Have you seen the Delta-Pi?

Posted by TheTechnicalNoob

|

Have you seen the Delta-Pi? November 22, 2013 08:01PM |

Registered: 10 years ago Posts: 153 |

I don't know if any of you have seen the Delta-Pi printer. Seems like a good alternative to the rostock!

I was looking at doing a rostock, but seeing this is much cheaper, and quite possibly more accurate than chinese linear rod I might just build this instead

The wiki page: [reprap.org]

Instead of using linear rod which can be expensive, Mike is using Stainless steel tube 3/4" (19mm) but 20mm will also work.

All credit goes to Mike, thank you for designing it!

Anybody here built one? Your thoughts?

Edited 2 time(s). Last edit at 11/22/2013 09:08PM by TheTechnicalNoob.

I was looking at doing a rostock, but seeing this is much cheaper, and quite possibly more accurate than chinese linear rod I might just build this instead

The wiki page: [reprap.org]

Instead of using linear rod which can be expensive, Mike is using Stainless steel tube 3/4" (19mm) but 20mm will also work.

All credit goes to Mike, thank you for designing it!

Anybody here built one? Your thoughts?

Edited 2 time(s). Last edit at 11/22/2013 09:08PM by TheTechnicalNoob.

|

Re: Have you seen the Delta-Pi? November 22, 2013 08:44PM |

Registered: 11 years ago Posts: 66 |

Hi TTN,

Thanks for the encouragement on my Delta-Pi Prototype. There are a few under construction around NZ and Australia. One in Auckland is doing a lot more printing than the prototype has. I had my own design of hot-end on it and it kept giving me problems and jamming on the PLA.

I've just got myself an E3D hot end to trial and I have high hopes for this.

I've also implemented a bed levelling probe like Johann's. That seems to be working well but the proof will come when I have the new hot-end installed.

One thing I will point out is that Delta-Pi uses Stainless steel tubes. 3/4" (19mm) or 20mm. The problem with using Aluminium tube as a bearing surface is that the soft aluminium surface is so easily damaged by dust and dirt and once it gets damaged it quickly deteriorates to the point of being useless.

The usual solution is to use rollers made of something even softer than the aluminium eg. delrin. But I preferred to stick with a hard steel surface and the polished stainless tube is cheap and readily available.

Thanks for the encouragement on my Delta-Pi Prototype. There are a few under construction around NZ and Australia. One in Auckland is doing a lot more printing than the prototype has. I had my own design of hot-end on it and it kept giving me problems and jamming on the PLA.

I've just got myself an E3D hot end to trial and I have high hopes for this.

I've also implemented a bed levelling probe like Johann's. That seems to be working well but the proof will come when I have the new hot-end installed.

One thing I will point out is that Delta-Pi uses Stainless steel tubes. 3/4" (19mm) or 20mm. The problem with using Aluminium tube as a bearing surface is that the soft aluminium surface is so easily damaged by dust and dirt and once it gets damaged it quickly deteriorates to the point of being useless.

The usual solution is to use rollers made of something even softer than the aluminium eg. delrin. But I preferred to stick with a hard steel surface and the polished stainless tube is cheap and readily available.

|

Re: Have you seen the Delta-Pi? November 22, 2013 11:11PM |

Registered: 10 years ago Posts: 153 |

|

Re: Have you seen the Delta-Pi? November 23, 2013 03:37AM |

Registered: 10 years ago Posts: 41 |

Actually, I am building a delta pi currently. I am experimenting with aluminum square pipe with a small inner diameter. So far so good. Biggest issue I have encountered is the parts are being printed on a printrbot simple which has just under a 100mm cubed print area so the hotend mount would not fit. Had to cut it into pieces in software and add bolting points. Also the printrbot spread out the edges of the print so fitting them around the aluminum square pipe has been... interesting. Will post when I have printed my first few tests.

|

Re: Have you seen the Delta-Pi? November 23, 2013 03:01PM |

Registered: 11 years ago Posts: 40 |

Mike,

An update for you, There's another one coming up soon in Ireland, I've got pretty much all of the parts now, the only thing left to do is to build it, and that's going to happen just as soon as I get my garage back to sanity, I want the floor space so that I don't keep falling over the thing. My plan for the bed is to use a piece of heavy aluminium plate, with a heat barrier on top of it, then a heater, with glass above that, held on to the aluminium by retainer clips at the edge. I will be using 3 mount points for the base plate rather than 4, that way, I avoid any issues with twisting of the plate when adjusting things.

I will also be using an E3d hot end, using bowden to connect it, apart from that, it will be very much to the design published. I may make it a bit taller, just to have the flexibility to experiment with other things.

I may partly enclose the frame with some ply, partly to give me the ability to retain heat in the print area, and partly to give even more rigidity to the tower, but that's for a bit further down the line.

For power, I got lucky, E-bay had some very high power Dell server power supplies, they are rated at 12 V 120 (yes one hundred and twenty) amps, I got 2 of them for under £20 each, and another £5 got me the interface card that goes in the server, so connecting them means I don't have to butcher the connectors at all, I can do all the wiring on the interface board. Means I can have very high power heated beds, or hot wire, or even a very high power router motor at a later stage, if I get really pushed, 24 V at 120 amps would be enough to arc weld with if I want to

I would be very interested in what you've done on the bed levelling side, and some details of how you're doing with Marlin, and at some stage, I'm going to beg for a copy of your parameters for Marlin, as that will for sure save me some pain in an area that I will readily admit to not fully understanding yet. I got my printed parts from a company in London, and while I've not assembled them yet, the quality looks very good indeed, and I'm very much looking forward to getting things up and running, with a longer term plan to use a large piece of what was the floor of a flight simulator (it's a substantial frame made of a lot of 2 x 1 box steel section with an 18mm OSB floor on it, and that's going to end up as the bed of a multi function machine, the plan being to be able to do things like hot wire cutting, and also larger printing, probably using a corexy concept, where the print head will be elevated above the bed, which will remain static, as it will be way too heavy to drive with steppers, and a corexy from aluminium section with steel rails for the movement bearings, probably based on your design, but that's for experimenting once the Delta Pi is up and running.

Cheers

Steve

Shore, if twas easy, we'd all be doin it

Irish Steve

An update for you, There's another one coming up soon in Ireland, I've got pretty much all of the parts now, the only thing left to do is to build it, and that's going to happen just as soon as I get my garage back to sanity, I want the floor space so that I don't keep falling over the thing. My plan for the bed is to use a piece of heavy aluminium plate, with a heat barrier on top of it, then a heater, with glass above that, held on to the aluminium by retainer clips at the edge. I will be using 3 mount points for the base plate rather than 4, that way, I avoid any issues with twisting of the plate when adjusting things.

I will also be using an E3d hot end, using bowden to connect it, apart from that, it will be very much to the design published. I may make it a bit taller, just to have the flexibility to experiment with other things.

I may partly enclose the frame with some ply, partly to give me the ability to retain heat in the print area, and partly to give even more rigidity to the tower, but that's for a bit further down the line.

For power, I got lucky, E-bay had some very high power Dell server power supplies, they are rated at 12 V 120 (yes one hundred and twenty) amps, I got 2 of them for under £20 each, and another £5 got me the interface card that goes in the server, so connecting them means I don't have to butcher the connectors at all, I can do all the wiring on the interface board. Means I can have very high power heated beds, or hot wire, or even a very high power router motor at a later stage, if I get really pushed, 24 V at 120 amps would be enough to arc weld with if I want to

I would be very interested in what you've done on the bed levelling side, and some details of how you're doing with Marlin, and at some stage, I'm going to beg for a copy of your parameters for Marlin, as that will for sure save me some pain in an area that I will readily admit to not fully understanding yet. I got my printed parts from a company in London, and while I've not assembled them yet, the quality looks very good indeed, and I'm very much looking forward to getting things up and running, with a longer term plan to use a large piece of what was the floor of a flight simulator (it's a substantial frame made of a lot of 2 x 1 box steel section with an 18mm OSB floor on it, and that's going to end up as the bed of a multi function machine, the plan being to be able to do things like hot wire cutting, and also larger printing, probably using a corexy concept, where the print head will be elevated above the bed, which will remain static, as it will be way too heavy to drive with steppers, and a corexy from aluminium section with steel rails for the movement bearings, probably based on your design, but that's for experimenting once the Delta Pi is up and running.

Cheers

Steve

Shore, if twas easy, we'd all be doin it

Irish Steve

|

Re: Have you seen the Delta-Pi? November 23, 2013 04:01PM |

Registered: 10 years ago Posts: 25 |

|

Re: Have you seen the Delta-Pi? November 24, 2013 01:25AM |

Registered: 10 years ago Posts: 153 |

Please tell me you're using fuses!Quote

Irish_Steve

120 amps would be enough to arc weld with if I want to

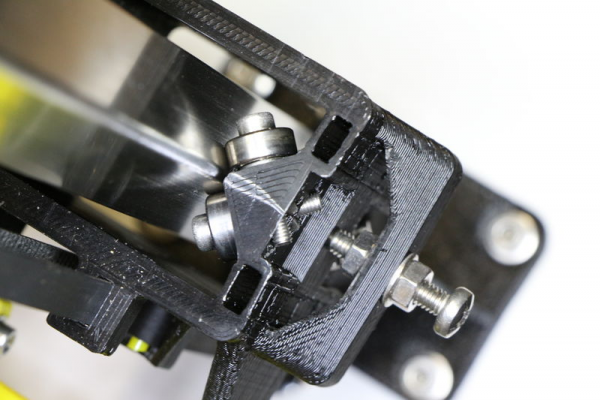

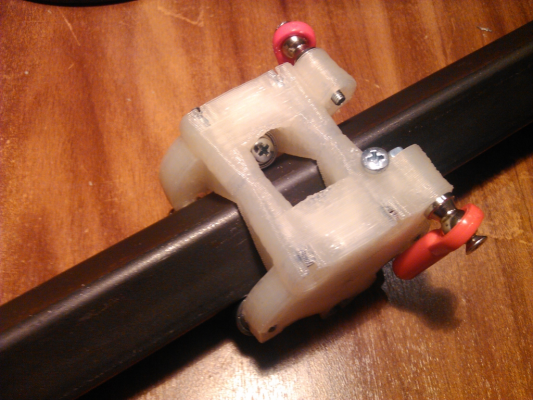

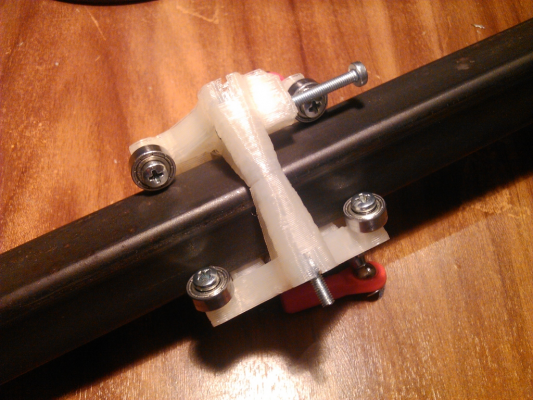

A very nice configuration on the square tube. Looks like he is using 6 bearings per carriage instead of 8.

Thats from [github.com]

Edited 3 time(s). Last edit at 11/24/2013 03:59AM by TheTechnicalNoob.

|

Re: Have you seen the Delta-Pi? November 24, 2013 06:49PM |

Registered: 11 years ago Posts: 40 |

Quote

TheTechnicalNoob

Please tell me you're using fuses!Quote

Irish_Steve

120 amps would be enough to arc weld with if I want to

At this stage, it's not wired up yet, but fuses will be the minimum, more likely I will put some fast acting circuit breakers in the loop as well, given the power that these things can throw out, I know they have a lot of protection in the PSU, but there's no point taking any chances in that area. They will need some serious cooling if I'm pulling high power, but that's easy enough to arrange. I'm hoping to also be able to use some of the same hardware to run a CNC router of some sort, once I can make things to go on it, that's one of the reasons for the Delta Pi, it will make it possible to fabricate parts for other devices.

Shore, if twas easy, we'd all be doin it

Irish Steve

|

Re: Have you seen the Delta-Pi? December 03, 2013 08:55PM |

Registered: 10 years ago Posts: 41 |

Update: I am much closer to built on my Delta-Pi. I did however run into one major snag which is going to require me to re-print an unspecified number of parts an unspecified number of times. My PrintrBot Simple badly skewed the prints along the Y axis as you go up Z, which resulted in the carriage handles being cock-eyed which resulted in the hot-end not being level, and significant strain on each of the rods. I have printed and attacked some y-sag compensators for the simple.. about to find out if it worked, as I am printing the first of the carriages with it.

|

Re: Have you seen the Delta-Pi? December 09, 2013 11:25PM |

Registered: 10 years ago Posts: 153 |

I recall reading about someone who reportedly used steel bearings on aluminium extrusions without problems by putting electrical heatshrink plastic around the bearings.

Can anybody confirm that this works well?

Mike, perhaps you would like to upgrade your delta-pi and try it? Perhaps you could even recommend it on the wiki page if it works successfully.

Edited 1 time(s). Last edit at 12/09/2013 11:33PM by TheTechnicalNoob.

Can anybody confirm that this works well?

Mike, perhaps you would like to upgrade your delta-pi and try it? Perhaps you could even recommend it on the wiki page if it works successfully.

Edited 1 time(s). Last edit at 12/09/2013 11:33PM by TheTechnicalNoob.

|

Re: Have you seen the Delta-Pi? December 10, 2013 07:53AM |

Registered: 10 years ago Posts: 1,381 |

Quote

TheTechnicalNoob

I recall reading about someone who reportedly used steel bearings on aluminium extrusions without problems by putting electrical heatshrink plastic around the bearings.

Can anybody confirm that this works well?

You either have your stories mixed up, or someone was joking around.

|

Re: Have you seen the Delta-Pi? December 10, 2013 06:27PM |

Registered: 10 years ago Posts: 41 |

|

Re: Have you seen the Delta-Pi? December 10, 2013 06:37PM |

Registered: 10 years ago Posts: 153 |

Quote

beamsaber

Is the problem with steel bearings on aluminum that the steel will eat it's way through the aluminum eventually?

Yes that's the problem.

Perhaps having something softer than aluminium (heatshrink plastic) around the bearings it will solve the problem.

Quote

mikep-nz

The problem with using Aluminium tube as a bearing surface is that the soft aluminium surface is so easily damaged by dust and dirt and once it gets damaged it quickly deteriorates to the point of being useless.

|

Re: Have you seen the Delta-Pi? December 10, 2013 11:59PM |

Registered: 10 years ago Posts: 41 |

|

Re: Have you seen the Delta-Pi? December 12, 2013 04:07PM |

Registered: 10 years ago Posts: 41 |

My printer made it's first movements two days ago, and I'm starting on configuring it now. I am starting to wonder if I should invest in a multimeter because I have no clear way to confirm all the lines running to the motors, thermistor, etc are solid, as I've had to crimp-splice each one at least twice.

|

Re: Have you seen the Delta-Pi? December 13, 2013 01:57PM |

Registered: 10 years ago Posts: 153 |

You could make a continuity indicator, or just try using your printer and see if it all works. A multimeter definitely will be handy if you plan on doing any projects involving electronics.Quote

beamsaber

My printer made it's first movements two days ago, and I'm starting on configuring it now. I am starting to wonder if I should invest in a multimeter because I have no clear way to confirm all the lines running to the motors, thermistor, etc are solid, as I've had to crimp-splice each one at least twice.

|

Re: Have you seen the Delta-Pi? December 23, 2013 05:14AM |

Registered: 10 years ago Posts: 153 |

|

Re: Have you seen the Delta-Pi? December 26, 2013 02:28PM |

Registered: 10 years ago Posts: 1,381 |

@TheTechnicalNoob,

Was it like this design?

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/26/2013 04:33PM by A2.

Quote

A2

Quote

TheTechnicalNoob

I recall reading about someone who reportedly used steel bearings on aluminium extrusions without problems by putting electrical heatshrink plastic around the bearings.

Can anybody confirm that this works well?

You either have your stories mixed up, or someone was joking around.

Was it like this design?

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/26/2013 04:33PM by A2.

|

Re: Have you seen the Delta-Pi? December 26, 2013 04:15PM |

Registered: 10 years ago Posts: 153 |

|

Re: Have you seen the Delta-Pi? December 28, 2013 11:16PM |

Registered: 11 years ago Posts: 66 |

Hi TTN,

I can't provide you with pictures but I am drawing on personal experience. The crossed roller design came from a friend's machine and he had used Aluminium with steel bearings. The machine was relatively new but already some of the bearing surfaces were becoming rough. My experience with using Aluminium as a bearing surface is that it has a very short lifespan in just about any application.

That's certainly true of any of the grades like 6060 or 6063 that you get in common extrusions. They are soft. Any dust, dirt and oils that gets on the hard surface of your roller will become embedded in the surface of the aluminium. The only way I am aware of that avoids this problem is to use a softer material for the roller. And that is why Makerslide works.

Feel free to test this for yourself and report back.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

I can't provide you with pictures but I am drawing on personal experience. The crossed roller design came from a friend's machine and he had used Aluminium with steel bearings. The machine was relatively new but already some of the bearing surfaces were becoming rough. My experience with using Aluminium as a bearing surface is that it has a very short lifespan in just about any application.

That's certainly true of any of the grades like 6060 or 6063 that you get in common extrusions. They are soft. Any dust, dirt and oils that gets on the hard surface of your roller will become embedded in the surface of the aluminium. The only way I am aware of that avoids this problem is to use a softer material for the roller. And that is why Makerslide works.

Feel free to test this for yourself and report back.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

|

Re: Have you seen the Delta-Pi? December 28, 2013 11:54PM |

Registered: 10 years ago Posts: 153 |

|

Re: Have you seen the Delta-Pi? December 29, 2013 04:14AM |

Registered: 12 years ago Posts: 82 |

Just a thought, as I'm about to build a similar design that will be using bearings on aluminum.

What about some sort of sticky backed thin rubber or silicon, that sticks in strips directly to the aluminium surface. Basically creating a soft surface without having to use the heat shrink method, which from what I understand can be a bit hit and miss.

Alternatively, would a printed plastic cover around the bearing be any good to prevent damage to the aluminium tubing/extrude?

Edited 1 time(s). Last edit at 12/29/2013 04:17AM by RickM.

What about some sort of sticky backed thin rubber or silicon, that sticks in strips directly to the aluminium surface. Basically creating a soft surface without having to use the heat shrink method, which from what I understand can be a bit hit and miss.

Alternatively, would a printed plastic cover around the bearing be any good to prevent damage to the aluminium tubing/extrude?

Edited 1 time(s). Last edit at 12/29/2013 04:17AM by RickM.

|

Re: Have you seen the Delta-Pi? December 29, 2013 04:58AM |

Registered: 10 years ago Posts: 153 |

As mike said, anything that is softer than aluminium to cover the bearings should work. Just make sure that whatever you put around the bearings has a consistent thickness and a smooth join if you use the sticky tape you mentioned.

Right now what I have in mind is a kossel scaled up x2 with all the prints 2x the size with 30mm aluminium extrusions. I may change my mind yet again, but I think I've settled on it. Good luck Rick

Right now what I have in mind is a kossel scaled up x2 with all the prints 2x the size with 30mm aluminium extrusions. I may change my mind yet again, but I think I've settled on it. Good luck Rick

|

Re: Have you seen the Delta-Pi? December 29, 2013 07:08PM |

Registered: 10 years ago Posts: 41 |

I just looked back up the thread and saw the "Roller invader" Kossel mod, which seems to be following the same idea as Delta Pi with the square tubes...

I'm curious as to whether the rollers from "Roller Invader" would work for the Delta-Pi with some modifications. The primary issue I am trying to alleviate is that the Delta-Pi carriages cannot be removed without dissassembling the entire primary frame.. Not something I am hoping I would have to do on a regular basis, considering the potential for damaging connectors or cracking plastic parts in the assembly. I also like that the "Roller Invader" carriages could be split into two prints. One of the issues I had with the Delta-Pi carriages is that they are a rather large part by Printrbot Simple standards, and so I ended up printing and re-printing them many times, wasting a lot of plastic in the process. Even now I do not have a perfect set, as one of the carriages has the rollers closer together on the bottom than the top, causing the carriage to rock back and forth when direction is changed. I tried tightening the carriage, but that only resulted in the carriage refusing to move at all because there was too much pressure on the bottom set of bearings.

Thoughts?

I'm curious as to whether the rollers from "Roller Invader" would work for the Delta-Pi with some modifications. The primary issue I am trying to alleviate is that the Delta-Pi carriages cannot be removed without dissassembling the entire primary frame.. Not something I am hoping I would have to do on a regular basis, considering the potential for damaging connectors or cracking plastic parts in the assembly. I also like that the "Roller Invader" carriages could be split into two prints. One of the issues I had with the Delta-Pi carriages is that they are a rather large part by Printrbot Simple standards, and so I ended up printing and re-printing them many times, wasting a lot of plastic in the process. Even now I do not have a perfect set, as one of the carriages has the rollers closer together on the bottom than the top, causing the carriage to rock back and forth when direction is changed. I tried tightening the carriage, but that only resulted in the carriage refusing to move at all because there was too much pressure on the bottom set of bearings.

Thoughts?

Sorry, only registered users may post in this forum.