|

Re: Worm Drive Grounded Delta Printer February 04, 2014 10:03AM |

Registered: 10 years ago Posts: 56 |

Quote

A2

@Solidus Labs:

It looks fantastic, I'm impressed, and it appears to be round, good job!

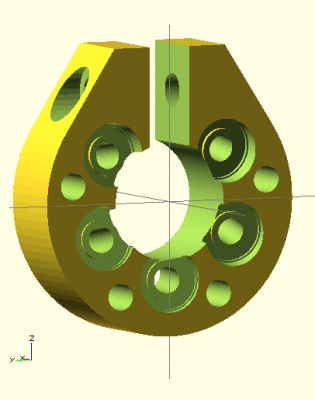

It looks like a joint shifted to create the step in the worm wheel tooth profile.

Will the cast resin parts include the extruder?

The standard appears to be RAMPS 1.4, + Arduino Mega2560 R3.

The ramps-fd looks great, but I don't have experience with any of them.

There is no step, the tooth profile is notched to fit the inner radius of the worm.

I would like to include a cast resin extruder but the wades based extruders aren't really mold friendly. I am still investigating/designing an alternative.

It will be interesting to see if there is any difference in performance with the added horsepower of the due vs the Mega2650

|

Re: Worm Drive Grounded Delta Printer February 04, 2014 05:20PM |

Registered: 10 years ago Posts: 1,381 |

@Solidus Labs:

FYI: Black plastic can have recycled plastic in it, never use black plastic for parts of value.

Natural, and white are your safest choices for filament.

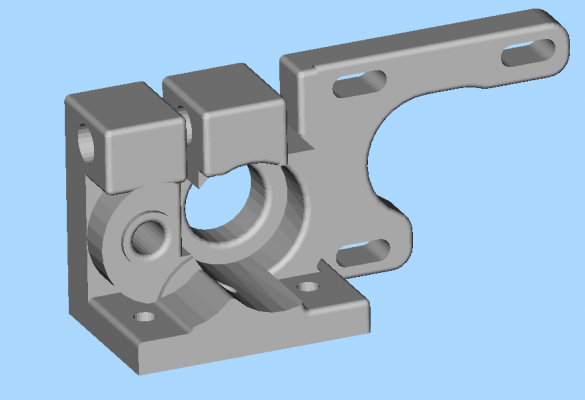

A few examples of extruders that I think can be modified for cast resin extruders:

I like this one by the_digital_dentist, it might be the easiest to resin cast:

[forums.reprap.org]

Raj's Minimalistic Extruder MK1 for Printrbot

[www.youtube.com] go to 6 min

[www.thingiverse.com]

Extruder Filament Replacement - Dual Spring

[www.thingiverse.com]

Minimalistic Mk7 replacement

[www.thingiverse.com]

Spring loaded extruder for Leapfrog Creatr

[www.thingiverse.com]

Ultimaker extruder update

All flat parts

[www.thingiverse.com]

Replicator 2 Extruder Upgrade

[www.thingiverse.com]

Drop in Paxtruder for MakerBot

All flat parts

[www.thingiverse.com]

Printable MK5 replacement filament drive

All flat parts

[www.thingiverse.com]

Ultimaker 1 Extruder M4 GueggelMod

All flat parts

After several original Ultimaker extruder broke, we decided to do a mod of our own

[www.thingiverse.com]

Edited 5 time(s). Last edit at 02/04/2014 05:31PM by A2.

FYI: Black plastic can have recycled plastic in it, never use black plastic for parts of value.

Natural, and white are your safest choices for filament.

A few examples of extruders that I think can be modified for cast resin extruders:

I like this one by the_digital_dentist, it might be the easiest to resin cast:

[forums.reprap.org]

Raj's Minimalistic Extruder MK1 for Printrbot

[www.youtube.com] go to 6 min

[www.thingiverse.com]

Extruder Filament Replacement - Dual Spring

[www.thingiverse.com]

Minimalistic Mk7 replacement

[www.thingiverse.com]

Spring loaded extruder for Leapfrog Creatr

[www.thingiverse.com]

Ultimaker extruder update

All flat parts

[www.thingiverse.com]

Replicator 2 Extruder Upgrade

[www.thingiverse.com]

Drop in Paxtruder for MakerBot

All flat parts

[www.thingiverse.com]

Printable MK5 replacement filament drive

All flat parts

[www.thingiverse.com]

Ultimaker 1 Extruder M4 GueggelMod

All flat parts

After several original Ultimaker extruder broke, we decided to do a mod of our own

[www.thingiverse.com]

Edited 5 time(s). Last edit at 02/04/2014 05:31PM by A2.

Attachments:

open | download - ScreenHunter_396 Feb. 04 16.10.jpg (45.8 KB)

open | download - ScreenHunter_395 Feb. 04 15.54.jpg (37.3 KB)

open | download - ScreenHunter_394 Feb. 04 15.47.jpg (59 KB)

open | download - ScreenHunter_393 Feb. 04 14.43.jpg (22.3 KB)

open | download - ScreenHunter_392 Feb. 04 14.39.jpg (19.2 KB)

open | download - ScreenHunter_391 Feb. 04 12.56.jpg (22.8 KB)

open | download - ScreenHunter_396 Feb. 04 16.10.jpg (45.8 KB)

open | download - ScreenHunter_395 Feb. 04 15.54.jpg (37.3 KB)

open | download - ScreenHunter_394 Feb. 04 15.47.jpg (59 KB)

open | download - ScreenHunter_393 Feb. 04 14.43.jpg (22.3 KB)

open | download - ScreenHunter_392 Feb. 04 14.39.jpg (19.2 KB)

open | download - ScreenHunter_391 Feb. 04 12.56.jpg (22.8 KB)

|

Re: Worm Drive Grounded Delta Printer February 04, 2014 10:40PM |

Registered: 10 years ago Posts: 56 |

Quote

A2

@Solidus Labs:

FYI: Black plastic can have recycled plastic in it, never use black plastic for parts of value.

Natural, and white are your safest choices for filament.

A few examples of extruders that I think can be modified for cast resin extruders:

I like this one by the_digital_dentist, it might be the easiest to resin cast:

[forums.reprap.org]

I can't quite agree with the 'never use black plastic for parts of value,' but I see where you are coming from. I have had very good results with the black PLA I am using. The digital dentist counter rotating threads is definitely interesting concept.

|

Re: Worm Drive Grounded Delta Printer February 05, 2014 03:49AM |

Registered: 10 years ago Posts: 1,381 |

I recognize that your parts are for a non life threatening, or life support application, and that there are sources of quality black plastic.

In hindsight, I may have used the word never too strongly.

It stems from my experience designing medical devices, where black plastic is typically avoided.

There are lot's of consumer products made with black plastic, which are of a high quality.

I have read in these forums complaints of users having trouble processing black plastic.

I surmised that their difficulties were due to using black filament that contained recycled plastic.

I have no aversion to purchasing black plastic for my own use, or specifying black plastic parts for non medical use.

Fillers, and recycled plastic can be blended into black plastic more readily than say a white plastic, and in most cases have no ill effect.

I have ideas to electroplate printed objects, and black plastic could pose a problem if it has fillers, and/or recycled plastic (I'm not referring to regrind plastic).

Without material certification you will not know if there was filler or recycled plastic added, other than to test the material.

An all black delta printer would look pretty cool

Edited 1 time(s). Last edit at 02/05/2014 06:40AM by A2.

In hindsight, I may have used the word never too strongly.

It stems from my experience designing medical devices, where black plastic is typically avoided.

There are lot's of consumer products made with black plastic, which are of a high quality.

I have read in these forums complaints of users having trouble processing black plastic.

I surmised that their difficulties were due to using black filament that contained recycled plastic.

I have no aversion to purchasing black plastic for my own use, or specifying black plastic parts for non medical use.

Fillers, and recycled plastic can be blended into black plastic more readily than say a white plastic, and in most cases have no ill effect.

I have ideas to electroplate printed objects, and black plastic could pose a problem if it has fillers, and/or recycled plastic (I'm not referring to regrind plastic).

Without material certification you will not know if there was filler or recycled plastic added, other than to test the material.

An all black delta printer would look pretty cool

Edited 1 time(s). Last edit at 02/05/2014 06:40AM by A2.

|

Re: Worm Drive Grounded Delta Printer February 06, 2014 04:42PM |

Registered: 10 years ago Posts: 26 |

Quote

Solidus Labs

I have ordered SLA prints of all the parts which I plan on using for master to make casting molds for short run production.

How does everyone feel about crowd funding the production?

Jon – Solidus Labs

So... this is to be a commercial machine? You are not releasing the files? Or do you plan to do both?

Honestly, the best part of this machine is that you can print so much of it. The original repraps were mostly just hardware store metal held together with a few small 3D printed parts. So this concept of "repraping" really wasn't... real. for the most part. This machine is as close to something you can actually print yourself as I have ever seen. Only the electronics, motor, drive screw and some nuts and bolts required.

The traditional rep raps are "print little, hardware store much" where as this design is "print much, hardware store a little".

casting it seems... well, mabey it will just be "buy a little, hardware store a little" but then I don't really see an advantage to it over e.g. a Printrbot Jr.

Am I missing something?

[www.linistepper.com] Open source stepper motor drivers.

|

Re: Worm Drive Grounded Delta Printer February 06, 2014 09:37PM |

Registered: 10 years ago Posts: 56 |

James,Quote

JamesNewton

Quote

Solidus Labs

I have ordered SLA prints of all the parts which I plan on using for master to make casting molds for short run production.

How does everyone feel about crowd funding the production?

Jon – Solidus Labs

So... this is to be a commercial machine? You are not releasing the files? Or do you plan to do both?

Honestly, the best part of this machine is that you can print so much of it. The original repraps were mostly just hardware store metal held together with a few small 3D printed parts. So this concept of "repraping" really wasn't... real. for the most part. This machine is as close to something you can actually print yourself as I have ever seen. Only the electronics, motor, drive screw and some nuts and bolts required.

The traditional rep raps are "print little, hardware store much" where as this design is "print much, hardware store a little".

casting it seems... well, mabey it will just be "buy a little, hardware store a little" but then I don't really see an advantage to it over e.g. a Printrbot Jr.

Am I missing something?

It is going to be open source. I will release the files when I am confident that the design is solid. Being able to print the printer is great if you have access to a printer. But since not everyone has access to a printer I wanted to use crowd funding to give some economies of scale benefit. Since the majority of the parts are printed, scaling with printing is not easily feasible and would require a fleet of printers. Casting the parts is kind of the middle ground where printing is prototyping and injection molding is long run manufacturing. Sure there are pro's and con's over Pb Jr. and the long list of cartesian bots and delta bots but my goal was to build a printer that was reasonably affordable, easy to produce, and easy to assemble. The assembly time should be somewhere from 1-2 hours. I think a great ancillary benefit is the printer is it is a real life application of trigonometry which fits in with the typical consumers of 3d printers, educators and inventors.

Jon - Solidus Labs

|

Re: Worm Drive Grounded Delta Printer February 07, 2014 01:50PM |

Registered: 10 years ago Posts: 26 |

Quote

Solidus Labs

It is going to be open source. I will release the files when I am confident that the design is solid. Being able to print the printer is great if you have access to a printer. But since not everyone has access to a printer I wanted to use crowd funding to give some economies of scale benefit. Since the majority of the parts are printed, scaling with printing is not easily feasible and would require a fleet of printers. Casting the parts is kind of the middle ground where printing is prototyping and injection molding is long run manufacturing. Sure there are pro's and con's over Pb Jr. and the long list of cartesian bots and delta bots but my goal was to build a printer that was reasonably affordable, easy to produce, and easy to assemble. The assembly time should be somewhere from 1-2 hours. I think a great ancillary benefit is the printer is it is a real life application of trigonometry which fits in with the typical consumers of 3d printers, educators and inventors.

Jon - Solidus Labs

Excellent! I would be interested in a kit of all parts, with assembly instructions. I probably wouldn't buy the 3D printed parts, since I could print them, but if they came as part of a full kit, then I would likely be willing to buy them just for convenience.

[www.linistepper.com] Open source stepper motor drivers.

|

Re: Worm Drive Grounded Delta Printer February 07, 2014 06:27PM |

Registered: 10 years ago Posts: 1,381 |

Springless, drop In ToM MK6+ replacement

[www.thingiverse.com]

This one looks easy to cast.

Split it down the center of the filament guide, if you don't want to deal with an insert, or drilling the filament guide.

I would consider using a rubber tube around the shaft of the idler bearing to give it a spring effect.

I wouldn't print/cast the pivot for the idler, use a bolt.

Edited 1 time(s). Last edit at 02/07/2014 06:28PM by A2.

[www.thingiverse.com]

This one looks easy to cast.

Split it down the center of the filament guide, if you don't want to deal with an insert, or drilling the filament guide.

I would consider using a rubber tube around the shaft of the idler bearing to give it a spring effect.

I wouldn't print/cast the pivot for the idler, use a bolt.

Edited 1 time(s). Last edit at 02/07/2014 06:28PM by A2.

|

Re: Worm Drive Grounded Delta Printer February 10, 2014 03:15PM |

Registered: 10 years ago Posts: 56 |

I spent the weekend testing, calibrating, and experimenting. I was trying to calibrate my router to no avail. I discovered a major backlash on my y axis so I am unable to cut any baseplates or print surfaces until I get it a new linear movement system.Quote

A2

Springless, drop In ToM MK6+ replacement

[www.thingiverse.com]

This one looks easy to cast.

Split it down the center of the filament guide, if you don't want to deal with an insert, or drilling the filament guide.

I would consider using a rubber tube around the shaft of the idler bearing to give it a spring effect.

I wouldn't print/cast the pivot for the idler, use a bolt.

A little off topic :

I am going to be switching to a thread-less ball screw configuration. I did an experiment using 20mm hardened rods and two of these beefed up ball-nuts and I was unable to make it slip. I plan on having 4x on the axis.

Back on topic :

I like the tom mk+ replacement but I really think the distance between the idler and drive needs to be variable, especially for nylon trimmer line. Also how does the direct drive handle 3mm and very fine print layers? I think it would have very low steps/unit.

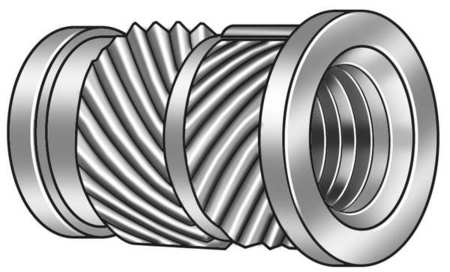

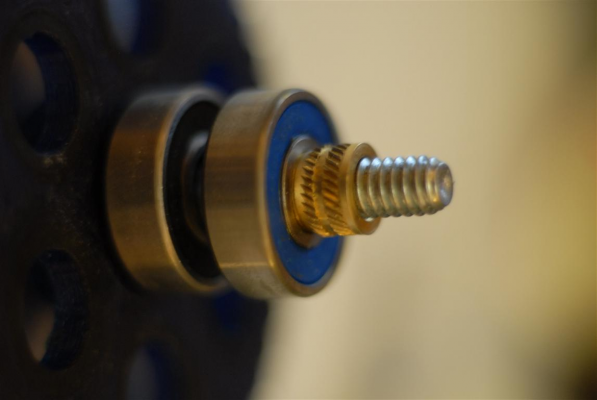

I have some 1/4-20 ultrasonic inserts which have a serrated teeth for gripping plastic which I have been experimenting with.

I turned down the tapered end to fit into a 608 bearing, the proof of concept extruder is testing out well. I will post some pictures as soon as I can.

|

Re: Worm Drive Grounded Delta Printer February 10, 2014 10:49PM |

Registered: 10 years ago Posts: 56 |

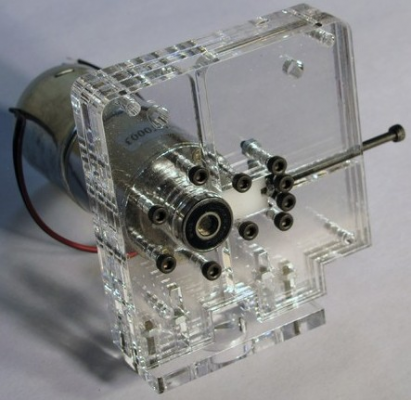

Here is a rough proof of concept. The insert works great to grip the filament and the slice in the body allows for tension adjustment. Next step is to draw it up in scad with nema 17 and machine mounts.

|

Re: Worm Drive Grounded Delta Printer February 10, 2014 11:52PM |

Registered: 10 years ago Posts: 1,381 |

Nice concept.

Might get away with using only Loctite Threadlocker Red 271 permanent locking?

Not sure about the life of brass, SS probably a better choice.

Might get away with using only Loctite Threadlocker Red 271 permanent locking?

Loctite® Threadlocker Red 271™ is designed for the permanent locking and sealing of threaded fasteners. The product cures when confined in the absence of air between close fitting metal surfaces. It protects threads from rust and corrosion and prevents loosening from shock and vibration. It is only removable once cured by heating up parts to 500°F (260°C). [www.loctiteproducts.com]

Not sure about the life of brass, SS probably a better choice.

|

Re: Worm Drive Grounded Delta Printer February 12, 2014 09:51PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer February 13, 2014 01:47PM |

Registered: 10 years ago Posts: 26 |

Quote

Solidus Labs

...in scad with nema 17 and machine mounts.

[www.thingiverse.com]

In case that helps.

[www.linistepper.com] Open source stepper motor drivers.

|

Re: Worm Drive Grounded Delta Printer February 15, 2014 07:50PM |

Registered: 10 years ago Posts: 56 |

Amidst rebuilding my router, here is the progress I have made on the extruder. The ultrasonic insert works very well to drive the plastic. A few more tweaks and an improved filament guide and I think it will be good to go...

|

Re: Worm Drive Grounded Delta Printer February 15, 2014 08:38PM |

Registered: 10 years ago Posts: 1,381 |

Looking good.

What is the motivation to design an extruder?

Will you be resin casting the extruder as well?

I'm unsure, but it appears that you are using a fixed gap between the idler and hob.

From what I have reviewed most filament drivers are using a spring to allow

the idler to move in-n-out to compensate for variations of filament diameters.

Of the components that are going to be resin cast,

have you allowed for draft to ease removal from the mold?

Looks like a lot of test prints in the background

Videos are always appreciated!

What is the motivation to design an extruder?

Will you be resin casting the extruder as well?

I'm unsure, but it appears that you are using a fixed gap between the idler and hob.

From what I have reviewed most filament drivers are using a spring to allow

the idler to move in-n-out to compensate for variations of filament diameters.

Of the components that are going to be resin cast,

have you allowed for draft to ease removal from the mold?

Looks like a lot of test prints in the background

Videos are always appreciated!

|

Re: Worm Drive Grounded Delta Printer February 15, 2014 08:54PM |

Registered: 10 years ago Posts: 56 |

Quote

A2

Looking good.

What is the motivation to design an extruder?

Will you be resin casting the extruder as well?

I'm unsure, but it appears that you are using a fixed gap between the idler and hob.

From what I have reviewed most filament drivers are using a spring to allow

the idler to move in-n-out to compensate for variations of filament diameters.

Of the components that are going to be resin cast,

have you allowed for draft to ease removal from the mold?

Looks like a lot of test prints in the background

Videos are always appreciated!

Hi A2,

The motivation for the extruder is to make one that is easily castable. It is true that most extruders have a spring or something to allow for changes in the filament diameter, perhaps I can incorporate a rubber washer to give some flexing. I have two extruders that work well, one has a spring and one does not. I will be using urethane or silicone molding rubber for the casting so adding a draft is not necessary unless it a very thin and long section. I think I will be good without.

Yea, the test prints led me to discover my hole spacing is not perfect in my print bed, and then the issues with my router which is why I am rebuilding my Y axis.

|

Re: Worm Drive Grounded Delta Printer February 21, 2014 06:07PM |

Registered: 10 years ago Posts: 56 |

Here is a little video of the extruder pushing some 3mm filament. I might still add a flange on the bottom to make it wades/greg foot print compatible. The ultrasonic insert and the tension bolt work very well.

[youtu.be]

The filament guide is just a simple clip

[youtu.be]

The filament guide is just a simple clip

|

Re: Worm Drive Grounded Delta Printer February 21, 2014 08:28PM |

Registered: 10 years ago Posts: 1,381 |

Good to see you're making progress.

Idea:

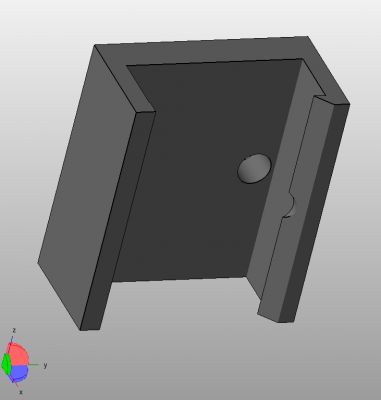

The lower filament guide cast it as a second piece.

This will allow you to pull from the mold in one axis, eliminating orthogonal core pins.

To attach it, add 2 holes in the same axis as that of the filament guide,

and from the bottom bolt it to the main part of the body.

To attach it use Hi-Lo Self-Tapping screws.

Idea:

The lower filament guide cast it as a second piece.

This will allow you to pull from the mold in one axis, eliminating orthogonal core pins.

To attach it, add 2 holes in the same axis as that of the filament guide,

and from the bottom bolt it to the main part of the body.

To attach it use Hi-Lo Self-Tapping screws.

|

Re: Worm Drive Grounded Delta Printer February 25, 2014 12:38AM |

Registered: 10 years ago Posts: 56 |

Yay my cnc router "The Minotaur" is back in action. Two base plates and 2 print beds cut.

|

Re: Worm Drive Grounded Delta Printer February 25, 2014 12:56AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer February 26, 2014 04:02AM |

Registered: 10 years ago Posts: 1,381 |

Quote

Solidus Labs

It will be interesting to see if there is any difference in performance with the added horsepower of the due vs the Mega2650

Are you going to rewrite the Marlin Firmware to work with an ARM controller?

If you do, it could be helpful to the other ARM controller boards, e.g. SmoothieBoard

RAMPS-FD

(Atmel SAM3X8E ARM Cortex-M3 CPU)

$49.95

RAMPS For Arduino Due

84 MHz Atmel 32-bit ARM Cortex-M3 CPU with USB OTG

[arduino.cc]

[www.geeetech.com]

File:RepRapFirmware-master.zip

[www.geeetech.com]

SmoothieBoard

$169.97

(NXP LPC 1768/9 32-bits Cortex-M3), and/or (LPC 1114 ARM Cortex-M0)

[shop.uberclock.com]

[smoothieware.org]

Edited 2 time(s). Last edit at 02/26/2014 04:06AM by A2.

|

Re: Worm Drive Grounded Delta Printer February 26, 2014 10:24AM |

Registered: 10 years ago Posts: 56 |

I have had a ramps-fd and due on my desk for a while but I have not had the time to do any hacking with it. It doesn't look like anyone else has put much effort into porting marlin to due because lack of due optimization. I might look into aprinter. It is supposed to support other delta configurations by defining a transformation class.

|

Re: Worm Drive Grounded Delta Printer February 26, 2014 03:50PM |

Registered: 10 years ago Posts: 1,381 |

APrinter firmware looks nice

Packed gcode working with APrinter firmware

It works very smoothly. On gcode produced by Cura I see a good 50% reduction in side.

Concerning firmware performance, I measure 15% less time spent in main loop processing with

AVR based boards (APrinter also supports RAMPS-FD/Ardiono Due which is an ARM).

This measurement was done using M916/917 which my firmware optionally implements for measuring time spent in main loop handlers.

For now, it would be nice if this, or something similar, was standardized and implemented in some common firmwares.

[forums.reprap.org]

I see RAMPS-FD is listed, I don't understand, what's not optimized.

Ports have been completed for the following boards:

Melzi (atmega1284p only),

RAMPS 1.0, 1.1/1.2 or 1.3/1.4 (only RAMPS 1.4 with atmega2560 is tested),

RAMPS-FD or other setup based on Arduino Due.

Teensy 3 (no board, needs manual wiring).

Implemented features

Highly configurable (at compile time) design. Extra heaters, fans and axes can be added easily,

and PWM frequencies for heaters and fans are individually adjustable.

Delta robot support. Additionally, new geometries can be added easily by defining a transform class.

Performance will be sub-optimal when using Delta on AVR platforms.

SD card printing (reading of sequential blocks only, no filesystem or partition support).

Optionally supports a custom packed g-code format for SD printing.

This results in about 50% size reduction and 15% reduction in main loop processing load (on AVR).

Bed probing using a microswitch (prints results, no correction yet).

The default main files for RAMPS1.4 and RAMPS-FD already support two extruders.

For use with multiple extruders, a g-code post-processor is provided to translate tool commands into motion of individual axes which the firmware understands.

If you have a fan on each extruder, the post-processor can control the fans so that only the fan for the current extruder is on.

Constant-acceleration motion with look-ahead planning.

To speed up calculations, the firmware will only calculate a new plan every LookaheadCommitCount commands.

Effectively, this allows increasing the lookahead count without an asymptotic increase of processing time, only limited by the available RAM.

Homing using min- or max-endstops. Can home multiple at once. where only 115200 is supported due to unfavourable interrupt priorities.es in parallel.

Heater control using PID or on-off control. The thermistor tables need to be generated with a Python script.

Each heater is configured with a Safe temperature range; a heater is turned off in case its temperature goes beyond the safe range.

Fan control (any number of fans).

Stepper control based on interrupts, with each stepper having its own timer interrupt.

Step times are computed analytically using the quadratic equation, employing custom assembly routines for sqrt and division on AVR.

This ensures that steps happen when they should, without one stepper ending a move faster than others due to accumulated rounding errors,

and stopping while all steppers finish.

Portable and ported design; three different microcontroller families are already supported.

Non-drifting heartbeat LED. Its period is exactly 1 second, subject to the precision of your oscillator.

The software is written in C++.

Extensive use of abstractions for hardware access and program structuring.

It should be possible to port the software on new platforms with little work.

In fact, the firmware already works on Arduino Due, which is based on an Atmel ARM microcontroller.

[github.com]

aprinter

Author(s) : Ambroz Bizjak

Status : Active as of Feb 2014

Written from scratch in C++ with a heavy dose of template metaprogramming.

[www.reprap.org]

Packed gcode working with APrinter firmware

It works very smoothly. On gcode produced by Cura I see a good 50% reduction in side.

Concerning firmware performance, I measure 15% less time spent in main loop processing with

AVR based boards (APrinter also supports RAMPS-FD/Ardiono Due which is an ARM).

This measurement was done using M916/917 which my firmware optionally implements for measuring time spent in main loop handlers.

For now, it would be nice if this, or something similar, was standardized and implemented in some common firmwares.

[forums.reprap.org]

Quote

Solidus Labs

It doesn't look like anyone else has put much effort into porting marlin to due because lack of due optimization.

I see RAMPS-FD is listed, I don't understand, what's not optimized.

Ports have been completed for the following boards:

Melzi (atmega1284p only),

RAMPS 1.0, 1.1/1.2 or 1.3/1.4 (only RAMPS 1.4 with atmega2560 is tested),

RAMPS-FD or other setup based on Arduino Due.

Teensy 3 (no board, needs manual wiring).

Implemented features

Highly configurable (at compile time) design. Extra heaters, fans and axes can be added easily,

and PWM frequencies for heaters and fans are individually adjustable.

Delta robot support. Additionally, new geometries can be added easily by defining a transform class.

Performance will be sub-optimal when using Delta on AVR platforms.

SD card printing (reading of sequential blocks only, no filesystem or partition support).

Optionally supports a custom packed g-code format for SD printing.

This results in about 50% size reduction and 15% reduction in main loop processing load (on AVR).

Bed probing using a microswitch (prints results, no correction yet).

The default main files for RAMPS1.4 and RAMPS-FD already support two extruders.

For use with multiple extruders, a g-code post-processor is provided to translate tool commands into motion of individual axes which the firmware understands.

If you have a fan on each extruder, the post-processor can control the fans so that only the fan for the current extruder is on.

Constant-acceleration motion with look-ahead planning.

To speed up calculations, the firmware will only calculate a new plan every LookaheadCommitCount commands.

Effectively, this allows increasing the lookahead count without an asymptotic increase of processing time, only limited by the available RAM.

Homing using min- or max-endstops. Can home multiple at once. where only 115200 is supported due to unfavourable interrupt priorities.es in parallel.

Heater control using PID or on-off control. The thermistor tables need to be generated with a Python script.

Each heater is configured with a Safe temperature range; a heater is turned off in case its temperature goes beyond the safe range.

Fan control (any number of fans).

Stepper control based on interrupts, with each stepper having its own timer interrupt.

Step times are computed analytically using the quadratic equation, employing custom assembly routines for sqrt and division on AVR.

This ensures that steps happen when they should, without one stepper ending a move faster than others due to accumulated rounding errors,

and stopping while all steppers finish.

Portable and ported design; three different microcontroller families are already supported.

Non-drifting heartbeat LED. Its period is exactly 1 second, subject to the precision of your oscillator.

The software is written in C++.

Extensive use of abstractions for hardware access and program structuring.

It should be possible to port the software on new platforms with little work.

In fact, the firmware already works on Arduino Due, which is based on an Atmel ARM microcontroller.

[github.com]

aprinter

Author(s) : Ambroz Bizjak

Status : Active as of Feb 2014

Written from scratch in C++ with a heavy dose of template metaprogramming.

[www.reprap.org]

|

Re: Worm Drive Grounded Delta Printer February 26, 2014 04:48PM |

Registered: 10 years ago Posts: 56 |

|

Re: Worm Drive Grounded Delta Printer March 12, 2014 01:51AM |

Registered: 10 years ago Posts: 56 |

SLS prints are really nice.

First urethane mold

First urethane mold

|

Re: Worm Drive Grounded Delta Printer March 12, 2014 08:04AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer March 12, 2014 11:47AM |

Registered: 11 years ago Posts: 28 |

|

Re: Worm Drive Grounded Delta Printer March 21, 2014 09:22PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Worm Drive Grounded Delta Printer March 24, 2014 10:57AM |

Registered: 10 years ago Posts: 56 |

Sorry for the lack of update, I have been away on a spring vacation. I have been working on the molds and there is still some print geometry issues with the beta machine even with the new base plate. Printing a circle comes out a little egg shaped. I am betting on this being fixed with the identical cast parts.

|

Re: Worm Drive Grounded Delta Printer March 31, 2014 11:25AM |

Registered: 10 years ago Posts: 56 |

I have 2 of the 6 molds done and casting parts.

I realized that I was getting some lateral flexing in the elbow so I have added a stiffener piece that completes the clevis and fits into the updated forearm design.

I realized that I was getting some lateral flexing in the elbow so I have added a stiffener piece that completes the clevis and fits into the updated forearm design.

Sorry, only registered users may post in this forum.