Worm Drive Grounded Delta Printer

Posted by Solidus Labs

|

Re: Worm Drive Grounded Delta Printer December 09, 2013 10:20AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer December 09, 2013 06:03PM |

Registered: 10 years ago Posts: 979 |

@Jon: I am not sure what is meant by a parallelogram linkage. Are you talking about something like THOR Simpson? It would only work if you do that to two arms. However, I would advise you to figure out what the weak link is and beef it up. (Mathematically, your position should be constrained so it is just a matter of sizing all the components to get acceptable rigidity.)

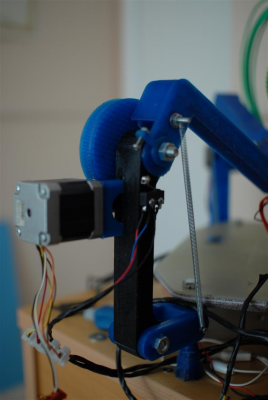

I know this would be annoying to do but the the worm needs to be registered with a pair of bearings and some thread clamps.

I would also consider splitting the shoulder gear and adding a torsion print as a backlash removal attempt.

Note: My apologies if you have already done some of these things.

Good luck!

Edited 1 time(s). Last edit at 12/09/2013 06:03PM by nicholas.seward.

I know this would be annoying to do but the the worm needs to be registered with a pair of bearings and some thread clamps.

I would also consider splitting the shoulder gear and adding a torsion print as a backlash removal attempt.

Note: My apologies if you have already done some of these things.

Good luck!

Edited 1 time(s). Last edit at 12/09/2013 06:03PM by nicholas.seward.

|

Re: Worm Drive Grounded Delta Printer December 10, 2013 12:03PM |

Registered: 10 years ago Posts: 56 |

Quote

nicholas.seward

@Jon: I am not sure what is meant by a parallelogram linkage. Are you talking about something like THOR Simpson? It would only work if you do that to two arms. However, I would advise you to figure out what the weak link is and beef it up. (Mathematically, your position should be constrained so it is just a matter of sizing all the components to get acceptable rigidity.)

I know this would be annoying to do but the the worm needs to be registered with a pair of bearings and some thread clamps.

I would also consider splitting the shoulder gear and adding a torsion print as a backlash removal attempt.

Note: My apologies if you have already done some of these things.

Good luck!

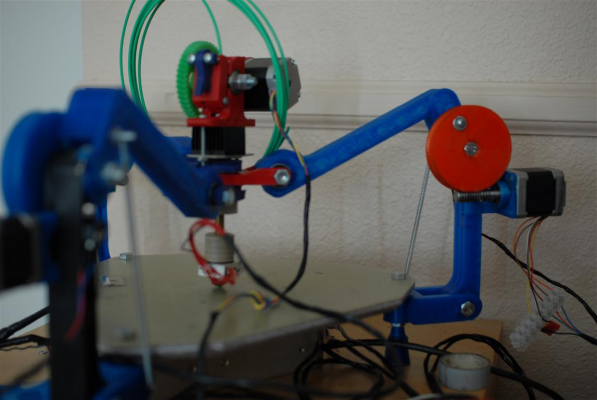

I agree, finding the weak link is the most prudent course. I have been working on a more beefier effector, the pivot arms are fairly small and could be the source of the flexing. I have been getting some grief printing the thicker parts in ABS. If that didn't solve the issue, then I was considering replacing one arm with a parallelogram like with the THOR simpson.

Here is a vid

Youtube

Edited 1 time(s). Last edit at 12/10/2013 12:15PM by Solidus Labs.

|

Re: Worm Drive Grounded Delta Printer December 10, 2013 12:15PM |

Registered: 10 years ago Posts: 979 |

@Solidus Labs: I think I know your main problem.

Test: Move the extruder to about 100mm above you surface. Press down and see if it is more rigid.

If it is more rigid, you just need to move your shoulder joints down so you stay far away from the planar singularity. (Your extruder is much closer to the joints than mine is.) That and beefing up your long arms should get you there. The shoulder looked good to me. Remember you don't need to add much plastic. You just need to add dimensionality to the arms. The rigidity is a function of b*h^3. If you just turn your arm on its side you will get 4 times the rigidity by my estimates. My theory is to go big with low infill.

Test: Move the extruder to about 100mm above you surface. Press down and see if it is more rigid.

If it is more rigid, you just need to move your shoulder joints down so you stay far away from the planar singularity. (Your extruder is much closer to the joints than mine is.) That and beefing up your long arms should get you there. The shoulder looked good to me. Remember you don't need to add much plastic. You just need to add dimensionality to the arms. The rigidity is a function of b*h^3. If you just turn your arm on its side you will get 4 times the rigidity by my estimates. My theory is to go big with low infill.

|

Re: Worm Drive Grounded Delta Printer December 10, 2013 01:17PM |

Registered: 10 years ago Posts: 1,381 |

Love the sound track

Tks for taking the time to post the video, love the eye candy!

A few ideas to consider.

Shoulder joint support structure:

I don't see a bottom triangular base tying the three shoulder joints together, ie. boxing in the structure.

Without a bottom base boxing in the shoulder joints, I can envision that the top plate is flexing (oil canning) downward, and the shoulder joints splaying outward.

Adding a bearing at the top and bottom of the rotational shoulder joint (Z axis), separated by as much space as is available will help with rigidity.

Tks for taking the time to post the video, love the eye candy!

A few ideas to consider.

Shoulder joint support structure:

I don't see a bottom triangular base tying the three shoulder joints together, ie. boxing in the structure.

Without a bottom base boxing in the shoulder joints, I can envision that the top plate is flexing (oil canning) downward, and the shoulder joints splaying outward.

Adding a bearing at the top and bottom of the rotational shoulder joint (Z axis), separated by as much space as is available will help with rigidity.

|

Re: Worm Drive Grounded Delta Printer December 10, 2013 01:38PM |

Registered: 10 years ago Posts: 56 |

*face palm* Ahh you’re right. Without even testing I can tell you it is more rigid.Quote

nicholas.seward

@Solidus Labs: I think I know your main problem.

Test: Move the extruder to about 100mm above you surface. Press down and see if it is more rigid.

If it is more rigid, you just need to move your shoulder joints down so you stay far away from the planar singularity. (Your extruder is much closer to the joints than mine is.) That and beefing up your long arms should get you there. The shoulder looked good to me. Remember you don't need to add much plastic. You just need to add dimensionality to the arms. The rigidity is a function of b*h^3. If you just turn your arm on its side you will get 4 times the rigidity by my estimates. My theory is to go big with low infill.

I move the horizontal pivot point up on the shoulder for more clearance but that also moves the horizontal singularity up.

Thanks for fresh pair of eyes.

|

Re: Worm Drive Grounded Delta Printer December 10, 2013 02:33PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer December 12, 2013 09:27AM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer January 04, 2014 08:47PM |

Registered: 10 years ago Posts: 167 |

|

Re: Worm Drive Grounded Delta Printer January 06, 2014 11:51AM |

Registered: 10 years ago Posts: 56 |

Quote

AbuMaia

How are things going? How do the new shoulders work out? Did they get rid of that singularity?

Sorry there has not been an update for a while. I was really busy over the holidays. The new shoulders have improved the flexing on the singularity quite a bit. I am currently rebuilding the hot end to extend farther down and get further from the singularity. The prototype I built has very good position stability but has heat zone and jamming issues. Lowering the nozzle has cut into the z height so I need to reprint longer upper arms as well.

- Jon @ Solidus Labs

|

Re: Worm Drive Grounded Delta Printer January 09, 2014 04:01PM |

Registered: 10 years ago Posts: 56 |

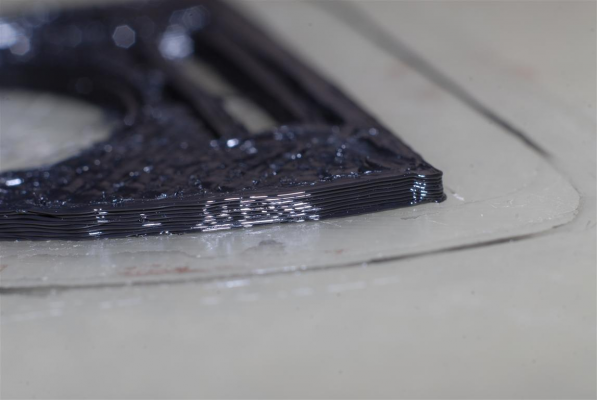

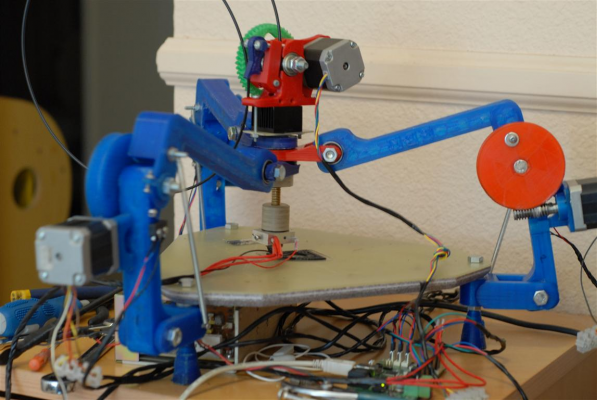

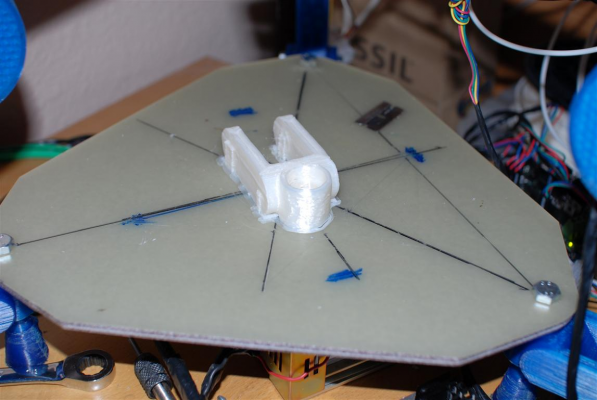

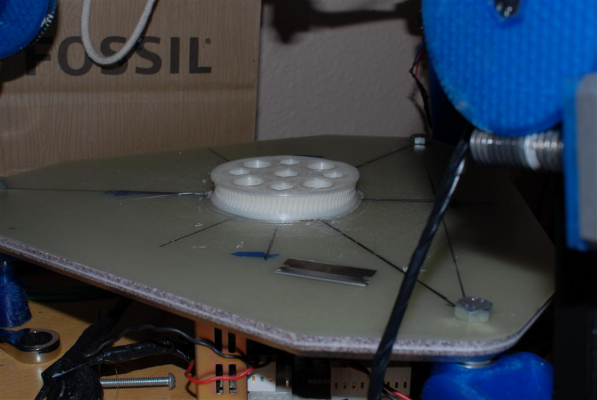

Yay! First “successful” print. There are still some flaws in the printing but I think I can fix that with some small tweaks in the calibration.

|

Re: Worm Drive Grounded Delta Printer January 09, 2014 04:47PM |

Registered: 10 years ago Posts: 979 |

|

Re: Worm Drive Grounded Delta Printer January 09, 2014 07:06PM |

Registered: 10 years ago Posts: 26 |

Excellent! Can't get much closer to the spirit of reprap than this! Almost everything is printed, only the motors, worm gear, electronics and hot end need be purchased. Well... a few bolts and bearings huh? But no belts, no long threaded rods, no metal cutting or shaping. I really hope you will release the files soon.

[www.linistepper.com] Open source stepper motor drivers.

[www.linistepper.com] Open source stepper motor drivers.

|

Re: Worm Drive Grounded Delta Printer January 09, 2014 07:17PM |

Registered: 10 years ago Posts: 1,381 |

@Jon,

Looks fantastic!

Got video candy?

*****************************************

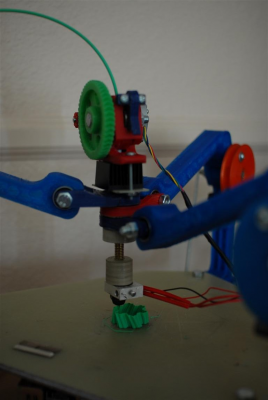

End effector Hub assembly:

I just noticed your hot end design/assembly!

It looks like you have a bespoke hollow threaded aluminum tube running down the center of your end effector hub.

Are you using the aluminum tube to sandwich the hub, and bearings tightly together so the assembly is ridged?

Are the 3 bearings touching each other, or is there plastic separating them?

The bearings look larger than 608's, what series are you using?

*****************************************

Redesign of the Hot end/end effector/hub:

To increase rigidity of the end effector I'm redesigning it to use a hollow threaded rod with bearings clamped in between.

Either an electric lamp fitting, vented SHCS, a vented stud, or your hollow threaded aluminum tube will be used.

A discussion about the end effector modification begins in the Lisa thread:

[forums.reprap.org]

Material suppliers:

Electric lamp fittings

[www.sizes.com]

1/4-27, Dia 6.35 mm (0.250"), 626 bearing 6x19 mm.

1/8-IP, Dia 10.29 mm, (0.405"), 6800 bearing 10x19 mm.

1/8-IP, Dia 10.29 mm, (0.405"), 6900 bearing 10x22 mm.

3/8-IP, Dia 17.15 mm, (0.675"), 6703 bearing 17x23 mm.

[www.bearingworks.com]

Lamp stuff

[www.profhdwr.com]

Lamp parts

[www.txlampparts.net]

3/8-ip nuts are 27 cents each at:

[www.iqlightbulbs.com]

M8x40mm, 7.41ea, Vented Socket Head Cap Screws

[www.mcmaster.com]

M8x50mm, $15.19ea, Vented Socket Head Cap Screws

[barnhillbolt.com]

5/16-18, $16.00ea, Hollow Threaded Studs

[www.mcmaster.com]

*****************************************

Hub offset:

I have a question about the end effector hub offset.

I want to design my arms to be inline with the end effector hub/pivot axis,

but I'm unsure if I'm violating the laws of physics.

In this image I can see that your end effector bore in the hub is offset relative to the arm.

Is this to prevent a singularity, or is it for some other reason?

Tks!

Looks fantastic!

Got video candy?

*****************************************

End effector Hub assembly:

I just noticed your hot end design/assembly!

It looks like you have a bespoke hollow threaded aluminum tube running down the center of your end effector hub.

Are you using the aluminum tube to sandwich the hub, and bearings tightly together so the assembly is ridged?

Are the 3 bearings touching each other, or is there plastic separating them?

The bearings look larger than 608's, what series are you using?

*****************************************

Redesign of the Hot end/end effector/hub:

To increase rigidity of the end effector I'm redesigning it to use a hollow threaded rod with bearings clamped in between.

Either an electric lamp fitting, vented SHCS, a vented stud, or your hollow threaded aluminum tube will be used.

A discussion about the end effector modification begins in the Lisa thread:

[forums.reprap.org]

Material suppliers:

Electric lamp fittings

[www.sizes.com]

1/4-27, Dia 6.35 mm (0.250"), 626 bearing 6x19 mm.

1/8-IP, Dia 10.29 mm, (0.405"), 6800 bearing 10x19 mm.

1/8-IP, Dia 10.29 mm, (0.405"), 6900 bearing 10x22 mm.

3/8-IP, Dia 17.15 mm, (0.675"), 6703 bearing 17x23 mm.

[www.bearingworks.com]

Lamp stuff

[www.profhdwr.com]

Lamp parts

[www.txlampparts.net]

3/8-ip nuts are 27 cents each at:

[www.iqlightbulbs.com]

M8x40mm, 7.41ea, Vented Socket Head Cap Screws

[www.mcmaster.com]

M8x50mm, $15.19ea, Vented Socket Head Cap Screws

[barnhillbolt.com]

5/16-18, $16.00ea, Hollow Threaded Studs

[www.mcmaster.com]

*****************************************

Hub offset:

I have a question about the end effector hub offset.

I want to design my arms to be inline with the end effector hub/pivot axis,

but I'm unsure if I'm violating the laws of physics.

In this image I can see that your end effector bore in the hub is offset relative to the arm.

Is this to prevent a singularity, or is it for some other reason?

Tks!

|

Re: Worm Drive Grounded Delta Printer January 10, 2014 09:44AM |

Registered: 11 years ago Posts: 58 |

|

Re: Worm Drive Grounded Delta Printer January 10, 2014 01:46PM |

Registered: 10 years ago Posts: 1,381 |

@Jon,

I'd like to verify that we have the newest version of the g-code preprocessor, is the math still the same?

What software language is this code written in?

tks!

I'd like to verify that we have the newest version of the g-code preprocessor, is the math still the same?

What software language is this code written in?

tks!

double La_1;

double La_2;

double La_3;

double Da_1;

double Da_2;

double Da_3;

double Ra_1;

double Ra_2;

double Ra_3;

Ra_1=sqrt(sq(cartesian[X_AXIS]-V1_X)+ sq(cartesian[Y_AXIS]-V1_Y));

Ra_2=sqrt(sq(cartesian[X_AXIS]-V2_X)+ sq(cartesian[Y_AXIS]-V2_Y));

Ra_3=sqrt(sq(cartesian[X_AXIS]-V3_X)+ sq(cartesian[Y_AXIS]-V3_Y));

La_1=sq(Ra_1-Nx+Sx)+sq(cartesian[Z_AXIS]-Sv+Nv1);

La_2=sq(Ra_2-Nx+Sx)+sq(cartesian[Z_AXIS]-Sv+Nv2);

La_3=sq(Ra_3-Nx+Sx)+sq(cartesian[Z_AXIS]-Sv+Nv3);

Da_1=((sqL1L2-La_1)/theta_CEND);

Da_2=((sqL1L2-La_2)/theta_CEND);

Da_3=((sqL1L2-La_3)/theta_CEND);

if (Da_1 <-1 || Da_1 > 1)

{

Da_1=floor(Da_1);

SERIAL_ECHOPGM("Arm Limit X\n");

}

if (Da_2 <-1 || Da_2 > 1)

{

Da_2=floor(Da_2);

SERIAL_ECHOPGM("Arm Limit Y\n");

}

if (Da_3 <-1 || Da_3 > 1)

{

Da_3=floor(Da_3);

SERIAL_ECHOPGM("Arm Limit Z\n");

}

delta[X_AXIS]= acos(Da_1)*rad2ang;

delta[Y_AXIS]= acos(Da_2)*rad2ang;

delta[Z_AXIS]= acos(Da_3)*rad2ang;

|

Re: Worm Drive Grounded Delta Printer January 11, 2014 01:09PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer January 11, 2014 01:21PM |

Registered: 10 years ago Posts: 56 |

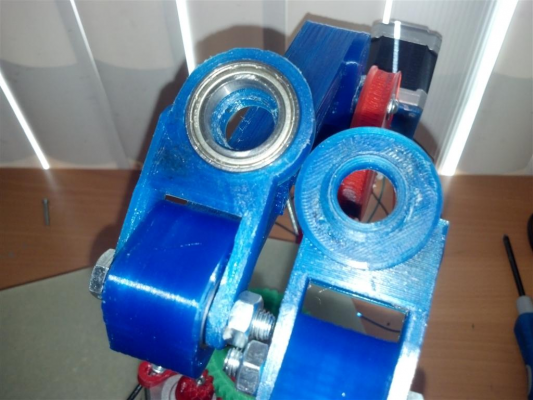

re:End effector Hub assembly:

Are you using the aluminum tube to sandwich the hub, and bearings tightly together so the assembly is ridged?

Yes the aluminum tube is threaded and screws the effector arms together.

Are the 3 bearings touching each other, or is there plastic separating them?

There is plastic separating them. In the second picture you can see the hubs recess into each other.

The bearings look larger than 608's, what series are you using?

They are 6804.

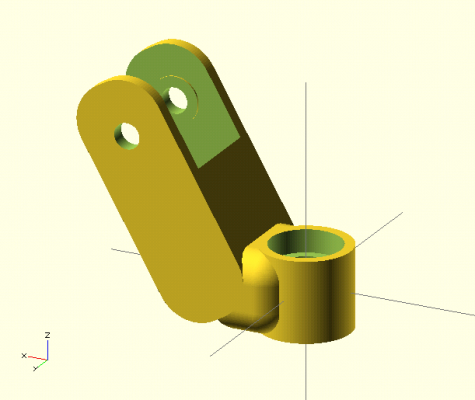

re:Hub offset:

In this image I can see that your end effector bore in the hub is offset relative to the arm.

Is this to prevent a singularity, or is it for some other reason?

The dogleg forearms have an off center shift, this is just shifting them back.

re:Hub offset

I'd like to verify that we have the newest version of the g-code preprocessor, is the math still the same?

What software language is this code written in?

The formulas are still the same, I might have changed/added a few variables. The language is Arduino, which is more or less c++.

Are you using the aluminum tube to sandwich the hub, and bearings tightly together so the assembly is ridged?

Yes the aluminum tube is threaded and screws the effector arms together.

Are the 3 bearings touching each other, or is there plastic separating them?

There is plastic separating them. In the second picture you can see the hubs recess into each other.

The bearings look larger than 608's, what series are you using?

They are 6804.

re:Hub offset:

In this image I can see that your end effector bore in the hub is offset relative to the arm.

Is this to prevent a singularity, or is it for some other reason?

The dogleg forearms have an off center shift, this is just shifting them back.

re:Hub offset

I'd like to verify that we have the newest version of the g-code preprocessor, is the math still the same?

What software language is this code written in?

The formulas are still the same, I might have changed/added a few variables. The language is Arduino, which is more or less c++.

|

Re: Worm Drive Grounded Delta Printer January 11, 2014 01:36PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer January 12, 2014 12:38PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer January 18, 2014 04:01PM |

Registered: 10 years ago Posts: 56 |

Small update:

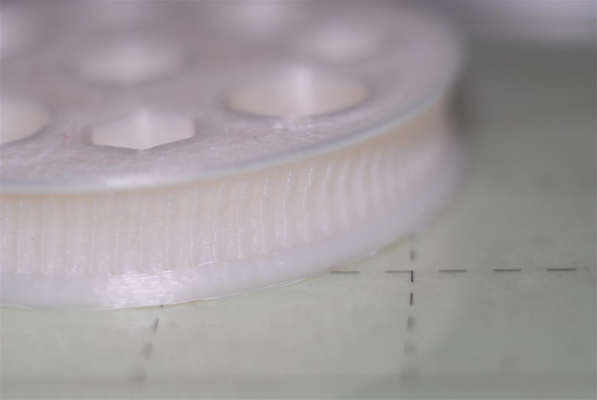

I printed new longer forearms which will give more printable Z area. After a bit of re-calibration, here are some photos.

I have ordered SLA prints of all the parts which I plan on using for master to make casting molds for short run production.

How does everyone feel about crowd funding the production?

Jon – Solidus Labs

I printed new longer forearms which will give more printable Z area. After a bit of re-calibration, here are some photos.

I have ordered SLA prints of all the parts which I plan on using for master to make casting molds for short run production.

How does everyone feel about crowd funding the production?

Jon – Solidus Labs

|

Re: Worm Drive Grounded Delta Printer January 26, 2014 11:45AM |

Registered: 10 years ago Posts: 56 |

Here is a pretty good milestone. I'm printing one of the GDR pieces on the GDR. Repraping...

[www.youtube.com]

[www.youtube.com]

|

Re: Worm Drive Grounded Delta Printer January 27, 2014 01:34PM |

Registered: 10 years ago Posts: 145 |

|

Re: Worm Drive Grounded Delta Printer January 27, 2014 03:19PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer January 28, 2014 10:44PM |

Registered: 10 years ago Posts: 56 |

The shoulder was fairly loose on the tolerances, it was probably 0.3 mm because of the low sub divisions. I was pushing the firmware pretty hard to get 16x microsteps and 50 sub divisions/sec at 60 mm/s. At this speed I was able to see some distortion on the faster curves.Quote

Guizmo

Hello Jon

How precise are the parts coming out of your machine? Are they usable as mechanic parts?

Thanks

The 16x microsteps works out to about .0037mm which is absurd. Setting the microsteps to 4x (.015) or 8x (0.0075) I can hike up the sub divisions to 200 and still maintain the higher speed.

The print fits into the upper arm after some reaming and cleanup so I think they are useable parts.

I lowered the print head so the build envelope is approximately the same. 180mm diameter x ~100mm z useable. All of the GDR parts will fit in the build envelope.Quote

A2

@SolidusLabs:

You have longer arms now, what is the size of the build envelope?

Can it accurately reproduce the arms, and worm wheel?

What is the print speed, and what do you think the top print speed will be after tuning the software, and calibration?

I am printing the worm wheel now. I’m printing at .48 nozzle @ 150 micron layer height and about 30mm/s which will take about 4 hours. I normally print them with a .28 nozzle so we shall see how the teeth come out. I prefer slower and accurate instead of fast and have to print again. 60mm/s is printing now but I think I can get it up to 100mm/s

|

Re: Worm Drive Grounded Delta Printer January 29, 2014 09:01PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer January 30, 2014 11:56AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer January 30, 2014 09:51PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer February 03, 2014 08:54PM |

Registered: 10 years ago Posts: 56 |

After printing about 20 calibration circles I'm about 97% there. I'm still dealing with some spherical issues from my base plate. My router needs a tuneup.

|

Re: Worm Drive Grounded Delta Printer February 04, 2014 02:04AM |

Registered: 10 years ago Posts: 1,381 |

@Solidus Labs:

It looks fantastic, I'm impressed, and it appears to be round, good job!

It looks like a joint shifted to create the step in the worm wheel tooth profile.

Will the cast resin parts include the extruder?

The standard appears to be RAMPS 1.4, + Arduino Mega2560 R3.

The ramps-fd looks great, but I don't have experience with any of them.

It looks fantastic, I'm impressed, and it appears to be round, good job!

It looks like a joint shifted to create the step in the worm wheel tooth profile.

Will the cast resin parts include the extruder?

The standard appears to be RAMPS 1.4, + Arduino Mega2560 R3.

The ramps-fd looks great, but I don't have experience with any of them.

Sorry, only registered users may post in this forum.