Joints for delta printer

Posted by Itai

|

Joints for delta printer October 28, 2013 11:11PM |

Registered: 10 years ago Posts: 4 |

[my first post here]

I'm starting the build of a delta printer.

I see that poeple are using either ball joints or universal joints.

I got some ball joints from HobbyKing and I'm not very happy with the quality. Then I found this part.

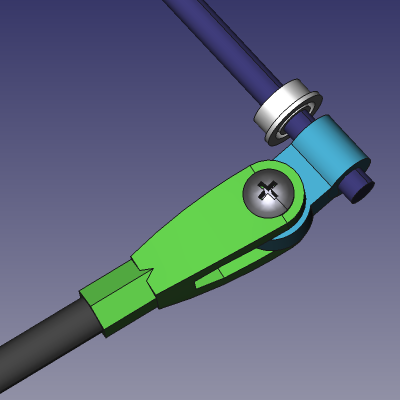

And here's the design that I consider:

Legend:

Dark blue: Axes. Supported by vall bearing, one to each vertical slide and three to the senter effector. use 3mm carbon rod.

Silver: Flanged ball bearing. 3mm ID.

Light blue: the arm side of HK part OR7-2601x5. Drilled to 3mm and attached to the end of each axis.

Light green: The clevis side of HK part OR7-2601x5.

Dark grey: 4mm carbon tube arm.

Have other peopele used similar desigh?

Pros:

Very simple to build. Ball bearing on all axes. Joint has almost no constraints.

Cons:

I'm not sure if the firmware supports the kinematics for this kind of joint. I may need to do all the math and then code it myself, which may take some time.

Without firmware corrections (using fixed arm length) there will be a very small error near the center, getting larger when away from the center.

I'm starting the build of a delta printer.

I see that poeple are using either ball joints or universal joints.

I got some ball joints from HobbyKing and I'm not very happy with the quality. Then I found this part.

And here's the design that I consider:

Legend:

Dark blue: Axes. Supported by vall bearing, one to each vertical slide and three to the senter effector. use 3mm carbon rod.

Silver: Flanged ball bearing. 3mm ID.

Light blue: the arm side of HK part OR7-2601x5. Drilled to 3mm and attached to the end of each axis.

Light green: The clevis side of HK part OR7-2601x5.

Dark grey: 4mm carbon tube arm.

Have other peopele used similar desigh?

Pros:

Very simple to build. Ball bearing on all axes. Joint has almost no constraints.

Cons:

I'm not sure if the firmware supports the kinematics for this kind of joint. I may need to do all the math and then code it myself, which may take some time.

Without firmware corrections (using fixed arm length) there will be a very small error near the center, getting larger when away from the center.

|

Re: Joints for delta printer October 29, 2013 04:30AM |

Registered: 10 years ago Posts: 732 |

Marlin firmware does not support this. I do not know about Repetier.

If it adds square roots or a lot of computations it is probably not worth it.

These work well: MP JET Ball Link (Ø7 mm, M3, M3 short)

[www.bigplanes.nl]

They claim to ship everywhere, but I do not know for what price. Maybe you can find a local soruce.

If it adds square roots or a lot of computations it is probably not worth it.

These work well: MP JET Ball Link (Ø7 mm, M3, M3 short)

[www.bigplanes.nl]

They claim to ship everywhere, but I do not know for what price. Maybe you can find a local soruce.

|

Re: Joints for delta printer October 29, 2013 09:38AM |

Registered: 10 years ago Posts: 8 |

|

Re: Joints for delta printer October 29, 2013 05:46PM |

Registered: 10 years ago Posts: 4 |

Thank you hercek and Graybeard.

I will first try to modify the firmware to compensate for the special geometry. I have looked at Marlin's source and if there are not hidden traps I see only one place where the inverse kinematics is calculated. That should not be too difficult.

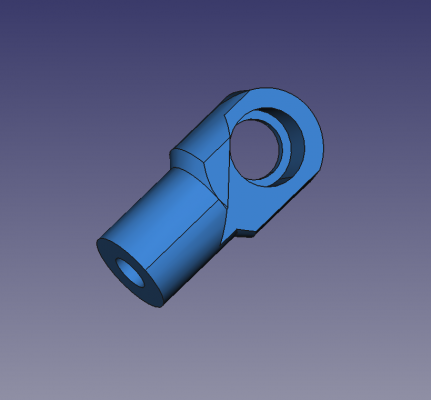

Another option is to replade the arm hinges (light blue in my first post) with parts similar to this.

Then I will not have to change the firmware. I think I can make these parts using a CNC router.

The BigPlanes ball links are kept as "plan C".

-- Itai

I will first try to modify the firmware to compensate for the special geometry. I have looked at Marlin's source and if there are not hidden traps I see only one place where the inverse kinematics is calculated. That should not be too difficult.

Another option is to replade the arm hinges (light blue in my first post) with parts similar to this.

Then I will not have to change the firmware. I think I can make these parts using a CNC router.

The BigPlanes ball links are kept as "plan C".

-- Itai

|

Re: Joints for delta printer October 30, 2013 07:30AM |

Registered: 10 years ago Posts: 732 |

Itai Wrote:

-------------------------------------------------------

> I will first try to modify the firmware to

> compensate for the special geometry. I have looked

> at Marlin's source and if there are not hidden

> traps I see only one place where the inverse

> kinematics is calculated. That should not be too

> difficult.

Yes, there is only one place in Marlin. The point is that you do not want to add something much more computationaly expensive. If you do, you will need either to use quicker proceesor than e.g. ATmega (an ARM board would do), or you will need to make delta segments per second smaller. But making it small has negative consequences for higher print speeds: [forums.reprap.org]

There are 3 sqrt calls in delta transformation (you will modify this) and another 3 in planner (time, speed, jerk computations). I'm not sure if all 3 sqrts in planner are called for each segment though. IIRC, a sqrt on ATmega takes about 150 ticks. My delta segments per second is set to 100 to avoid stuttering with the standard delta kinematics.

-------------------------------------------------------

> I will first try to modify the firmware to

> compensate for the special geometry. I have looked

> at Marlin's source and if there are not hidden

> traps I see only one place where the inverse

> kinematics is calculated. That should not be too

> difficult.

Yes, there is only one place in Marlin. The point is that you do not want to add something much more computationaly expensive. If you do, you will need either to use quicker proceesor than e.g. ATmega (an ARM board would do), or you will need to make delta segments per second smaller. But making it small has negative consequences for higher print speeds: [forums.reprap.org]

There are 3 sqrt calls in delta transformation (you will modify this) and another 3 in planner (time, speed, jerk computations). I'm not sure if all 3 sqrts in planner are called for each segment though. IIRC, a sqrt on ATmega takes about 150 ticks. My delta segments per second is set to 100 to avoid stuttering with the standard delta kinematics.

|

Re: Joints for delta printer October 30, 2013 09:57PM |

Registered: 10 years ago Posts: 51 |

|

Re: Joints for delta printer October 31, 2013 05:48AM |

Registered: 10 years ago Posts: 732 |

|

Re: Joints for delta printer October 31, 2013 04:23PM |

Registered: 10 years ago Posts: 4 |

Thanks for the link, hercek. There's a lot of useful info but I'm not yet sure of the meaning. I may not have all the answers until I actually build the machine and run my own tests.

Yes, it's going to be ATmega. I already have a Rumba and a friend who is also building a printer got a RAMPS controller. So far we are getting other components. It may take us some time before we can actually start the construction.

-- Itai

Yes, it's going to be ATmega. I already have a Rumba and a friend who is also building a printer got a RAMPS controller. So far we are getting other components. It may take us some time before we can actually start the construction.

-- Itai

|

Re: Joints for delta printer November 13, 2013 05:53AM |

Registered: 10 years ago Posts: 39 |

Sorry, only registered users may post in this forum.