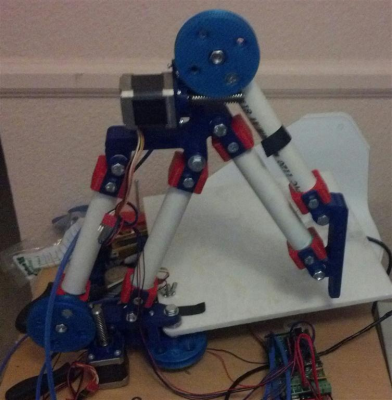

Worm Drive Grounded Delta Printer

Posted by Solidus Labs

|

Re: Worm Drive Grounded Delta Printer March 31, 2014 12:07PM |

Registered: 10 years ago Posts: 1,381 |

Tks for the update, the cast parts look good.

What resin are you using, it would be visually interesting to cast it clear, the white parts look stylish.

If you plan to advertise your printer, black is the worse color (magazine editors don't like it, and even forbid it), white, and bright colors show off the product best.

If the resin is rubbery, you might need to add a filler (glass fibers) to the worm wheel to stiffen up the cast part.

Maybe a filler will help with the geometry issues too.

I've used glass micro spheres in epoxy, it makes it brittle.

For structural strength cotton flock is added to epoxy, I've seen it used on kit planes.

What resin are you using, it would be visually interesting to cast it clear, the white parts look stylish.

If you plan to advertise your printer, black is the worse color (magazine editors don't like it, and even forbid it), white, and bright colors show off the product best.

If the resin is rubbery, you might need to add a filler (glass fibers) to the worm wheel to stiffen up the cast part.

Maybe a filler will help with the geometry issues too.

I've used glass micro spheres in epoxy, it makes it brittle.

For structural strength cotton flock is added to epoxy, I've seen it used on kit planes.

|

Re: Worm Drive Grounded Delta Printer March 31, 2014 01:08PM |

Registered: 10 years ago Posts: 56 |

Quote

A2

Tks for the update, the cast parts look good.

What resin are you using, it would be visually interesting to cast it clear, the white parts look stylish.

If you plan to advertise your printer, black is the worse color (magazine editors don't like it, and even forbid it), white, and bright colors show off the product best.

If the resin is rubbery, you might need to add a filler (glass fibers) to the worm wheel to stiffen up the cast part.

Maybe a filler will help with the geometry issues too.

I've used glass micro spheres in epoxy, it makes it brittle.

For structural strength cotton flock is added to epoxy, I've seen it used on kit planes.

I am using an epoxy resin and aluminum hydrate as a filler and to help prevent shrinkage. Cotton flock and fiberglass can make it difficult to pour the epoxy and fill the mold if the fibers are too long. I have some very short 1/32" milled fiberglass but that tends to make the epoxy brittle as well. If the strength of the casts become an issue I may test 1/16" length fibers. Also the colorant is powdered tempura paint.

Jon @ Solidus Labs

|

Re: Worm Drive Grounded Delta Printer March 31, 2014 11:18PM |

Registered: 10 years ago Posts: 1,381 |

Some thing to test if you use chopped glass, or any thing that thickens the resin up,

add some glass micro spheres, I believe it makes the epoxy flow more.

When I first used glass micro spheres I was applying it to a vertical surface,

and to my surprise it ran down like water.

I'm using West System products.

add some glass micro spheres, I believe it makes the epoxy flow more.

When I first used glass micro spheres I was applying it to a vertical surface,

and to my surprise it ran down like water.

I'm using West System products.

|

Re: Worm Drive Grounded Delta Printer April 07, 2014 01:35AM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer April 07, 2014 02:05AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer April 12, 2014 09:36PM |

Registered: 11 years ago Posts: 364 |

|

Re: Worm Drive Grounded Delta Printer April 20, 2014 04:06AM |

Registered: 10 years ago Posts: 56 |

So calibrating the GDR is a major chore. I have spent the last 3 weeks working on a calibration process but nothing to publish yet.

Because of the calibration difficulties, I have lost my motivation to crowd source this project. So I decided to open the project by making a release.

The current revision of GDR STL files are posted to GIT excluding extruder and hot end.

https://github.com/solidusLabs

If you like this project and you want to contribute, feel free to donate.

Donate

Because of the calibration difficulties, I have lost my motivation to crowd source this project. So I decided to open the project by making a release.

The current revision of GDR STL files are posted to GIT excluding extruder and hot end.

https://github.com/solidusLabs

If you like this project and you want to contribute, feel free to donate.

Donate

|

Re: Worm Drive Grounded Delta Printer April 20, 2014 05:07AM |

Registered: 10 years ago Posts: 1,381 |

I think that the GDR, and Gus-Simpson family of 3d printers are pretty clever machines, and solve some major evolutionary hurdles, such as eliminating a lot of precision machined metal components. If there's a possibility that they can print to blueprint specification, then it's worth spending our time on solving.

There are many contributors on Reprap with highly specialized skills, and unique experiences that want to help people to be successful in their endeavors.

How about explaining the math, mechanics, and coding challenges that you are facing so they can focus their efforts on solving these issues.

I am very impressed with the work that you and Nicholas have shared. I hope others see the value of your contributions as I do, and offer their expert support to advance this branch of 3d printing.

There are many contributors on Reprap with highly specialized skills, and unique experiences that want to help people to be successful in their endeavors.

How about explaining the math, mechanics, and coding challenges that you are facing so they can focus their efforts on solving these issues.

I am very impressed with the work that you and Nicholas have shared. I hope others see the value of your contributions as I do, and offer their expert support to advance this branch of 3d printing.

|

Re: Worm Drive Grounded Delta Printer April 20, 2014 08:50PM |

Registered: 10 years ago Posts: 979 |

Solidus Labs: What problems are you having? My goal for this summer is to self-replicate. For now calibration will be painful and manual. I have a ARM based controller coming that I will use to do z probing and real math.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: Worm Drive Grounded Delta Printer April 22, 2014 12:08PM |

Registered: 10 years ago Posts: 56 |

I guess the core of the calibration difficulties is which variable do I change to correct issues. I have spent the last 4 months experimenting with this; systematically testing all of the variables to see how it effects the geometry. There are 10 variables per arm. This becomes interesting/maddening when you change a variable that you wound expect a change in geometry and after leveling the plane, nothing changes.

So enough venting, here is what I am doing about this.

Spreadsheet simulation

I have made a spread sheet that simulates the calculations using all of the variables. I feel really stupid for not doing this in the first place. Now i can see variable changes without 20-30 minutes of configuring.

calibration circle

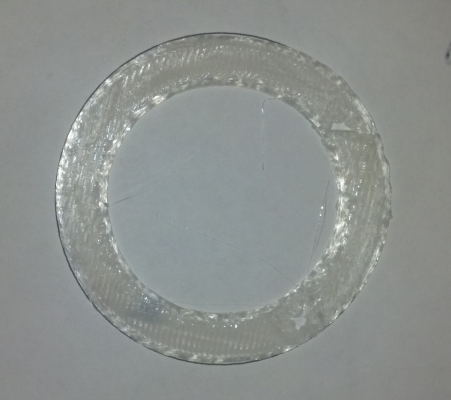

A printable circle with 90mm radius and 120 degree lines. Print this out and align it with the nozzle center and the back-middle arm minimum position (0x90) to see geometry issues.

Measure measure measure

Something like this is extremely helpful for measuring nozzle height and effector arm heights.

[www.harborfreight.com]

A compass is also helpful for comparing actual arm angle with the angle given in the spread sheet.

With all the measurable values correct, the only variables that can change your XY geometry is the SIN and COS of your vector radius or the distance from the center to the shoulder attachment.

So where am I at? I have all the minimum arm vectors aligning with my calibration circle, I need to do some more calibration on the maximums.

Here is a vid of the minimums.

[www.youtube.com]

Edited 2 time(s). Last edit at 04/22/2014 12:54PM by Solidus Labs.

So enough venting, here is what I am doing about this.

Spreadsheet simulation

I have made a spread sheet that simulates the calculations using all of the variables. I feel really stupid for not doing this in the first place. Now i can see variable changes without 20-30 minutes of configuring.

calibration circle

A printable circle with 90mm radius and 120 degree lines. Print this out and align it with the nozzle center and the back-middle arm minimum position (0x90) to see geometry issues.

Measure measure measure

Something like this is extremely helpful for measuring nozzle height and effector arm heights.

[www.harborfreight.com]

A compass is also helpful for comparing actual arm angle with the angle given in the spread sheet.

With all the measurable values correct, the only variables that can change your XY geometry is the SIN and COS of your vector radius or the distance from the center to the shoulder attachment.

So where am I at? I have all the minimum arm vectors aligning with my calibration circle, I need to do some more calibration on the maximums.

Here is a vid of the minimums.

[www.youtube.com]

Edited 2 time(s). Last edit at 04/22/2014 12:54PM by Solidus Labs.

|

Re: Worm Drive Grounded Delta Printer April 22, 2014 12:51PM |

Registered: 10 years ago Posts: 26 |

I just want to STRONGLY agree with what A2 said here:

The GDR is, as far as I can tell, the MOST 3D PRINTABLE printer out there. With the release of your files, there should be great motivation for developers who are really good with the firmware to help out. This is exciting stuff!

And it sounds like you are making progress on it after all. I've kicked in a bit to help motivate you (less than you are worth, certainly) and just to make sure you know that we are solidly behind Solidus. ,o)

Now, can I assume that the goal here is to use the spreadsheet to figure out how to adjust parameters in order to accomplish self calibration?

[www.linistepper.com] Open source stepper motor drivers.

Quote

A2

I think that the GDR, and Gus-Simpson family of 3d printers are pretty clever machines, and solve some major evolutionary hurdles, such as eliminating a lot of precision machined metal components. If there's a possibility that they can print to blueprint specification, then it's worth spending our time on solving.

The GDR is, as far as I can tell, the MOST 3D PRINTABLE printer out there. With the release of your files, there should be great motivation for developers who are really good with the firmware to help out. This is exciting stuff!

And it sounds like you are making progress on it after all. I've kicked in a bit to help motivate you (less than you are worth, certainly) and just to make sure you know that we are solidly behind Solidus. ,o)

Now, can I assume that the goal here is to use the spreadsheet to figure out how to adjust parameters in order to accomplish self calibration?

[www.linistepper.com] Open source stepper motor drivers.

|

Re: Worm Drive Grounded Delta Printer April 22, 2014 01:36PM |

Registered: 10 years ago Posts: 56 |

Awesome, Thank you very much.Quote

JamesNewton

I just want to STRONGLY agree with what A2 said here:

Quote

A2

I think that the GDR, and Gus-Simpson family of 3d printers are pretty clever machines, and solve some major evolutionary hurdles, such as eliminating a lot of precision machined metal components. If there's a possibility that they can print to blueprint specification, then it's worth spending our time on solving.

The GDR is, as far as I can tell, the MOST 3D PRINTABLE printer out there. With the release of your files, there should be great motivation for developers who are really good with the firmware to help out. This is exciting stuff!

And it sounds like you are making progress on it after all. I've kicked in a bit to help motivate you (less than you are worth, certainly) and just to make sure you know that we are solidly behind Solidus. ,o)

Now, can I assume that the goal here is to use the spreadsheet to figure out how to adjust parameters in order to accomplish self calibration?

I haven't thrown in the towel yet. The spreadsheet is a helpful tool for figuring out "I said to go here, but you moved somewhere else, why?"

A self calibration routine is quite the difficult task. Leveling the vector planes is quite easy with adjusting the homing screws, but accurate printing from the XY coordinate system is much more difficult.

|

Re: Worm Drive Grounded Delta Printer April 24, 2014 02:07AM |

Registered: 10 years ago Posts: 56 |

Aaah! its soo close. A few more tweaks and it should be a nice circle.

|

Re: Worm Drive Grounded Delta Printer April 24, 2014 11:29AM |

Registered: 10 years ago Posts: 1,381 |

Wow!, that looks great

In this day, and age of high tech stuff who would think that some one would get excited to see a simple circle.. lol

I'm interested in you sharing your story of enlightenment of how you got it to work.

It looks like between 1-o'clock, and 5-o'clock (0.33%) is where your math needs more work, is this correct?

Congrats and Tks!

Edited 2 time(s). Last edit at 04/24/2014 11:34AM by A2.

In this day, and age of high tech stuff who would think that some one would get excited to see a simple circle.. lol

I'm interested in you sharing your story of enlightenment of how you got it to work.

It looks like between 1-o'clock, and 5-o'clock (0.33%) is where your math needs more work, is this correct?

Congrats and Tks!

Edited 2 time(s). Last edit at 04/24/2014 11:34AM by A2.

|

Re: Worm Drive Grounded Delta Printer June 02, 2014 04:05PM |

Registered: 10 years ago Posts: 56 |

GDR development has stalled a bit so I started a new thread for SAPE. Kind of an evolution/branch from GDR

http://forums.reprap.org/read.php?185,364030

http://forums.reprap.org/read.php?185,364030

|

Re: Worm Drive Grounded Delta Printer November 09, 2015 02:22AM |

Registered: 11 years ago Posts: 364 |

Sorry, only registered users may post in this forum.