Simple" Delta Printer September 28, 2013 12:05PM |

Registered: 10 years ago Posts: 110 |

ProfessorBean, that's an interesting point. I'm starting to think about how I could break the base pieces up into smaller pieces that bolt together. The 100mm x 100mm print area of the Printrbot Simple is really small for the base and top parts of the 3DR. I thought about making two halves that bolt to the 20x20 extrusions. However even that is too large for the 100mm bed on the Simple. It looks like I'd probably need to have one part that contained the extrusion, rod, and motor mounts. And then have bolt-on wings on either side to create the equivalent of one base piece. This probably wouldn't be as clean looking as the current design, but it would allow printing a 3DR "Simple"on a Printrbot Simple. And that would be cool.

My goal is to recycle a Printrbot Simple into a 3DR "Simple." Right now my bill of materials for the upgrade from a Simple to a 3DR Simple is at $130 US, which includes a 170mm diameter Borosillicate glass print bed ($25).

I'll have to play around with this :-). Thanks for the suggestion.

My goal is to recycle a Printrbot Simple into a 3DR "Simple." Right now my bill of materials for the upgrade from a Simple to a 3DR Simple is at $130 US, which includes a 170mm diameter Borosillicate glass print bed ($25).

I'll have to play around with this :-). Thanks for the suggestion.

|

Re: 3DR "Simple" Delta Printer September 29, 2013 12:54AM |

Registered: 10 years ago Posts: 110 |

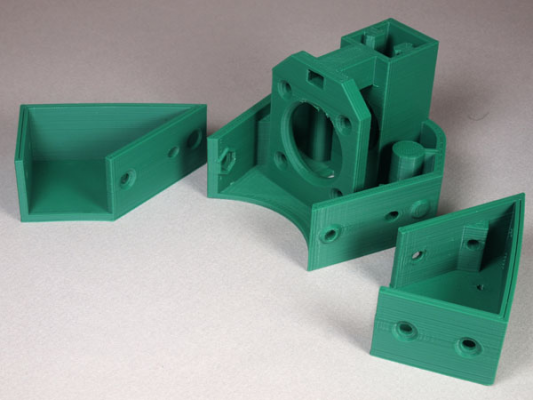

I've redesigned the base so the parts can be printed on a Printrbot Simple, which means all parts have to be less than 100mm x 100mm. This means there are now nine parts that make up the base instead of the previous three. Here is what the computer rendering looks like:

I'm currently printing out a set of three parts so I can build one third of the base. If that goes well, I'll print out the parts for the entire base. It's certainly nice having a fast printer (the MendelMax 2.0) for doing these test prints.

Edited 1 time(s). Last edit at 09/29/2013 12:55AM by JohnSL.

I'm currently printing out a set of three parts so I can build one third of the base. If that goes well, I'll print out the parts for the entire base. It's certainly nice having a fast printer (the MendelMax 2.0) for doing these test prints.

Edited 1 time(s). Last edit at 09/29/2013 12:55AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer September 30, 2013 11:59PM |

Registered: 10 years ago Posts: 110 |

It's starting to come together. Yesterday I printed the three parts that make up a third of the base. I went through several iterations before the parts you see here, which are themselves not even final. I added alignment dimples and indentations between the three parts, which makes it really easy to assemble these parts perfectly. I also added nut indentations in so you don't need a wrench to assembly the parts. I'm pretty happy with how these turned out, so I'm printing the next generation of parts in order to assembly the second third of the base.

Edited 1 time(s). Last edit at 10/01/2013 12:00AM by JohnSL.

Edited 1 time(s). Last edit at 10/01/2013 12:00AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 01, 2013 01:40AM |

Registered: 10 years ago Posts: 31 |

That's AMASING! it's like you reached into my brain and pulled out exactly what I was imagining!

I am still fighting and arguing with my simple trying to convince it that printing a circle is WAY better than an oval, I'm making small steps towards a nice acceptable circle.... i hope to soon start printing the machine that will replace the simple used to print it, now that would be the ultimate replication, to turn a simple into a delta using the simple to print everything first.

I was wondering, do the holes and nut recesses match the hardware used to assemble the simple? If I didn't have to buy new nuts and bolts to assemble the new delta simple that would be the ultimate badassary!

I am still fighting and arguing with my simple trying to convince it that printing a circle is WAY better than an oval, I'm making small steps towards a nice acceptable circle.... i hope to soon start printing the machine that will replace the simple used to print it, now that would be the ultimate replication, to turn a simple into a delta using the simple to print everything first.

I was wondering, do the holes and nut recesses match the hardware used to assemble the simple? If I didn't have to buy new nuts and bolts to assemble the new delta simple that would be the ultimate badassary!

|

Re: 3DR "Simple" Delta Printer October 01, 2013 11:00PM |

Registered: 10 years ago Posts: 110 |

Thanks ProfessorBean!

There are some good posts on calibration on the Printrbottalk.com forums. Here are a couple that might help you:

[www.printrbottalk.com]

[www.printrbottalk.com]

The holes are for M4 screws and nuts. Whereas most of the screws and nuts on the simple are M3. I hadn't even though about using M3 hardware to connect the triangular pieces together since RichRap used M4 hardware. Darn you! Now I'm going to have to think about it now.

Edited 1 time(s). Last edit at 10/01/2013 11:00PM by JohnSL.

There are some good posts on calibration on the Printrbottalk.com forums. Here are a couple that might help you:

[www.printrbottalk.com]

[www.printrbottalk.com]

The holes are for M4 screws and nuts. Whereas most of the screws and nuts on the simple are M3. I hadn't even though about using M3 hardware to connect the triangular pieces together since RichRap used M4 hardware. Darn you! Now I'm going to have to think about it now.

Edited 1 time(s). Last edit at 10/01/2013 11:00PM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 02, 2013 02:39AM |

Registered: 10 years ago Posts: 31 |

@JohnSL

HA I have read and read and asked for assistance on the Printrbottalk forums and no one has yet to help me, so I just do trial and error stuff.

on another note, I am part native American and like my ancestors that killed an animal and used EVERY part of it, I am a fan of reusing EVERY part of the simple lol right down to the nuts and bolts, since you had already had an amazing idea to turn a simple into a delta, I figured I'd throw 2 cents at you and see what stuck. Haha. Now if I can incorporate a way to use the laser cut wood in the transmutation of a simple into a delta, well that would be super awesome, however I don't see any way to use that, for the time being anyways....

HA I have read and read and asked for assistance on the Printrbottalk forums and no one has yet to help me, so I just do trial and error stuff.

on another note, I am part native American and like my ancestors that killed an animal and used EVERY part of it, I am a fan of reusing EVERY part of the simple lol right down to the nuts and bolts, since you had already had an amazing idea to turn a simple into a delta, I figured I'd throw 2 cents at you and see what stuck. Haha. Now if I can incorporate a way to use the laser cut wood in the transmutation of a simple into a delta, well that would be super awesome, however I don't see any way to use that, for the time being anyways....

|

Re: 3DR "Simple" Delta Printer October 02, 2013 03:47PM |

Registered: 10 years ago Posts: 31 |

HAHA hilarious, I found the added weight of my heated bed that I added to my simple caused belt slippage on the Y axis when in printed in honeycomb pattern fill, plus caused the belt to slip on the Y, then the Y axis drove into the end stop switch and caused a wire to break off which caused a fault in the simple so everything works and the circles are round again. i am realy looking forward to upgrading the simple to a delta.

oh and is there an insert of some sorts that turns the round print surface square? I already have a 6x6 heated bed from printrbot currently being used on the simple, without a thermister, just a laser temperature finder and a fan to keep the bed at around 80 c ... lol sorry to keep adding options to your already, Swiss-army-knife level, delta 3d printer.

oh and is there an insert of some sorts that turns the round print surface square? I already have a 6x6 heated bed from printrbot currently being used on the simple, without a thermister, just a laser temperature finder and a fan to keep the bed at around 80 c ... lol sorry to keep adding options to your already, Swiss-army-knife level, delta 3d printer.

|

Re: 3DR "Simple" Delta Printer October 03, 2013 05:25AM |

Registered: 10 years ago Posts: 219 |

Looks very promising, just stick with your simple concept idea, once you publish your files, I will build one!

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

|

Re: 3DR "Simple" Delta Printer October 04, 2013 10:29PM |

Registered: 10 years ago Posts: 110 |

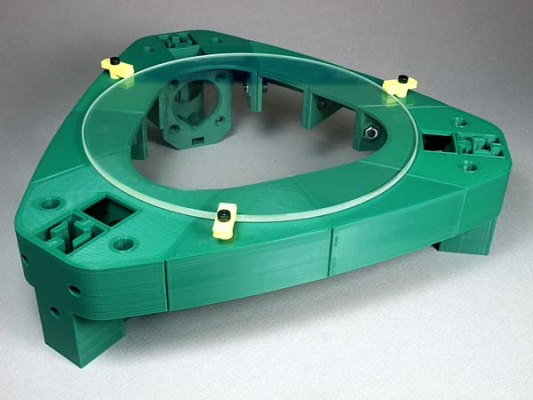

I'm making progress. I finished printing out and assembling all the parts for the base. I also received a 170mm diameter glass plate. The clips that hold on the bed are a little far away from the bed. So I either need to design longer clips, or I need to move the clip holes slightly closer to the center. The good news is that I only need to reprint three out of the nine parts that make up the base, so it won't take that long to print.

What do you think? Should I move the holes closer to the center, or design longer bed clips?

Edited 1 time(s). Last edit at 10/04/2013 10:29PM by JohnSL.

What do you think? Should I move the holes closer to the center, or design longer bed clips?

Edited 1 time(s). Last edit at 10/04/2013 10:29PM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 05, 2013 02:55AM |

Registered: 10 years ago Posts: 31 |

I say just add an extra clip to each side, so instead of having one on each side you use 2 one for each "wing", that would make the bed nice and solid, it is coming along nicely, I really like the design, that also makes it easier to replace damaged sections should a stepper motor over heat to the point it warps and/or melts the mount, or any other accidents that may happen and damage a section. Plus you can design a straight piece to bolt between each of the flat segments to increase the available print area, and to make it truly modular, make arms that hold the print head with parts that can be printed and bolted in to extend the arms, instead of having to reprint everything, you'd just print a few pieces.

Edited 4 time(s). Last edit at 10/05/2013 04:33AM by ProfessorBean.

Edited 4 time(s). Last edit at 10/05/2013 04:33AM by ProfessorBean.

|

Re: 3DR "Simple" Delta Printer October 05, 2013 05:23AM |

Registered: 10 years ago Posts: 46 |

looking good John

How about using slots instead of holes, that way bed clips are adjustable for what ever diameter bed people can get hold of locally ?

One side effect of designing for the Printrbot Simple, is that it makes it easier to print on the 3DR, making it a bit more reprap (I think dia of motor mount is about 150mm, making it a bit tight on 170mm dia bed, not sure mind haven't tried it)

How about using slots instead of holes, that way bed clips are adjustable for what ever diameter bed people can get hold of locally ?

One side effect of designing for the Printrbot Simple, is that it makes it easier to print on the 3DR, making it a bit more reprap (I think dia of motor mount is about 150mm, making it a bit tight on 170mm dia bed, not sure mind haven't tried it)

|

Re: 3DR "Simple" Delta Printer October 05, 2013 03:00PM |

Registered: 10 years ago Posts: 110 |

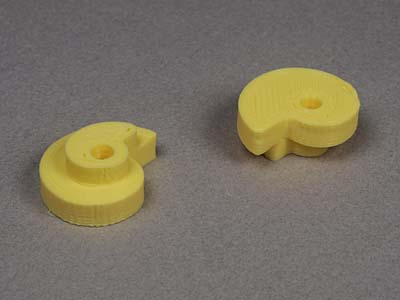

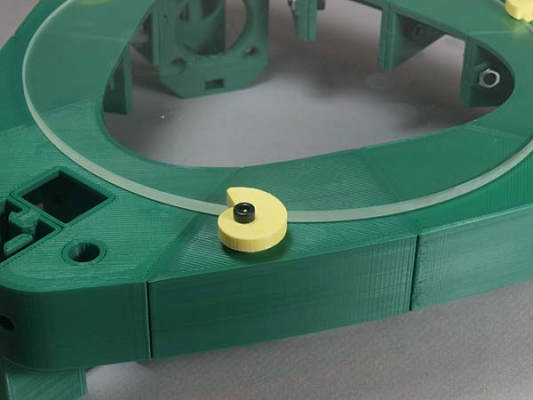

I came up with another idea:

The underside of the spiral pushes the glass toward the center, while the top clamps down on it.

I'm still playing around with the size of the spiral--I think I need to make it one or two mm larger in diameter (or at least the underside. But this works very nicely.

Edited 1 time(s). Last edit at 10/05/2013 03:03PM by JohnSL.

The underside of the spiral pushes the glass toward the center, while the top clamps down on it.

I'm still playing around with the size of the spiral--I think I need to make it one or two mm larger in diameter (or at least the underside. But this works very nicely.

Edited 1 time(s). Last edit at 10/05/2013 03:03PM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 05, 2013 03:47PM |

Registered: 10 years ago Posts: 31 |

|

Re: 3DR "Simple" Delta Printer October 07, 2013 12:35AM |

Registered: 10 years ago Posts: 110 |

@ProfessorBean, I'm almost ready to publish the first set of files. Just this morning I redid a couple parts on the base. I think the base pieces are ready to publish, but I'd like to assemble a little more of the printer before I'll be sure.

Speaking of publishing them, where would be the best place? Should I for RichRap's project on Github?

Yesterday I worked on mounting stepper motors with Spectra spools. The wires on the stepper motors weren't long enough to make it up to the top of the printer, which meant I needed to either spice the wires (like RichRap did), or add connectors on the bottom. I chose the latter, and purchased some 4-pin Molex connectors. These are crimp-on connectors, but just to be sure I added solder after crimping. Here is where things stand at the moment:

Edited 1 time(s). Last edit at 10/07/2013 12:35AM by JohnSL.

Speaking of publishing them, where would be the best place? Should I for RichRap's project on Github?

Yesterday I worked on mounting stepper motors with Spectra spools. The wires on the stepper motors weren't long enough to make it up to the top of the printer, which meant I needed to either spice the wires (like RichRap did), or add connectors on the bottom. I chose the latter, and purchased some 4-pin Molex connectors. These are crimp-on connectors, but just to be sure I added solder after crimping. Here is where things stand at the moment:

Edited 1 time(s). Last edit at 10/07/2013 12:35AM by JohnSL.

Sorry, only registered users may post in this forum.