3DR "Simple" Delta Printer

Posted by JohnSL

|

Re: 3DR "Simple" Delta Printer October 07, 2013 01:16AM |

Registered: 10 years ago Posts: 31 |

|

Re: 3DR "Simple" Delta Printer October 07, 2013 11:09PM |

Registered: 11 years ago Posts: 32 |

|

Re: 3DR "Simple" Delta Printer October 09, 2013 03:08PM |

Registered: 12 years ago Posts: 8 |

Hi John,

I like your idea very much. I am thinking about building a delta for a loger time. At that time Rostock did not exist. But I decided to do my own construction first. It´s half finished. It will be completely closed, fast and hopefully accurate. Minimum number of printed parts, industrial grade parts instead. Will be something between a RepRap and an industrial grade printer. But it´s way to complicated for anybody to built one. Thought it would be easier. Over engineered. I don´t think I will publish it.

In the meantime I found Richraps 3DR, loved it, started ordering parts etc. But I want to use 8mm rods and IGUS bushings, because they will be more quiet, I think and lighter. 8mm is my standard. My first plan was to take the 3DR parts and bore the holes to 8mm. Then I found your post. 8mm rods, perfect. Will built your design. But version 2. Got a Mendelmax 1.0. So no need for small parts for me.

I like microswitches. Simply because I still have lots of them, but no hall´Os. I also have some optos. A very simple way would be to print a part which holds the microswitch and is hight adjustable through a screw. Best way would be to use the extrusion slot which faces inward as guidance. The screwhead faces upwards, is attaced to the top cover, and secured with a nut under the cover. So you can use an Allen key to adjust the endstops. Hope you understand my idea. Perhaps I should make a drawing and post a picture. Mhm... just design that part. But I don´t have Solidworks here, only 123Design, so you cannot modify them if needed...

Hope you will have the design finished soon, so I can start printing and building. Will have all parts next week, I hope. One big parcel arrived today...

After this one I will build a bigger one and a very small transportable version. Right now I don´t have the time for designing. Two printers to finish, first.

Best Regards,

Philip

I like your idea very much. I am thinking about building a delta for a loger time. At that time Rostock did not exist. But I decided to do my own construction first. It´s half finished. It will be completely closed, fast and hopefully accurate. Minimum number of printed parts, industrial grade parts instead. Will be something between a RepRap and an industrial grade printer. But it´s way to complicated for anybody to built one. Thought it would be easier. Over engineered. I don´t think I will publish it.

In the meantime I found Richraps 3DR, loved it, started ordering parts etc. But I want to use 8mm rods and IGUS bushings, because they will be more quiet, I think and lighter. 8mm is my standard. My first plan was to take the 3DR parts and bore the holes to 8mm. Then I found your post. 8mm rods, perfect. Will built your design. But version 2. Got a Mendelmax 1.0. So no need for small parts for me.

I like microswitches. Simply because I still have lots of them, but no hall´Os. I also have some optos. A very simple way would be to print a part which holds the microswitch and is hight adjustable through a screw. Best way would be to use the extrusion slot which faces inward as guidance. The screwhead faces upwards, is attaced to the top cover, and secured with a nut under the cover. So you can use an Allen key to adjust the endstops. Hope you understand my idea. Perhaps I should make a drawing and post a picture. Mhm... just design that part. But I don´t have Solidworks here, only 123Design, so you cannot modify them if needed...

Hope you will have the design finished soon, so I can start printing and building. Will have all parts next week, I hope. One big parcel arrived today...

After this one I will build a bigger one and a very small transportable version. Right now I don´t have the time for designing. Two printers to finish, first.

Best Regards,

Philip

|

Re: 3DR "Simple" Delta Printer October 10, 2013 12:20AM |

Registered: 10 years ago Posts: 110 |

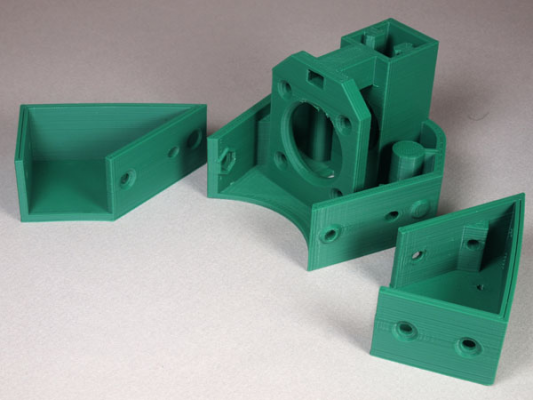

Thanks all for the support. I've been busy working on the top parts. Here's what I have so far:

@Duesentrieb, I think I follow you (but perhaps not) about mounting the microswitches. The design I have now includes a place for the switches. They're not shown in this picture because I need to buy some M2.5 nuts (I have the bolts from my Printrbot Simple, but no nuts). I had thought about making them adjustable, and then I had second thoughts. As I understand deltas (not very well yet), you want all the end stops at exactly the same position. On a Cartesian bot, you want the Z end stop adjustable so you can tune the Z height. But with a delta, you want a known position, and then you adjust the distance from there down to the bed. At least, that's the way the 3DR is designed.

I think if you made the endstops adjustable, it would both change the center position of the extruder at "zero," and also change the height a little.

P.S. I'm busy printing out the final parts for the top, and then I'm going to do a test assembly. My plan is to cut the slots in the extrusions for the wires after my test assembly.

Edited 1 time(s). Last edit at 10/10/2013 12:22AM by JohnSL.

@Duesentrieb, I think I follow you (but perhaps not) about mounting the microswitches. The design I have now includes a place for the switches. They're not shown in this picture because I need to buy some M2.5 nuts (I have the bolts from my Printrbot Simple, but no nuts). I had thought about making them adjustable, and then I had second thoughts. As I understand deltas (not very well yet), you want all the end stops at exactly the same position. On a Cartesian bot, you want the Z end stop adjustable so you can tune the Z height. But with a delta, you want a known position, and then you adjust the distance from there down to the bed. At least, that's the way the 3DR is designed.

I think if you made the endstops adjustable, it would both change the center position of the extruder at "zero," and also change the height a little.

P.S. I'm busy printing out the final parts for the top, and then I'm going to do a test assembly. My plan is to cut the slots in the extrusions for the wires after my test assembly.

Edited 1 time(s). Last edit at 10/10/2013 12:22AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 10, 2013 10:07AM |

Registered: 12 years ago Posts: 8 |

hey John

A very nice build/design i look forward to being able to have a go at building this i like the idea of being able to print smaller blocks rather than larger pieces so if you have a failed print for whatever reason its not a big piece that is going to be discarded

i look forward to seeing more from you matey

stay calm and carry on printing

big jay

A very nice build/design i look forward to being able to have a go at building this i like the idea of being able to print smaller blocks rather than larger pieces so if you have a failed print for whatever reason its not a big piece that is going to be discarded

i look forward to seeing more from you matey

stay calm and carry on printing

big jay

|

Re: 3DR "Simple" Delta Printer October 10, 2013 05:20PM |

Registered: 12 years ago Posts: 8 |

John,

you are right. On a deltabot you want all the endstops to be in exact the same position, that´s correct. The problem is to build the printer that perfect. If one endstop is 1mm higher than the others, the plane in which the printer operates is not parallel to the printbed. It is tilted. So when you print the first layer on one side the distance is correct and the print is perfect there, but on the other side the distance is a little to high, let´s say 1mm. The first layer in this area will not stick very well to the bed or the extruded lines will be curvy. It´s the same effect as on a Cartesian printer, when one of your Nuts on the Z-rods is higher than the other. You have to turn one motor by hand to finetune, until the distance is the same. So on a delta you need the adjustable endstops to align the three axis RELATIVE to each other. For the total height, you change a number in the firmware, as you said.

Another possibility would be to make the bed adjustable, so that you can tilt the bed the same way as the plane is tilted in which the delta operates. So they would be parallel again. But I think makeing the endstops adjustable is better.

So you should integrate adjustable endstops. Which part moves, the switch or the thing touching it, does not matter. Of course you can also inegrate a screw in the carriages, which touches the endstop. By screwing it out you make the distance bigger, screwing it in makes it smaller… But I prefer moving the endswitch. This is more difficult to do, but the weight of the carriage is a little lower. The lighter the moving parts, the higher the acceleration and printing speed. I will optimize all moving parts for weight. I want mine to be really fast.

Hope my thoughts are right. Correct me, if I am wrong.

Best Regards,

Philip

P.S.: Theoretically it would be enough to make two endstops adjustable, but to have more identical parts it makes more sense to make all adjustable.

you are right. On a deltabot you want all the endstops to be in exact the same position, that´s correct. The problem is to build the printer that perfect. If one endstop is 1mm higher than the others, the plane in which the printer operates is not parallel to the printbed. It is tilted. So when you print the first layer on one side the distance is correct and the print is perfect there, but on the other side the distance is a little to high, let´s say 1mm. The first layer in this area will not stick very well to the bed or the extruded lines will be curvy. It´s the same effect as on a Cartesian printer, when one of your Nuts on the Z-rods is higher than the other. You have to turn one motor by hand to finetune, until the distance is the same. So on a delta you need the adjustable endstops to align the three axis RELATIVE to each other. For the total height, you change a number in the firmware, as you said.

Another possibility would be to make the bed adjustable, so that you can tilt the bed the same way as the plane is tilted in which the delta operates. So they would be parallel again. But I think makeing the endstops adjustable is better.

So you should integrate adjustable endstops. Which part moves, the switch or the thing touching it, does not matter. Of course you can also inegrate a screw in the carriages, which touches the endstop. By screwing it out you make the distance bigger, screwing it in makes it smaller… But I prefer moving the endswitch. This is more difficult to do, but the weight of the carriage is a little lower. The lighter the moving parts, the higher the acceleration and printing speed. I will optimize all moving parts for weight. I want mine to be really fast.

Hope my thoughts are right. Correct me, if I am wrong.

Best Regards,

Philip

P.S.: Theoretically it would be enough to make two endstops adjustable, but to have more identical parts it makes more sense to make all adjustable.

|

Re: 3DR "Simple" Delta Printer October 11, 2013 12:35AM |

Registered: 10 years ago Posts: 4 |

|

Re: 3DR "Simple" Delta Printer October 11, 2013 01:57PM |

Registered: 10 years ago Posts: 31 |

this is an awesome design, in-between the "wings" (the left, right and motor housing) on each set you can add 3 straight printed pieces on the top and bottom sets to scale up the size of the printer, then add taller rods, longer carriage arms and larger printbed, theoretically it could easily go up to a 600 mm build volume maybe more.

|

Re: 3DR "Simple" Delta Printer October 11, 2013 03:24PM |

Registered: 10 years ago Posts: 1 |

JohnSL, I just stumbled across this post from the Printrbot forums and am very excited to see how this turns out! I just purchased a Printrbot Simple a few weeks ago, and while it's been a great tool to get started with 3D printing, I'm quickly realizing its limitations and flaws. Being able to reuse the parts from it and easily upgrade to a delta printer like this is a great idea! I've already been looking around recently to see what upgrade paths are out there. Since I only have a Simple currently and wouldn't be able to print out all the parts for this, I'd definitely be interested in a "buy it forward" type program when the time comes. I'll definitely be keeping an eye on your progress! Thanks for all your work!

|

Re: 3DR "Simple" Delta Printer October 12, 2013 06:09AM |

Registered: 10 years ago Posts: 1 |

|

Re: 3DR "Simple" Delta Printer October 12, 2013 03:11PM |

Registered: 10 years ago Posts: 110 |

Thanks everyone!

@Duesentrieb, The top assembly can be adjusted to level it. I now have the top assembly in place, and I discovered that you can move each side up and down a few mm without any problems. So that should provide the adjustment required to get everything parallel and printing well.

@uphiearl, I don't have plans at the moment to support anything other than 20mm extrusions. Perhaps once I have this working and have parts published, I can look at that.

@akudaikon, all of the parts are small enough so they can be printed on the Printrbot Simple. ProfessorBean prodded me in that direction, and it eliminates the need for a buy it forward program. So the idea is that you can print all the parts you need, and even test assembly of a lot of the printer, before you will need to disassemble your Printrbot Simple.

On another note, I took this printer to the bi-weekly maker group at work, where there were a couple of others who have experience with Delta printers. They expressed some concerns that this design isn't sturdy enough. Once fully assembled, it can wiggle a little. I'm not sure yet if it wiggles more than RichRap's design. My plan is to continue building the design and see what happens. If the print quality and speed aren't where I want it, I'll probably need to add some additional bracing to the top and bottom, or some cross bracing between the top and bottom.

Can anyone who's built a RichRap 3DR let me know if this is an issue with the 3DR as well?

In any event, this is where I'm at right now:

It's now outgrown my photo booth, so it's becoming hard to photograph well.

Edited 1 time(s). Last edit at 10/12/2013 03:12PM by JohnSL.

@Duesentrieb, The top assembly can be adjusted to level it. I now have the top assembly in place, and I discovered that you can move each side up and down a few mm without any problems. So that should provide the adjustment required to get everything parallel and printing well.

@uphiearl, I don't have plans at the moment to support anything other than 20mm extrusions. Perhaps once I have this working and have parts published, I can look at that.

@akudaikon, all of the parts are small enough so they can be printed on the Printrbot Simple. ProfessorBean prodded me in that direction, and it eliminates the need for a buy it forward program. So the idea is that you can print all the parts you need, and even test assembly of a lot of the printer, before you will need to disassemble your Printrbot Simple.

On another note, I took this printer to the bi-weekly maker group at work, where there were a couple of others who have experience with Delta printers. They expressed some concerns that this design isn't sturdy enough. Once fully assembled, it can wiggle a little. I'm not sure yet if it wiggles more than RichRap's design. My plan is to continue building the design and see what happens. If the print quality and speed aren't where I want it, I'll probably need to add some additional bracing to the top and bottom, or some cross bracing between the top and bottom.

Can anyone who's built a RichRap 3DR let me know if this is an issue with the 3DR as well?

In any event, this is where I'm at right now:

It's now outgrown my photo booth, so it's becoming hard to photograph well.

Edited 1 time(s). Last edit at 10/12/2013 03:12PM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 14, 2013 03:57AM |

Registered: 10 years ago Posts: 31 |

@JonhSl you know you might be able to kill any stability issues by creating a slide lock system between all the pieces so they would lock together then be bolted, sort of like a dove tail or some other equally strong wood working joint, however i don't know how difficult that may be to add and subsequently print... this little delta may not be "simple" enough for the simple... that is if you get too much wiggle, however i don't see a point in speculating when you're so close to making a test print. i will wait and see.

also just a thought, if you moved the electronics board to some kind of remote or bolt on housing and attach it to the bottom out of the way of the stepper motors it would make connections a lot easier and take away some mass at the top, to lessen the possibility of the machine being unstable and move around too much.

Edited 1 time(s). Last edit at 10/14/2013 04:01AM by ProfessorBean.

also just a thought, if you moved the electronics board to some kind of remote or bolt on housing and attach it to the bottom out of the way of the stepper motors it would make connections a lot easier and take away some mass at the top, to lessen the possibility of the machine being unstable and move around too much.

Edited 1 time(s). Last edit at 10/14/2013 04:01AM by ProfessorBean.

|

Re: 3DR "Simple" Delta Printer October 15, 2013 12:25AM |

Registered: 10 years ago Posts: 110 |

Yesterday I managed to get the Delta version of Marlin downloaded onto the Printrboard in my 3DR "Simple". I'd added the endstops, carriages, and the effector (no extruder yet), and I wanted to see it working.

My first attempts were pretty frustrating, but I finally got it homing and moving correctly. At this point, however, I noticed that the Z was changing when I was moving it only in the X and Y directions. Hmmm, what to do. I searched for documentation on how to decide what values to use, but the best thing I found were short one-line comments in the Marlin source code. So I've taken stab at describing with pictures and text what each value means, and how to measure it. You can find it here:

[trains.socha.com]

Please let me know if you find any mistakes so I can correct them.

My first attempts were pretty frustrating, but I finally got it homing and moving correctly. At this point, however, I noticed that the Z was changing when I was moving it only in the X and Y directions. Hmmm, what to do. I searched for documentation on how to decide what values to use, but the best thing I found were short one-line comments in the Marlin source code. So I've taken stab at describing with pictures and text what each value means, and how to measure it. You can find it here:

[trains.socha.com]

Please let me know if you find any mistakes so I can correct them.

|

Re: 3DR "Simple" Delta Printer October 15, 2013 02:58PM |

Registered: 10 years ago Posts: 31 |

|

Re: 3DR "Simple" Delta Printer October 16, 2013 12:14AM |

Registered: 10 years ago Posts: 110 |

ProfessorBean, your wish is my command. Here are my current, in process files, on Github:

[github.com]

I would not advise trying to build a printer from these parts yet, but they're up there. I have both SolidWorks 2011 files as well as exported STL files. The STL files are the as-built so far files, while the SolidWorks files are in flux. This weekend I started to redesign the bottom parts to be a lot stiffer, but I'm not done yet. I'll post some more details in a little while.

[github.com]

I would not advise trying to build a printer from these parts yet, but they're up there. I have both SolidWorks 2011 files as well as exported STL files. The STL files are the as-built so far files, while the SolidWorks files are in flux. This weekend I started to redesign the bottom parts to be a lot stiffer, but I'm not done yet. I'll post some more details in a little while.

|

Re: 3DR "Simple" Delta Printer October 16, 2013 01:20AM |

Registered: 10 years ago Posts: 110 |

Here is what I have in mind for the new, stiffer base pieces:

There are two major changes I made. First, I've added an inner wall. So instead of having a U shape for the walls, the walls now go completely around. This makes a much stiffer box.

Second, I added screws to both the top and the bottom, instead of along the center of each face. Having four points instead of two should greatly stiffen the base.

For comparison, here is what I had before:

Edited 1 time(s). Last edit at 10/16/2013 01:21AM by JohnSL.

There are two major changes I made. First, I've added an inner wall. So instead of having a U shape for the walls, the walls now go completely around. This makes a much stiffer box.

Second, I added screws to both the top and the bottom, instead of along the center of each face. Having four points instead of two should greatly stiffen the base.

For comparison, here is what I had before:

Edited 1 time(s). Last edit at 10/16/2013 01:21AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 16, 2013 01:23PM |

Registered: 10 years ago Posts: 31 |

|

Re: 3DR "Simple" Delta Printer October 17, 2013 01:53AM |

Registered: 10 years ago Posts: 110 |

@ProfessorBean, I'm using SolidWorks 2011, so you should be able to open my files (but not the other way around).

The new design should be a lot more stable. Last night I printed out two of the pieces and tried them out. They're very, very strong, so I think this will take care of the wiggle problem:

I've also made some progress on mounting the hot end. Once again, I ended designing my own parts, which I'll go into in more detail when it's not so late. The idea is to have two halves that clamp together and hold both the hot end and the push-fit in place very tightly, while still being easy to print:

Now I have to build the extruder and attach a Bowden tube before I can try printing.

Edited 2 time(s). Last edit at 10/17/2013 01:55AM by JohnSL.

The new design should be a lot more stable. Last night I printed out two of the pieces and tried them out. They're very, very strong, so I think this will take care of the wiggle problem:

I've also made some progress on mounting the hot end. Once again, I ended designing my own parts, which I'll go into in more detail when it's not so late. The idea is to have two halves that clamp together and hold both the hot end and the push-fit in place very tightly, while still being easy to print:

Now I have to build the extruder and attach a Bowden tube before I can try printing.

Edited 2 time(s). Last edit at 10/17/2013 01:55AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 17, 2013 12:48PM |

Registered: 13 years ago Posts: 118 |

Thank you  for posting your work thus far. I am happy to report that the STL's you posted of the larger parts (non-Simple parts) with the 8MM rod holes are able to be imported and rendered in OpenSCAD. Unfortunately, the same is/was not true of the Sketchup rendered parts.

for posting your work thus far. I am happy to report that the STL's you posted of the larger parts (non-Simple parts) with the 8MM rod holes are able to be imported and rendered in OpenSCAD. Unfortunately, the same is/was not true of the Sketchup rendered parts.

Did you ever try to print one of the larger parts, and if so, was it strong (non-flexible) compared to the first Simple prototype?

-Jay

for posting your work thus far. I am happy to report that the STL's you posted of the larger parts (non-Simple parts) with the 8MM rod holes are able to be imported and rendered in OpenSCAD. Unfortunately, the same is/was not true of the Sketchup rendered parts.

for posting your work thus far. I am happy to report that the STL's you posted of the larger parts (non-Simple parts) with the 8MM rod holes are able to be imported and rendered in OpenSCAD. Unfortunately, the same is/was not true of the Sketchup rendered parts.Did you ever try to print one of the larger parts, and if so, was it strong (non-flexible) compared to the first Simple prototype?

-Jay

|

Re: 3DR "Simple" Delta Printer October 19, 2013 01:45AM |

Registered: 10 years ago Posts: 110 |

@jaydmdigital, yes, I printed the larger parts and was planning on going that route before ProfessorBean suggested I make the parts printable on the Printrbot Simple. The larger parts are strong because they're three pieces instead of nine. That being said, my new design for the nine pieces should be stronger than my old larger part (new one below).

I've just updated the larger file (since I still had both configurations in my SolidWorks part file) so it should be even stiffer than RichRap's 3DR. I accomplished this by adding two rows for screws instead of a single row. I also added alignment bumps and dimples for precise alignment of the base parts:

You can find the new STL file here: [github.com]

Edited 1 time(s). Last edit at 10/19/2013 01:47AM by JohnSL.

I've just updated the larger file (since I still had both configurations in my SolidWorks part file) so it should be even stiffer than RichRap's 3DR. I accomplished this by adding two rows for screws instead of a single row. I also added alignment bumps and dimples for precise alignment of the base parts:

You can find the new STL file here: [github.com]

Edited 1 time(s). Last edit at 10/19/2013 01:47AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 20, 2013 09:55AM |

Registered: 10 years ago Posts: 5 |

Hey John I love what you're doing here. I have a Printrbot Jr that I plan to convert into your "Simple"

3DR

What was the total cost of all the materials you bought besides the Simple parts? What length of rods and extrusions did you use? Also, where did you get your joints you used for the arms?

If it's cheap enough, Printrbot sells the Simple materials without the laser cut wood for 40 bucks less, which means people can build a nice delta printer for under $350

3DR

What was the total cost of all the materials you bought besides the Simple parts? What length of rods and extrusions did you use? Also, where did you get your joints you used for the arms?

If it's cheap enough, Printrbot sells the Simple materials without the laser cut wood for 40 bucks less, which means people can build a nice delta printer for under $350

|

Re: 3DR "Simple" Delta Printer October 20, 2013 02:48PM |

Registered: 10 years ago Posts: 110 |

Thanks cjdj3. I don't have a final cost of the extra parts yet. The cost I have is about $130, which does not include the pneumatic fittings ($6 for two) for the Bowden tube (about $8), or the tube itself. So figure an extra cost of $150 is about right. I'm using 450mm extrusion and 400mm rods, which with my current design gives a maximum print height of about 155mm. And yes, purchasing the Printrbot Simple kit without the laser-cut parts is less than sourcing the parts separately, so it's a good deal.

The print diameter, I'm not yet sure about. I asked people with running 3DR printers about their experience, and it sounds like it's about 110mm, which is a lot smaller than the 170mm diameter glass plate I have. As a result, I'm planning on increasing the size of the printed parts so I'll have closer to the full print diameter of the glass plate (and still keep the parts printable on a Printrbot Simple).

The print diameter, I'm not yet sure about. I asked people with running 3DR printers about their experience, and it sounds like it's about 110mm, which is a lot smaller than the 170mm diameter glass plate I have. As a result, I'm planning on increasing the size of the printed parts so I'll have closer to the full print diameter of the glass plate (and still keep the parts printable on a Printrbot Simple).

|

Re: 3DR "Simple" Delta Printer October 20, 2013 04:17PM |

Registered: 10 years ago Posts: 5 |

I've been looking at some of your models thus far in solidworks and prepping the stl's to possibly print. I was wondering what settings you used to print your parts such as fill density, fill pattern, support material etc. One of the major questions I have is do you use support material when printing? There are a number of areas on the motor mount piece that have overhangs that I would think need support material and yet on your photos that you posted earlier, it would appear that no support material was used. Did you remove it and then take the photo or were you actually able to print without it?

Edited 1 time(s). Last edit at 10/20/2013 04:17PM by CAD321.

Edited 1 time(s). Last edit at 10/20/2013 04:17PM by CAD321.

|

Re: 3DR "Simple" Delta Printer October 20, 2013 08:21PM |

Registered: 10 years ago Posts: 110 |

CAD321, I would suggest holding off a bit before you make the parts, as I've identified a list of things I'm going to change before the "official" release of this design. The files that are on Github are very much a work in progress. Here are some of the things I plan to change:

I've done some initial test prints, and the results look promising. However, for some reason, the set screws on the spools keep coming loose, which then creates lot of print problems. Once installed in the printer, the set screws are a little hard to reach, which is why I want to change the design. I might also have to put some thread lock on the screws to keep them from coming loose.

I've also discovered that I don't have quite enough clearance between the spools and the round holes near the extrusions, because the spools sometimes rub against the hole.

As to printing, I used Kisslicer (which isn't very good with bridging) without support material, layer height of 0.2mm, and infill of 25%. I'm pretty amazed that even without good bridging support, the parts still come out usable.

- Make it wider to allow about 160mm diameter print area

- Allow more clearance for the fishing line spools

- Make it easier to get to set screws for fishing line spools

- Provide a bed leveling system (or automatic bed leveling)

- Include a fan mount on the effector or sides

- Include some holes on the top parts to allow zip ties for holding wires in place

I've done some initial test prints, and the results look promising. However, for some reason, the set screws on the spools keep coming loose, which then creates lot of print problems. Once installed in the printer, the set screws are a little hard to reach, which is why I want to change the design. I might also have to put some thread lock on the screws to keep them from coming loose.

I've also discovered that I don't have quite enough clearance between the spools and the round holes near the extrusions, because the spools sometimes rub against the hole.

As to printing, I used Kisslicer (which isn't very good with bridging) without support material, layer height of 0.2mm, and infill of 25%. I'm pretty amazed that even without good bridging support, the parts still come out usable.

|

Re: 3DR "Simple" Delta Printer October 21, 2013 01:44AM |

Registered: 10 years ago Posts: 110 |

As I mentioned above, I've been working on a redesign of this printer. I've taken care of the issues with the spools in this new design, and I've also made the base wider so you'll be able to use nearly the entire 170mm diameter bed. Here is what I have so far (I still have to redo the top):

Edited 1 time(s). Last edit at 10/21/2013 01:44AM by JohnSL.

Edited 1 time(s). Last edit at 10/21/2013 01:44AM by JohnSL.

|

Re: 3DR "Simple" Delta Printer October 23, 2013 06:39AM |

Registered: 12 years ago Posts: 8 |

|

Re: 3DR "Simple" Delta Printer October 28, 2013 05:20PM |

Registered: 10 years ago Posts: 99 |

I found the link to JohnSL and this discussion about 3DR "Simple" Delta Printer.

I opened up my box from Printrbot on 10/16 and assembled my Simple with the help of a neighbor, a recent college graduate in EE & Computer Science, finished on 10/19.

I have not been able to spend as much time as I would like working with it, even though I am retired.

Part of my process is a steep learning curve, never having used the software before.

Wow, there are a lot of parameters to check, calibrate and recheck and recalibrate.

So many variables.

I really want to get a Delta printer in 2014 and have researched the Mini Kossel.

This discussion is interesting because I might switch to working on getting a 3DR.

I like the idea of the plastic parts made by a 3D printer to assemble another.

I have not gotten mine completely calibrated and working with the software quite yet, but I am definitely getting closer.

Here is a video of my first print……and a list of the problems.

Printrbot Simple First Print

I am reading backwards on the posts. Looking forward to seeing a 3DR working.

I opened up my box from Printrbot on 10/16 and assembled my Simple with the help of a neighbor, a recent college graduate in EE & Computer Science, finished on 10/19.

I have not been able to spend as much time as I would like working with it, even though I am retired.

Part of my process is a steep learning curve, never having used the software before.

Wow, there are a lot of parameters to check, calibrate and recheck and recalibrate.

So many variables.

I really want to get a Delta printer in 2014 and have researched the Mini Kossel.

This discussion is interesting because I might switch to working on getting a 3DR.

I like the idea of the plastic parts made by a 3D printer to assemble another.

I have not gotten mine completely calibrated and working with the software quite yet, but I am definitely getting closer.

Here is a video of my first print……and a list of the problems.

Printrbot Simple First Print

I am reading backwards on the posts. Looking forward to seeing a 3DR working.

|

Re: 3DR "Simple" Delta Printer October 29, 2013 05:30PM |

Registered: 10 years ago Posts: 145 |

|

Re: 3DR "Simple" Delta Printer October 30, 2013 02:25PM |

Registered: 10 years ago Posts: 1 |

|

Re: 3DR "Simple" Delta Printer November 01, 2013 08:06AM |

Registered: 11 years ago Posts: 2 |

Hello JohnSL,

I printed the 3x bottom motor mount , simple version, some weeks ago, now I want to print the wings but I noticed these have changed with 4 bolts instead of two, I didn't save the previous STL and I don't have solidworks, could you publish these "old" (2 bolts) versions on github? I would not want to reprint the motor mounts, I like your idea about the extra wall but I think it could be stiff enough with 2 bolts per side.

Thanks

J.

I printed the 3x bottom motor mount , simple version, some weeks ago, now I want to print the wings but I noticed these have changed with 4 bolts instead of two, I didn't save the previous STL and I don't have solidworks, could you publish these "old" (2 bolts) versions on github? I would not want to reprint the motor mounts, I like your idea about the extra wall but I think it could be stiff enough with 2 bolts per side.

Thanks

J.

Sorry, only registered users may post in this forum.