3DR "Simple" Delta Printer

Posted by JohnSL

|

Re: 3DR "Simple" Delta Printer June 09, 2014 07:53AM |

Registered: 10 years ago Posts: 172 |

very nice!

I have finished reprinting my frame pieces and will begin moving everything over to the new frame. My previous frame pieces were not that great quality wise due to slicer and printer related issues. The new parts are some of the best parts I've ever made.

For what it's worth, I transitioned away from Kapton tape on glass to just hairspray on glass. The ABS sticks like mad when the plate is hot and just pops right off as it cools down. The surface finish is a nice matte finish and I had ZERO issues with warping because the first layer stuck so well to the hairspray/glass.

I have finished reprinting my frame pieces and will begin moving everything over to the new frame. My previous frame pieces were not that great quality wise due to slicer and printer related issues. The new parts are some of the best parts I've ever made.

For what it's worth, I transitioned away from Kapton tape on glass to just hairspray on glass. The ABS sticks like mad when the plate is hot and just pops right off as it cools down. The surface finish is a nice matte finish and I had ZERO issues with warping because the first layer stuck so well to the hairspray/glass.

|

Re: 3DR "Simple" Delta Printer June 09, 2014 03:46PM |

Registered: 14 years ago Posts: 27 |

Nice design!

Anyone had problems from slightly warped parts or too tight a fit?

My towers ended up slightly angled, since i had to force them into sockets.

Is that a common kind of problem with the design?

Maybe add some bolts to secure them in an initially more wobbly socket ala rostock (to allow for adjustments)?

The frame itself (4 bolt per link version) appear quite rigid, definitely more so than my wood + smooth rods rostock variant that wobbles at any interesting speed.

What are your settings (layer thickness, infill)?

It took me about 9 hours (morning to evening), to print the 9 parts of the base on two printers running at 20 mm/s and 40 mm/s, with 0.4mm layers.

Anyone had problems from slightly warped parts or too tight a fit?

My towers ended up slightly angled, since i had to force them into sockets.

Is that a common kind of problem with the design?

Maybe add some bolts to secure them in an initially more wobbly socket ala rostock (to allow for adjustments)?

The frame itself (4 bolt per link version) appear quite rigid, definitely more so than my wood + smooth rods rostock variant that wobbles at any interesting speed.

Interesting.Quote

umdpru

My bottom frame took a total of 34 hours of print time for all 9 pieces.

...

These times are for my machine running at 80mm/s and 500mm/s^2 acceleration settings.

What are your settings (layer thickness, infill)?

It took me about 9 hours (morning to evening), to print the 9 parts of the base on two printers running at 20 mm/s and 40 mm/s, with 0.4mm layers.

|

Re: 3DR "Simple" Delta Printer June 13, 2014 12:58PM |

Registered: 10 years ago Posts: 172 |

I printed all of my parts on my cupcake CNC at .2mm LH and 60% infill. I am fairly confidant that my actual print speed never got to 80mm/s because the acceleration is so low. It's more likely that the average print speeds of my machine was closer to 30-40mm/s with highs on longer straights approaching 60-80mm/s. Also, My first layer is set to 30% speed and my perimiter speeds are lowered by 50% IIRC.

My second frame is much truer than the first. I assembled the extrusions and smooth rods to the end pieces and it's absolutely stiffer than the first and everything is square now. the towers on my previous frame spiraled (weren't square to the base).

My second frame is much truer than the first. I assembled the extrusions and smooth rods to the end pieces and it's absolutely stiffer than the first and everything is square now. the towers on my previous frame spiraled (weren't square to the base).

|

Re: 3DR "Simple" Delta Printer June 13, 2014 02:12PM |

Registered: 10 years ago Posts: 172 |

|

Re: 3DR "Simple" Delta Printer June 18, 2014 01:27PM |

Registered: 10 years ago Posts: 172 |

|

Re: 3DR "Simple" Delta Printer June 18, 2014 09:33PM |

Registered: 10 years ago Posts: 4 |

|

Re: 3DR "Simple" Delta Printer June 18, 2014 10:18PM |

Registered: 10 years ago Posts: 172 |

|

Re: 3DR "Simple" Delta Printer June 19, 2014 02:26AM |

Registered: 10 years ago Posts: 4 |

|

Re: 3DR "Simple" Delta Printer June 26, 2014 03:59PM |

Registered: 12 years ago Posts: 138 |

Need some advice.

Hi!

I'm running: Ramps 1.4 w A4988. Spectra line with Wantai Nema 17 Stepper Motor 42BYGHW811 70oz-in 48mm 2.5A.(Same a Rich used on his from the blog).

Is this normal?

I did some testing. If I do the paper calibration, I bring my nozzle to the bed and I have just enough clearance. I can still move the paper. If I cut the power, I can no longer move the paper, or slip it under the nozzle. the nozzle has dropped.

I did increase the DEFAULT_STEPPER_DEACTIVE_TIME to 400 from 60.

If I G28, then cut power it does drop a tiny bit. Maybe 1mm? The effector will very easily stay in the top position. In fact it still requires some force to manually push the effector down.

I can't measure the difference, but I'd say it is 3-4 times harder to push the end effector up as it is to push it down (without power).

Prior to trying to calibrate this today. My end effector was parked at the top. It did not appear to be slidding down, even after a couple month of no power. So, it's not as iff it is slowly rolling down to the bottom. What is obvious now is that tiny (1mm?) drop at the removal of power.

So, I don't believe it is the firmware, I corrected the timeout

I don't think it is the spectra .

And these are supposed to be good motors. Same motors RichRap used.

Any thoghts?

Thanks

Maxi

And my end effector is pretty light.

Hi!

I'm running: Ramps 1.4 w A4988. Spectra line with Wantai Nema 17 Stepper Motor 42BYGHW811 70oz-in 48mm 2.5A.(Same a Rich used on his from the blog).

Is this normal?

I did some testing. If I do the paper calibration, I bring my nozzle to the bed and I have just enough clearance. I can still move the paper. If I cut the power, I can no longer move the paper, or slip it under the nozzle. the nozzle has dropped.

I did increase the DEFAULT_STEPPER_DEACTIVE_TIME to 400 from 60.

If I G28, then cut power it does drop a tiny bit. Maybe 1mm? The effector will very easily stay in the top position. In fact it still requires some force to manually push the effector down.

I can't measure the difference, but I'd say it is 3-4 times harder to push the end effector up as it is to push it down (without power).

Prior to trying to calibrate this today. My end effector was parked at the top. It did not appear to be slidding down, even after a couple month of no power. So, it's not as iff it is slowly rolling down to the bottom. What is obvious now is that tiny (1mm?) drop at the removal of power.

So, I don't believe it is the firmware, I corrected the timeout

I don't think it is the spectra .

And these are supposed to be good motors. Same motors RichRap used.

Any thoghts?

Thanks

Maxi

And my end effector is pretty light.

|

Re: 3DR "Simple" Delta Printer June 26, 2014 06:38PM |

Registered: 10 years ago Posts: 99 |

@disneytoy

Yes,the motors stop and thehot end drops, all the time, every time, yet this is not important to the results.

when printing the motors are always "on"

when you are leveling the print plane with the nozzle the motors should always be "on" and the nozzle "HOT" because it gets longer/closer to the print bed when hot.

look on Youtube for Jay Couture videos about calibratin and leveling the print bed by printing part of one layer of a square.

This way you can get it down to 0.02mm but only after you have done the paper test with a hot nozzle and the motors on.

Yes,the motors stop and thehot end drops, all the time, every time, yet this is not important to the results.

when printing the motors are always "on"

when you are leveling the print plane with the nozzle the motors should always be "on" and the nozzle "HOT" because it gets longer/closer to the print bed when hot.

look on Youtube for Jay Couture videos about calibratin and leveling the print bed by printing part of one layer of a square.

This way you can get it down to 0.02mm but only after you have done the paper test with a hot nozzle and the motors on.

|

Re: 3DR "Simple" Delta Printer June 26, 2014 08:11PM |

Registered: 11 years ago Posts: 32 |

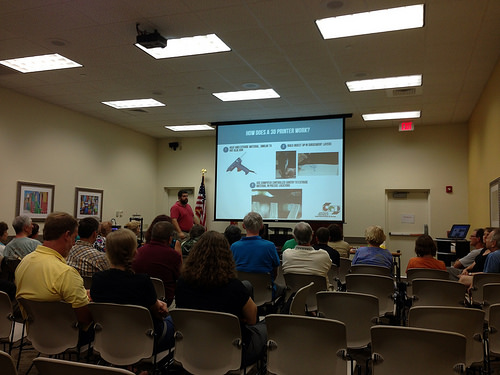

I thought I'd share a bit of fun I had last night using my 3DR Simple Delta as a demo unit at the local library: a few months back, the library contacted me and asked if I would stop by to give an 'Introduction to 3D printing' presentation. I thought it was a great idea and it wound up turning out quite well last night. Lots of folks were interested in 3D printing and in particular thought the Delta was quite neat! I also had fun using it as an example of how a 3D printer can 3D print another printer since I'd used my Mendel to print the parts for my 3DR Simple. Bit of a sidetrack from the discussion in this thread, but thought it was worth sharing  Went so well I've already been asked to give the same presentation at a different library branch!

Went so well I've already been asked to give the same presentation at a different library branch!

If anyone is interested in doing something similar, here are my slides if you'd like content to reuse or start with:

Dropbox ( this is the best version, has tons of embedded animated GIFs but clocks in at 64MB ): [www.dropbox.com]

SlideShare - [www.slideshare.net]

I have two WMV conversions of the videos linked in the presentation that I can make available as well, stripped them out to share the slides though since they balloon the presentation up to 200MB

edit: Almost forgot to mention -- I'd love to be able to run my 3DR simple as a standalone unit when I bring it around for demos, but doing so will require adding a LCD with input. I already have a Printrbot LCD screen, but I don't see it supported in the Marlin firmware unless I missed something. Anyone have pointers for getting a LCD added quickly? Am I better off switching out my controller and using a different LCD/input combo?

Edited 3 time(s). Last edit at 06/26/2014 08:17PM by PierreB.

Went so well I've already been asked to give the same presentation at a different library branch!

Went so well I've already been asked to give the same presentation at a different library branch!If anyone is interested in doing something similar, here are my slides if you'd like content to reuse or start with:

Dropbox ( this is the best version, has tons of embedded animated GIFs but clocks in at 64MB ): [www.dropbox.com]

SlideShare - [www.slideshare.net]

I have two WMV conversions of the videos linked in the presentation that I can make available as well, stripped them out to share the slides though since they balloon the presentation up to 200MB

edit: Almost forgot to mention -- I'd love to be able to run my 3DR simple as a standalone unit when I bring it around for demos, but doing so will require adding a LCD with input. I already have a Printrbot LCD screen, but I don't see it supported in the Marlin firmware unless I missed something. Anyone have pointers for getting a LCD added quickly? Am I better off switching out my controller and using a different LCD/input combo?

Edited 3 time(s). Last edit at 06/26/2014 08:17PM by PierreB.

|

Re: 3DR "Simple" Delta Printer June 26, 2014 11:55PM |

Registered: 12 years ago Posts: 138 |

Quote

RTurnock

@disneytoy

Yes,the motors stop and thehot end drops, all the time, every time, yet this is not important to the results.

when printing the motors are always "on"

when you are leveling the print plane with the nozzle the motors should always be "on" and the nozzle "HOT" because it gets longer/closer to the print bed when hot.

look on Youtube for Jay Couture videos about calibratin and leveling the print bed by printing part of one layer of a square.

This way you can get it down to 0.02mm but only after you have done the paper test with a hot nozzle and the motors on.

Thank you. A fellow Delta guy was helping a newbe (me) to calibrate my 3DR. The he set it to go to 3mm off the bed. But after a bit of a chat it had dropped. He suggested the problem was my spindles slipping, even though they are amazingly tight, and there was vurtually no forces on the motor. We did change that motor timeout in configuration.adv.h from 60 to 400.

I was concerned that maybe my Spectra needs to be tighter? But if you say that the motor will shift a few degrees upon losing its power, I won't worry about that.

I was told that because it was doing that, he could not calibrate it for me.

So close. I've been working on this thing for 8 months. I figure I'm at 98%. I have a J-head issue to resolve, This calibration and I should be printing soon.

Thanks!

|

Re: 3DR "Simple" Delta Printer June 27, 2014 11:55PM |

Registered: 10 years ago Posts: 99 |

Quote

disneytoy

Quote

RTurnock

@disneytoy

Yes,the motors stop and thehot end drops, all the time, every time, yet this is not important to the results.

when printing the motors are always "on"

when you are leveling the print plane with the nozzle the motors should always be "on" and the nozzle "HOT" because it gets longer/closer to the print bed when hot.

look on Youtube for Jay Couture videos about calibratin and leveling the print bed by printing part of one layer of a square.

This way you can get it down to 0.02mm but only after you have done the paper test with a hot nozzle and the motors on.

Thank you. A fellow Delta guy was helping a newbe (me) to calibrate my 3DR. The he set it to go to 3mm off the bed. But after a bit of a chat it had dropped. He suggested the problem was my spindles slipping, even though they are amazingly tight, and there was vurtually no forces on the motor. We did change that motor timeout in configuration.adv.h from 60 to 400.

I was concerned that maybe my Spectra needs to be tighter? But if you say that the motor will shift a few degrees upon losing its power, I won't worry about that.

I was told that because it was doing that, he could not calibrate it for me.

So close. I've been working on this thing for 8 months. I figure I'm at 98%. I have a J-head issue to resolve, This calibration and I should be printing soon.

Thanks!

@disneytoy

Weird, what do we do when we get advice that turns out to be misdirection? We learn?

You should be able to get within 0.1mm using post-it notes. I use mini-post-it notes. Then....

Use this youtube video and you will get within 0.02mm across a flat print plane.

[youtu.be]

|

Re: 3DR "Simple" Delta Printer July 01, 2014 03:26PM |

Registered: 10 years ago Posts: 172 |

Richard,

I found the issue with my 3DR simple, I believe. I gave up on it for a while and built a MK from ultibots that prints fantastically. During that build, I decided to print a "torture test" model on the Cupcake CNC that I had used to print both of the frames on the 3DR simple. Well, after the torture test model was complete, I examined it and found that the square box was out of square. My X and Y axes aren't square to each other. It's a real punch in the gut to know that this has existed. I think I will build a Z-probe for it and attempt to use Rich Cattel's auto calibration firmware. If that doesn't work then I'll print a new frame on the MK and try one last time! IF that doesn't work then the parts are going into a Tantillus!

for what it's worth, I was able to calibrate the MK in about an hour manually. I haven't fine tuned it like you have yours. I just don't see that I have a need to get that good with it.

I found the issue with my 3DR simple, I believe. I gave up on it for a while and built a MK from ultibots that prints fantastically. During that build, I decided to print a "torture test" model on the Cupcake CNC that I had used to print both of the frames on the 3DR simple. Well, after the torture test model was complete, I examined it and found that the square box was out of square. My X and Y axes aren't square to each other. It's a real punch in the gut to know that this has existed. I think I will build a Z-probe for it and attempt to use Rich Cattel's auto calibration firmware. If that doesn't work then I'll print a new frame on the MK and try one last time! IF that doesn't work then the parts are going into a Tantillus!

for what it's worth, I was able to calibrate the MK in about an hour manually. I haven't fine tuned it like you have yours. I just don't see that I have a need to get that good with it.

|

Re: 3DR "Simple" Delta Printer July 01, 2014 07:27PM |

Registered: 10 years ago Posts: 99 |

Quote

umdpru

Richard,

I found the issue with my 3DR simple, I believe. I gave up on it for a while and built a MK from ultibots that prints fantastically. During that build, I decided to print a "torture test" model on the Cupcake CNC that I had used to print both of the frames on the 3DR simple. Well, after the torture test model was complete, I examined it and found that the square box was out of square. My X and Y axes aren't square to each other. It's a real punch in the gut to know that this has existed. I think I will build a Z-probe for it and attempt to use Rich Cattel's auto calibration firmware. If that doesn't work then I'll print a new frame on the MK and try one last time! IF that doesn't work then the parts are going into a Tantillus!

for what it's worth, I was able to calibrate the MK in about an hour manually. I haven't fine tuned it like you have yours. I just don't see that I have a need to get that good with it.

Great! Good to hear your insightful problem solving skills are working for you.

Unfortunately, I don't believe the Auto Calibration will help you with the XY axes being out of square. But I've been known to be wrong. The auto calibration is to make sure you have a level/flat printing plane across the whole surface.

Not being square could be a structural issue, or a steps/unit calibration setting in firmware.

not sure whether to upgrade my Printrbot Simple to XL or to build a new Delta/Kossel with parts from 3DR Simple and new parts, like Azteeg X5, 2020 to go bigger and stronger, sliders by Jay Couture.......

Take Care

|

Re: 3DR "Simple" Delta Printer July 03, 2014 06:22PM |

Registered: 12 years ago Posts: 138 |

[Thanks for the video.

I have a question. My motors are 1/16 step. w/ a4988s. I use Rich's spindles. When I try fine adjusting the z in Repetier using manual controls. If I am say lowering the Z with the 0.1mm arrows. I can observe maybe 2 or 3 movements then upon the next click no movement at all. Someone said that the steps are not fine enough to handle 0.1mm? In Jay's video he is tuning to the next decimal. 0.XXmm. Am I not understanding the resolution here?

Should every 0.1mm click on the z axis register 0.1mm?

Thank you. A fellow Delta guy was helping a newbe (me) to calibrate my 3DR. The he set it to go to 3mm off the bed. But after a bit of a chat it had dropped. He suggested the problem was my spindles slipping, even though they are amazingly tight, and there was vurtually no forces on the motor. We did change that motor timeout in configuration.adv.h from 60 to 400.

I was concerned that maybe my Spectra needs to be tighter? But if you say that the motor will shift a few degrees upon losing its power, I won't worry about that.

I was told that because it was doing that, he could not calibrate it for me.

So close. I've been working on this thing for 8 months. I figure I'm at 98%. I have a J-head issue to resolve, This calibration and I should be printing soon.

Thanks![/quote]

@disneytoy

Weird, what do we do when we get advice that turns out to be misdirection? We learn?

You should be able to get within 0.1mm using post-it notes. I use mini-post-it notes. Then....

Use this youtube video and you will get within 0.02mm across a flat print plane.

[youtu.be][/quote]

I have a question. My motors are 1/16 step. w/ a4988s. I use Rich's spindles. When I try fine adjusting the z in Repetier using manual controls. If I am say lowering the Z with the 0.1mm arrows. I can observe maybe 2 or 3 movements then upon the next click no movement at all. Someone said that the steps are not fine enough to handle 0.1mm? In Jay's video he is tuning to the next decimal. 0.XXmm. Am I not understanding the resolution here?

Should every 0.1mm click on the z axis register 0.1mm?

Quote

RTurnock

@disneytoy

Yes,the motors stop and thehot end drops, all the time, every time, yet this is not important to the results.

when printing the motors are always "on"

when you are leveling the print plane with the nozzle the motors should always be "on" and the nozzle "HOT" because it gets longer/closer to the print bed when hot.

look on Youtube for Jay Couture videos about calibratin and leveling the print bed by printing part of one layer of a square.

This way you can get it down to 0.02mm but only after you have done the paper test with a hot nozzle and the motors on.

Thank you. A fellow Delta guy was helping a newbe (me) to calibrate my 3DR. The he set it to go to 3mm off the bed. But after a bit of a chat it had dropped. He suggested the problem was my spindles slipping, even though they are amazingly tight, and there was vurtually no forces on the motor. We did change that motor timeout in configuration.adv.h from 60 to 400.

I was concerned that maybe my Spectra needs to be tighter? But if you say that the motor will shift a few degrees upon losing its power, I won't worry about that.

I was told that because it was doing that, he could not calibrate it for me.

So close. I've been working on this thing for 8 months. I figure I'm at 98%. I have a J-head issue to resolve, This calibration and I should be printing soon.

Thanks![/quote]

@disneytoy

Weird, what do we do when we get advice that turns out to be misdirection? We learn?

You should be able to get within 0.1mm using post-it notes. I use mini-post-it notes. Then....

Use this youtube video and you will get within 0.02mm across a flat print plane.

[youtu.be][/quote]

|

Re: 3DR "Simple" Delta Printer July 07, 2014 03:50PM |

Registered: 9 years ago Posts: 1 |

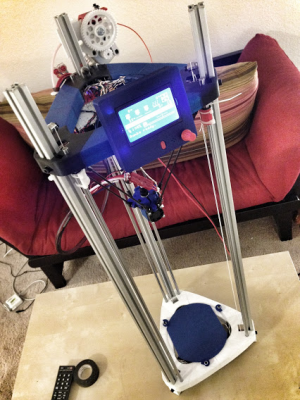

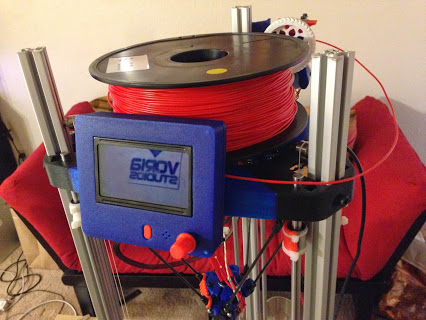

I built a 3DR Simple without a Printrbot Simple because I could print all of the parts on my Buccaneer. The printer I built is pretty tall, with a maximum build height of around 43cm:

(I've since moved the extruder closer to the center of the printer to reduce the length of the Bowden tube, and made other changes which you can see in some of the pictures below)

I ended up going with an E3D hot-end and needed to make several modifications to the effector:

You can download the design here.

I also made a blower fan mount and blower duct that work great with the new effector.

I also made an adjustable mount for attaching an LCD:

I also made a quick-but-suprisingly-effective mounting adapter that allows me to mount the RUMBA electronics to the top of my 3DR Simple:

Thanks John for coming up with this 3DR variant! I've quite enjoyed building it.

And, finally, self replication:

Edited 2 time(s). Last edit at 07/07/2014 04:14PM by darco.

(I've since moved the extruder closer to the center of the printer to reduce the length of the Bowden tube, and made other changes which you can see in some of the pictures below)

I ended up going with an E3D hot-end and needed to make several modifications to the effector:

You can download the design here.

I also made a blower fan mount and blower duct that work great with the new effector.

I also made an adjustable mount for attaching an LCD:

I also made a quick-but-suprisingly-effective mounting adapter that allows me to mount the RUMBA electronics to the top of my 3DR Simple:

Thanks John for coming up with this 3DR variant! I've quite enjoyed building it.

And, finally, self replication:

Edited 2 time(s). Last edit at 07/07/2014 04:14PM by darco.

|

Re: 3DR "Simple" Delta Printer July 08, 2014 01:33PM |

Registered: 10 years ago Posts: 172 |

Quote

RTurnock

Quote

umdpru

Richard,

I found the issue with my 3DR simple, I believe. I gave up on it for a while and built a MK from ultibots that prints fantastically. During that build, I decided to print a "torture test" model on the Cupcake CNC that I had used to print both of the frames on the 3DR simple. Well, after the torture test model was complete, I examined it and found that the square box was out of square. My X and Y axes aren't square to each other. It's a real punch in the gut to know that this has existed. I think I will build a Z-probe for it and attempt to use Rich Cattel's auto calibration firmware. If that doesn't work then I'll print a new frame on the MK and try one last time! IF that doesn't work then the parts are going into a Tantillus!

for what it's worth, I was able to calibrate the MK in about an hour manually. I haven't fine tuned it like you have yours. I just don't see that I have a need to get that good with it.

Great! Good to hear your insightful problem solving skills are working for you.

Unfortunately, I don't believe the Auto Calibration will help you with the XY axes being out of square. But I've been known to be wrong. The auto calibration is to make sure you have a level/flat printing plane across the whole surface.

Not being square could be a structural issue, or a steps/unit calibration setting in firmware.

not sure whether to upgrade my Printrbot Simple to XL or to build a new Delta/Kossel with parts from 3DR Simple and new parts, like Azteeg X5, 2020 to go bigger and stronger, sliders by Jay Couture.......

Take Care

From what I understand, the autocalibratoin in RichC's firmware will determine tower errors and make corrections. I'm not interested in it, though. I believe I will be taking apart my 3dr simnple and making either another MK with 2020 extrusions and printed sliders or I'll build a CoreXY printer.

The 3DR was a fun experiement and started me down the delta platform but I think tha'ts all it will be. I just can't bear the thought of printing an entire third frame to fix the issues with it without knowing if that's all that was wrong with it.

|

Re: 3DR "Simple" Delta Printer July 08, 2014 07:06PM |

Registered: 10 years ago Posts: 99 |

umdpru,

"The 3DR was a fun experiement and started me down the delta platform but I think tha'ts all it will be. I just can't bear the thought of printing an entire third frame to fix the issues with it without knowing if that's all that was wrong with it."

Yes, me too. Just finished taking the 3DR Simple apart. Now I have all the parts to build a Smartrap by Smartfriendz.

I will cut the 50cm rods to 30cm.

Use the Ubis hot end, printrboard, endstop switches, etc. Just need to build another extruder, since I move the Greg's Wade over to my Kossel.

The 3DR Simple is not scaleable like the Kossel and Smartrap designs.

If the Smartrap works, I will probably convert my Printrbot Simple to the Smartrap with 30cm rods. Then I will have two Smartraps and a kossel.

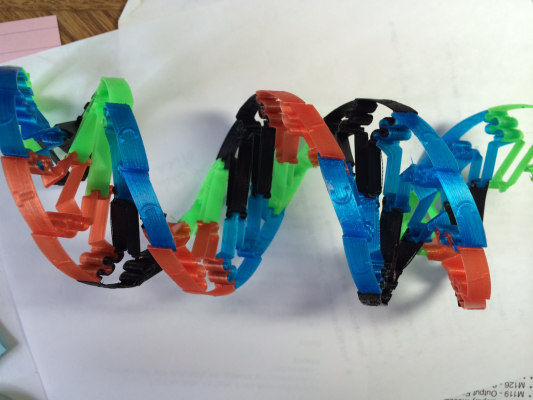

I printed DNA parts, the nucleotides ATGC with the international approved colors, A is green, T is red, G is black, C is blue. Then snapped them together and made a helix.

I want to do more education related prints and work with the local high school to build 3D printers.

Edited 1 time(s). Last edit at 07/08/2014 07:06PM by RTurnock.

"The 3DR was a fun experiement and started me down the delta platform but I think tha'ts all it will be. I just can't bear the thought of printing an entire third frame to fix the issues with it without knowing if that's all that was wrong with it."

Yes, me too. Just finished taking the 3DR Simple apart. Now I have all the parts to build a Smartrap by Smartfriendz.

I will cut the 50cm rods to 30cm.

Use the Ubis hot end, printrboard, endstop switches, etc. Just need to build another extruder, since I move the Greg's Wade over to my Kossel.

The 3DR Simple is not scaleable like the Kossel and Smartrap designs.

If the Smartrap works, I will probably convert my Printrbot Simple to the Smartrap with 30cm rods. Then I will have two Smartraps and a kossel.

I printed DNA parts, the nucleotides ATGC with the international approved colors, A is green, T is red, G is black, C is blue. Then snapped them together and made a helix.

I want to do more education related prints and work with the local high school to build 3D printers.

Edited 1 time(s). Last edit at 07/08/2014 07:06PM by RTurnock.

|

Re: 3DR "Simple" Delta Printer July 10, 2014 03:28PM |

Registered: 10 years ago Posts: 172 |

|

Re: 3DR "Simple" Delta Printer August 29, 2014 04:41PM |

Registered: 9 years ago Posts: 1 |

Hi John. Excellent work. Thank you. I may take the plunge soon.

For John or anyone,

I understand the intent to keep things small and "simple", but could this design be adapted to use extrusions to connect the corner pieces instead of the printed mid sections? I am thinking this would allow one to scale the print diameter.

For John or anyone,

I understand the intent to keep things small and "simple", but could this design be adapted to use extrusions to connect the corner pieces instead of the printed mid sections? I am thinking this would allow one to scale the print diameter.

|

Re: 3DR "Simple" Delta Printer September 01, 2014 08:12PM |

Registered: 14 years ago Posts: 3,742 |

The model is the DNA Playset by emmett, published Feb 10, 2012!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: 3DR "Simple" Delta Printer September 01, 2014 10:12PM |

Registered: 10 years ago Posts: 110 |

Quote

Trung

Hi John. Excellent work. Thank you. I may take the plunge soon.

For John or anyone,

I understand the intent to keep things small and "simple", but could this design be adapted to use extrusions to connect the corner pieces instead of the printed mid sections? I am thinking this would allow one to scale the print diameter.

Thanks.

Of course, you can do anything :-). Seriously, though, what you're describing is basically the Kossel design: [reprap.org], which is an excellent design with a lot of builders and support.

|

Re: 3DR "Simple" Delta Printer January 22, 2016 11:57PM |

Registered: 9 years ago Posts: 31 |

I'm leaning towards making a 3DR Simple. But I'm kind of concerned that it seems like the previous post here is the latest on this printer. Is this a totally dead project? If so, why? I'm looking for something I can print with my 100mm x 100mm x 100mm print area and the 3DR Simple looks compelling to me.

|

Re: 3DR "Simple" Delta Printer March 03, 2016 12:18AM |

Registered: 10 years ago Posts: 31 |

Not quite dead yet, i still have that old simple, i slowly worked kinks out and tuned it however i found that my particular model of simple came with laser cut birch wood that the two rod holes for my Z axis were cut off center to one another so no matter what i did there was no way possible to ever fix the printer so it could print the parts for a simple delta version, thus i fell into the conundrum of "needing a 3d printer to repair my 3d printer" aka "rock - hard place". i have recently invested in a "kossel" knock-off that i hope will serve me better then the messed up printrbot simple. that being said, something went wrong with my new delta 3d printer's arduino controller and i find myself in need of that old printrboard from the simple... funny how things go around. i will post an updated firmware as soon as i can.

|

Re: 3DR "Simple" Delta Printer March 29, 2016 10:12AM |

Registered: 10 years ago Posts: 8 |

I too, started looking at this project when it first came out, and then have about half the parts. I am missing the printed parts, Traxxas joints and then the Spectra fishing line. I think I will go the GT2 belt route, but I did not see any STL file for it. Funkymonk posted some STL files on page 5 of this thread, but I don't understand how the carriage file posted works for GT2 belts.

|

Re: 3DR "Simple" Delta Printer April 02, 2016 01:20AM |

Registered: 10 years ago Posts: 31 |

So some design implements on the Simple Delta, First after printing either set of stl files (6 piece / 12 piece), which are still on John_sl 's github, for the top and bottom, omit the smooth rod, just use the 2020 aluminum extrusion then second, print a set of carriages and effector head for the kossel those have everything needed for the GT2 belts and the rollers ride nice in the 2020 t slots, you can just increase/decrease your arm length accordingly.

|

Re: 3DR "Simple" Delta Printer April 02, 2016 01:24AM |

Registered: 10 years ago Posts: 8 |

I'm not quite sure what you mean by omitting the smooth rod? I already have the bottom pieces for the 3DR simple printed (9 pieces, I'm not sure where you got 12 from).Quote

ProfessorBean

So some design implements on the Simple Delta, First after printing either set of stl files (6 piece / 12 piece), which are still on John_sl 's github, for the top and bottom, omit the smooth rod, just use the 2020 aluminum extrusion then second, print a set of carriages and effector head for the kossel those have everything needed for the GT2 belts and the rollers ride nice in the 2020 t slots, you can just increase/decrease your arm length accordingly.

Will the files provided by Funkymonk also work for converting the 3DR to GT2 belts?

Sorry, only registered users may post in this forum.